Aromatizatian catalytic material and preparation method thereof

A technology of catalytic materials and oxides, applied in chemical instruments and methods, physical/chemical process catalysts, catalytic cracking, etc., can solve the cracking aromatization activity of molecular sieves, affect the acid distribution of molecular sieves, affect the pore structure of molecular sieves, etc., to achieve Good thermal and hydrothermal stability, high crystallinity, and high aromatization selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The preparation method of the catalytic material provided by the present invention comprises several steps of removing the template agent from the molecular sieve and converting it into an ammonium type molecular sieve, impregnating the organic solvent and modifying the metal:

[0036] a, the former powder of molecular sieve is roasted to remove template agent, according to molecular sieve: ammonia salt: H 2 O=1:(0.1~1):(5~10) weight ratio Mix and stir the molecular sieve, ammonium salt and water for removing the templating agent evenly, exchange at room temperature to 100°C for at least 0.3 hours, filter and dry to obtain Ammonium molecular sieve;

[0037] B, according to the liquid / solid mass ratio of organic solvent and molecular sieve is (0.2~20): the amount of 1, organic solvent and ammonium type molecular sieve obtained in step a are mixed uniformly, at 15 ℃~maintaining the temperature that solution is liquid phase , impregnated for at least 0.5 hours, filtered a...

Embodiment 1

[0057] Example 1 illustrates the properties of the Cu-β molecular sieve prepared by the method provided by the present invention.

[0058] Take 10 g of the pretreated molecular sieve sample B-25 in Comparative Example 1, add it into a beaker containing 10 g of n-octane, mix well, and treat for 1 hour.

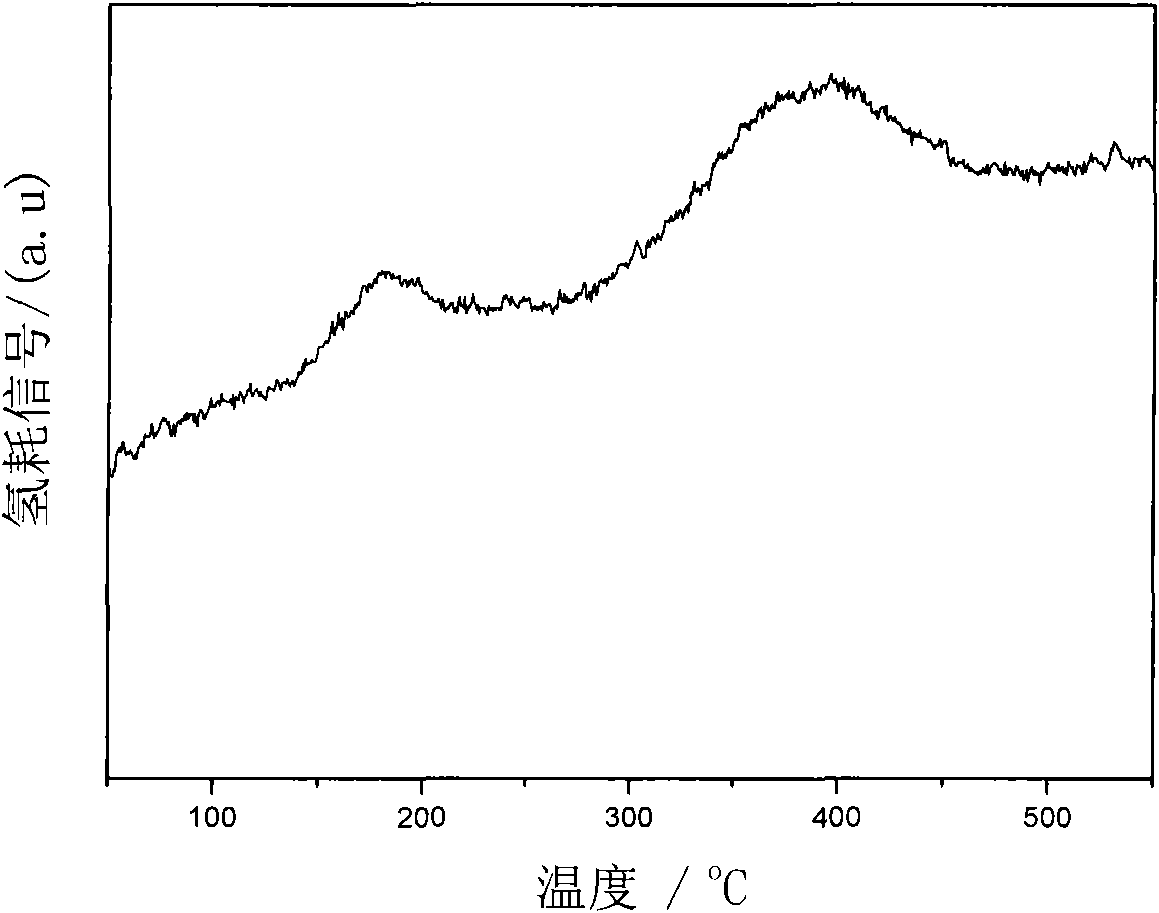

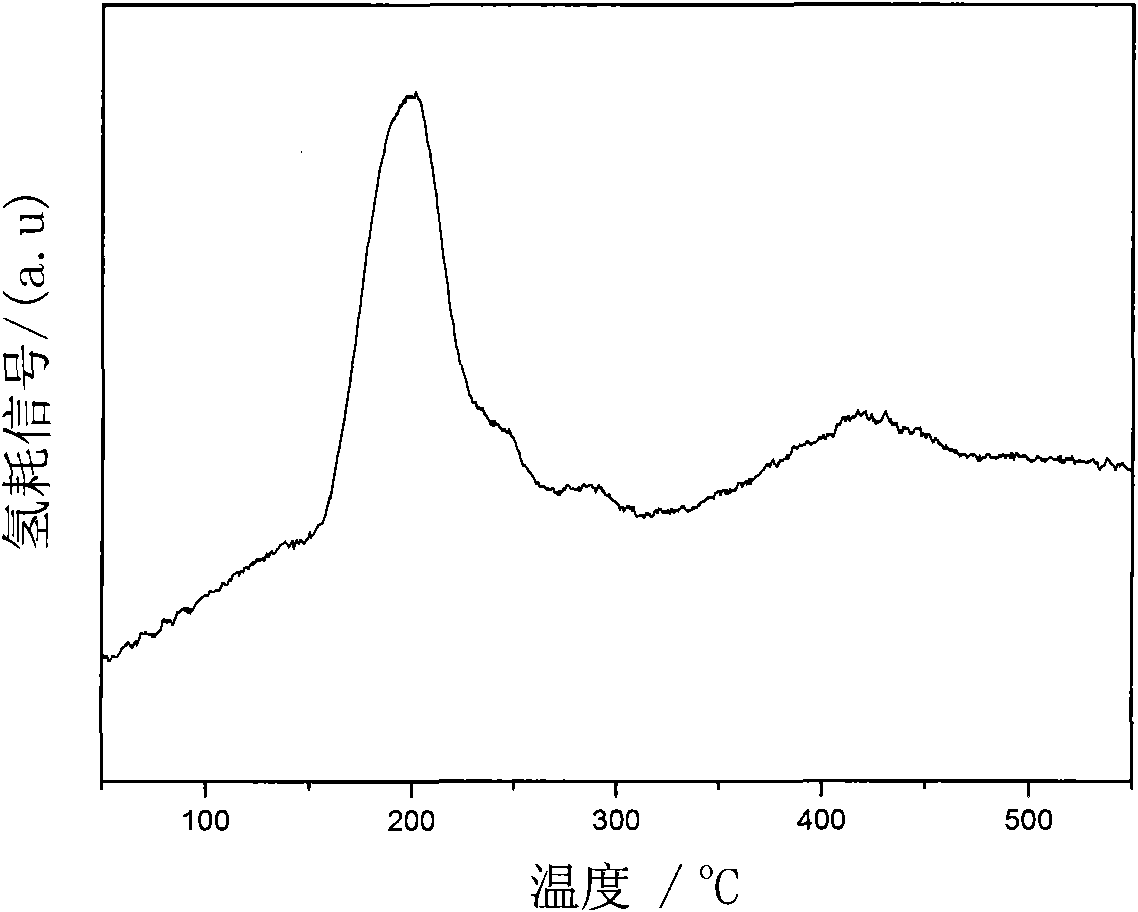

[0059] Place the treated molecular sieve in 2g of copper nitrate aqueous solution with a concentration of 19wt%, mix evenly, dry at 60°C for 10 hours after impregnating for 2 hours, then bake at 550°C for 2 hours in an air atmosphere, and then water at 800°C The Cu-β molecular sieve sample obtained by steam heat treatment for 4 hours is designated as A-1. Its anhydrous chemical expression is: 0.08Na 2 O 8.02Al 2 o 3 1.5CuO 90.4SiO 2 . Its H 2 -TPR analysis see Figure 4 , it can be seen from the figure that the existence state of CuO is CuO-Al 2 o 3 : CuO=1.15:1, its physical and chemical properties and acid properties are shown in Table 1.

Embodiment 2

[0061] Example 2 illustrates the preparation method of the aromatization catalytic material Cu-β molecular sieve provided by the present invention.

[0062] (1) Molecular sieve pretreatment: take SiO 2 / Al 2 o 3 The β-type molecular sieve with a molar ratio of 150 is calcined at a temperature of 350°C to 550°C to remove the template agent. According to molecular sieve: NH 4 NO 3 :H 2 The weight ratio of O=1:1:10 was exchanged at 90° C. for 0.5 hour, and the filter cake was filtered and dried to obtain molecular sieve pretreated sample B-150.

[0063] (2) Take 10 grams of B-150, add it to a beaker containing 8 grams of isooctane, and mix well.

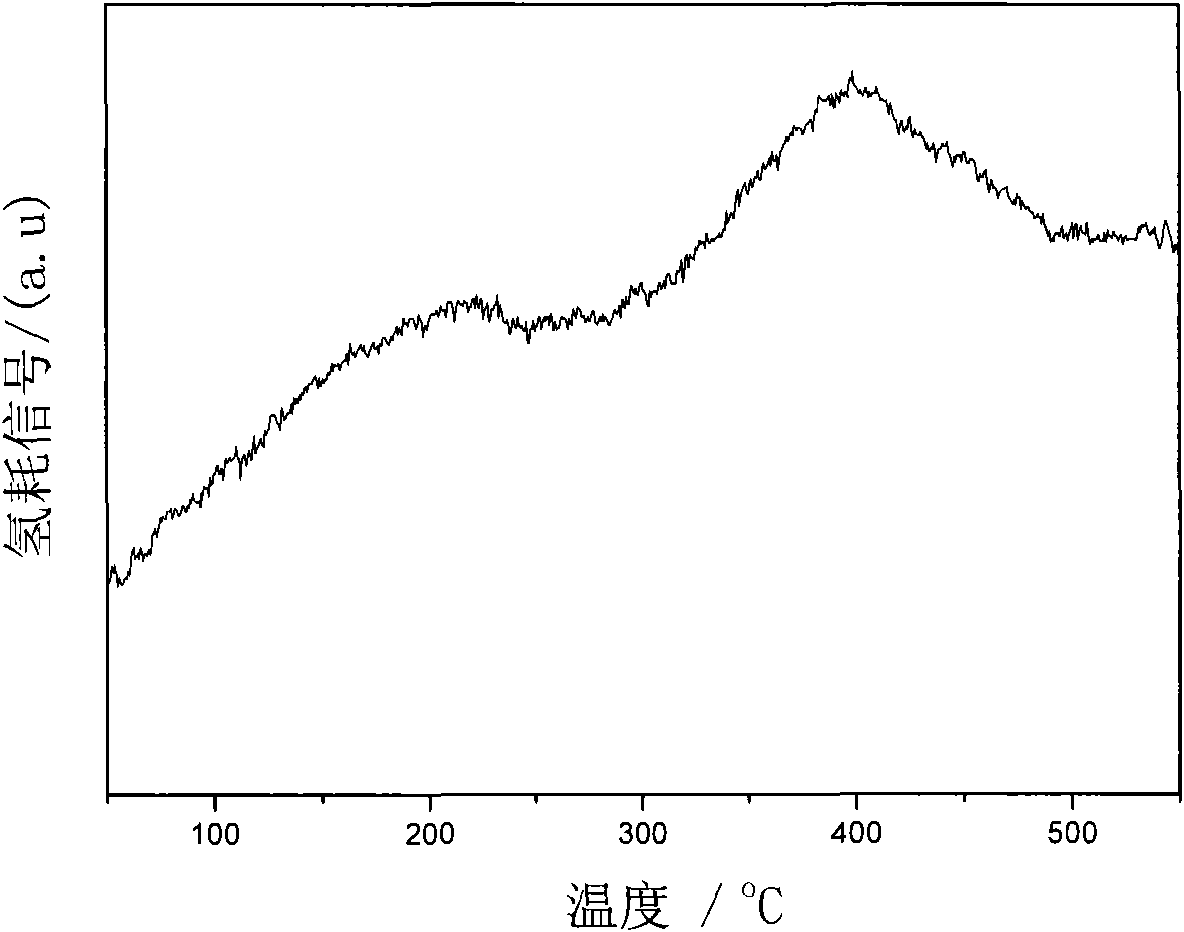

[0064] (3) Add the sample obtained in step (2) into 4 g of copper nitrate aqueous solution with a concentration of 9.5 wt %, mix evenly, and immerse for 2 hours. Then dry at 80°C for 8 hours, bake at 550°C for 2 hours in an air atmosphere, and then heat-treat with water vapor at 800°C for 4 hours to obtain a Cu-β molecular sieve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com