Modified Y zeolite and its preparation method and application

A zeolite and modification technology, applied in the field of preparation of modified Y zeolite, can solve the problems of low yield of catalytically cracked gasoline, poor hydrothermal stability, and difficulty in meeting catalytic cracking, and achieve improved coke selectivity, high heat and water Thermal stability, the effect of improving the conversion rate of heavy oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

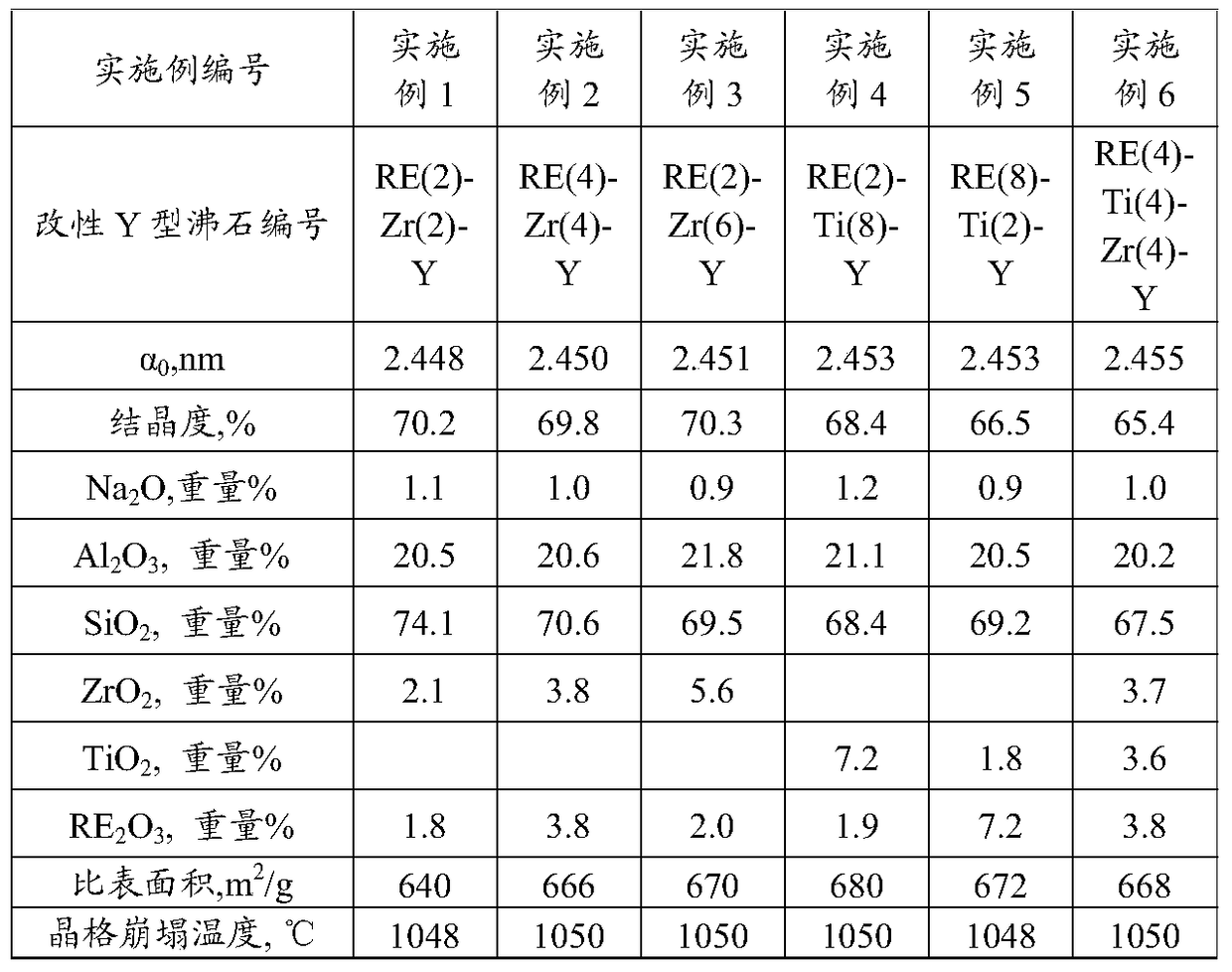

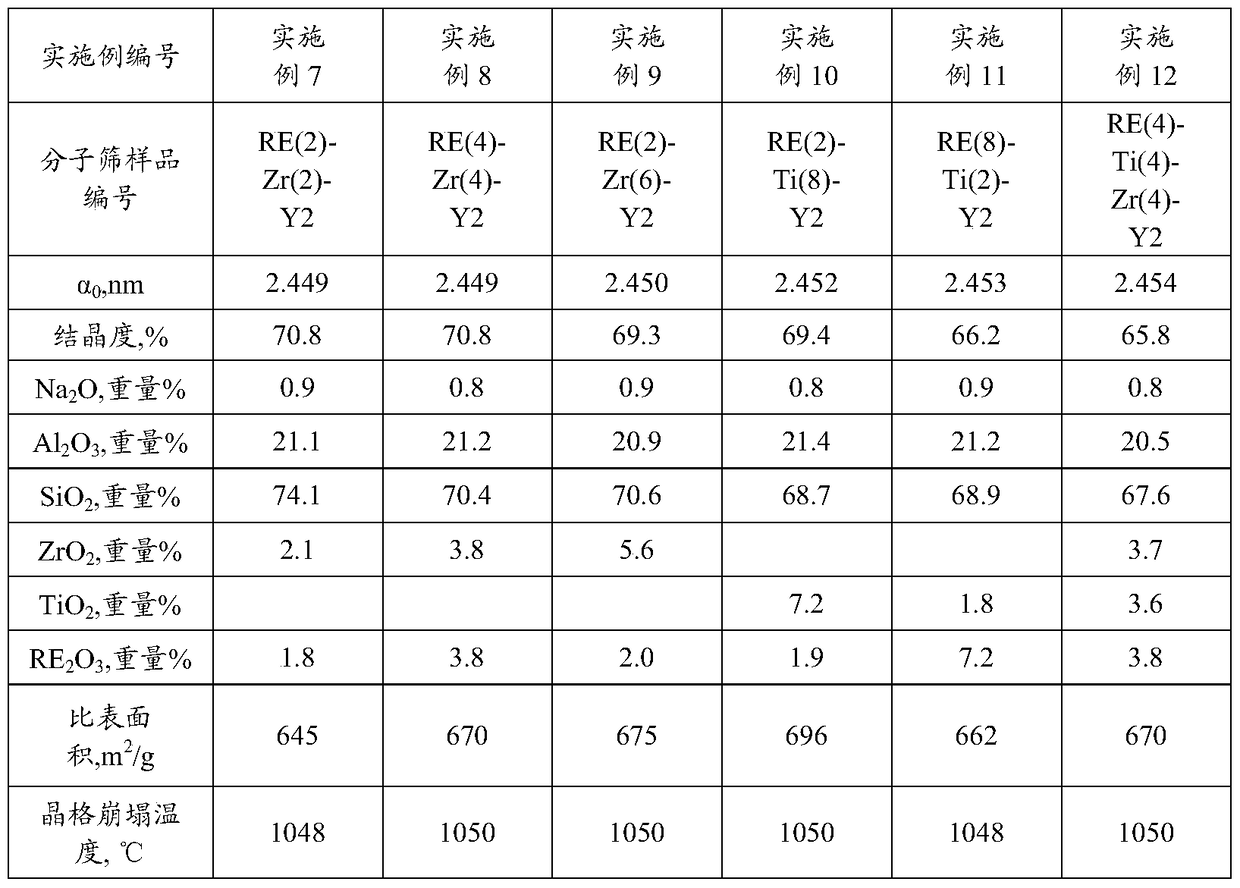

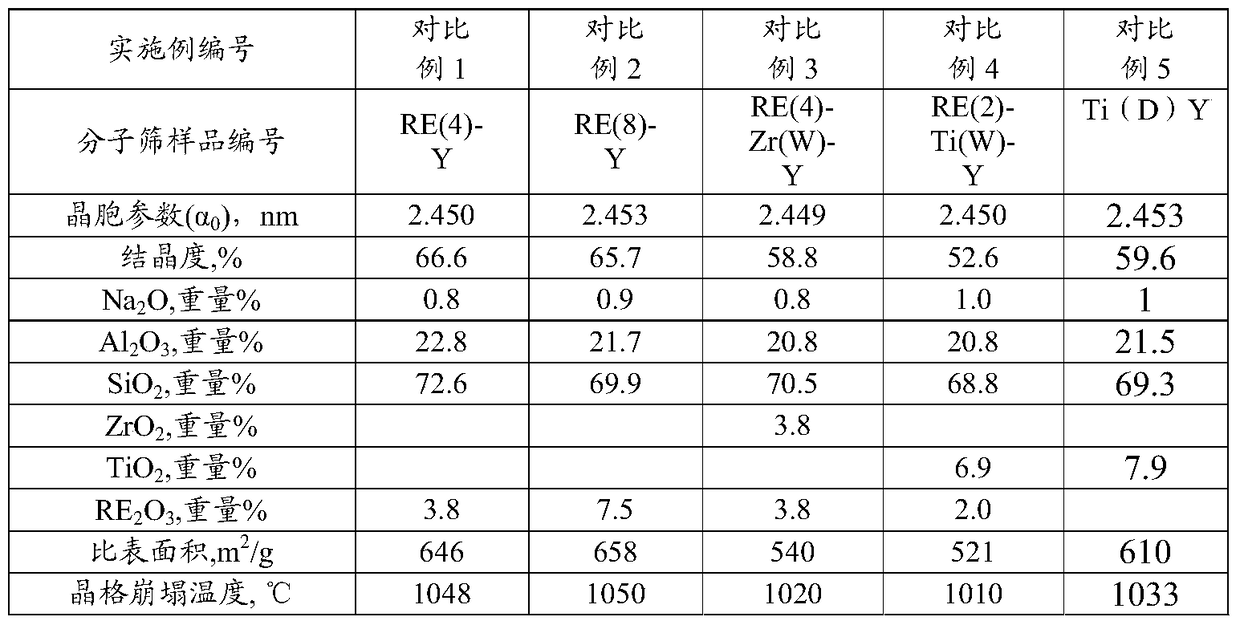

Examples

Embodiment 1

[0038] At room temperature, get 200g NaY zeolite (dry basis 75% by weight), after beating with 1500g deionized water, add 45 grams (NH 4 ) 2 SO 4 and 11.3 mL of RECl 3 Aqueous solution (RE 2 o 3 Concentration 270 g / L), rare earth salt (in RE 2 o 3 The weight ratio of ammonium salt: NaY zeolite: deionized water is 0.02:0.3:1:10, the pH value of the slurry is adjusted to 3.8 with 5% by weight of dilute hydrochloric acid, then heated to 90°C for 1 hour, filtered and used Washing with deionized water, roasting the filter cake at 600°C and 100% water vapor for 2 hours to obtain rare earth modified Y zeolite RE(2)-Y, the water content of which is 3% by weight;

[0039] Get 12ml ethanol and add 180ml deionized water, add 5mol / L acetic acid aqueous solution 3ml, adjust solution pH value to 3.7 with 10mol / L ammonium hydroxide aqueous solution, then add 10.5g zirconium nitrate Zr (NO 3 ) 4 ·5H 2 O is dissolved in the above buffer solution to obtain an impregnating solution. Mix...

Embodiment 2

[0041] At room temperature, take 200g NaY zeolite (dry basis 75% by weight), after beating with 2250g deionized water, add 75g ammonium chloride and 22.2ml RECl 3 Aqueous solution (RE 2 o 3 270 g / L), rare earth salts (in RE 2 o 3Calculated): ammonium salt: NaY zeolite: the weight ratio of deionized water is 0.04:0.5:1:15, the pH value of the slurry is adjusted to 3.6 with 5% dilute hydrochloric acid, then the temperature is raised to 90 ° C for 1 hour, filtered and used Washing with ionized water, drying the filter cake, and then roasting at 650° C. and 100% water vapor for 2 hours to obtain rare earth modified Y zeolite RE(4)-Y, the water content of which is 2% by weight;

[0042] Get 12ml of ethanol and add 180ml of deionized water, continue to add 3ml of acetic acid aqueous solution with a concentration of 5mol / L acetic acid, adjust the pH value to 4.5 with a concentration of 10mol / L ammonium hydroxide aqueous solution, and dissolve 15.7g of zirconium oxychloride ZrOCl ...

Embodiment 3

[0044] At room temperature, get 200g NaY zeolite (dry basis 75% by weight), after beating with 3000g deionized water, add 30 grams of ammonium chloride and 11.1 milliliters of RECl 3 Solution (RE 2 o 3 Concentration 270 g / L), rare earth salt (in RE 2 o 3 Meter): ammonium salt: NaY zeolite: the weight ratio of deionized water is 0.02:0.2:1:20, the pH value of the slurry is adjusted to 3.8 with dilute hydrochloric acid with a concentration of 5% by weight, and then the temperature is raised to 85° C. for exchange for 2 hours. Filter and wash with deionized water, dry the filter cake, and then roast at 550°C and 100% water vapor for 3 hours to obtain rare earth modified Y zeolite RE(2)-Y with a water content of 3% by weight;

[0045] Get 12ml ethanol and add 180ml deionized water, continue to add 5mol / L acetic acid aqueous solution 3ml, obtain mixed solution, adjust the pH value of described mixed solution with 10mol / L ammonium hydroxide aqueous solution to be 3.2, obtain buff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com