Patents

Literature

240results about How to "Suppress cracks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite Particle for Electrode, Method for Producing the Same and Secondary Battery

InactiveUS20080160409A1Improve electronic conductivityExcellent initial charge/discharge characteristicMaterial nanotechnologyElectrode manufacturing processesFiberSurface layer

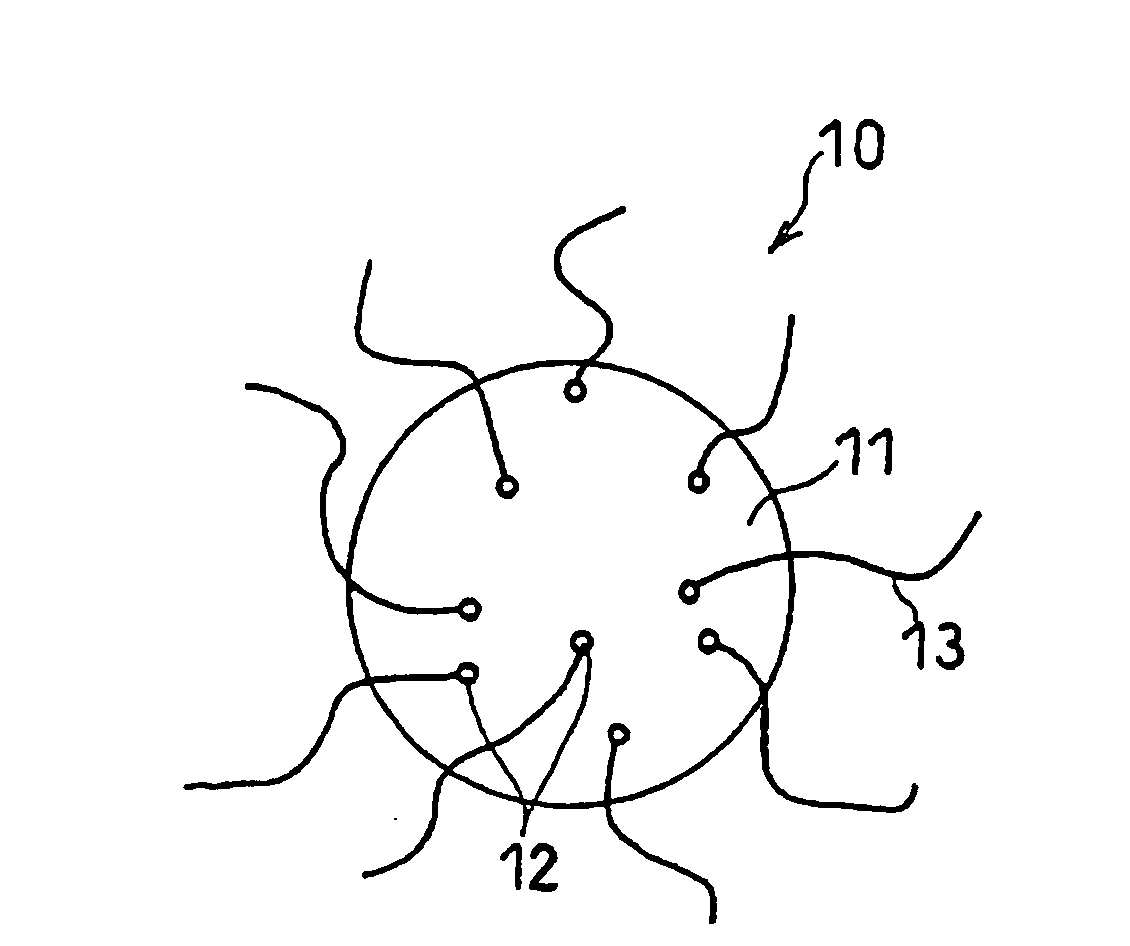

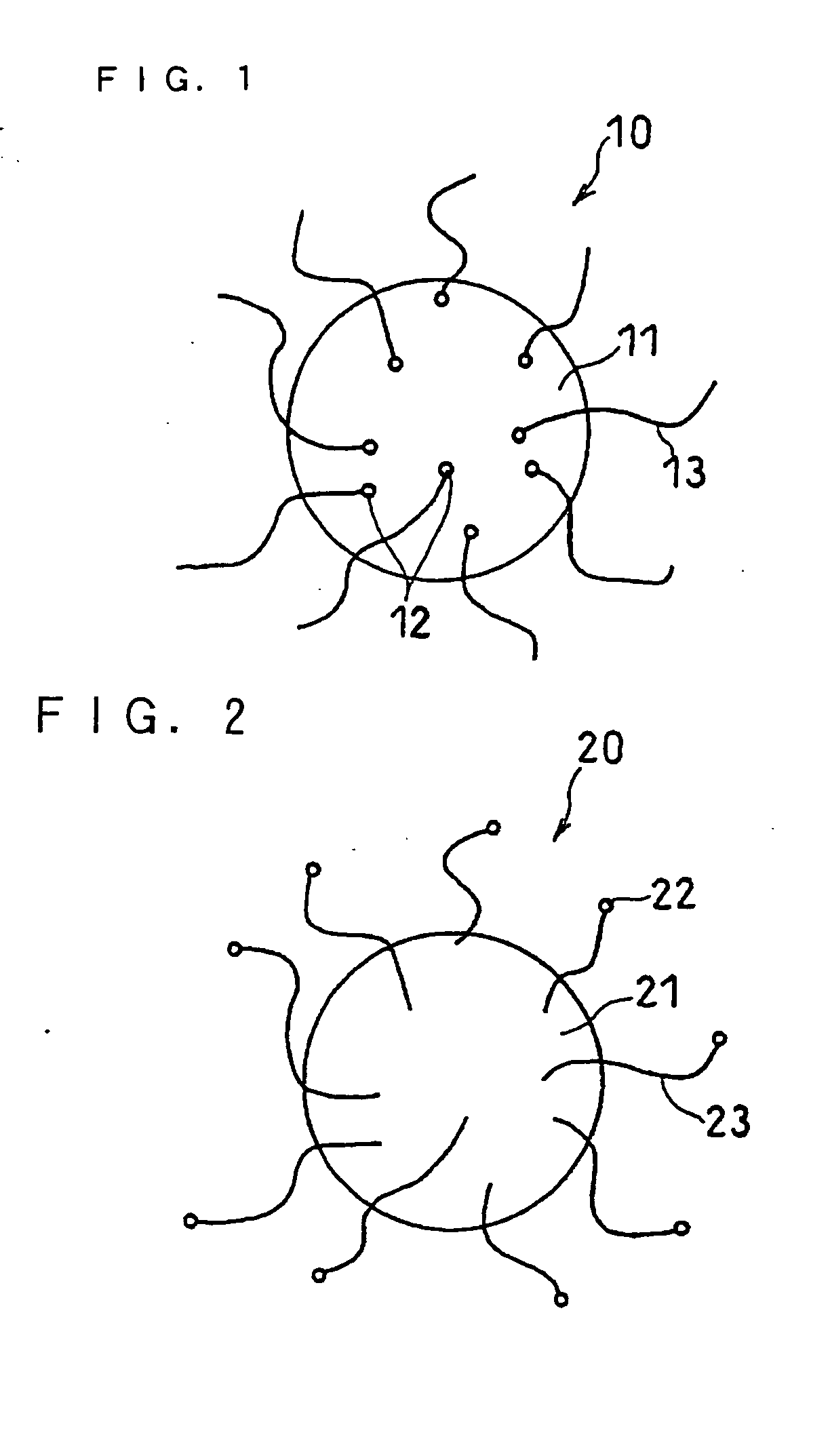

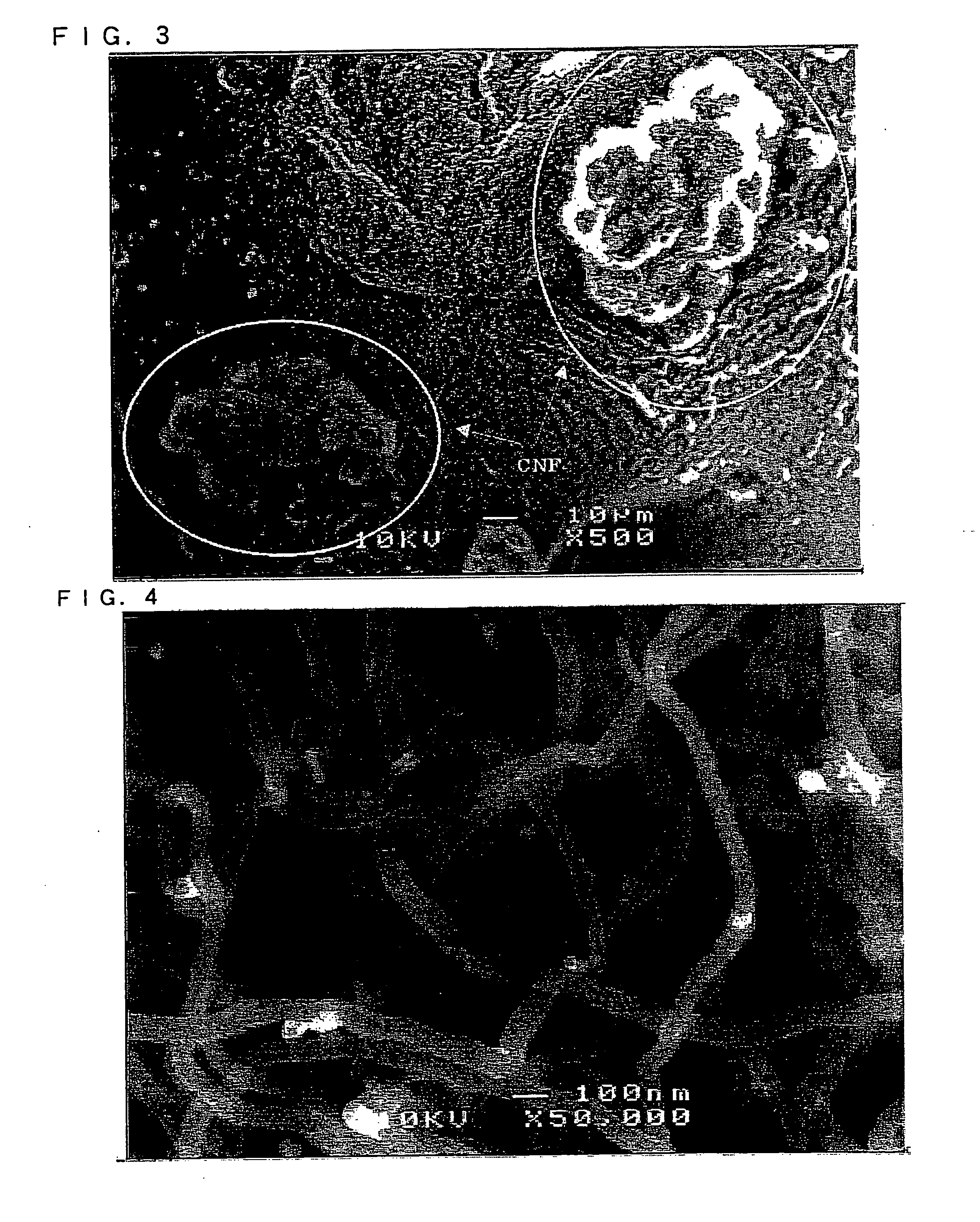

A composite particle for an electrode including an active material particle, carbon nanofibers bonded to the surface of the active material particle, and a catalyst element for promoting the growth of the carbon nanofibers, wherein the active material particle includes an electrochemically active phase. As the catalyst element, for example, Au, Ag, Pt, Ru, Ir, Cu, Fe, Co, Ni, Mo, Mn and the like are used. The composite particle for an electrode may be produced, for example, by means of a method which includes: a step of preparing an active material particle including a catalyst element for promoting the growth of carbon nanofibers at least in the surface layer of the active material particle; and a step of growing carbon nanofibers on the surface of the active material particle in an atmosphere including a raw material gas.

Owner:PANASONIC CORP

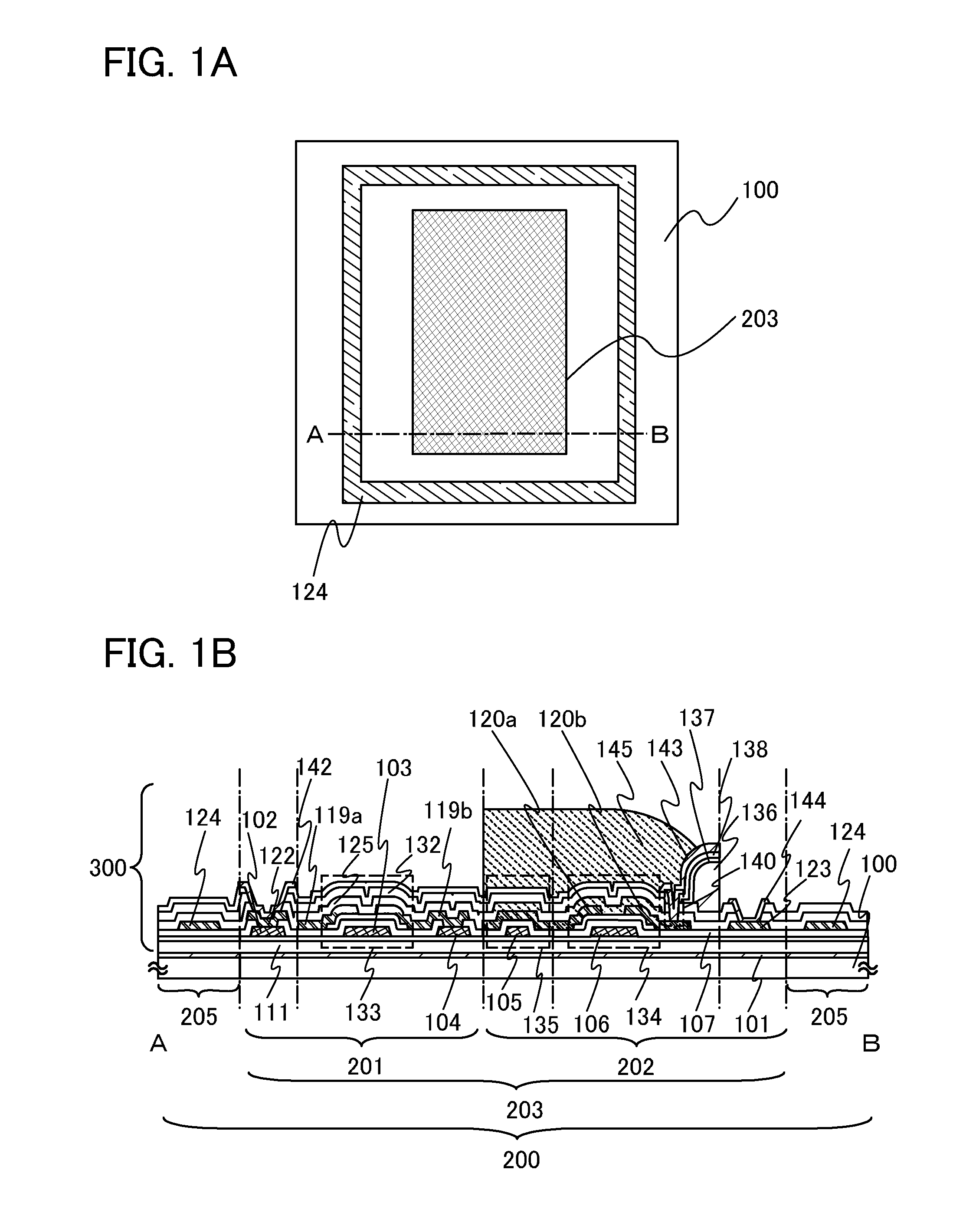

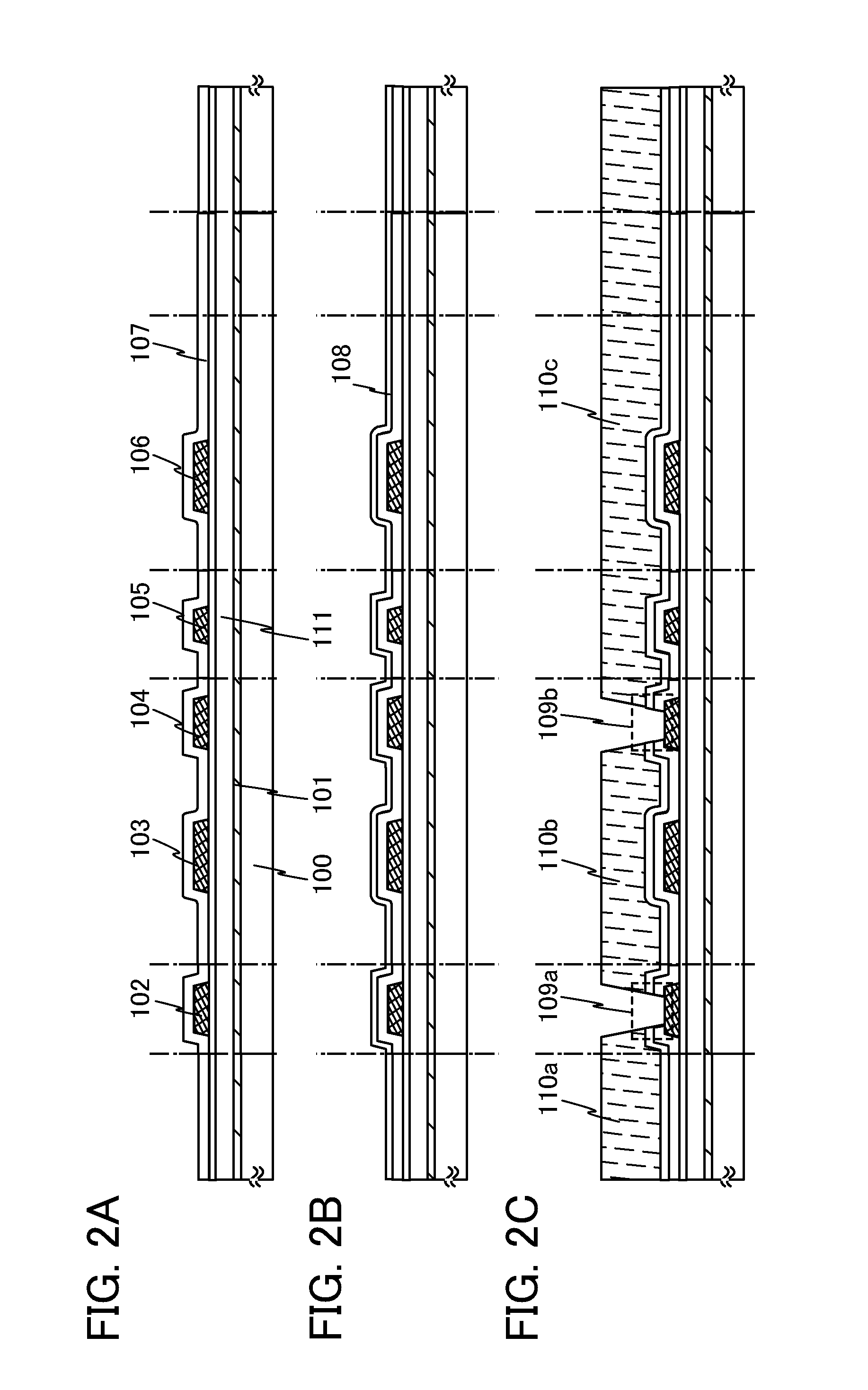

Semiconductor device

ActiveUS20070057337A1Suppressed dislocationReduce layeringLaser detailsSolid-state devicesNitrogenSemiconductor device

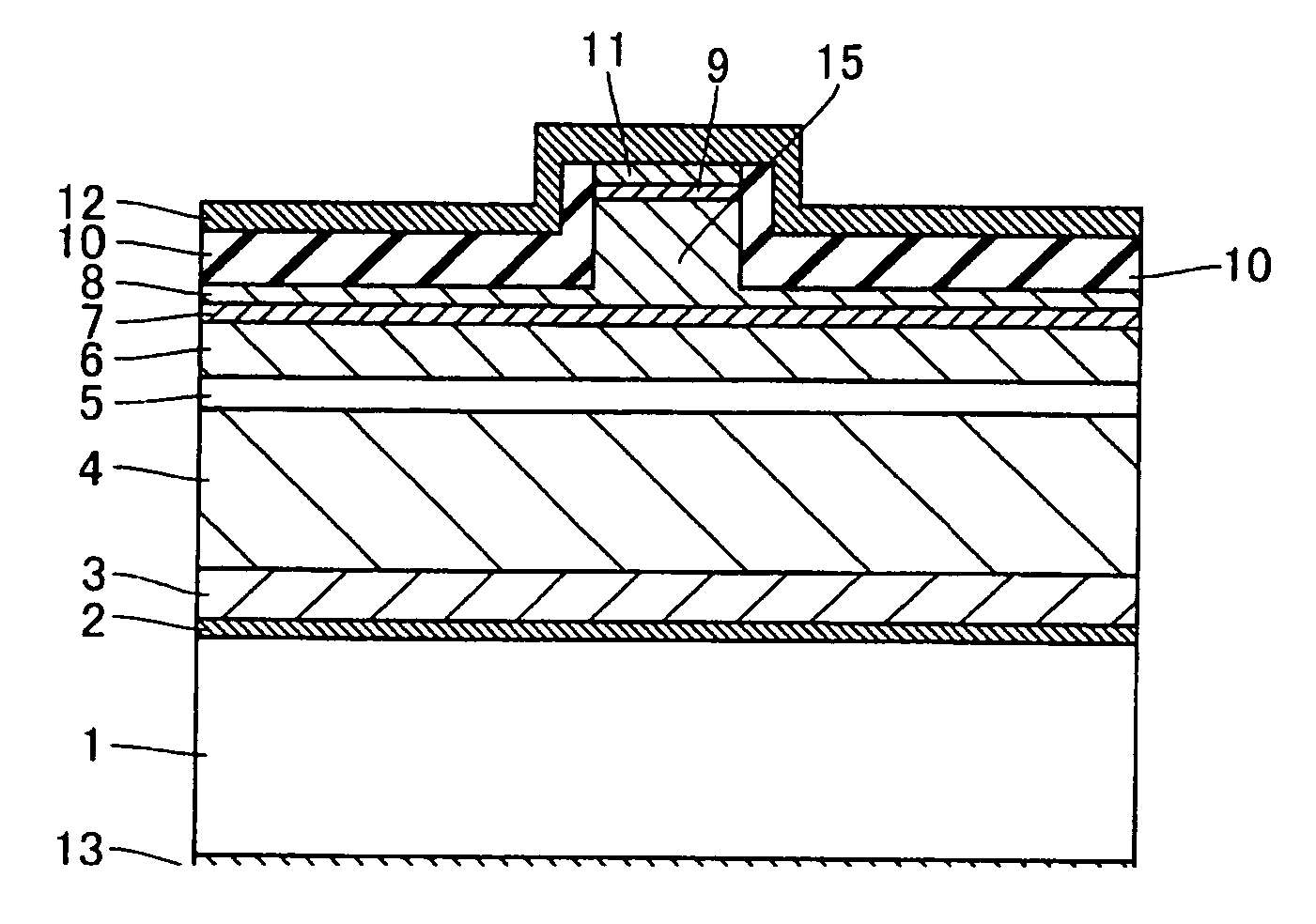

A semiconductor device includes a semiconductor substrate formed of at least two kinds of group III elements and nitrogen, an active layer formed on the semiconductor substrate, and a nitride semiconductor layer formed on a surface of the semiconductor substrate and formed between the semiconductor substrate and the active layer. The nitride semiconductor layer is formed of the same constituent elements of the semiconductor substrate. A composition ratio of the lightest element among the group III elements of the nitride semiconductor layer is higher than a composition ratio of the corresponding element of the semiconductor substrate.

Owner:EPISTAR CORP

Process for the conversion of ethane to aromatic hydrocarbons

ActiveUS20090209794A1Limit initial cracking activitySacrificing activityMolecular sieve catalystsMolecular sieve catalystBenzenePlatinum

A process for producing aromatic hydrocarbons which comprises (a) contacting ethane with a dehyroaromatization aromatic catalyst which is comprised of about 0.005 to about 0.1 wt % platinum, an amount of gallium which is equal to or greater than the amount of the platinum, from about 10 to about 99.9 wt % of an aluminosilicate, and a binder, and (b) separating methane, hydrogen, and C2-5 hydrocarbons from the reaction products of step (a) to produce aromatic reaction products including benzene.

Owner:SHELL USA INC

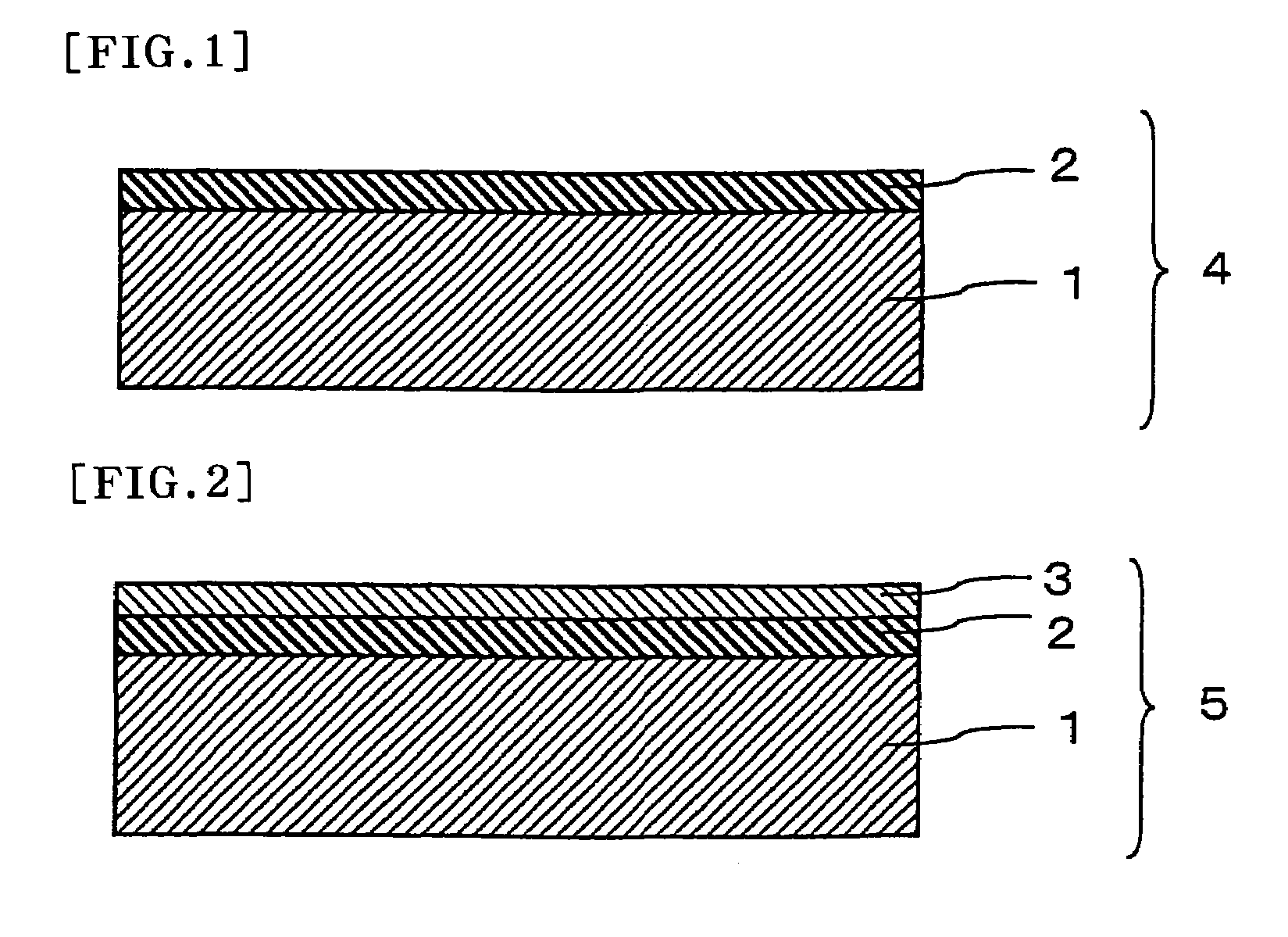

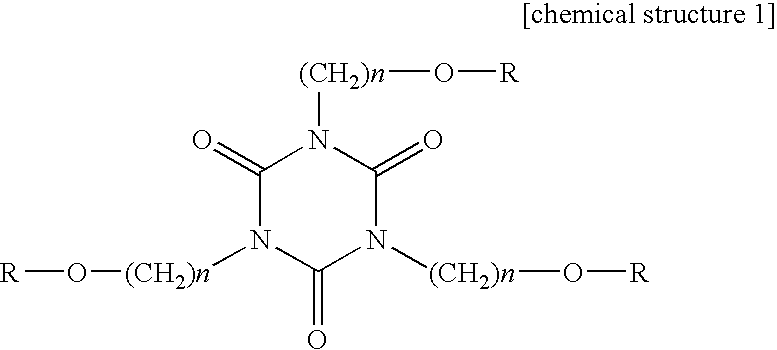

Hard coat film, antireflection hard coat film, optical element and image display

InactiveUS20070178297A1Suppress cracksCurl suppressionSynthetic resin layered productsCellulosic plastic layered productsOptoelectronicsHardness

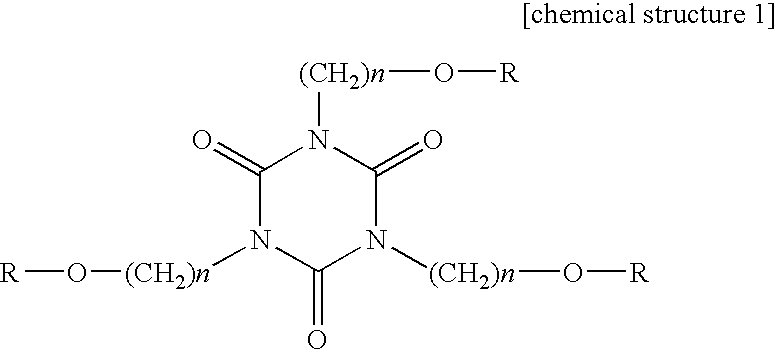

A hard coat film of the present invention comprises a hard coat layer, which is a cured coat layer, provided on at least one side of a transparent plastic film substrate, wherein a hard coat layer forming material comprises urethane acrylate (A); isocyanuric acid acrylate (B) and inorganic ultrafine particles (C), and has a high hardness and suppresses curling due to cracking and cure shrinkage.

Owner:NITTO DENKO CORP

Process and apparatus for upgrading FCC product with additional reactor with catalyst recycle

InactiveUS6866771B2Increase undesirable crackingLower catalytic temperatureTreatment with plural serial cracking stages onlyCatalytic crackingCracking reactionChemistry

Owner:UOP LLC

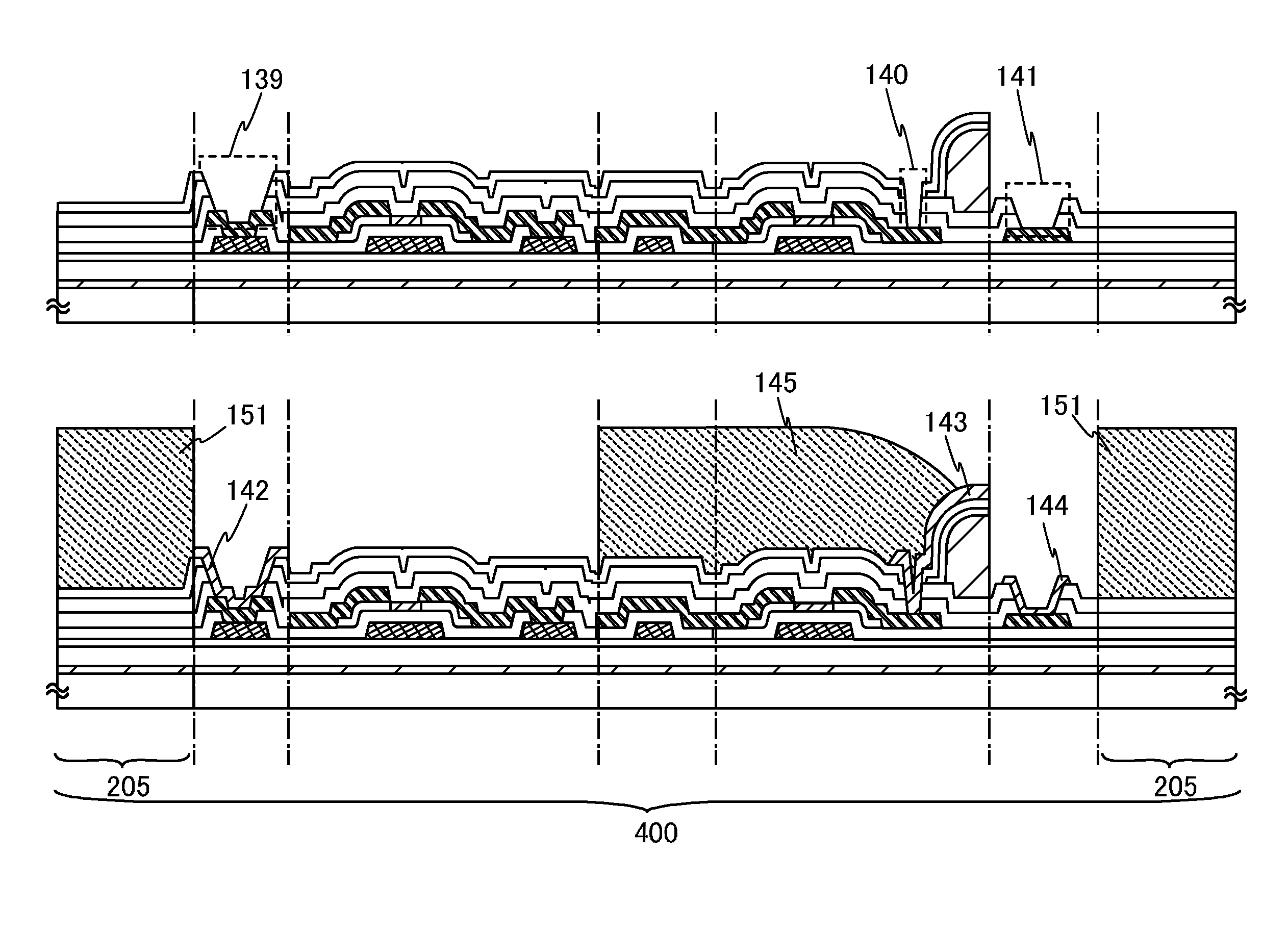

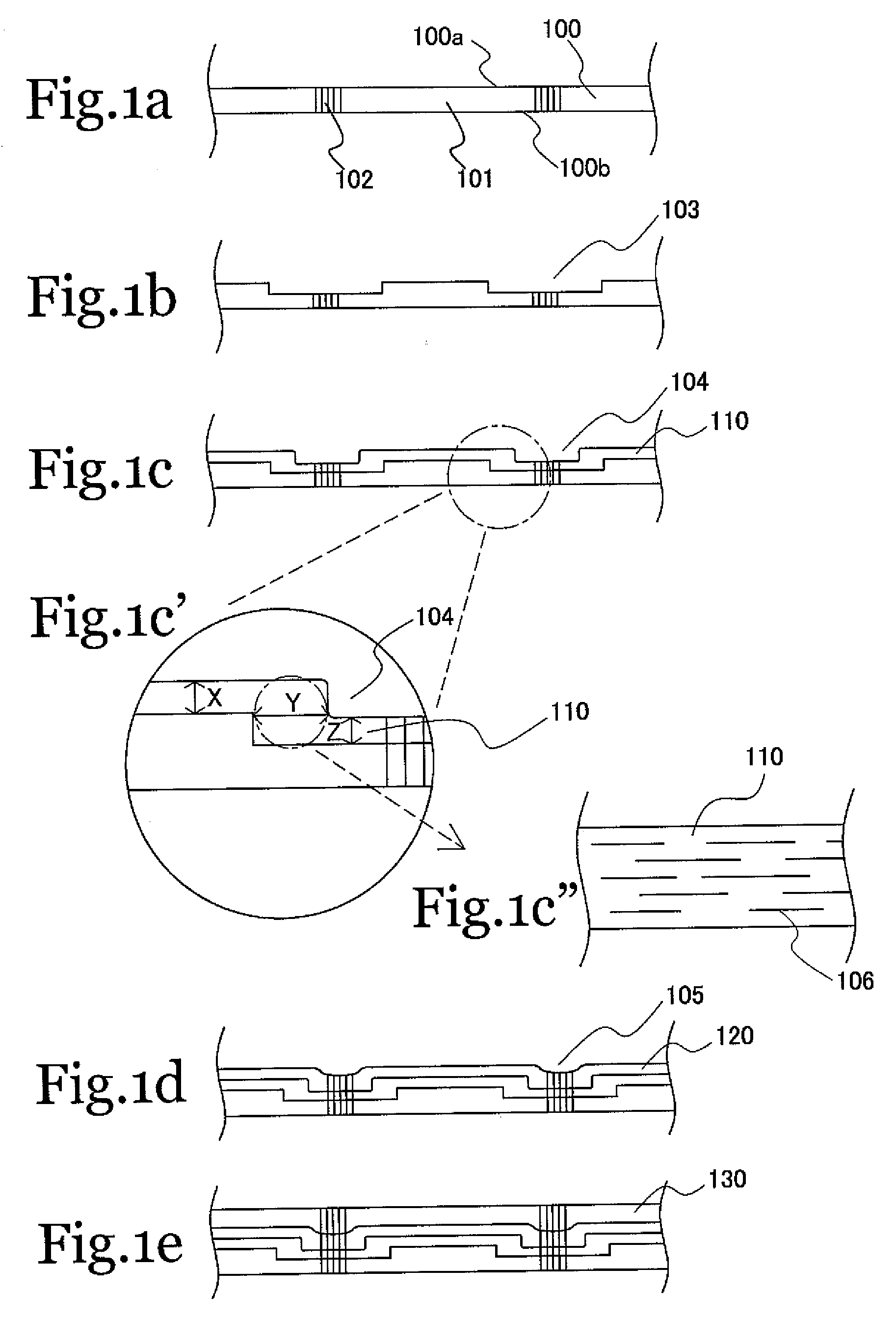

Method for manufacturing semiconductor device

ActiveUS20110318889A1Crack suppressionHigh yield manufacturingSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringMetal

An object is to provide a manufacturing method of a semiconductor device in which a defect in characteristics due to a crack occurring in a semiconductor device is reduced. Provision of a crack suppression layer formed of a metal film in the periphery of a semiconductor element makes it possible to suppress a crack occurring from the outer periphery of a substrate and reduce damage to the semiconductor element. In addition, even if the semiconductor device is subjected to physical forces from the outer periphery in separation and transposition steps, progression (growth) of a crack to the semiconductor device can be suppressed by the crack suppression layer.

Owner:SEMICON ENERGY LAB CO LTD

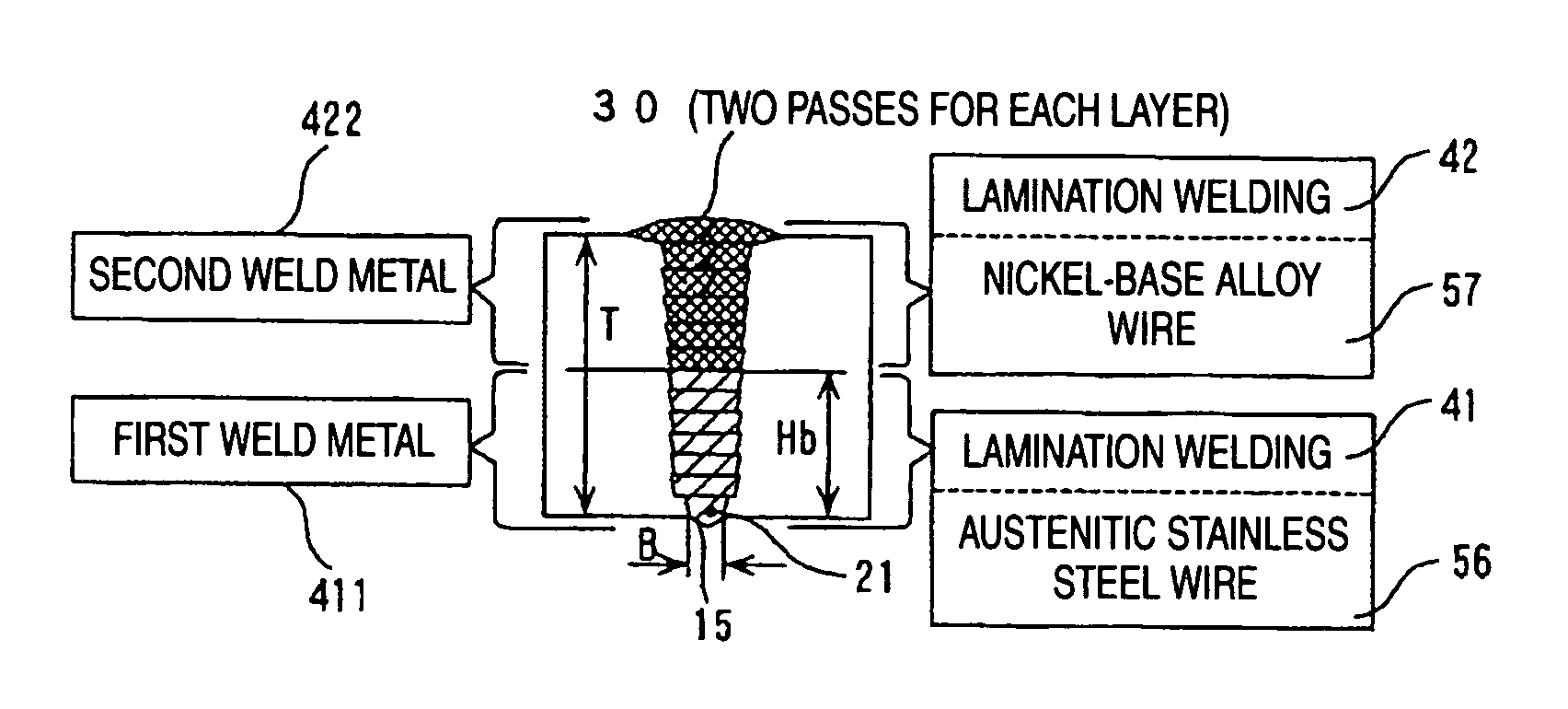

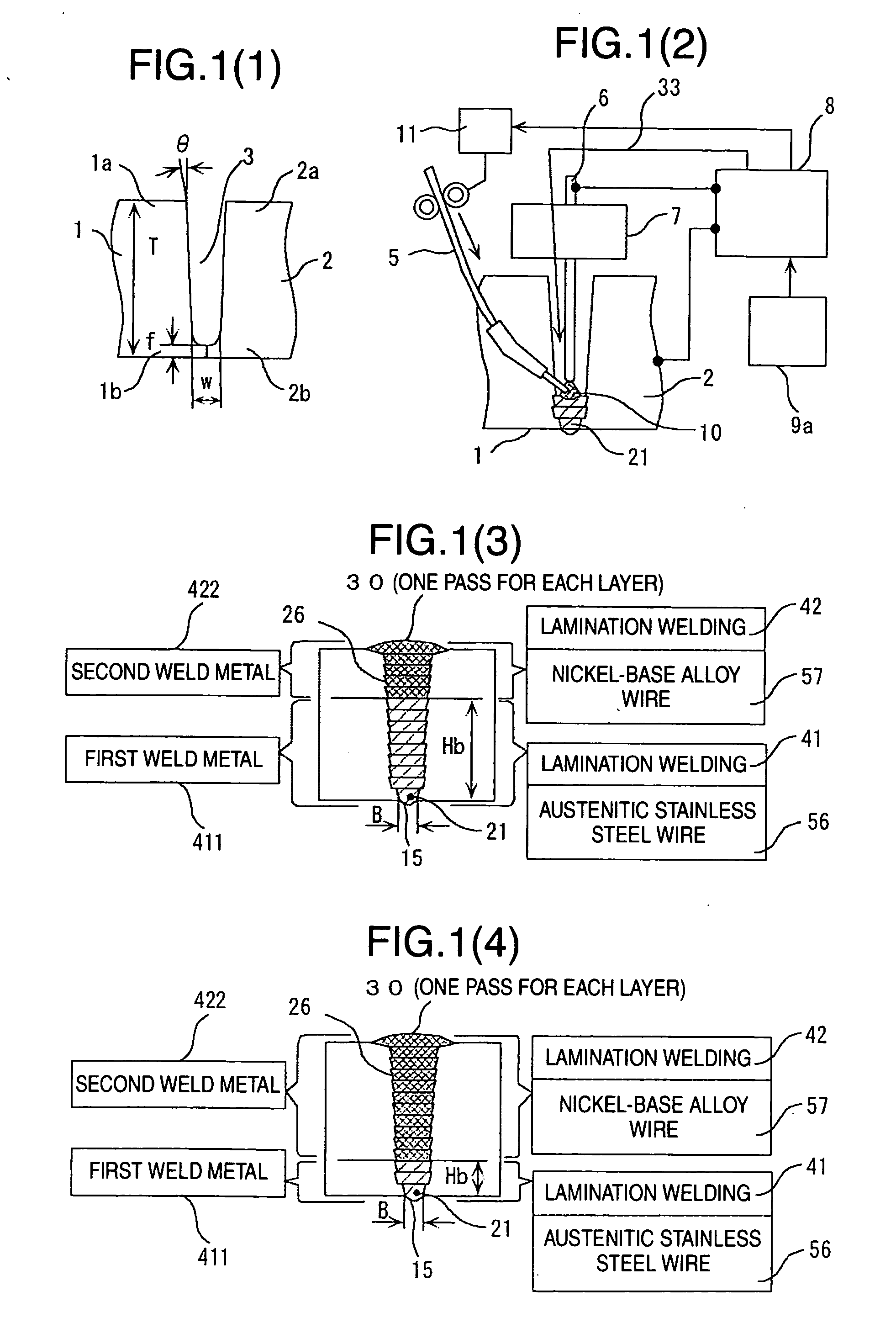

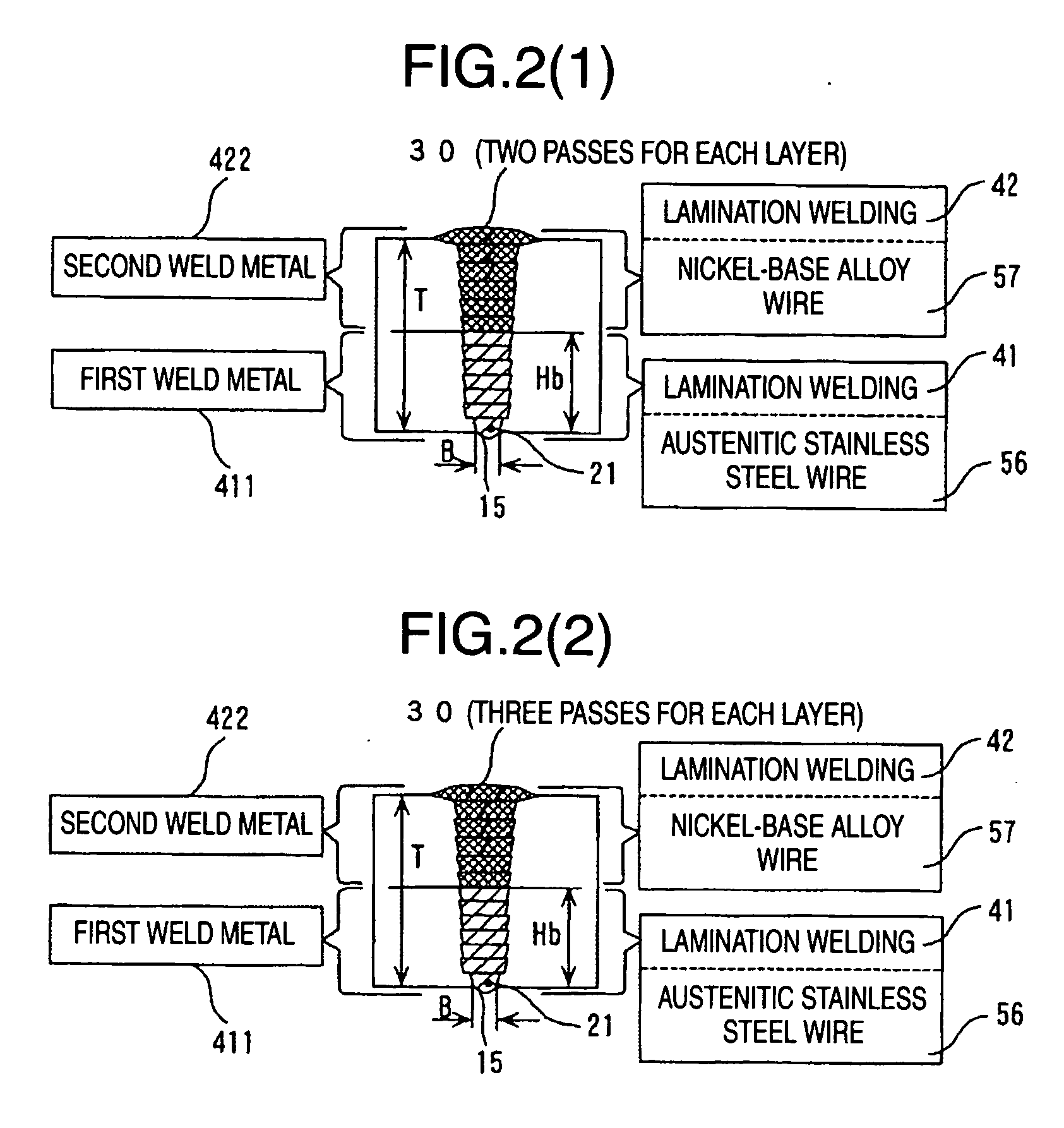

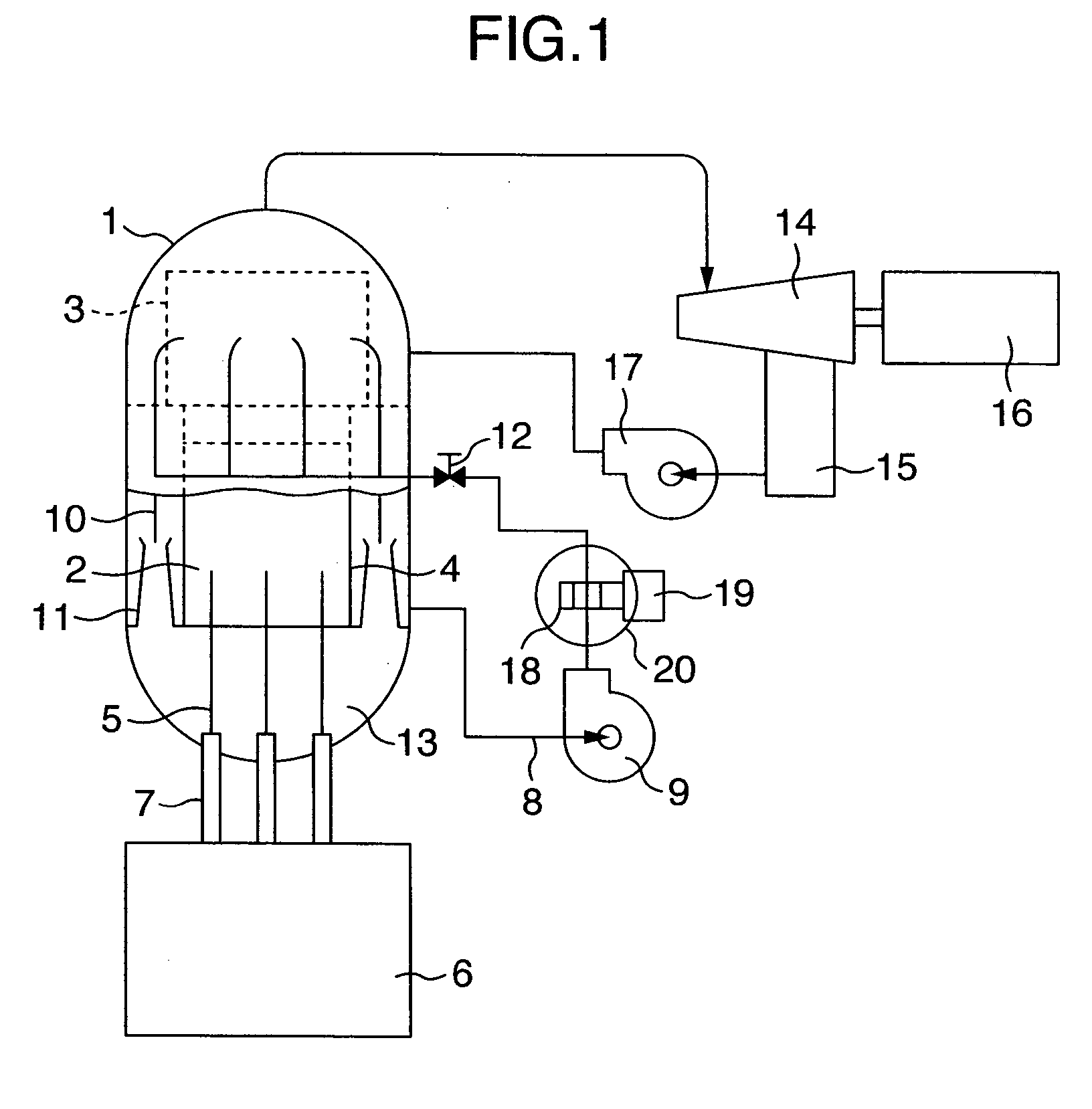

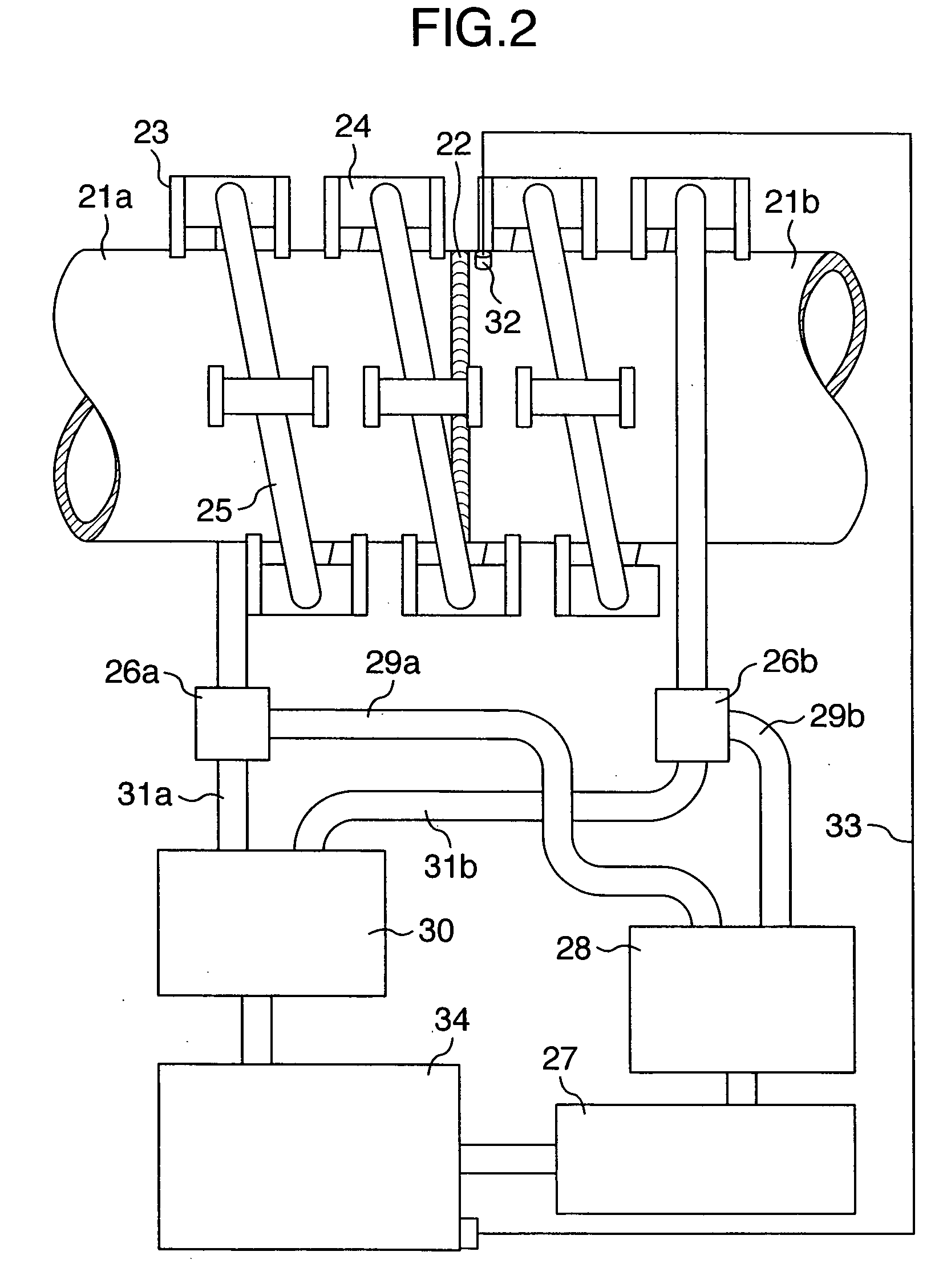

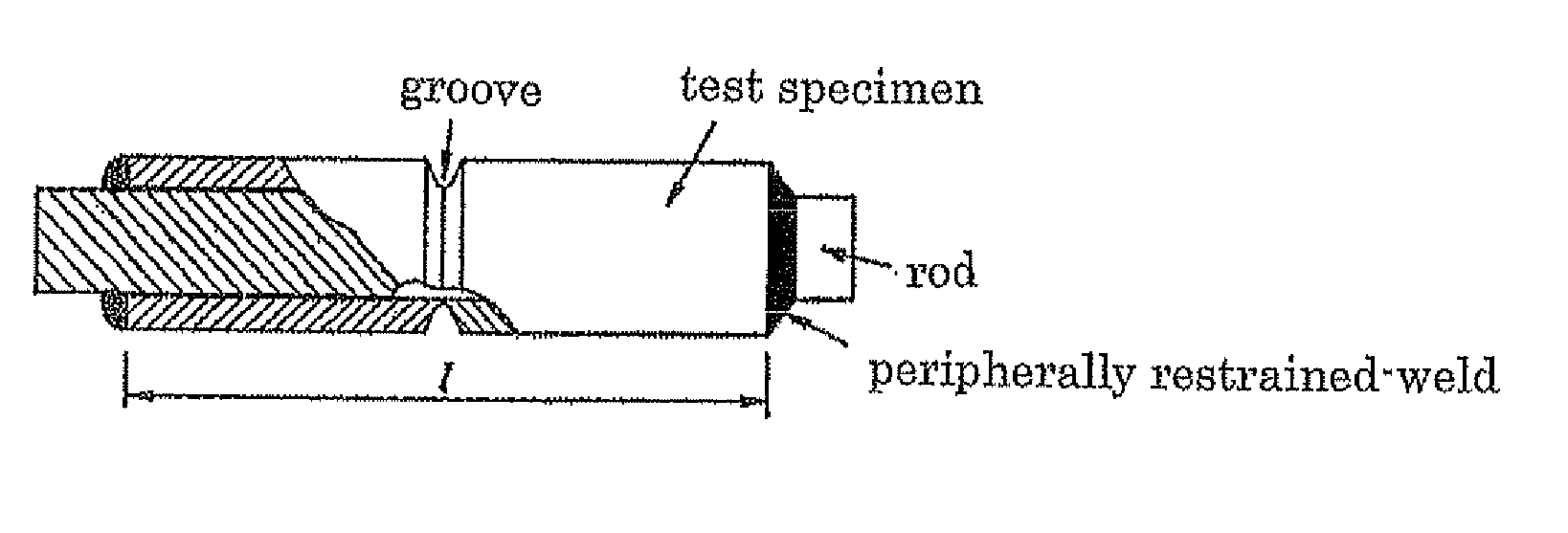

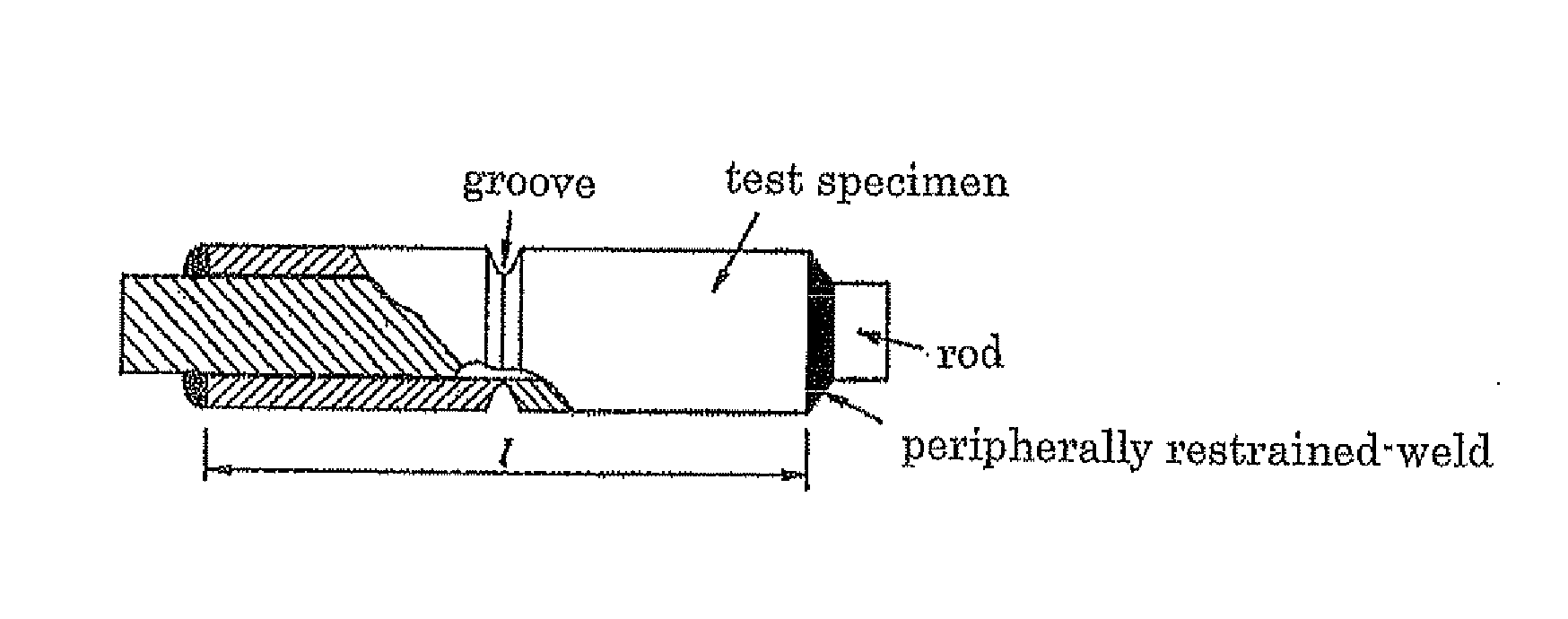

Welding process for stainless steel piping

InactiveUS20060201915A1Suppresses stress corrosion crackingReduce residual stressArc welding apparatusWelding/soldering/cutting articlesAlloyAustenite

The present invention has an object to reduce residual stress in a tensile direction of a weld on the inner side in contact with reactor water of austenitic stainless steel piping, and to change the residual stress into compressive stress, to reduce stress corrosive cracking. The present invention provides a welding process for stainless steel piping of laminating two types of welding wire made of different materials in a groove of austenitic stainless steel piping, including at least one of a first layer penetration welding step of performing a predetermined back bead width on the back side of the groove bottom and a tack welding step, a first lamination welding step of lamination welding of austenitic stainless steel wire from the bottom to the top of the groove, and a second lamination welding step of lamination welding of nickel-base alloy wire to a final layer at the top of the groove.

Owner:HITACHI LTD

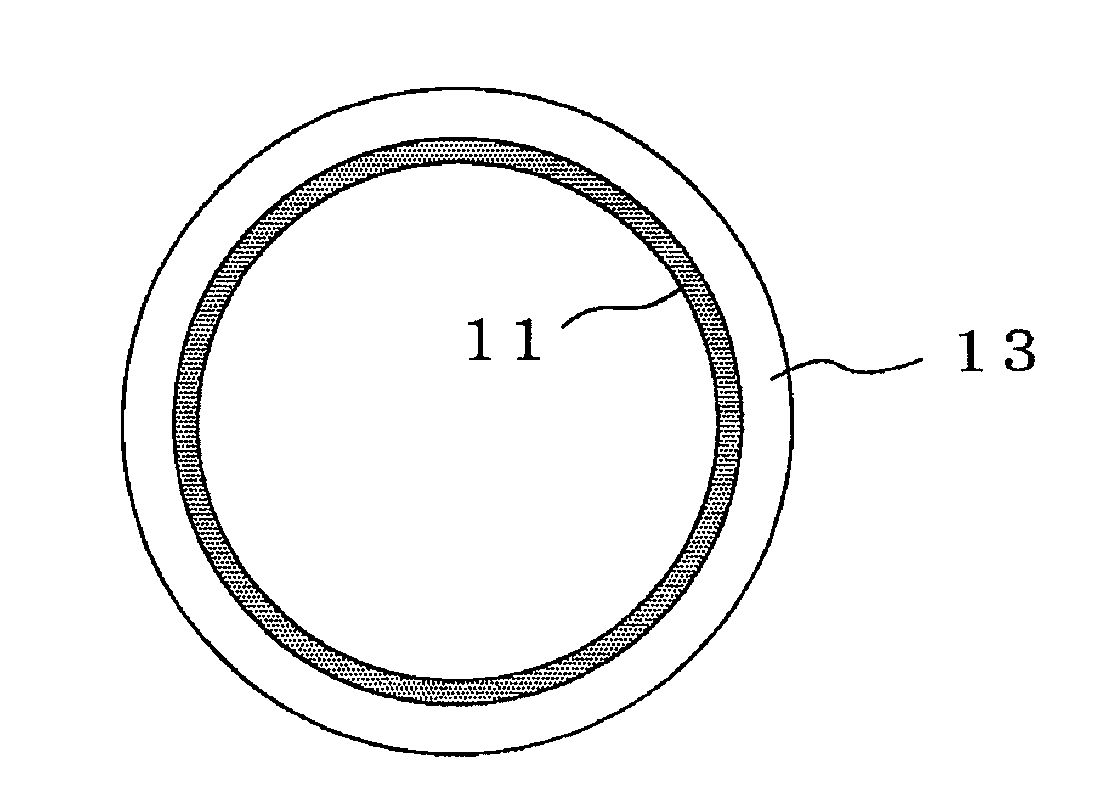

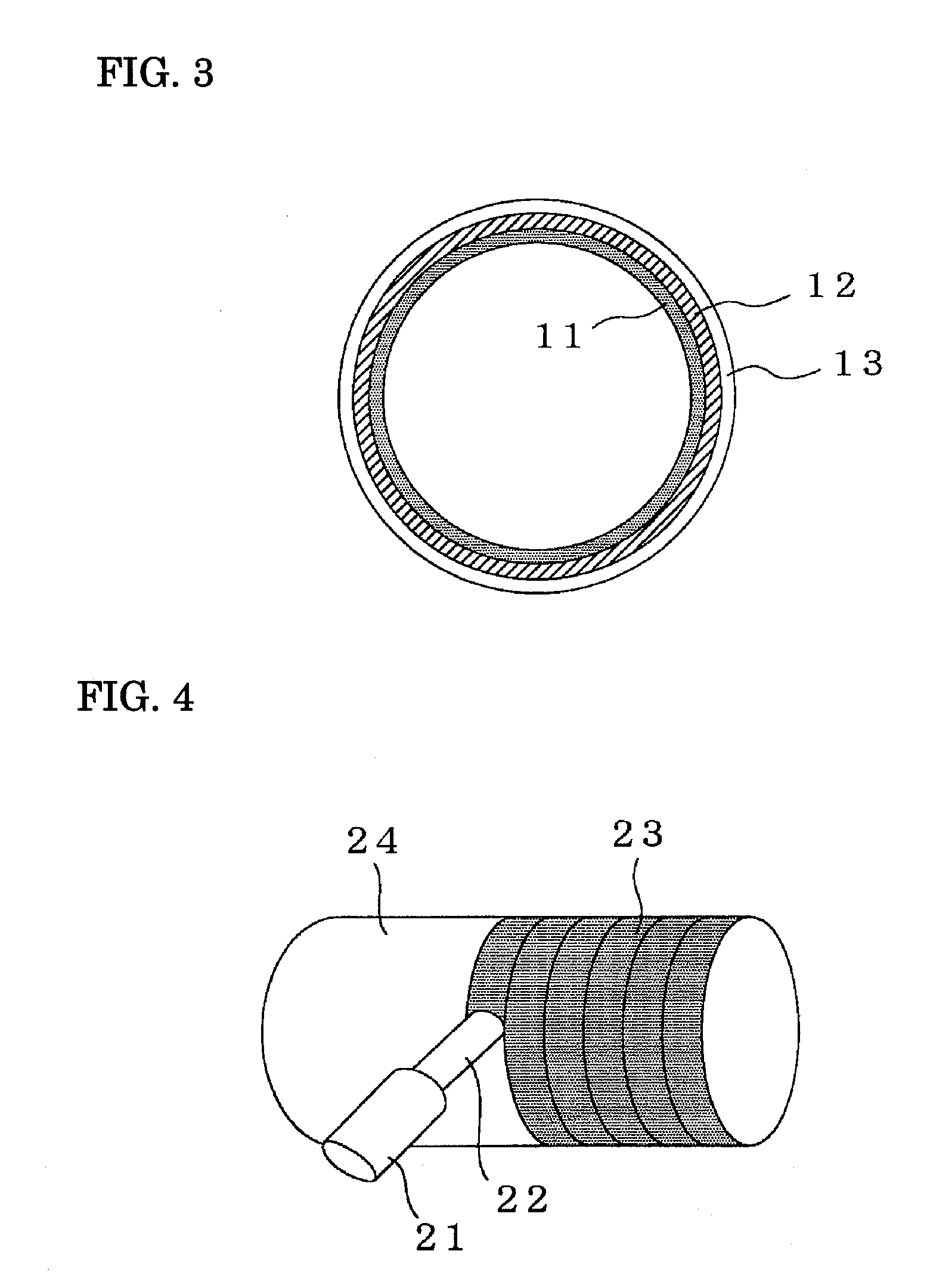

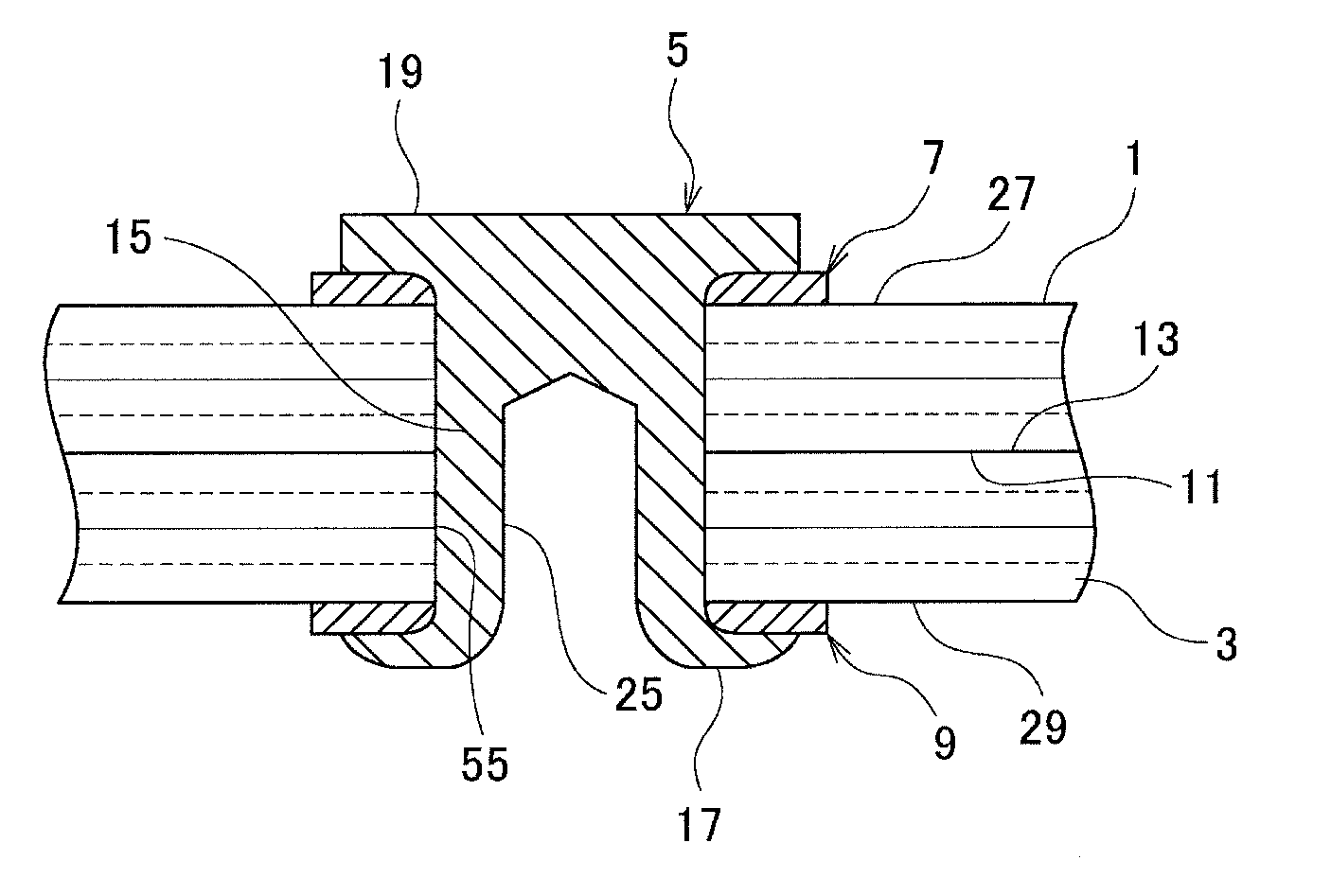

Polyimide tube, method for production thereof, method for production of polyimide varnish, and fixing belt

ActiveUS20100055365A1Improve thermal conductivityModulus improvementSynthetic resin layered productsCeramic shaping apparatusBoron nitrideVarnish

A polyimide tube composed of a polyimide resin composition in which 5 to 23.5 volume percent of boron nitride and 1 to 15 volume percent of an acicular substance are dispersed as a filler in a polyimide resin on the basis of the total volume of the composition, a method of producing the tube, a method of producing a polyimide varnish used for producing the tube, and a fixing belt including the tube as a base member are provided.

Owner:SUMITOMO ELECTRIC IND LTD +1

Substrate joining method using rivet, and joining structure

InactiveUS20130340239A1Avoid stress concentrationSuppresses separationRivetsSheet joiningPunchingRivet

A joining method includes punching respective laminated plate materials by a rivet shaft portion of a SPR, forming a crimp portion at the front end of the rivet shaft portion, and fastening and joining the laminated plate materials between the rivet head portion and the crimp portion. Washers are laid on and brought into contact with respective opposite surfaces relative to joining surfaces of the laminated plate materials, the washers each having an inner hole through which the rivet shaft portion is allowed to pass, the washers are used as jigs at the time of the punching, the punching by means of the rivet shaft portion is performed along the inner holes of the washers, and the joining is performed so that the washers left between the rivet head and the crimp portion and the opposite surfaces.

Owner:NIHON UNIVERSITY

Hard coat film, antireflection hard coat film, optical element and image display

InactiveUS7569269B2High hardnessCurl suppressionSynthetic resin layered productsCellulosic plastic layered productsPolymer scienceCarbamate

Owner:NITTO DENKO CORP

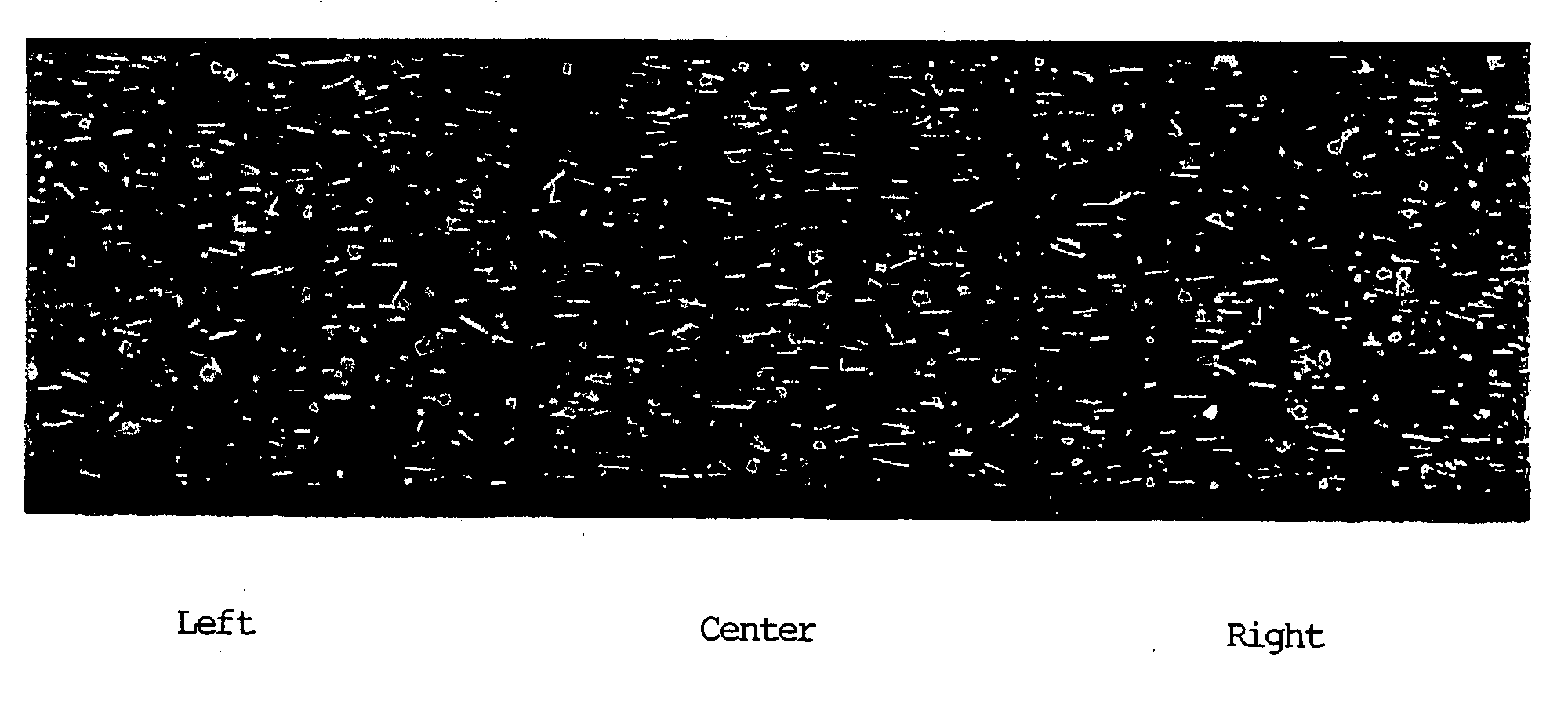

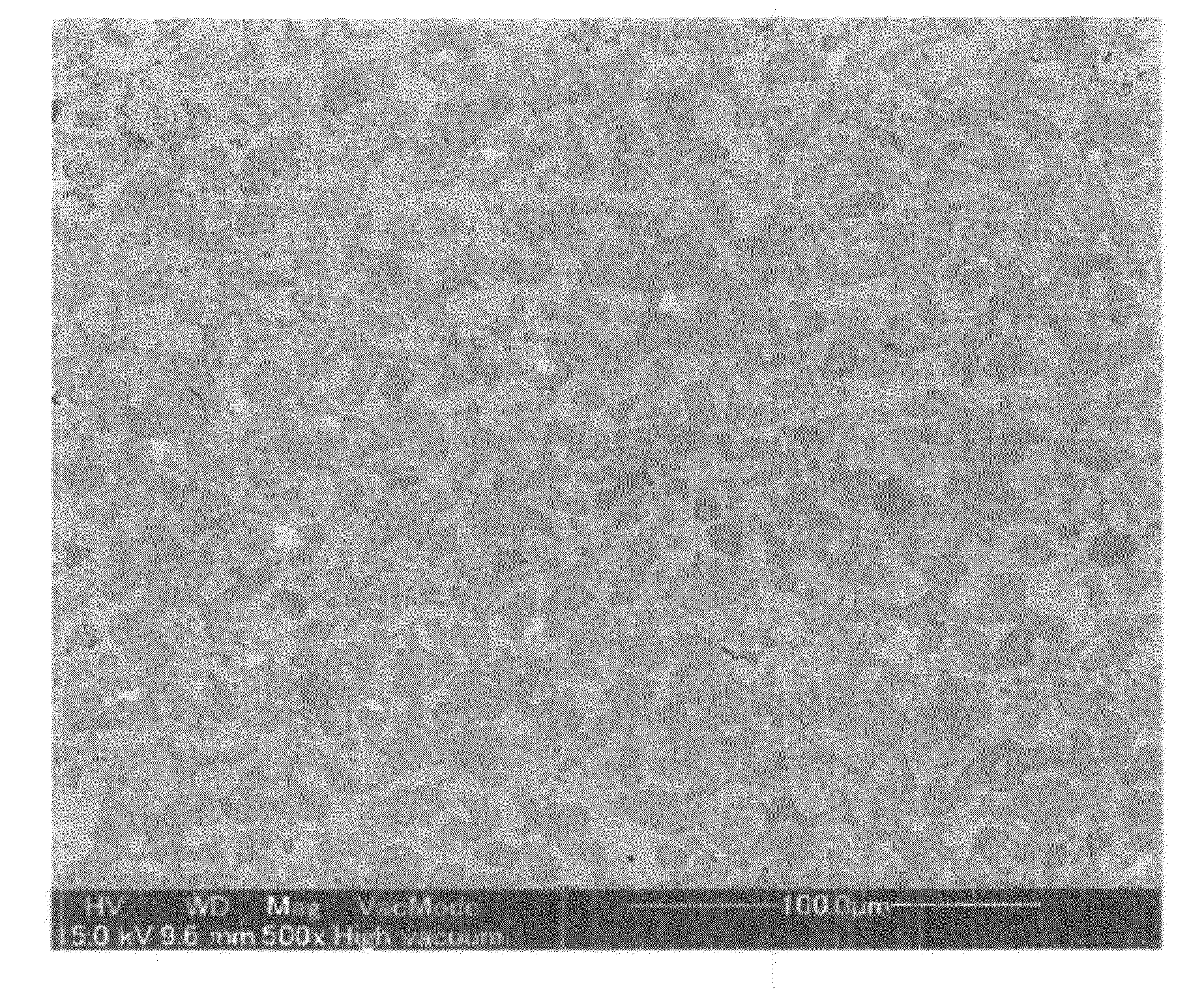

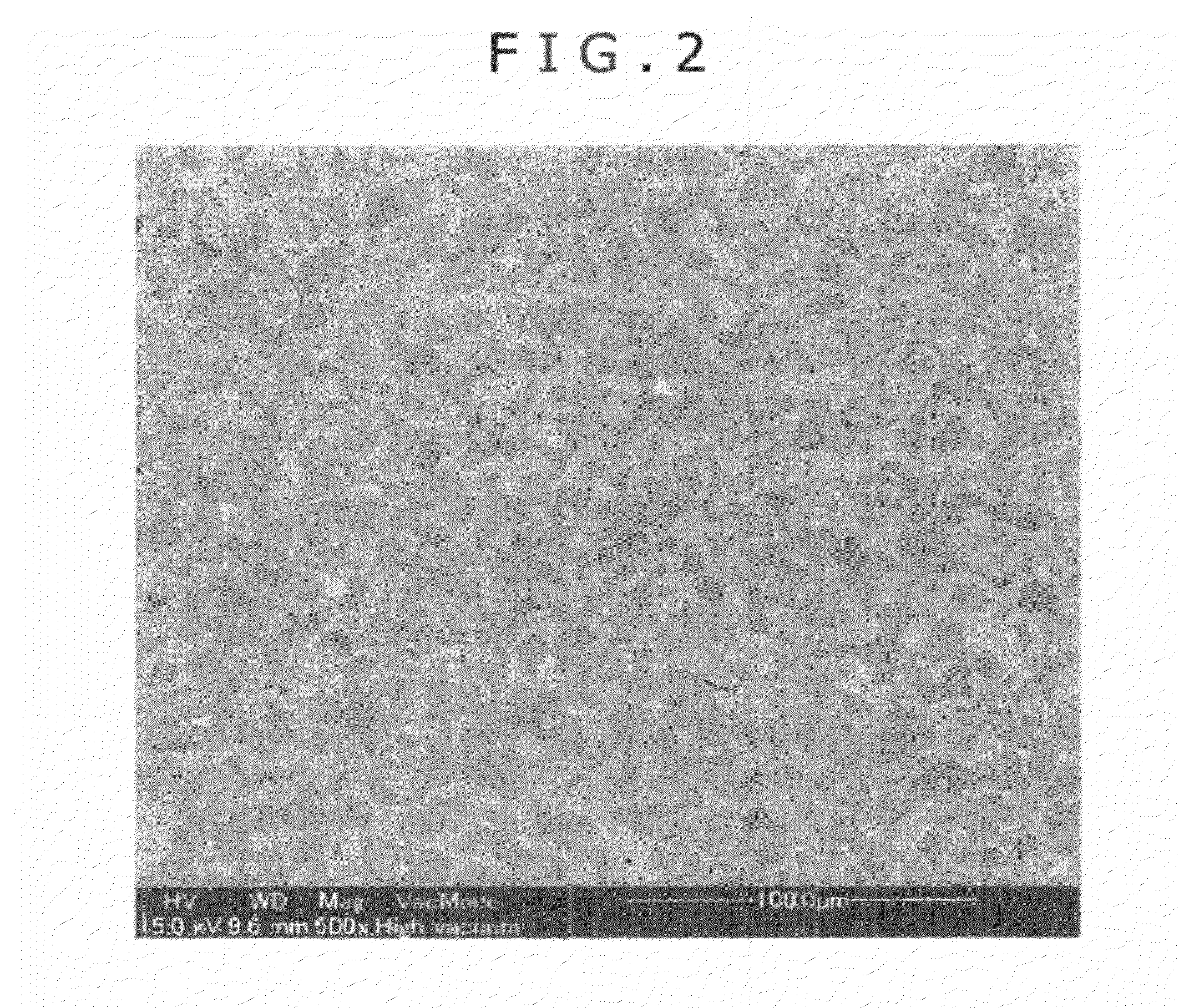

Al-Ni-rare earth element alloy sputtering target

InactiveUS20060180250A1OmissionSuppresses cracking of solderVacuum evaporation coatingSputtering coatingRare-earth elementAlloy

An Al-base alloy sputtering target consisting Ni and one or more rare earth elements, wherein there are 5.0×104 / mm2 or more compounds whose aspect ratio is 2.5 or higher and whose equivalent diameter is 0.2 μm or larger, when a cross sectional surface perpendicular to the plane of the target is observed at a magnification of 2000 or higher.

Owner:KOBE STEEL LTD +1

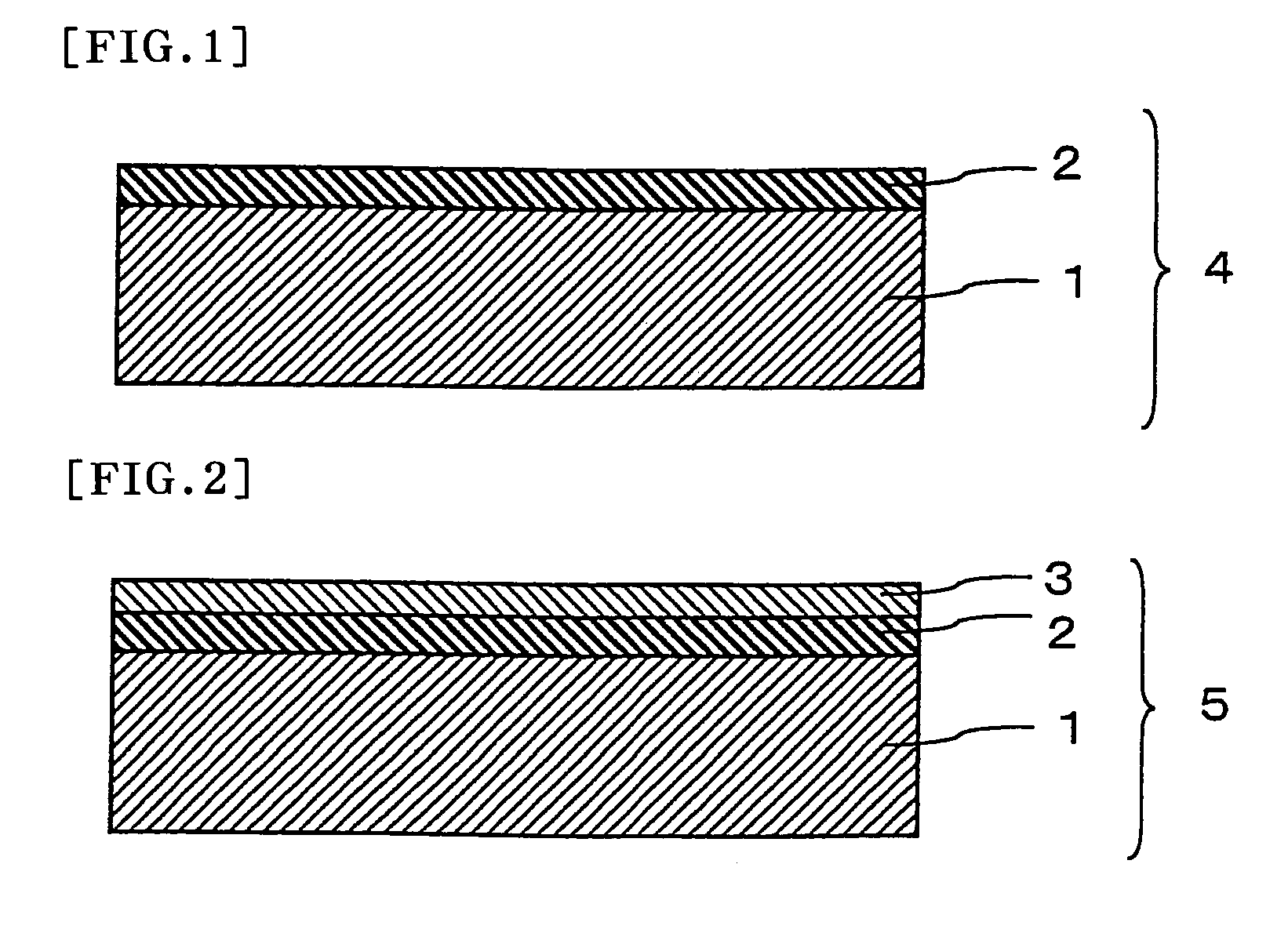

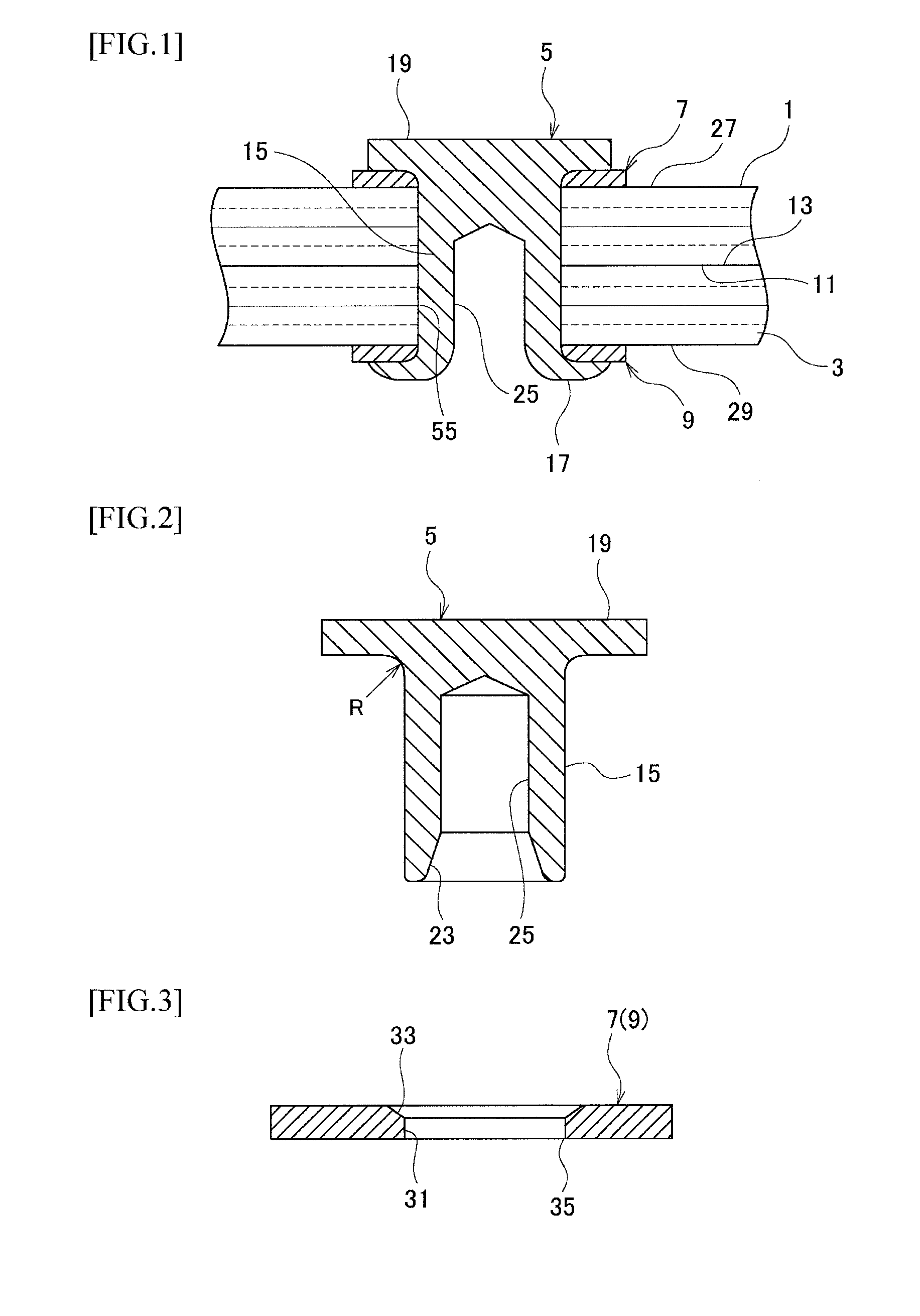

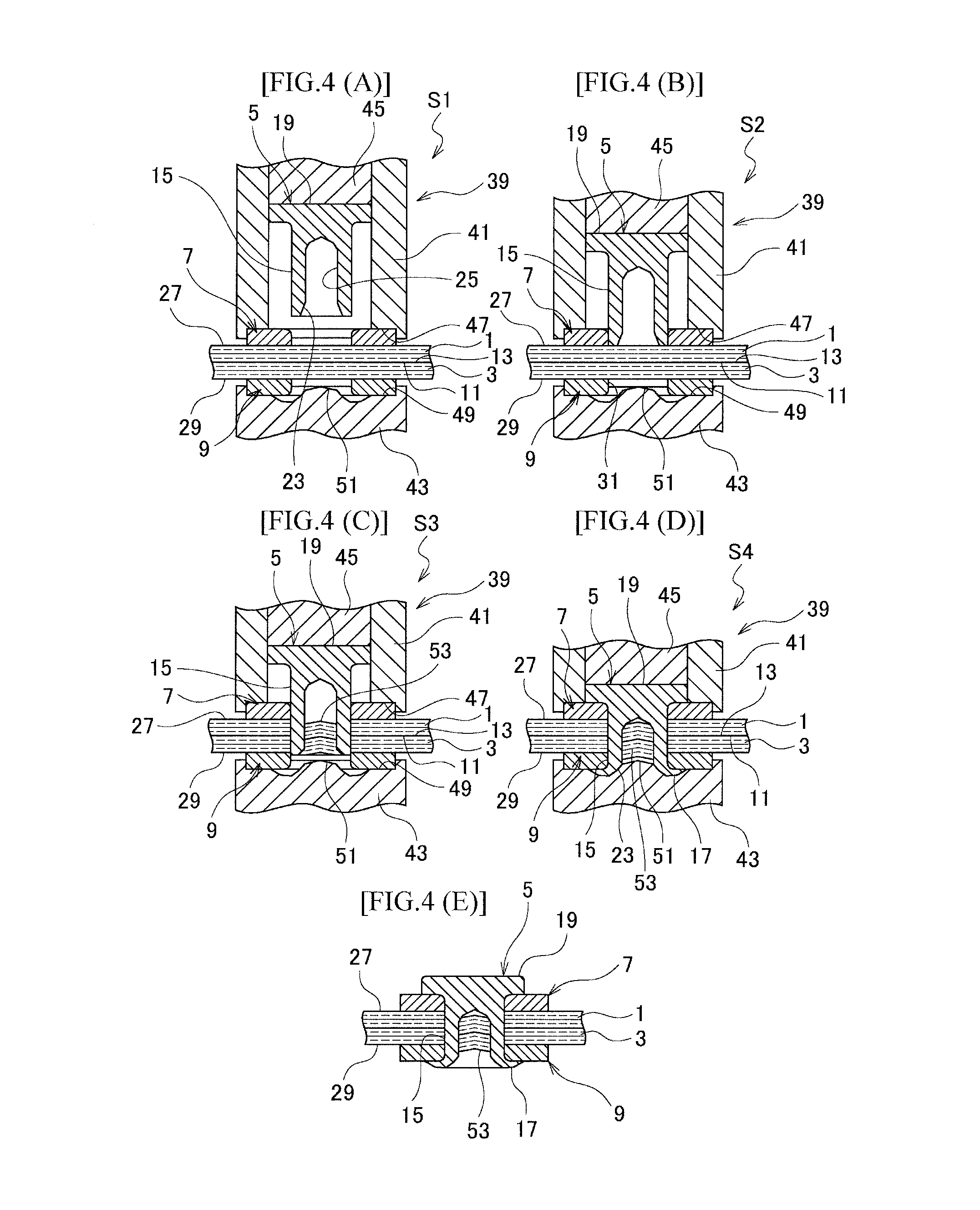

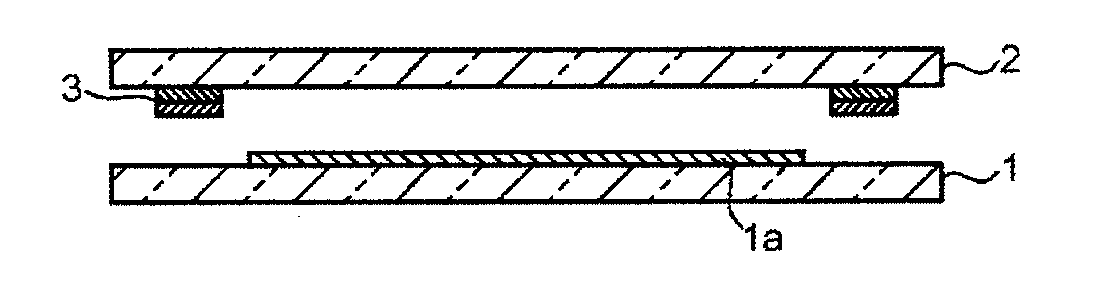

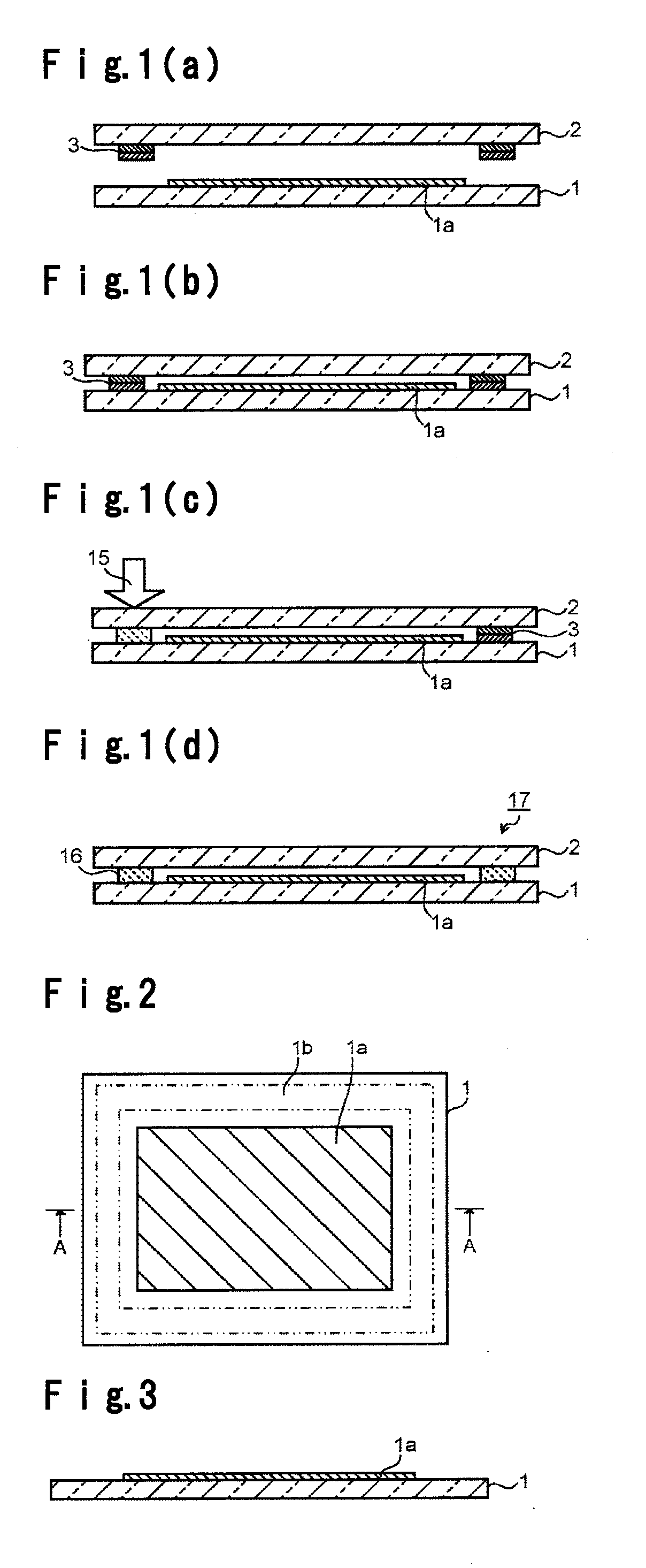

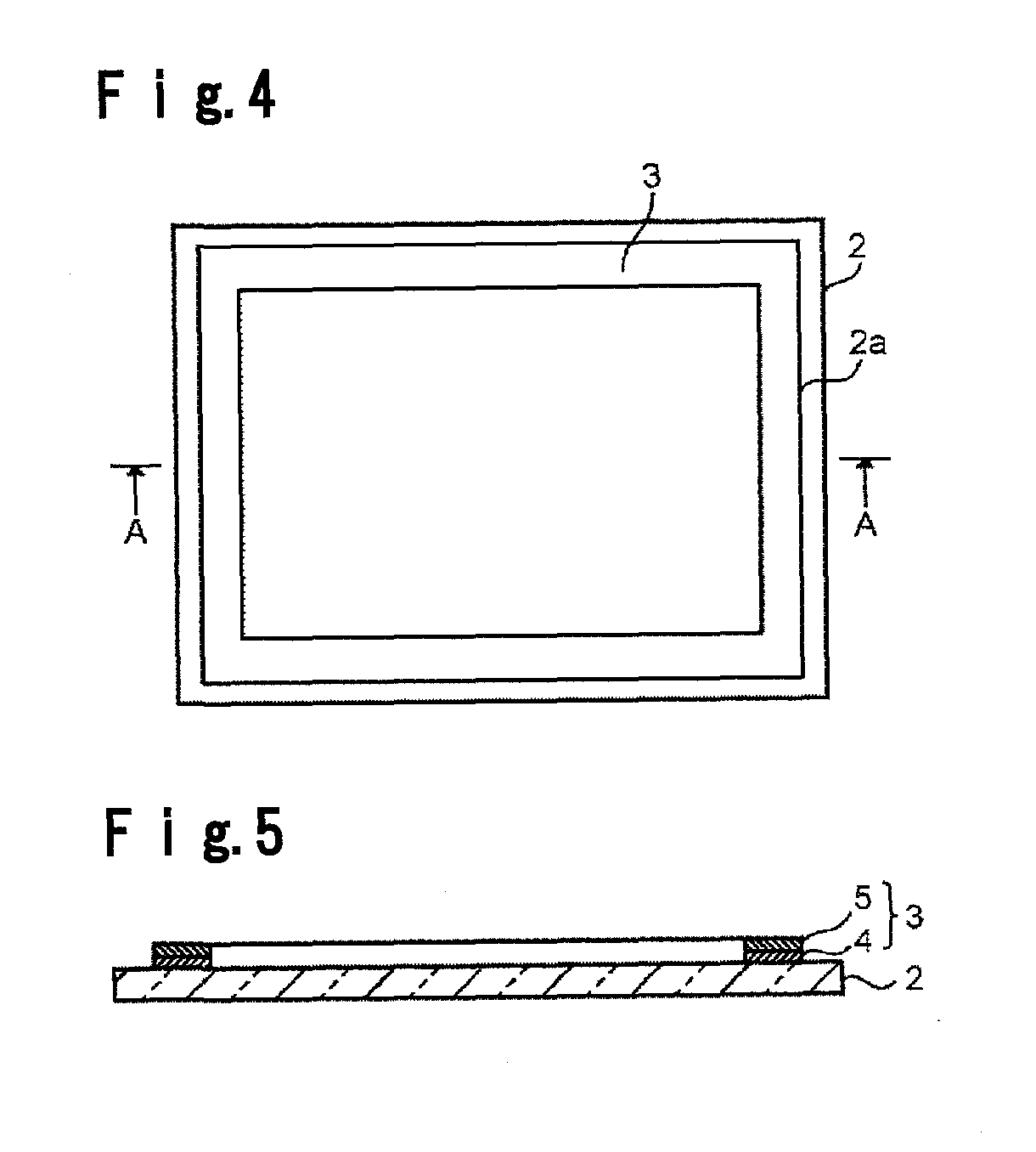

Process for producing glass member provided with sealing material layer and process for producing electronic device

InactiveUS20110209813A1Suppress cracksSuppress separationElectrolytic capacitorsFinal product manufactureMetallurgyLaser light

Laser sealing property and reliability of a glass panel are increased by suppressing cracks, fractures, separation and the like of glass substrates and a sealing material layer at the time of laser sealing.A first paste for a sealing material containing no laser absorbent and a second paste for a sealing material containing a laser absorbent are applied in this order on a sealing region 2a of a glass substrate 2. A laminate film of a coating layer 11 of the first paste for a sealing material and a coating layer 12 of the second paste for a sealing material is fired, to form a sealing material layer 3 having a laminated structure of a layer 4 of the first glass material for sealing and a layer 5 of the second glass material for sealing. The second glass substrate 2 having such a sealing material layer 3 is laminated with a glass substrate having an element-formed region, and the sealing material layer 3 is irradiated with a laser light from the side of the layer 4 of the first glass material for sealing through the second glass substrate 2 for bonding.

Owner:ASAHI GLASS CO LTD

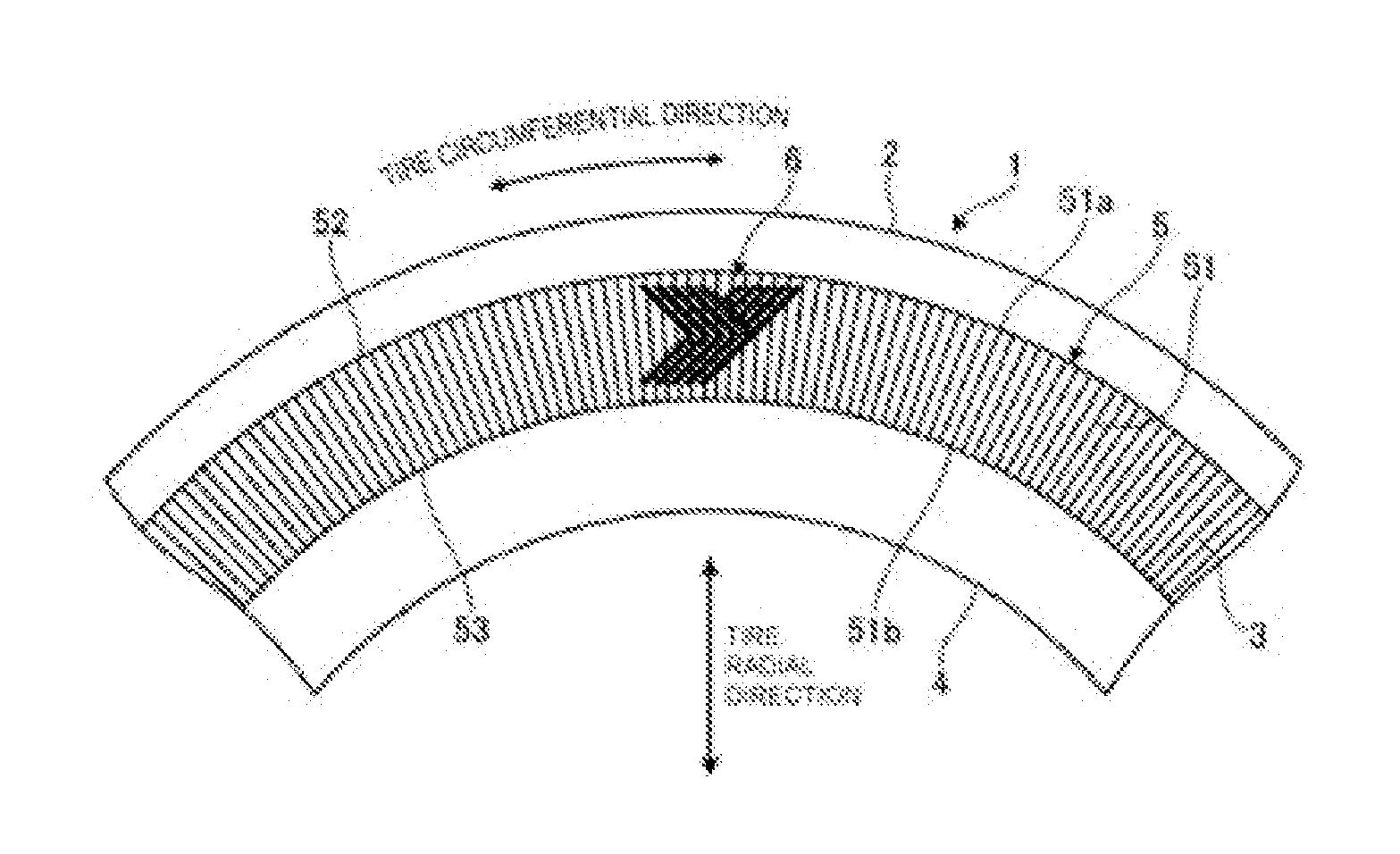

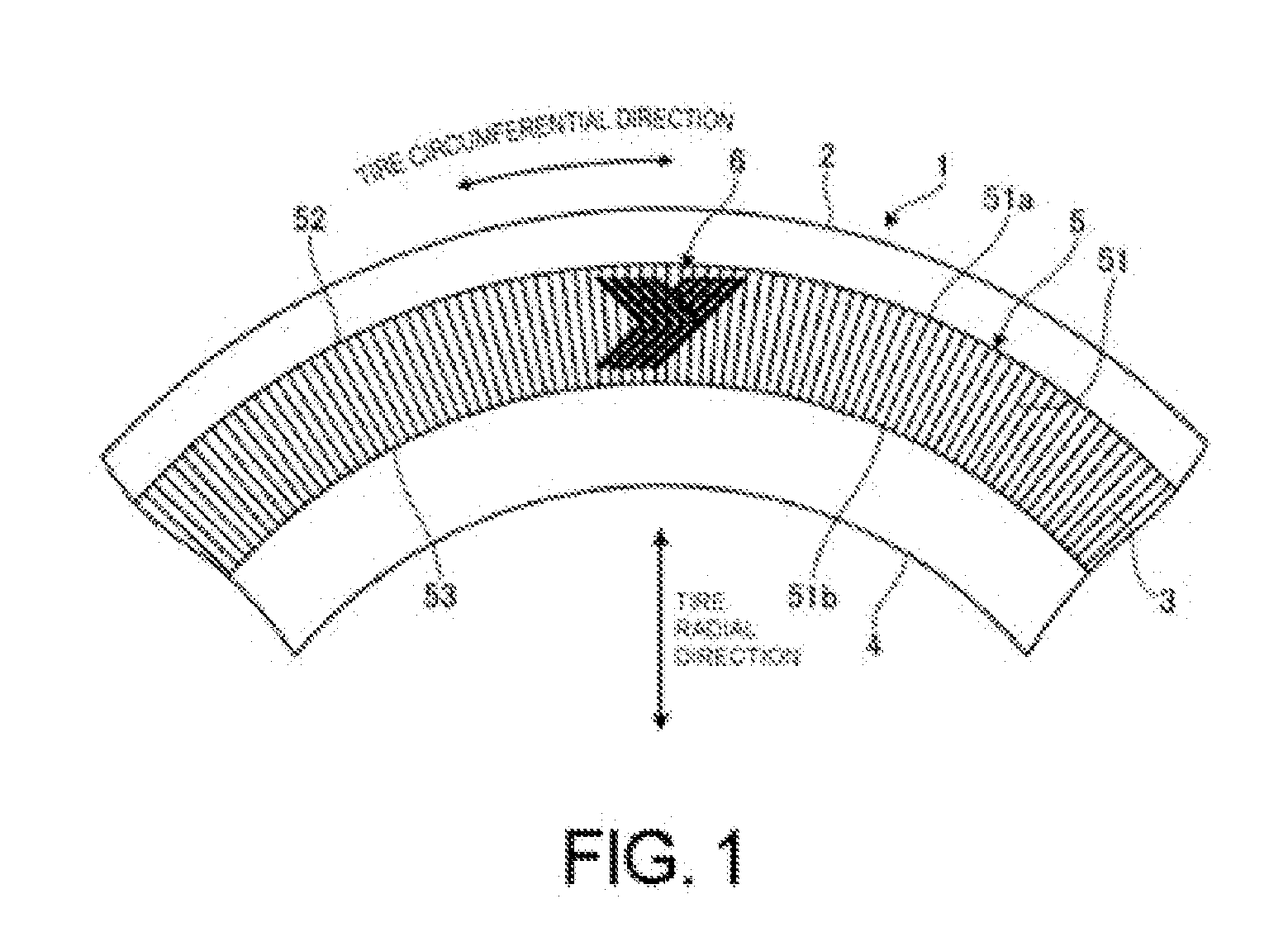

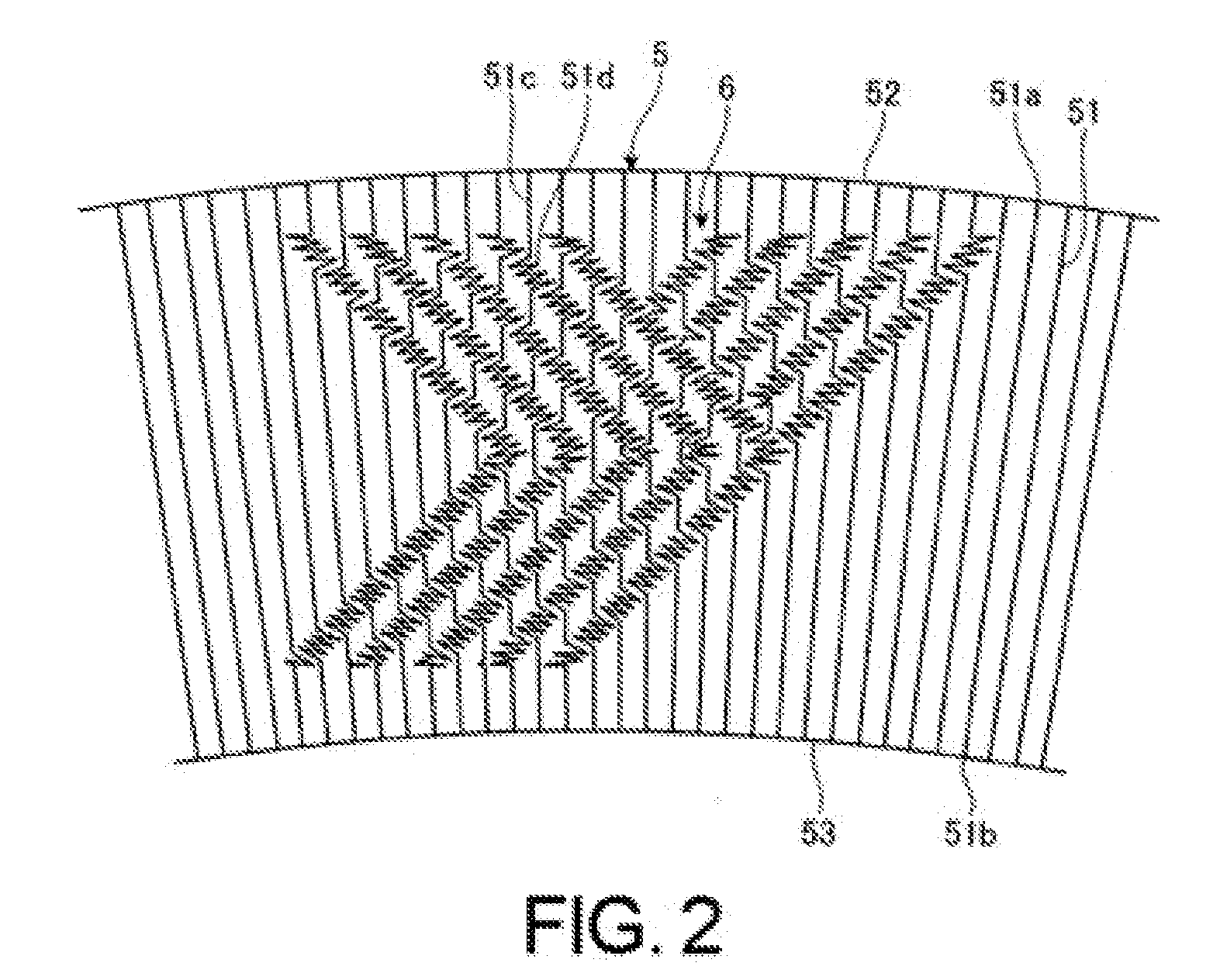

Pneumatic tire

ActiveUS20110139326A1Difficult to obtainDifference in stiffnessTyresInflatable tyresEngineeringReference line

Protruding ridges on a surface of a side wall portion extending in a tire radial direction for a predetermined range in the tire radial direction and being provided in a plurality in a row arrangement in a tire circumferential direction, wherein the ridges are formed continuously in the predetermined range from a first edge in the tire radial direction to a second edge; and characters are formed by the ridges including reference parts provided on a reference line that connects the first edge in the tire radial direction to the second edge, and curved parts that depart from and return to the reference line by bending or curving.

Owner:YOKOHAMA RUBBER CO LTD

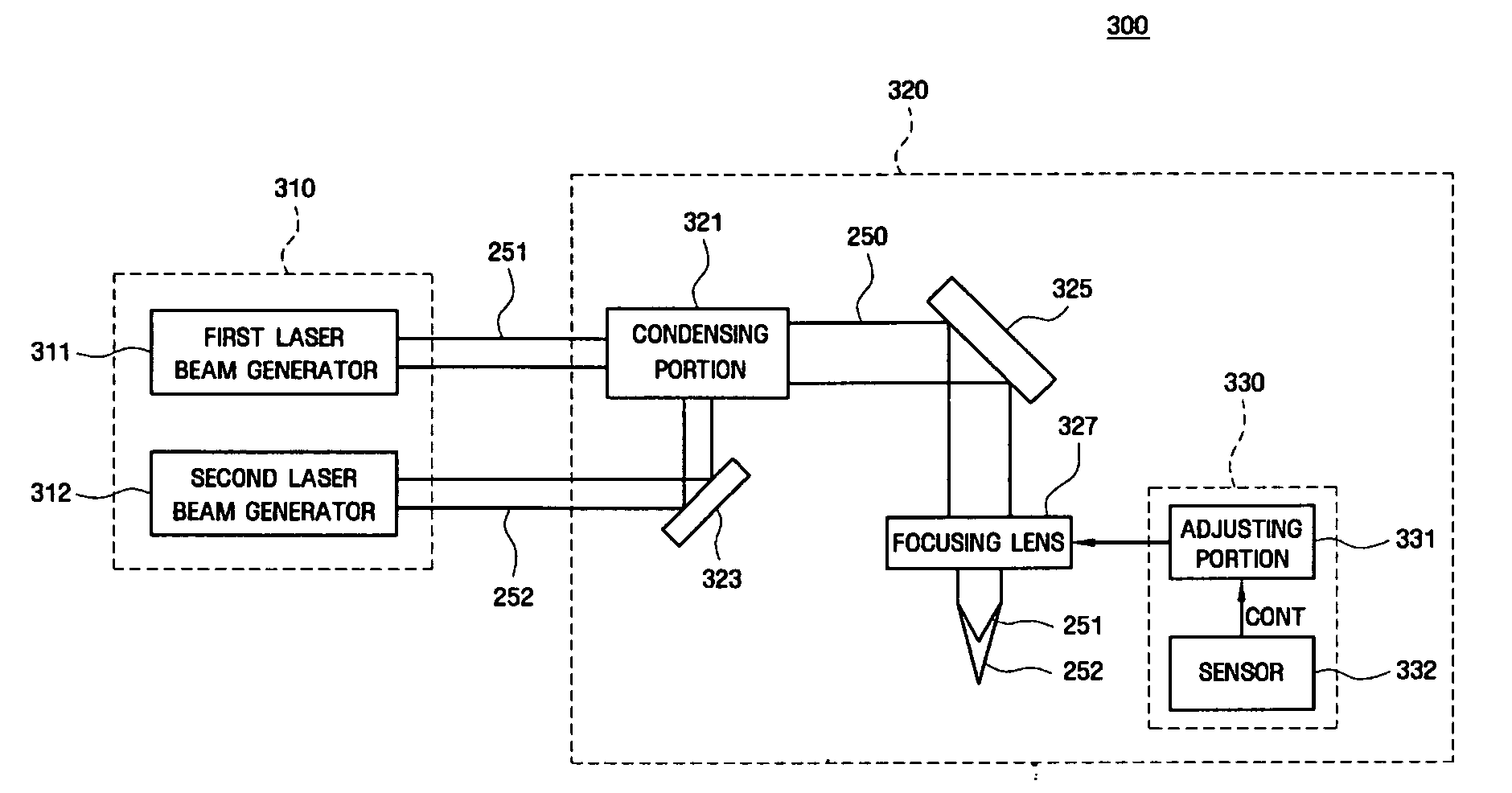

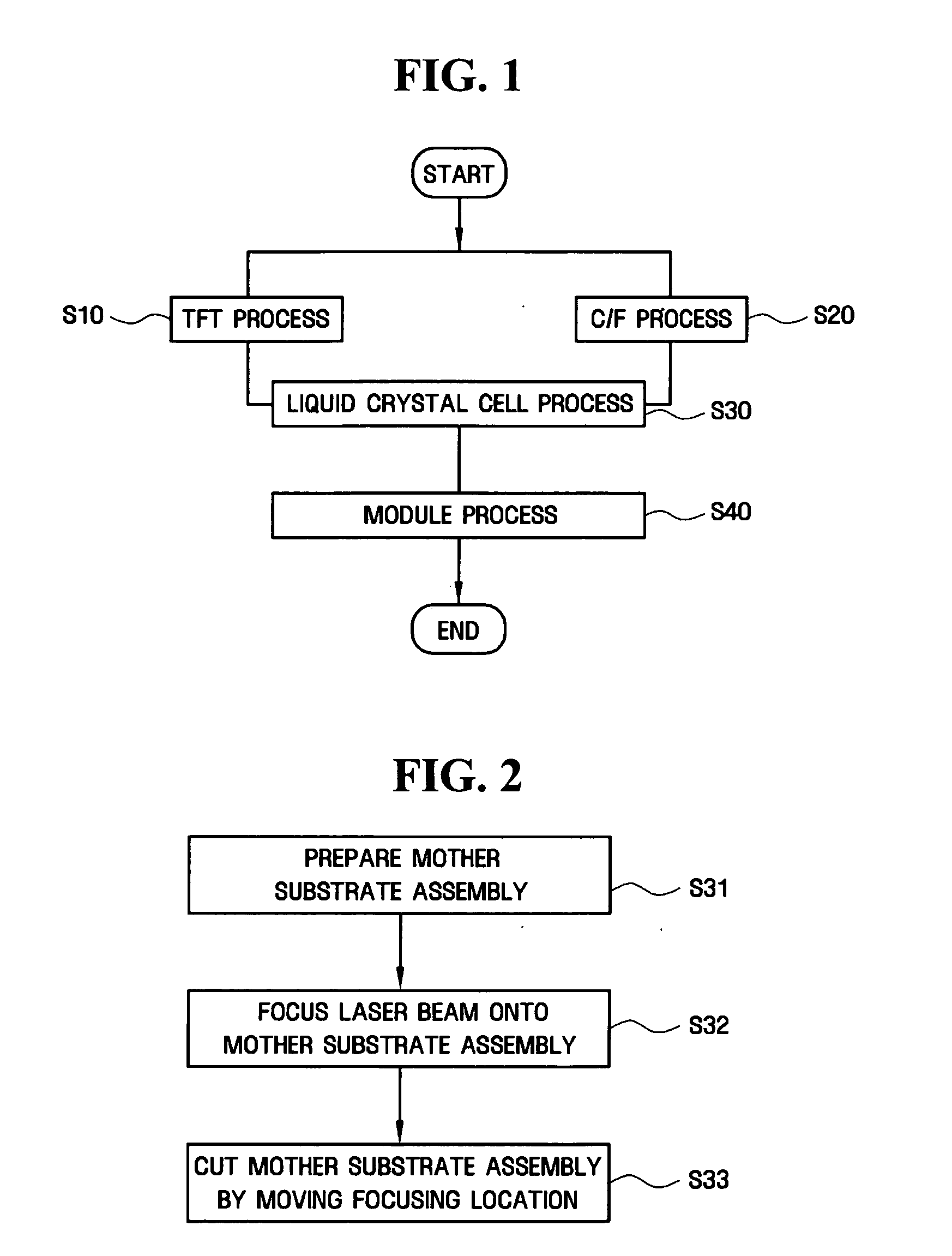

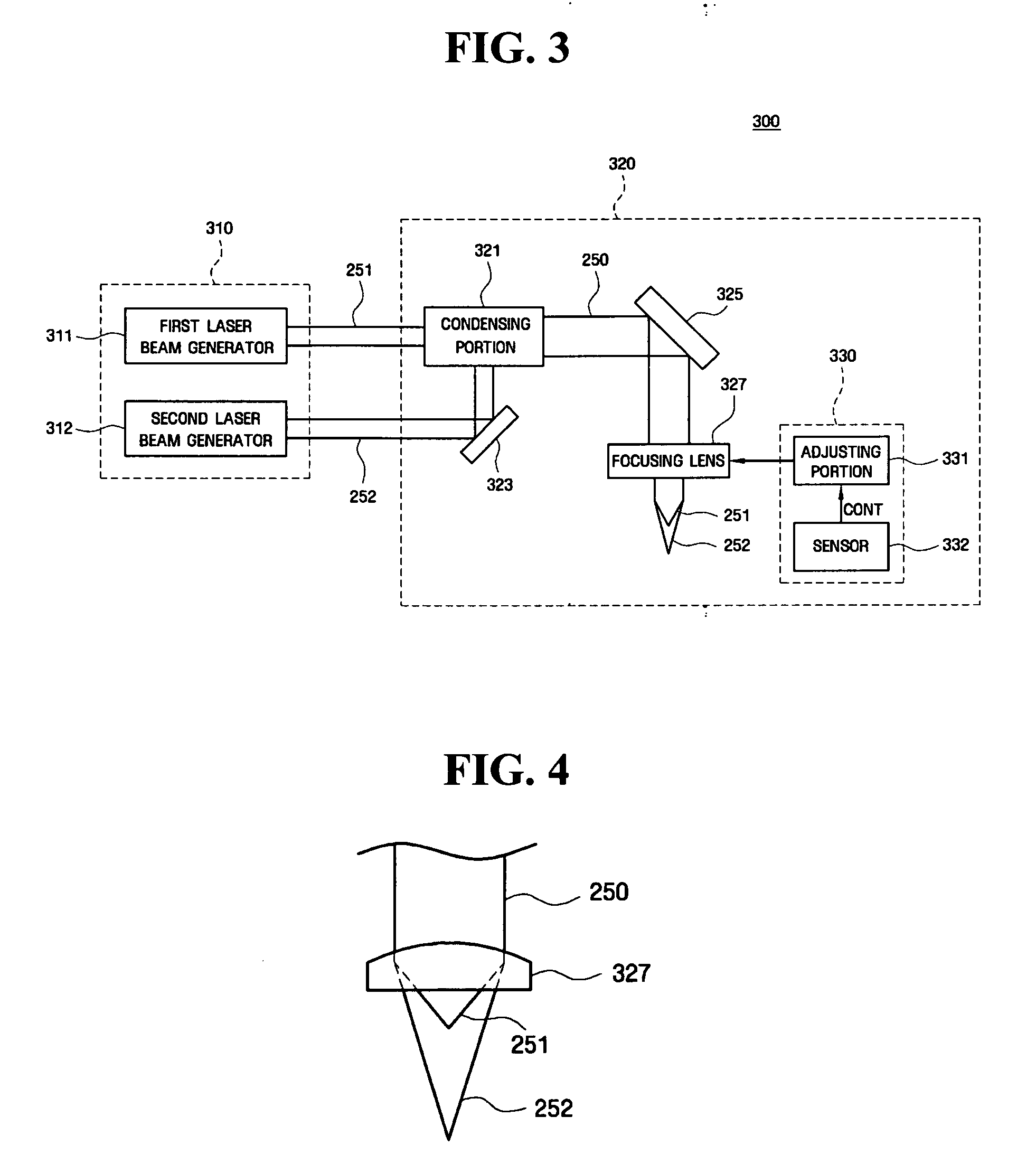

Method for cutting substrate and substrate cutting apparatus using the same

A substrate cutting method and a substrate cutting apparatus cut a substrate by simultaneously irradiating at least two laser beams having different wavelengths onto top and bottom surfaces of the substrate. The substrate cutting method includes preparing a mother substrate assembly having a thin film transistor (TFT) mother substrate and a color filter mother substrate, focusing at least two laser beams onto at least two different locations spaced apart from each other on a perpendicular relative to a surface of the mother substrate assembly simultaneously, and cutting the mother substrate assembly by the at least two different focused locations.

Owner:SAMSUNG ELECTRONICS CO LTD

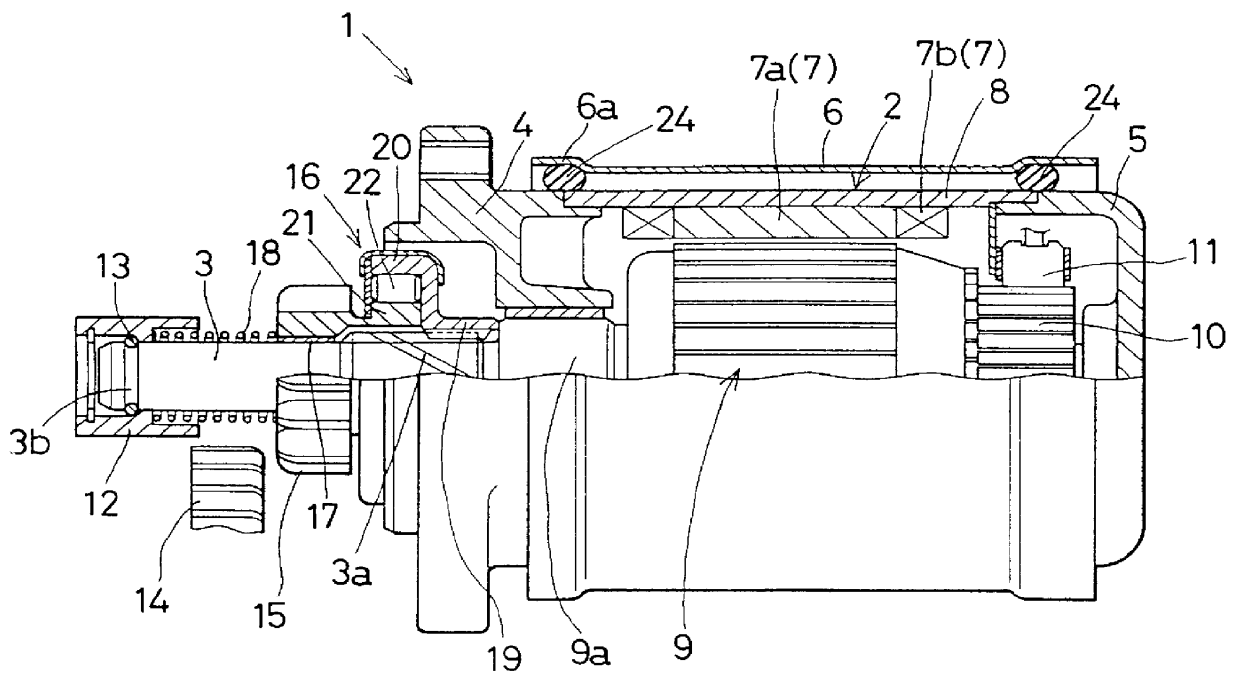

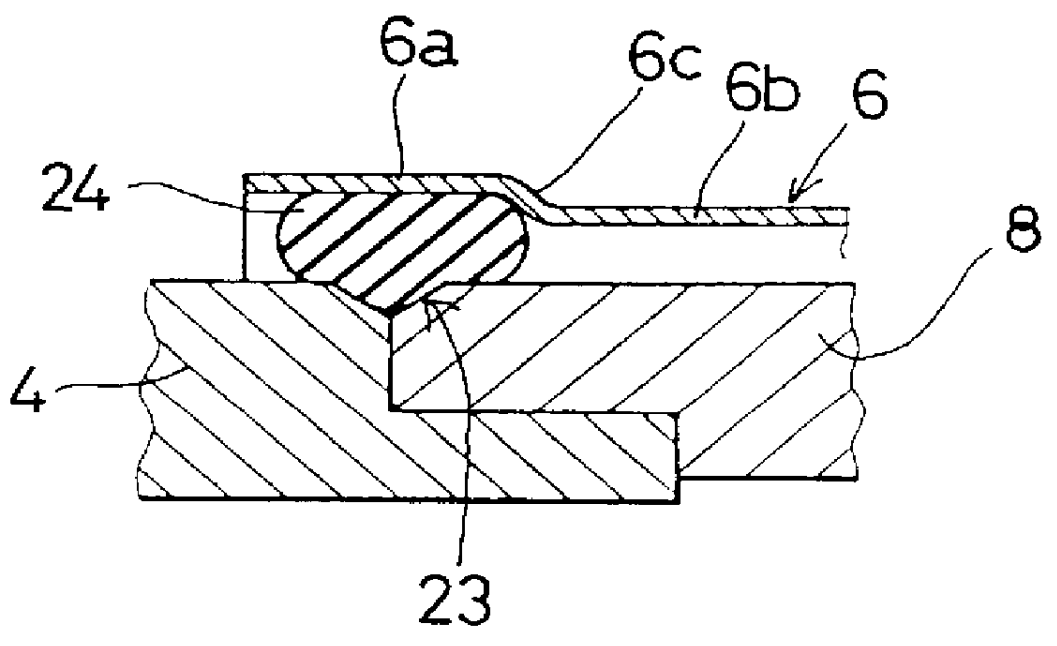

Brush holding device

InactiveUS6066907ASuppress cracksSuppress wearRotary current collectorElectric motor startersThermal insulationEngineering

In a starter having a motor yoke, a housing and an end frame forming a cylindrical starter frame, a cylindrical thermal insulation cover is fitted around the starter frame through rubber-made elastic rings. The rings are tightly fitted in V-shaped grooves formed circumferentially on fitting faces, one being between the housing and the yoke and the other being between the yoke and the end frame. Each ring is pressed radially inward by a large diameter part of the thermal insulation cover to fill in the V-shaped groove and contact the fitting face. Further, in a motor for the starter, a resilient plate sheet is disposed between a commutator and a brush holder to return a brush passing therethrough to the original position when the brush tends to move during sliding contact with the commutator.

Owner:DENSO CORP

Process and apparatus for upgrading FCC product with additional reactor with catalyst recycle

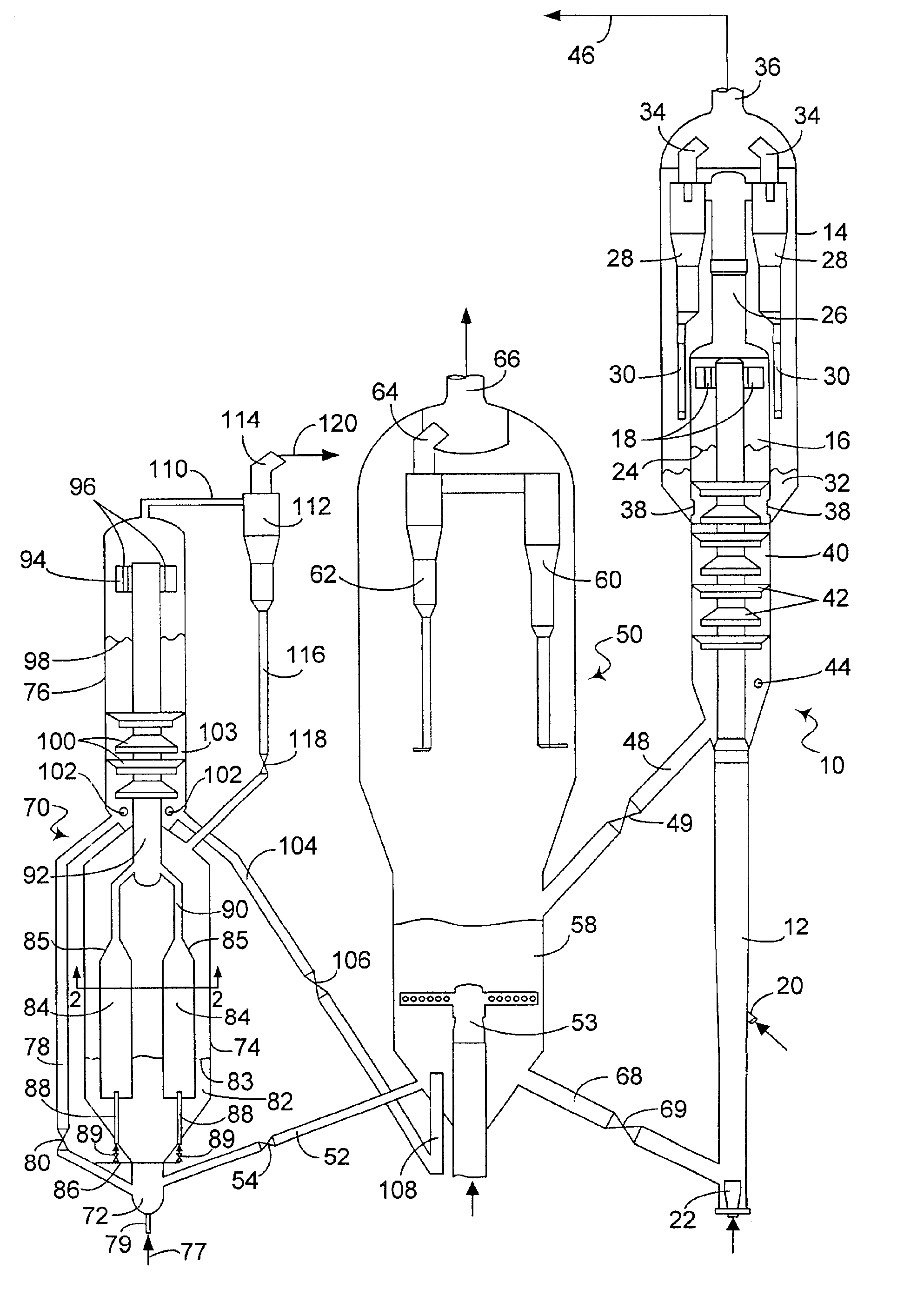

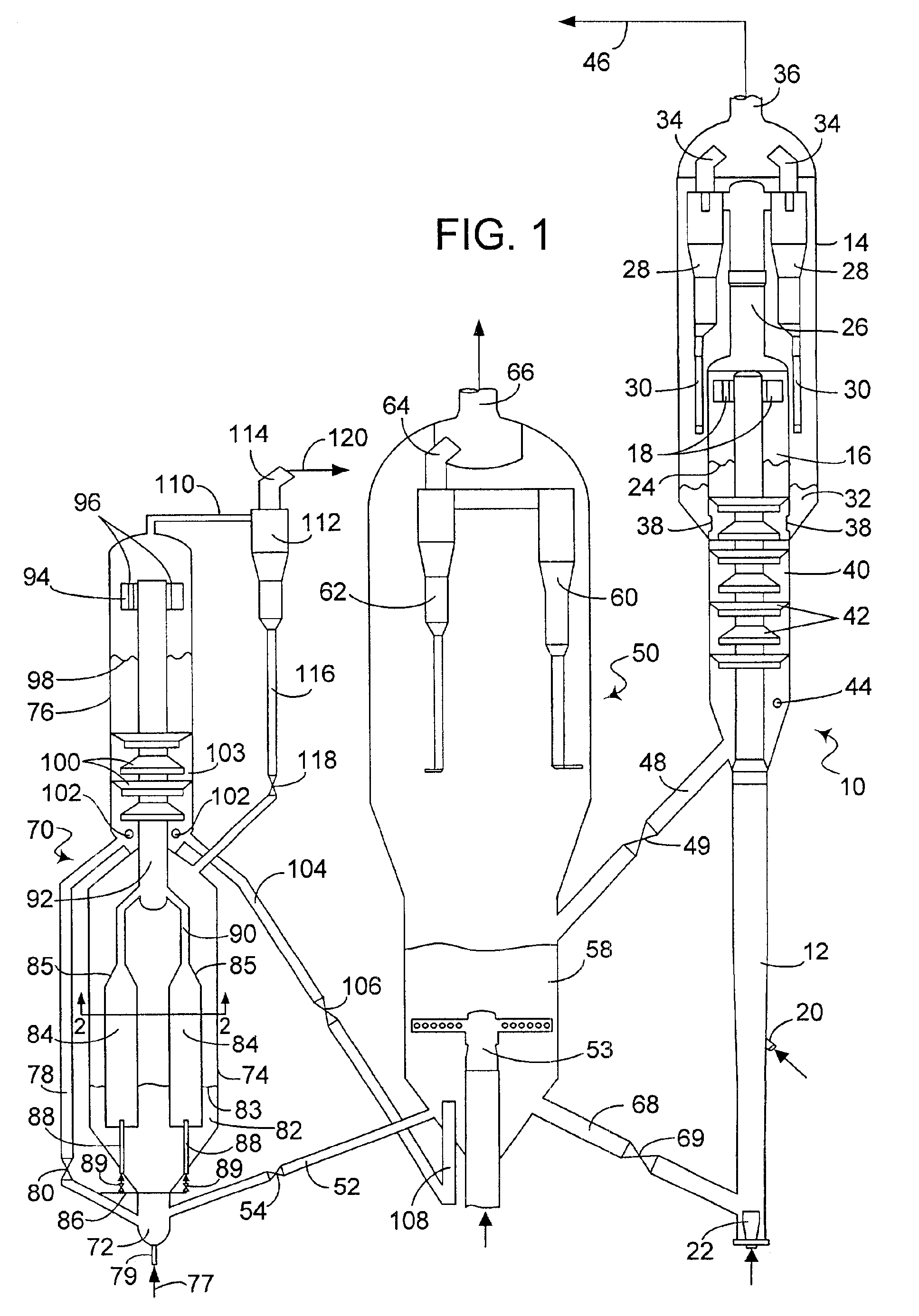

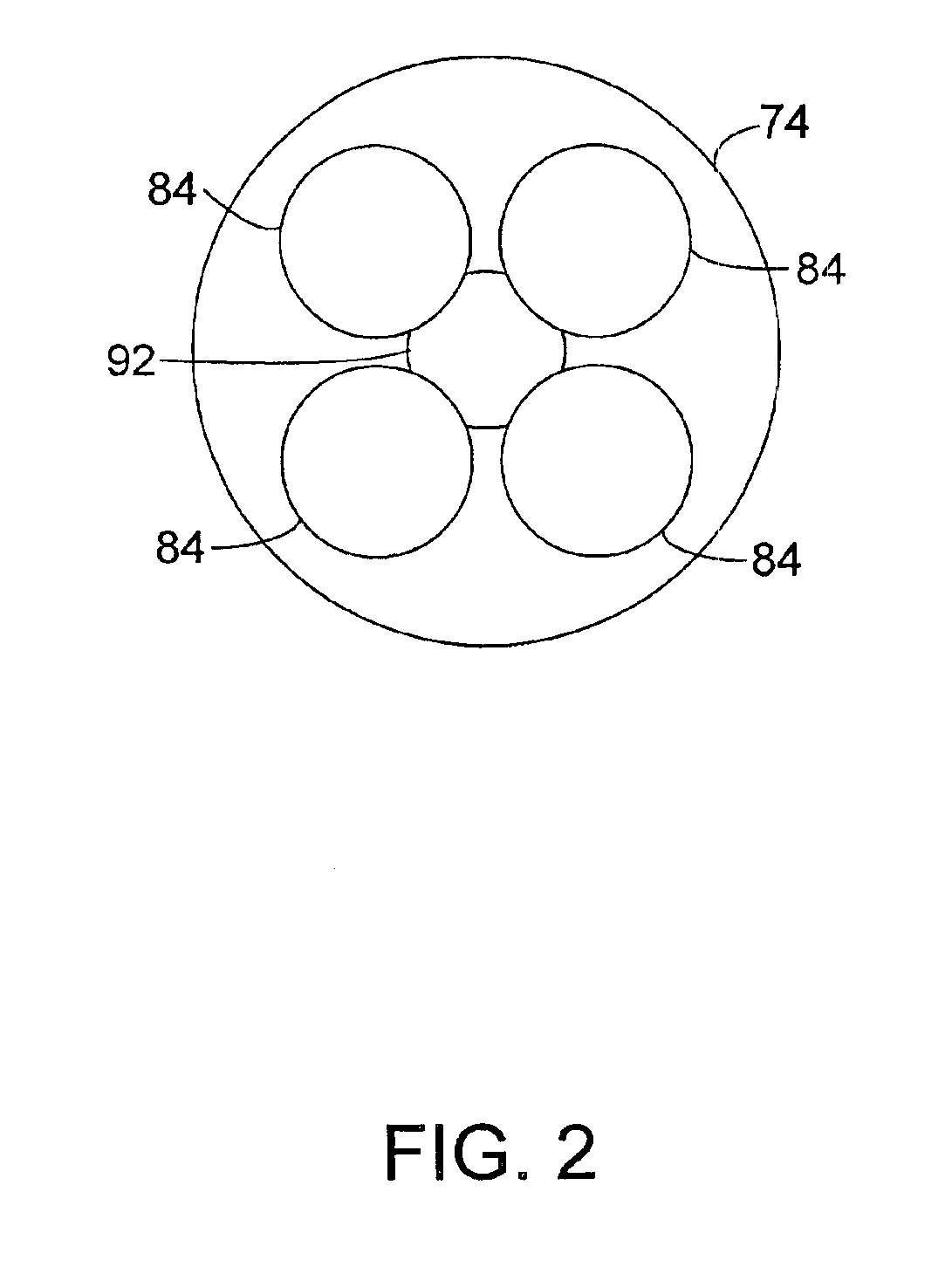

InactiveUS20050074371A1Increase undesirable crackingLower catalytic temperatureTreatment with plural serial cracking stages onlyCatalytic crackingCracking reactionChemistry

A process and apparatus is disclosed for contacting feed with mixed catalyst in a secondary reactor that is incorporated into an FCC reactor. The mixed catalyst used in the secondary reactor is regenerated catalyst from a regenerator that regenerates spent catalyst from an FCC reactor that is mixed with spent catalyst from either the FCC reactor or the secondary reactor. The mixing of spent and regenerated catalyst reduces the catalyst temperature and tempers catalyst activity to inhibit both thermal and catalytic cracking reactions.

Owner:LOMAS DAVID A +1

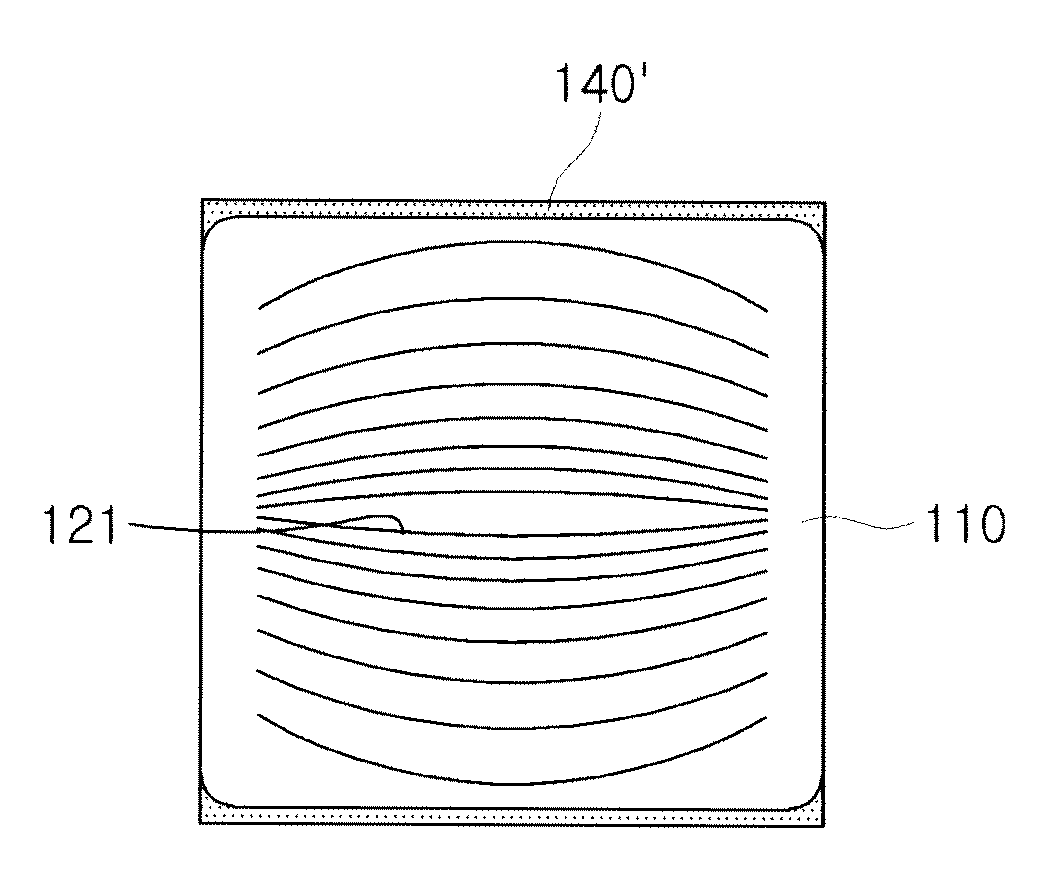

Light scanning apparatus and image forming apparatus

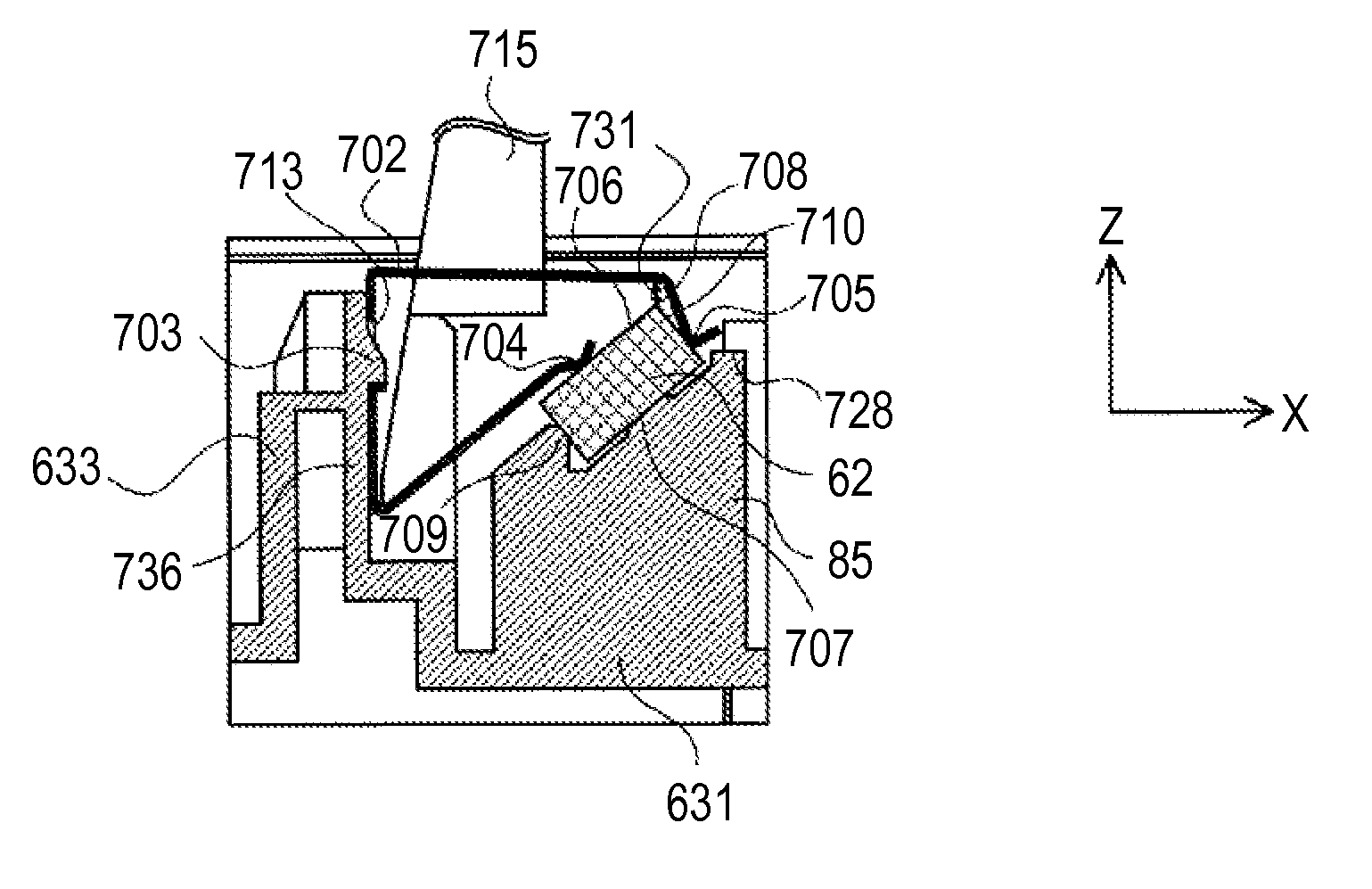

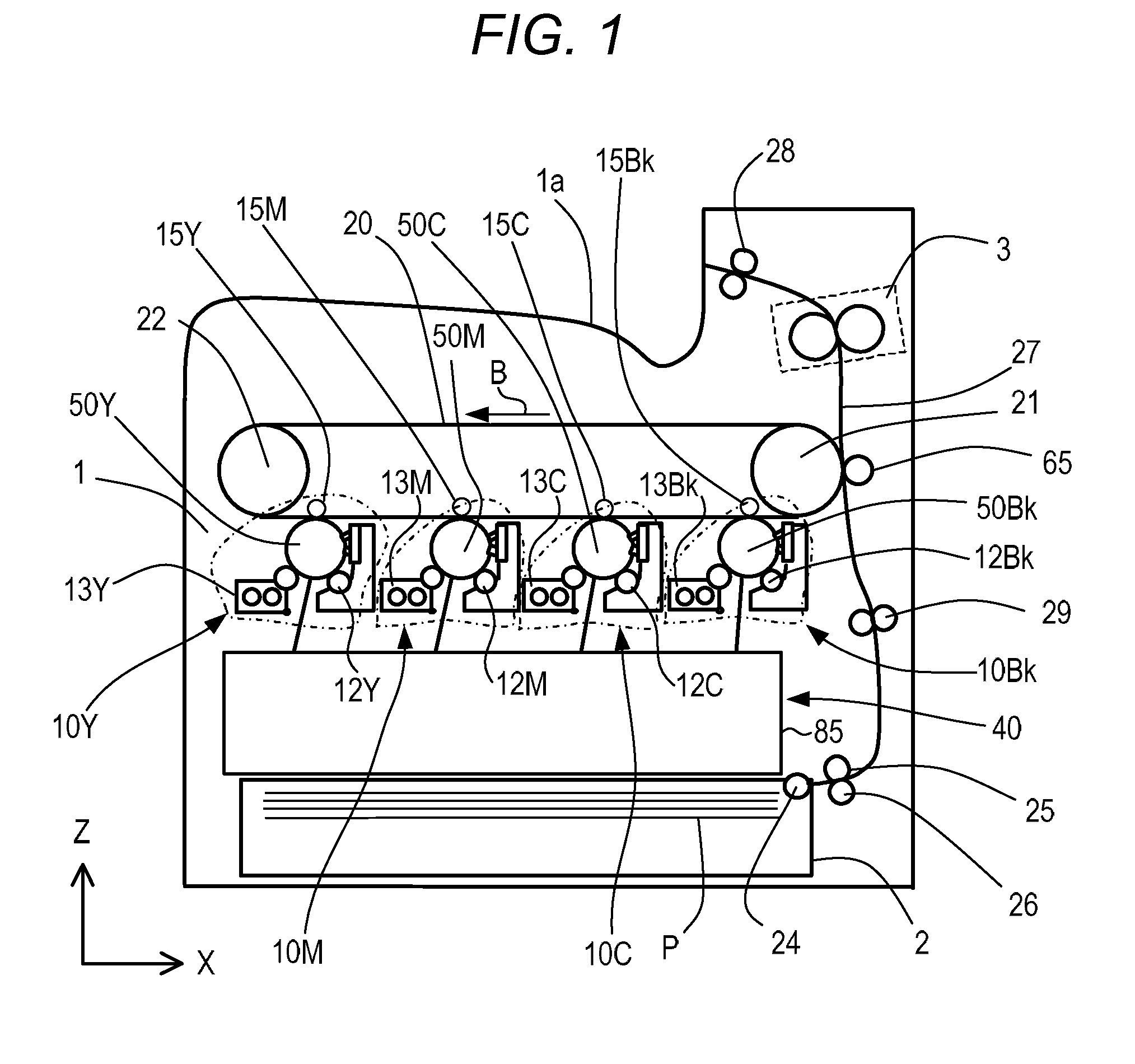

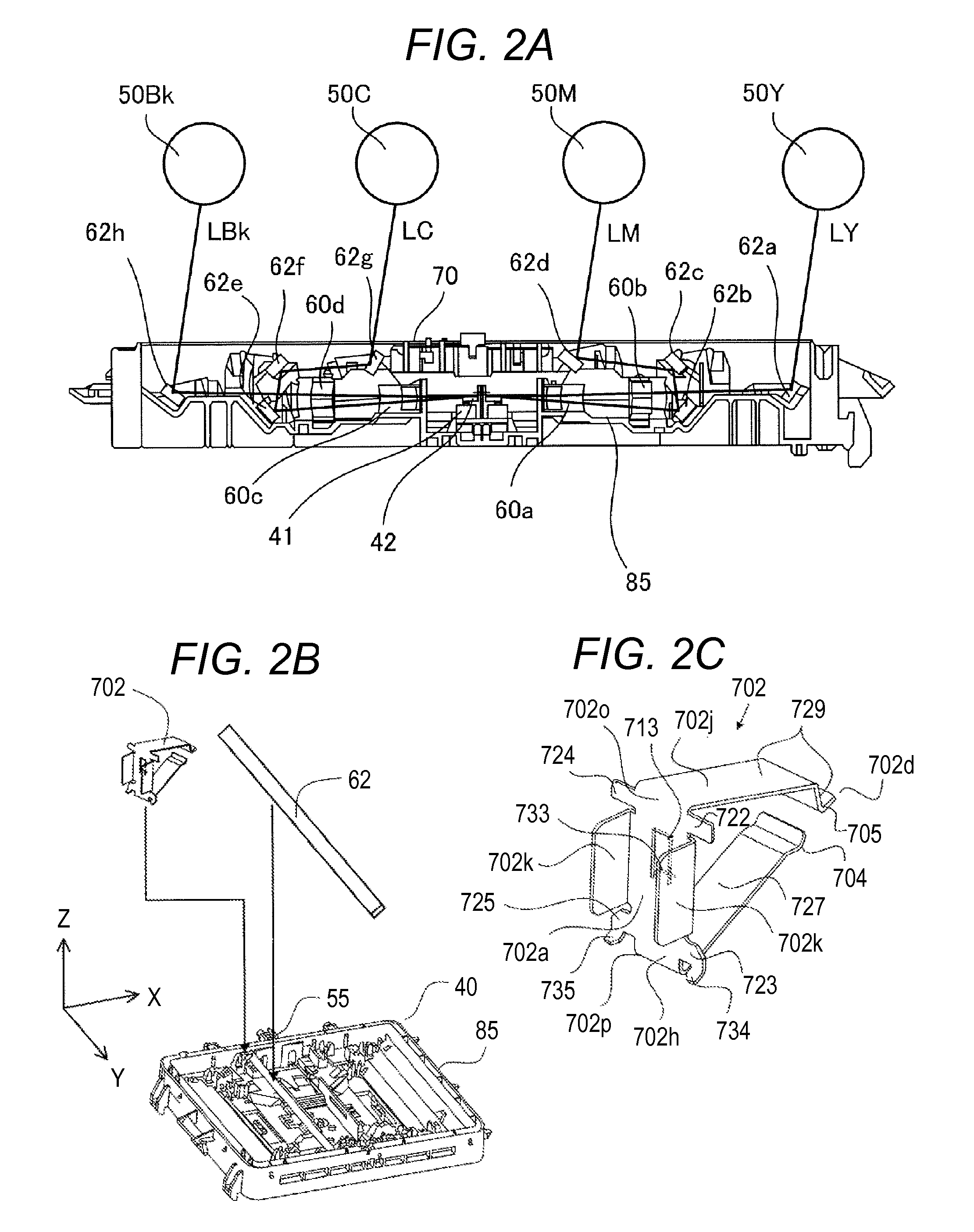

ActiveUS9195063B2Suppresses of chippingSuppress cracksElectrographic process apparatusMountingsLight beamLight scanning

A light scanning apparatus, including: a light source; a deflector configured to deflect the light beam from the light source to scan a photosensitive member; an optical member configured to guide the light beam; a housing including a housing engaging portion and a supporting portion configured to support the optical member; a leaf spring including a pressing portion and a leaf spring engaging portion; and an abutment portion, wherein, in a process in which the housing engaging portion and the leaf spring engaging portion are moved from a second state in which the leaf spring engaging portion is not engaged with the housing engaging portion to a first state in which the leaf spring engaging portion is engaged with the housing engaging portion, the pressing portion is moved from the abutment portion to the optical member.

Owner:CANON KK

Base Film and Pressure-Sensitive Adhesive Sheet Provided Therewith

ActiveUS20140079947A1Suppress cracksProduction can be suppressedFilm/foil adhesivesSemiconductor/solid-state device detailsOligomerEngineering

To prevent bumps on the circuit side of a bump-bearing wafer from getting crushed when grinding the back side of said wafer while protecting the circuit side with a surface-protection sheet, and also to minimize the formation of dimples and cracks on the side being ground.[Solution] This base film for a pressure-sensitive adhesive sheet bonded to a semiconductor wafer comprises: (A) a layer obtained by using energy rays to cure a formulation containing a urethane (meth)acrylate oligomer and a thiol-group-containing compound; and (B) a layer comprising a thermoplastic resin.

Owner:LINTEC CORP +1

Pneumatic Tire

InactiveUS20090137701A1Improve balanceReduce fuel consumptionSpecial tyresTyre tread bands/patternsSilane couplingButadiene-styrene rubber

A pneumatic tire having excellent balance between low fuel consumption and grip property and capability of suppressing crack generation in a tread groove bottom while maintaining abrasion resistance is provided. The pneumatic tire has a tread formed from a rubber composition includes per 100 parts by weight of a diene rubber containing a styrene-butadiene rubber, from 30 to 150 parts by weight of a reinforcing filler containing from 20 to 100 parts by weight of silica, and from 5 to 40 parts by weight of a carboxyl-terminally modified liquid polybutadiene, and further includes a silane coupling agent in an amount of from to 25 parts by weight per 100 parts by weight of the silica.

Owner:TOYO TIRE & RUBBER CO LTD

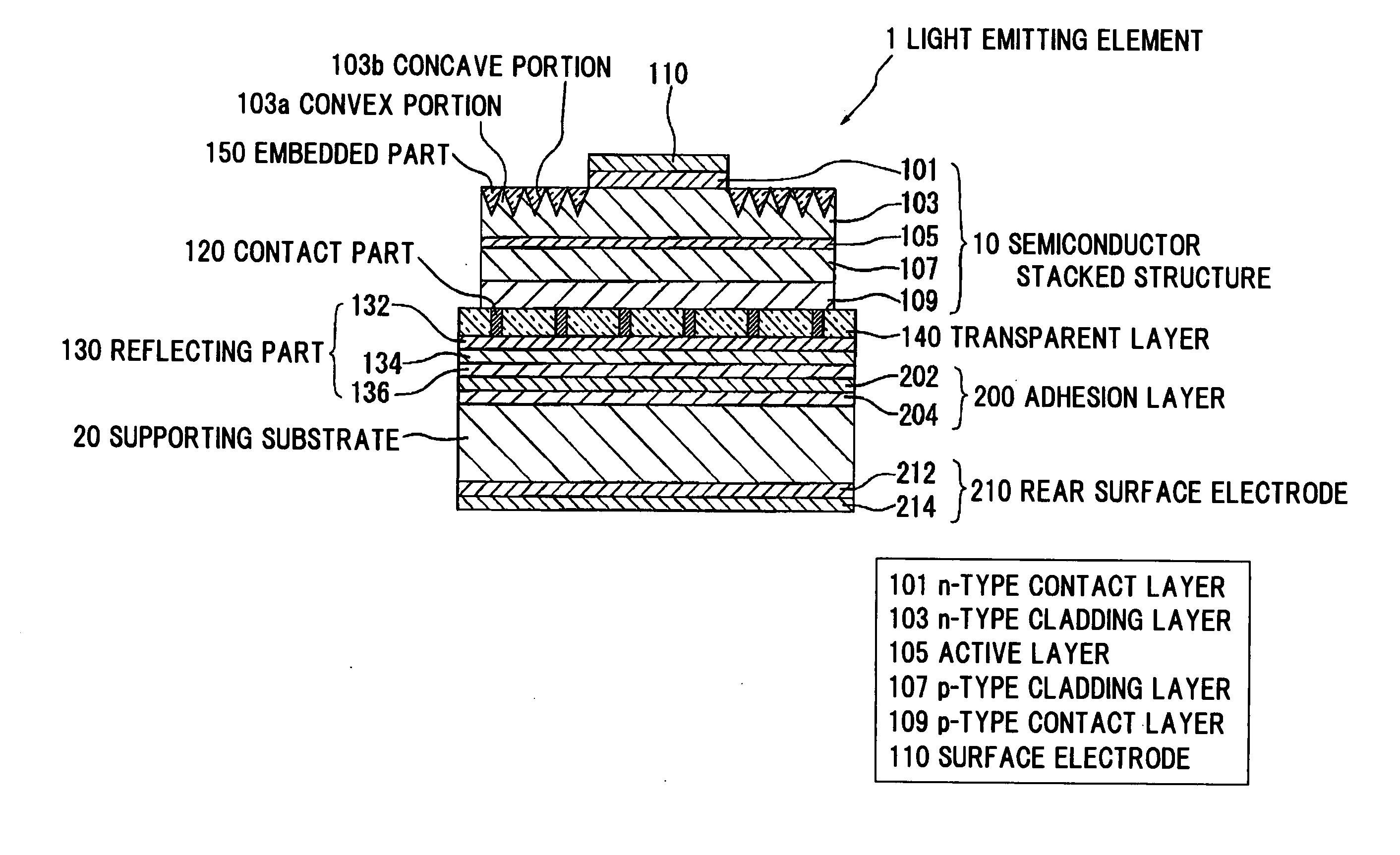

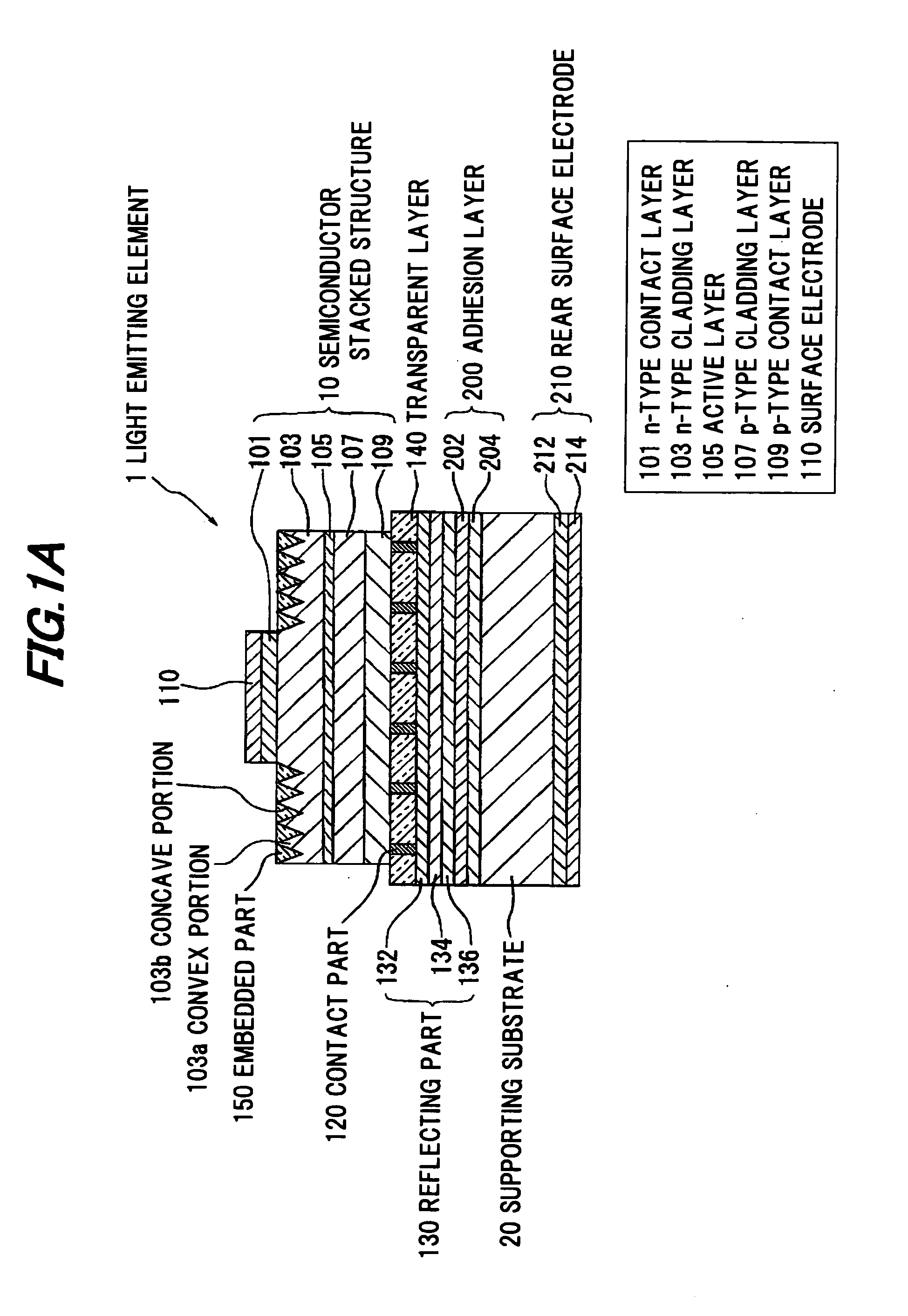

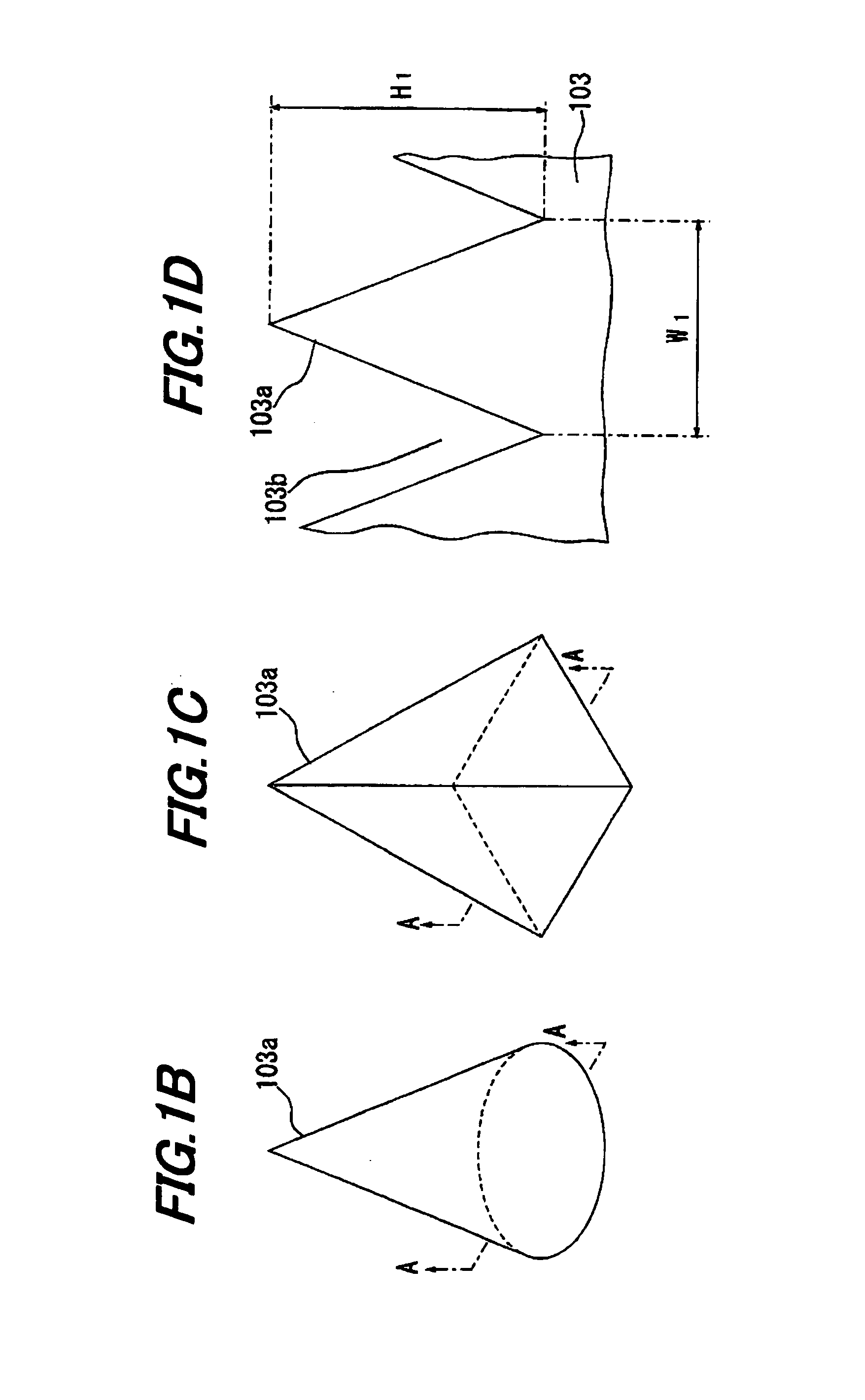

Light emitting element

InactiveUS20100117109A1Relieve stressSuppress cracksSolid-state devicesSemiconductor devicesElectrical conductorSemiconductor package

A light emitting element includes a semiconductor stacked structure including a first semiconductor layer of first conductivity type, a second semiconductor layer of second conductivity type different from the first conductivity type and an active layer sandwiched between the first semiconductor layer and the second semiconductor layer. The light emitting element further includes a plurality of convex portions formed on one surface of the semiconductor stacked structure, and an embedded part for transmitting a light emitted from the active layer and reducing stress generated in the plurality of convex portions, the embedded part being formed between two adjacent convex portions of the plurality of convex portions.

Owner:HITACHI CABLE

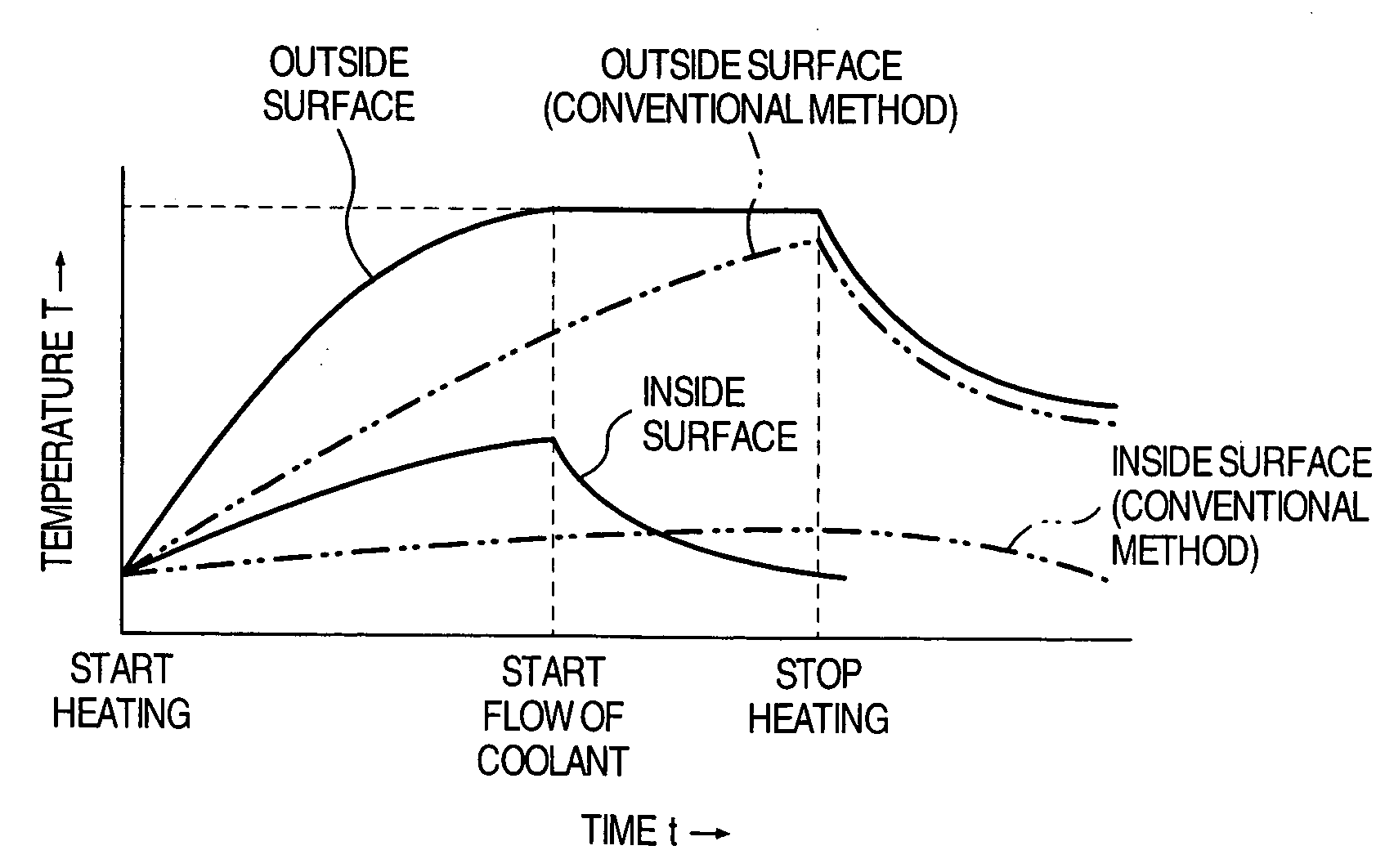

Heat treatment method and device for piping

InactiveUS20060113010A1Prevents stress corrosion crackingSuppress cracksIncreasing energy efficiencyFurnace typesTemperature differenceEngineering

In a method for heat treatment of an existing pipe constituting a piping system, for converting the residual stress at a welded metallic portion and a welding heat influenced portion of the inside surface of the pipe, into a compressive stress and thereby generate the compressive stress in the inside surface of the existing pipe, a coolant is retained in the pipe; an arbitrary portion of the outside surface of the pipe is heated; thereby a temperature distribution little in temperature difference is produced in the wall surface of the pipe at the heated portion; and then the coolant is allowed to flow. By converting the residual stress at the welded metallic portion and the welding heat influenced portion of the inside surface of the pipe, into the compressive stress, stress corrosion cracking generated from the welded metallic portion and the welding heat influenced portion can be suppressed.

Owner:HITACHI LTD

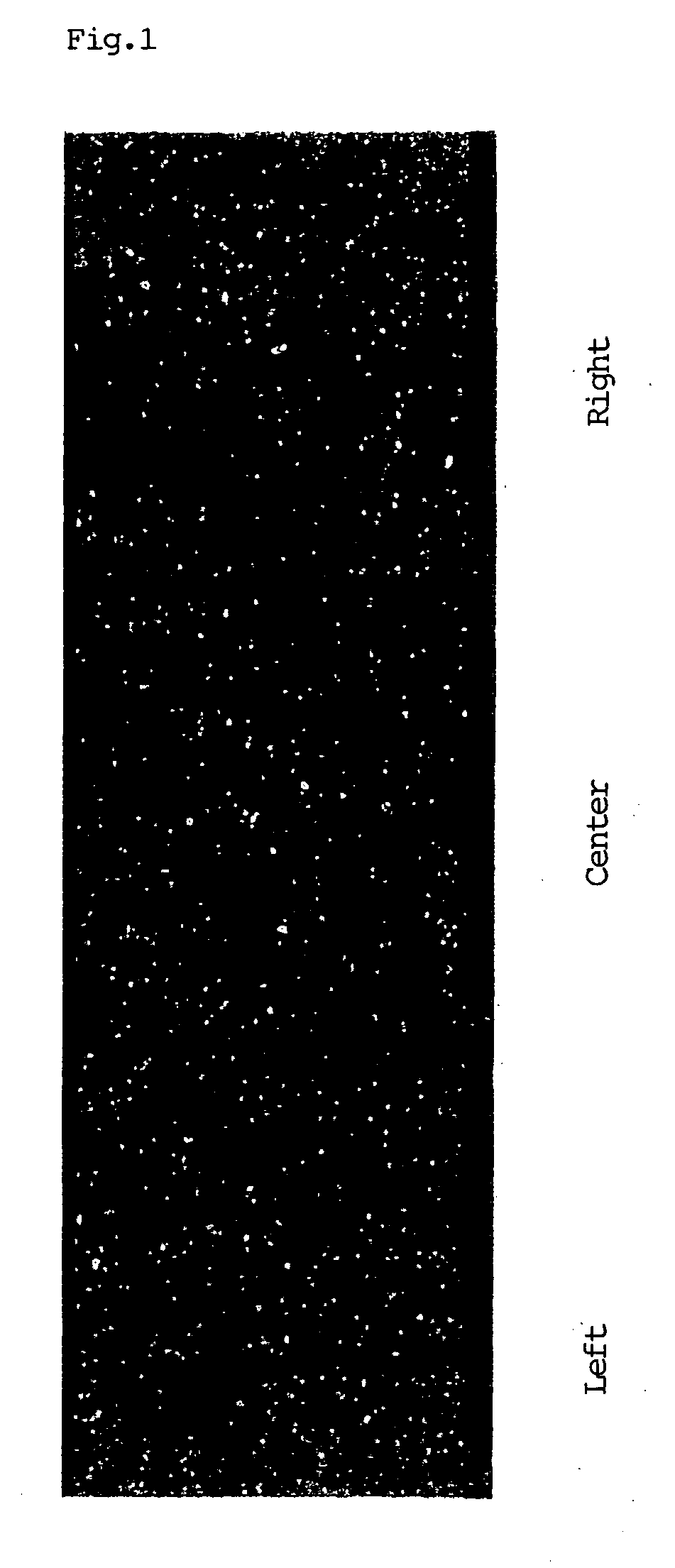

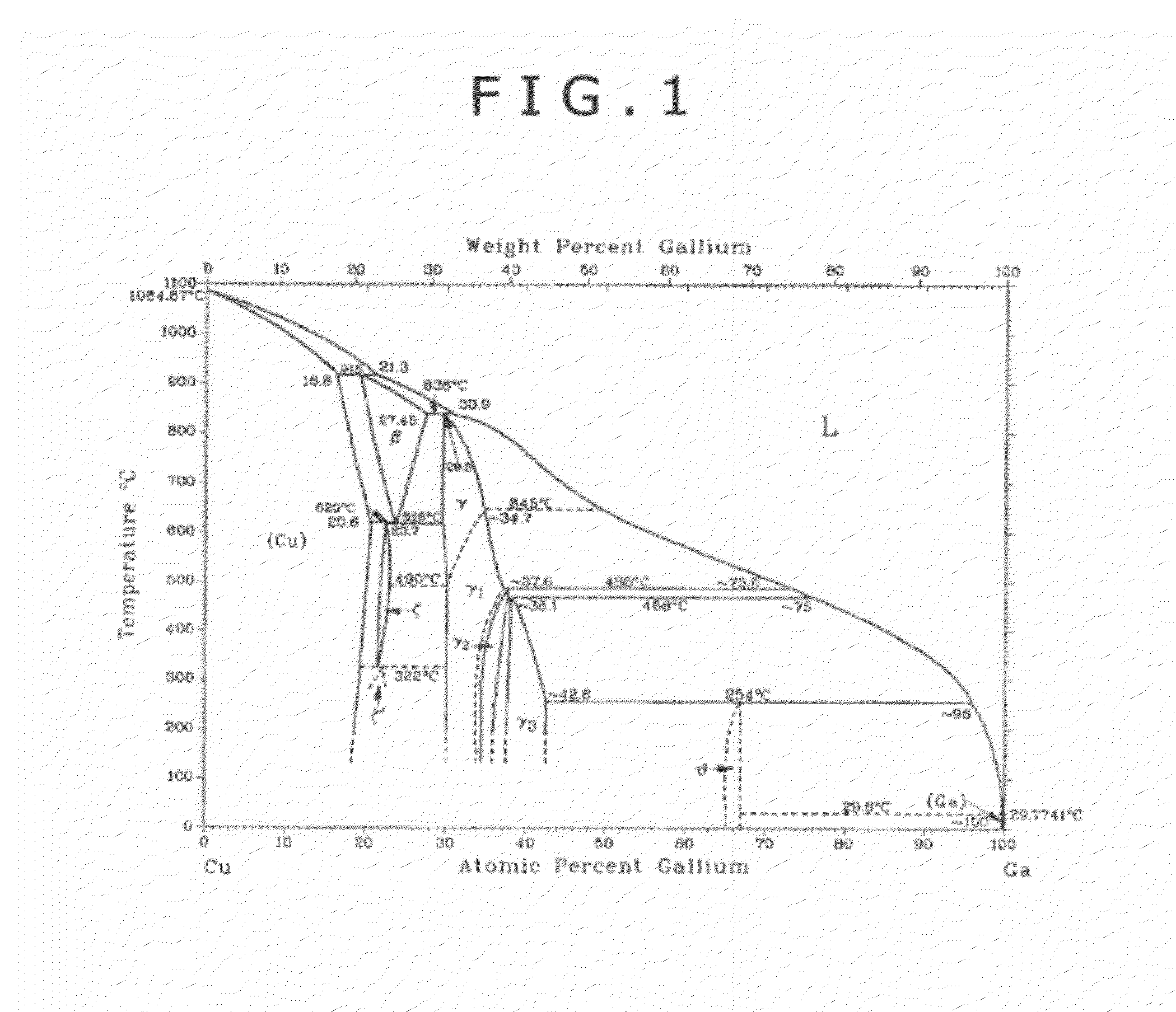

Cu-ga alloy sputtering target and manufacturing method thereof

Disclosed is a Cu—Ga alloy sputtering target which enables the formation of a Cu—Ga sputtering film having excellent uniformity in film component composition (film uniformity), enables the reduction of occurrence of arcing during sputtering, has high strength, and rarely undergoes cracking during sputtering. Specifically disclosed is a Cu—Ga alloy sputtering target which comprises a Cu-based alloy containing Ga, has an average crystal particle diameter of 10 μm or less, and has a porosity of 0.1% or less.

Owner:KOBELCO RES INST

Welding material and welded joint structure

InactiveUS20100136361A1Suppress weld solidification crackingExcellent in weld solidification cracking resistanceFurnace typesWelding/cutting media/materialsAlloyAustenite

A welding material, to be used for welding a base metal made of an austenitic alloy comprising C≦2.0%, Si≦4.0%, Mn: 0.01 to 3.0%, P: more than 0.03% to not more 0.3%, S≦0.03%, Cr: 12 to 35%, Ni: 6 to 80%, sol. Al: 0.001 to 1% and N≦0.3%, with the balance being Fe and impurities to a base metal made of another austenitic alloy, which comprises C: more than 0.3% to 3.0%, Si≦4.0%, Mn≦3.0%, P≦0.03%, S≦0.03%, Cr: more than 22% to 55%, Ni: more than 30% to not more than 70%, sol. Al: 0.001 to 1% and N≦0.3%, with the balance being Fe and impurities can suppress the weld solidification cracking which occurs in an austenitic alloy having a high P content and showing fully austenitic solidification. Therefore, the said welding material can be widely used in such fields where a welding fabrication is required. The said welding material may contain a specific amount or amounts of one or more elements selected from Cu, Mo, W, V, Nb, Ti, Ta, Zr, Hf, Co, B, Ca, Mg and REM.

Owner:NIPPON STEEL CORP

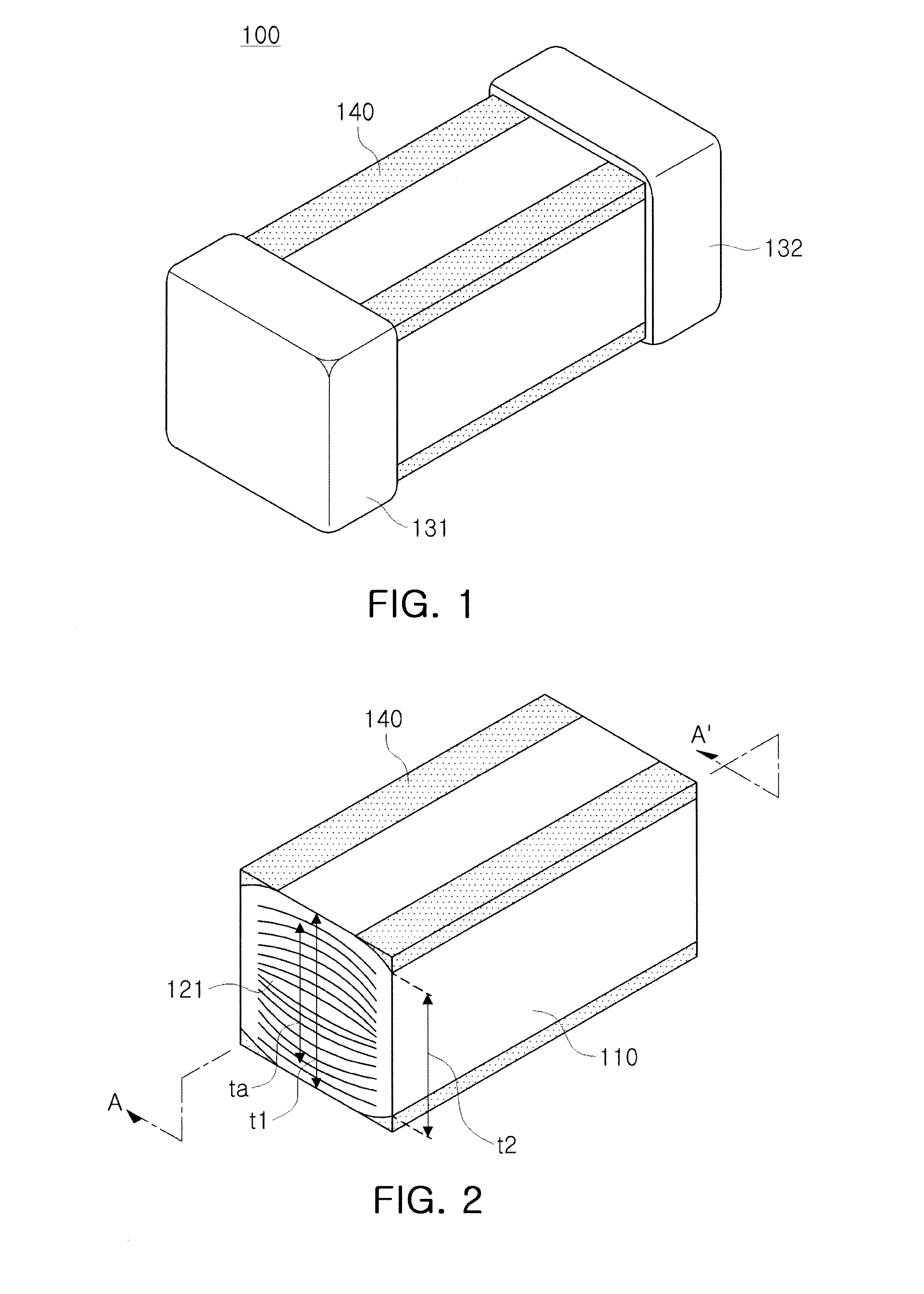

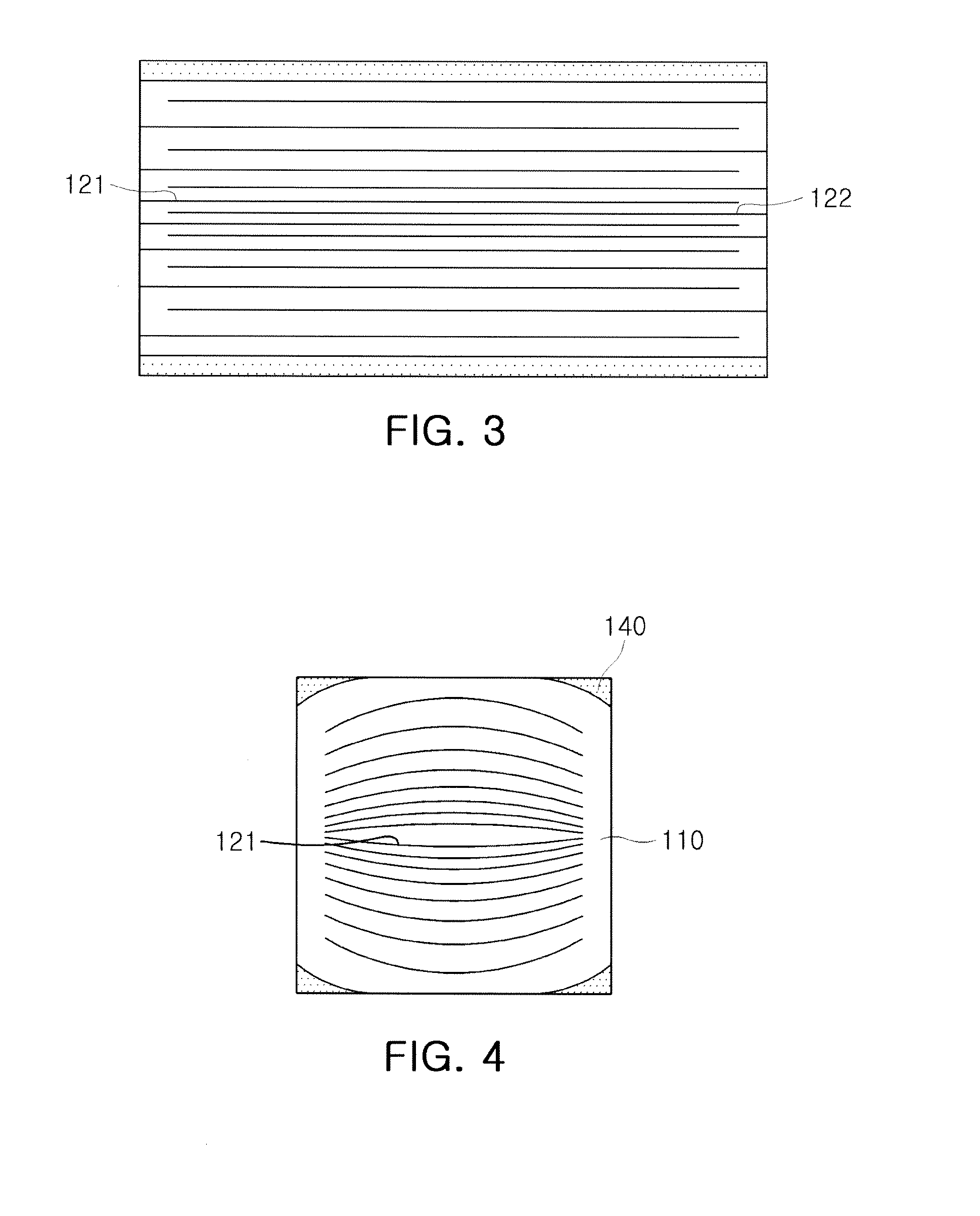

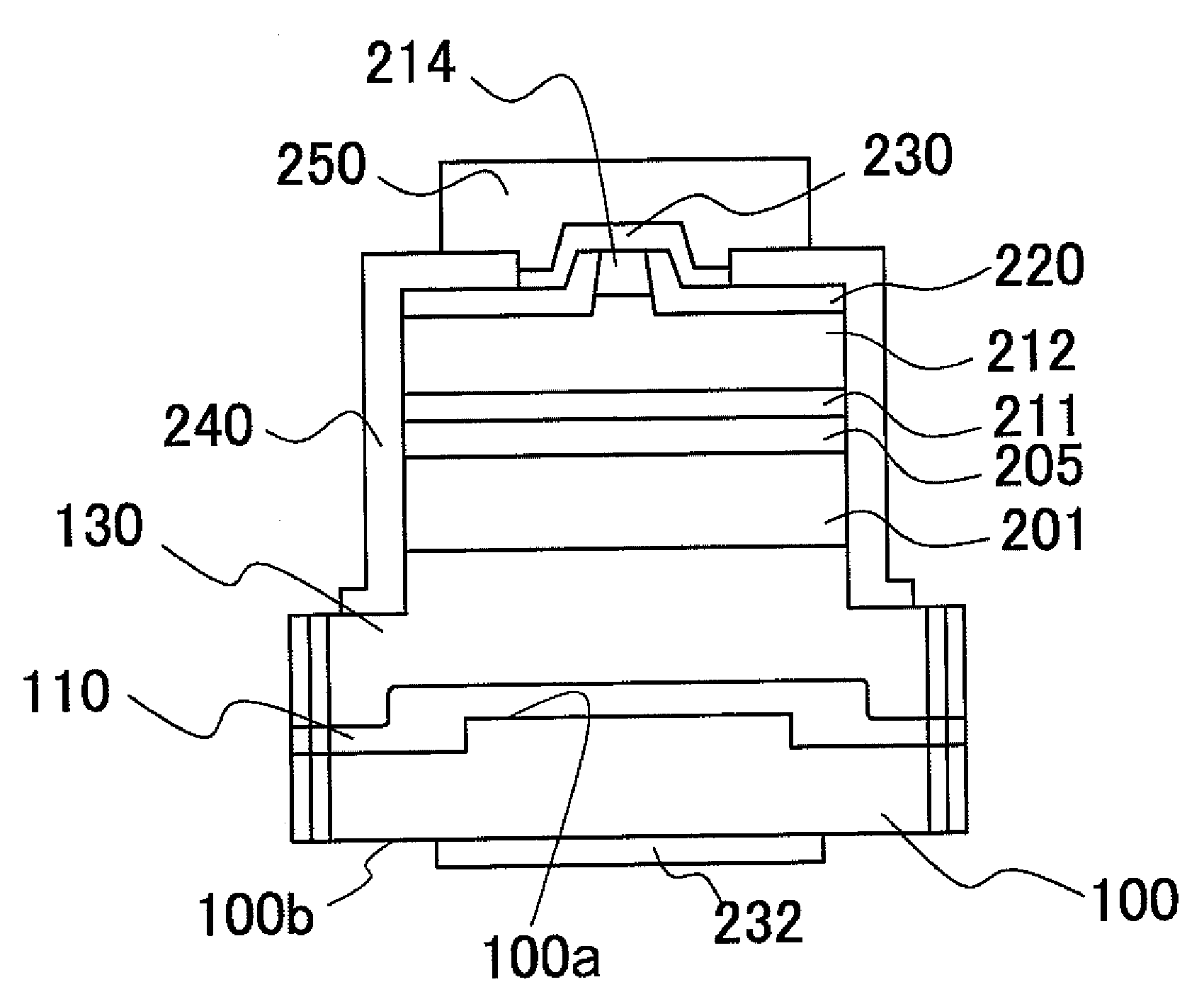

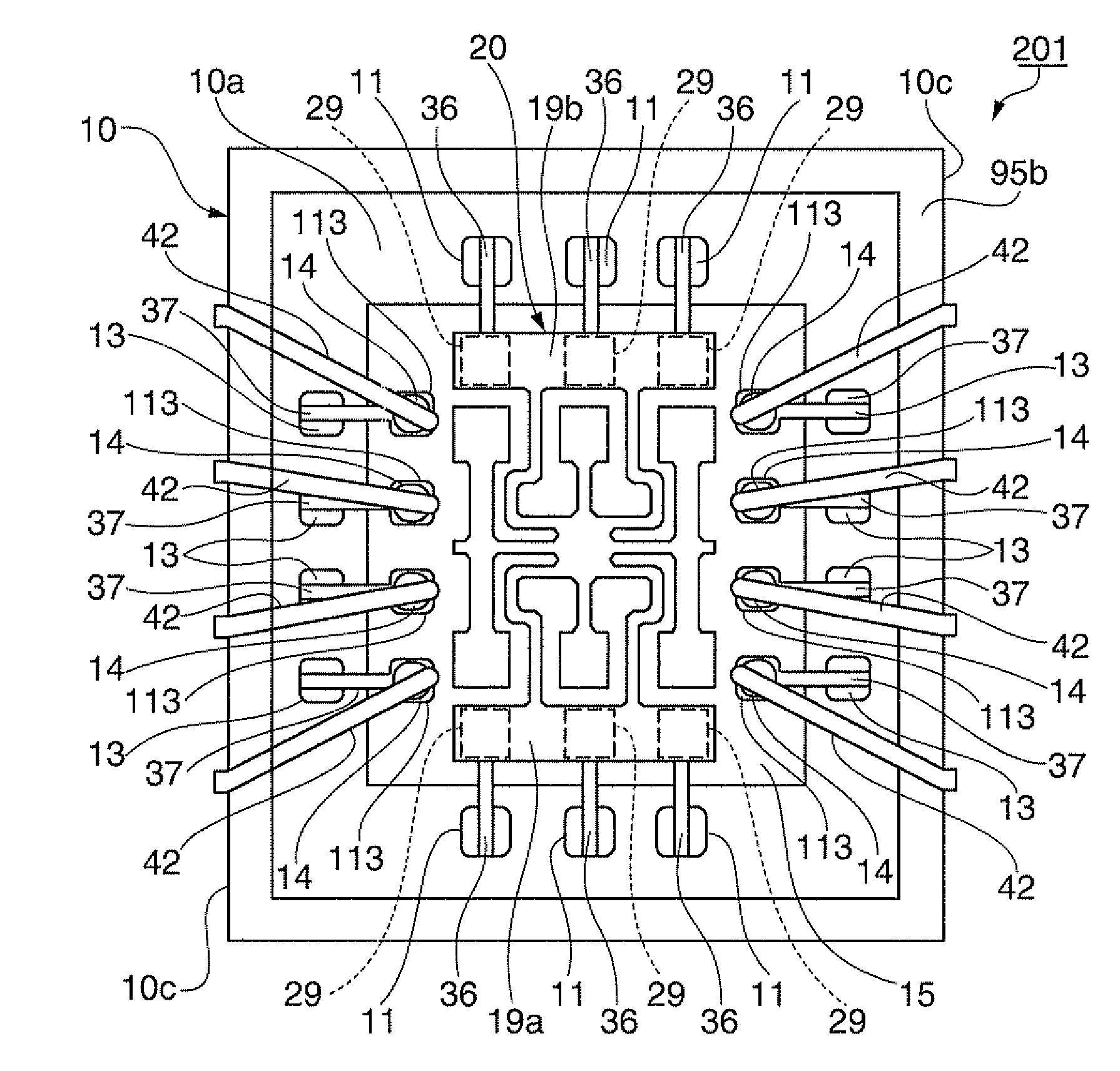

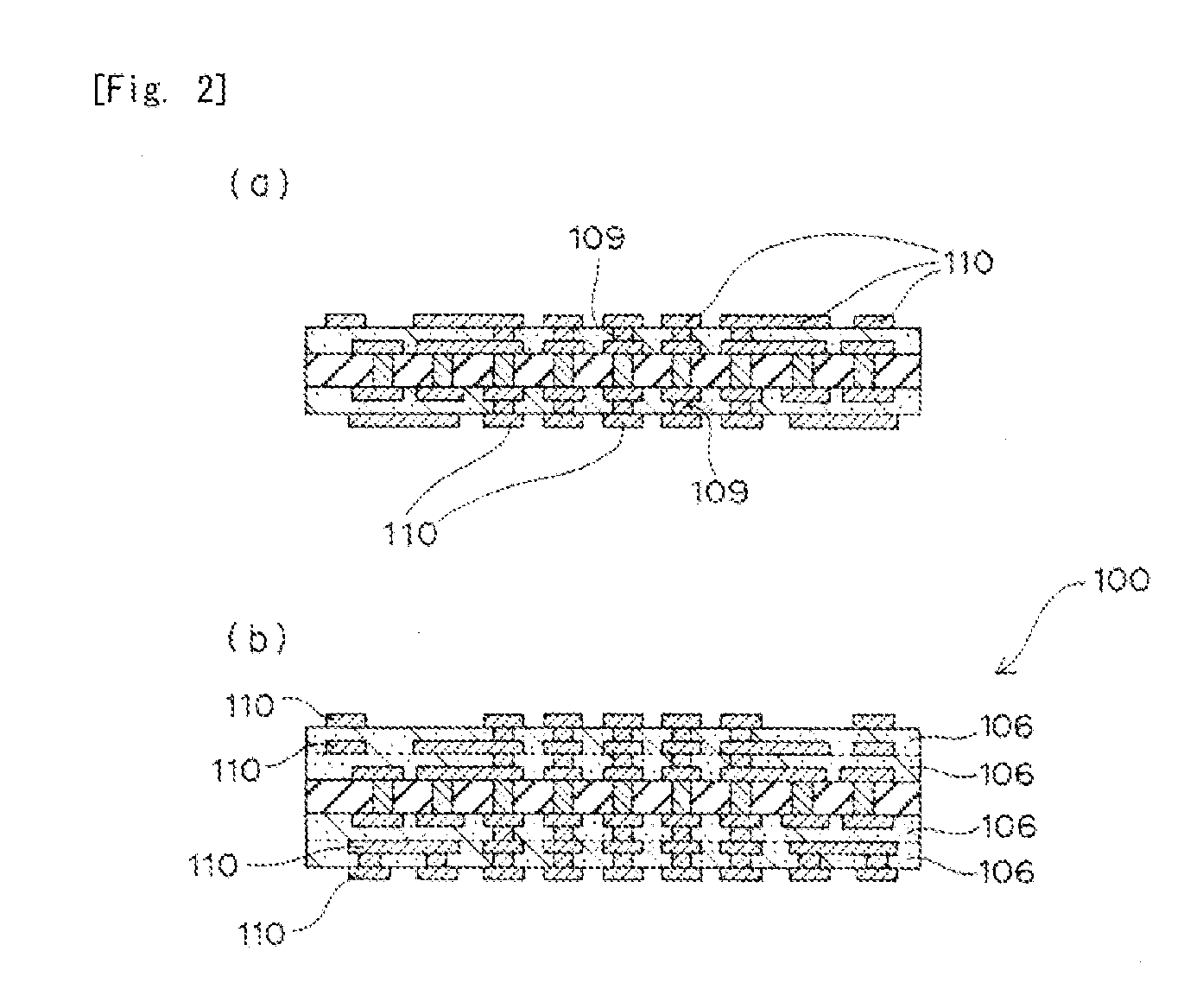

Multilayered ceramic electronic component and manufacturing method of the same

ActiveUS20140022690A1Suppress cracksSuppress delaminationFixed capacitor dielectricStacked capacitorsMetallurgyElectronic component

There is provided a multilayered ceramic electronic component including: a ceramic body in which a plurality of dielectric layers are stacked; a plurality of first and second internal electrodes formed on at least one of the dielectric layers and alternately exposed through both ends of the ceramic body in a stacking direction of the ceramic body; an a step compensation cover including a ceramic material having a viscosity higher than that of a ceramic material included in the ceramic body and formed on at least one of an upper surface and a lower surface of the ceramic body.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

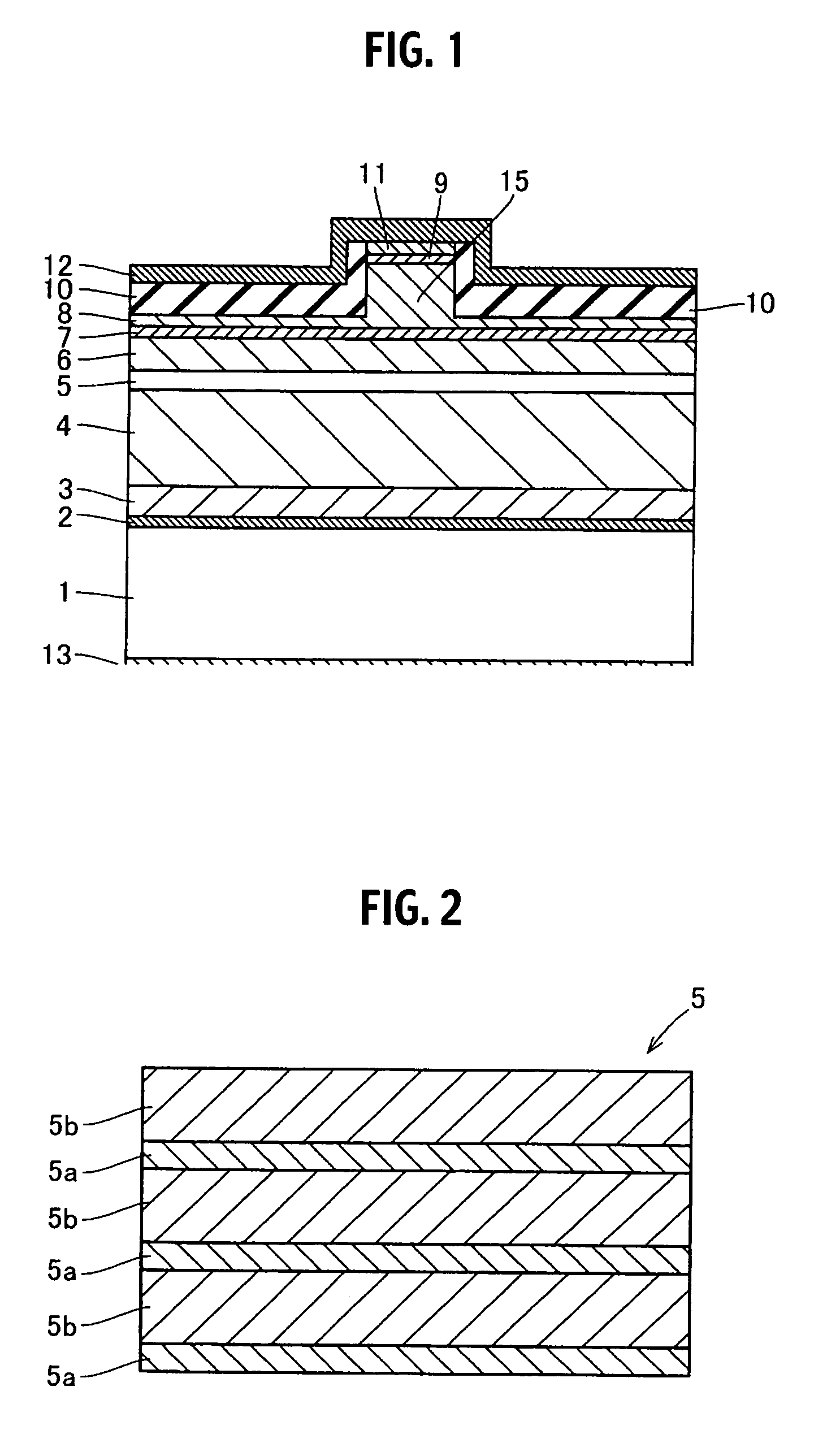

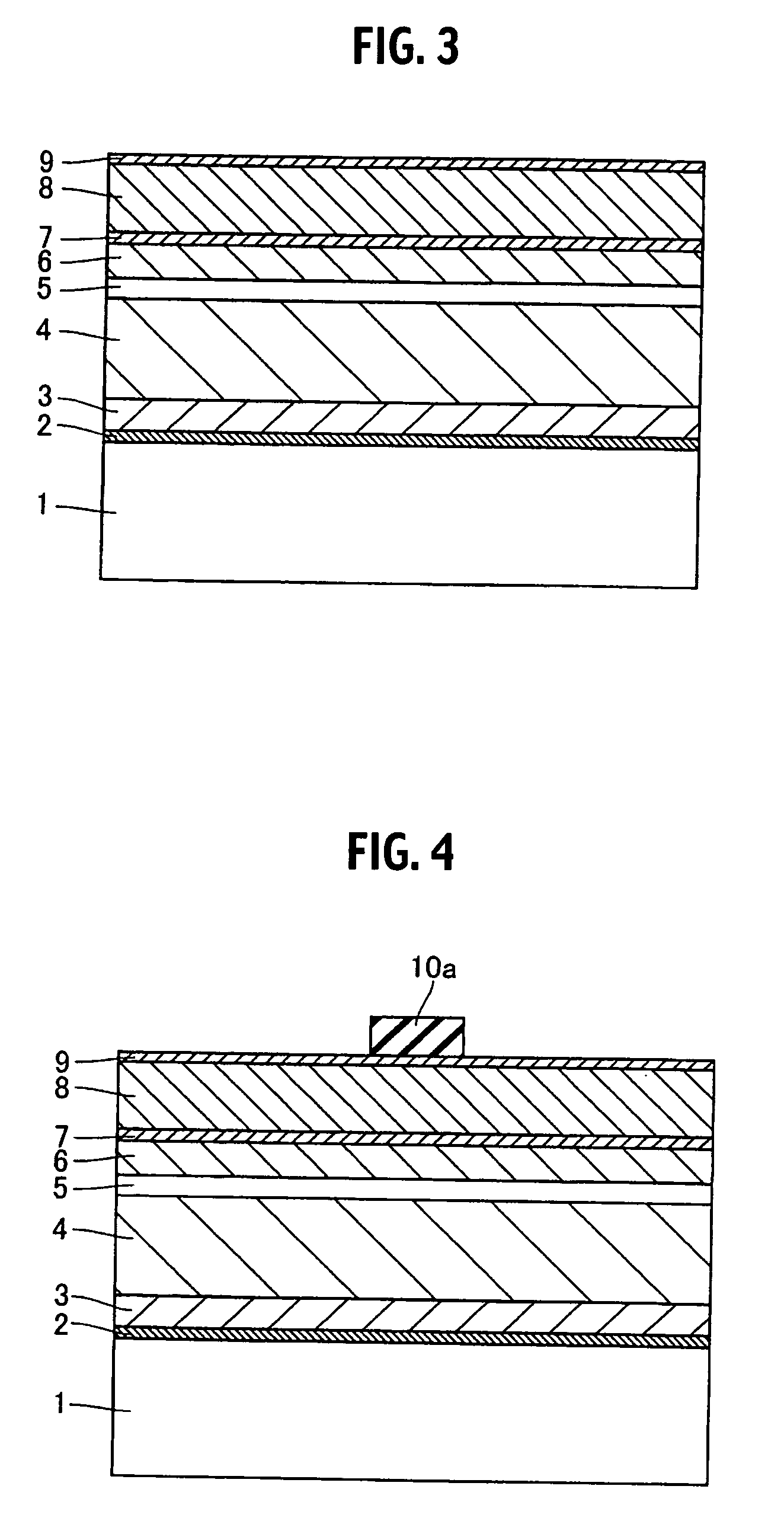

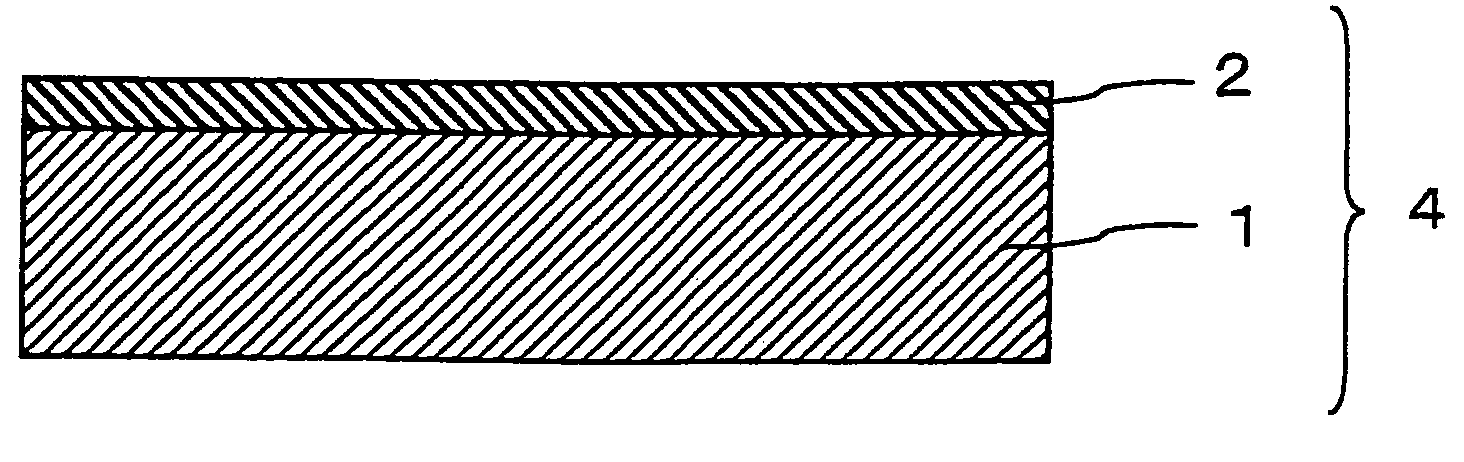

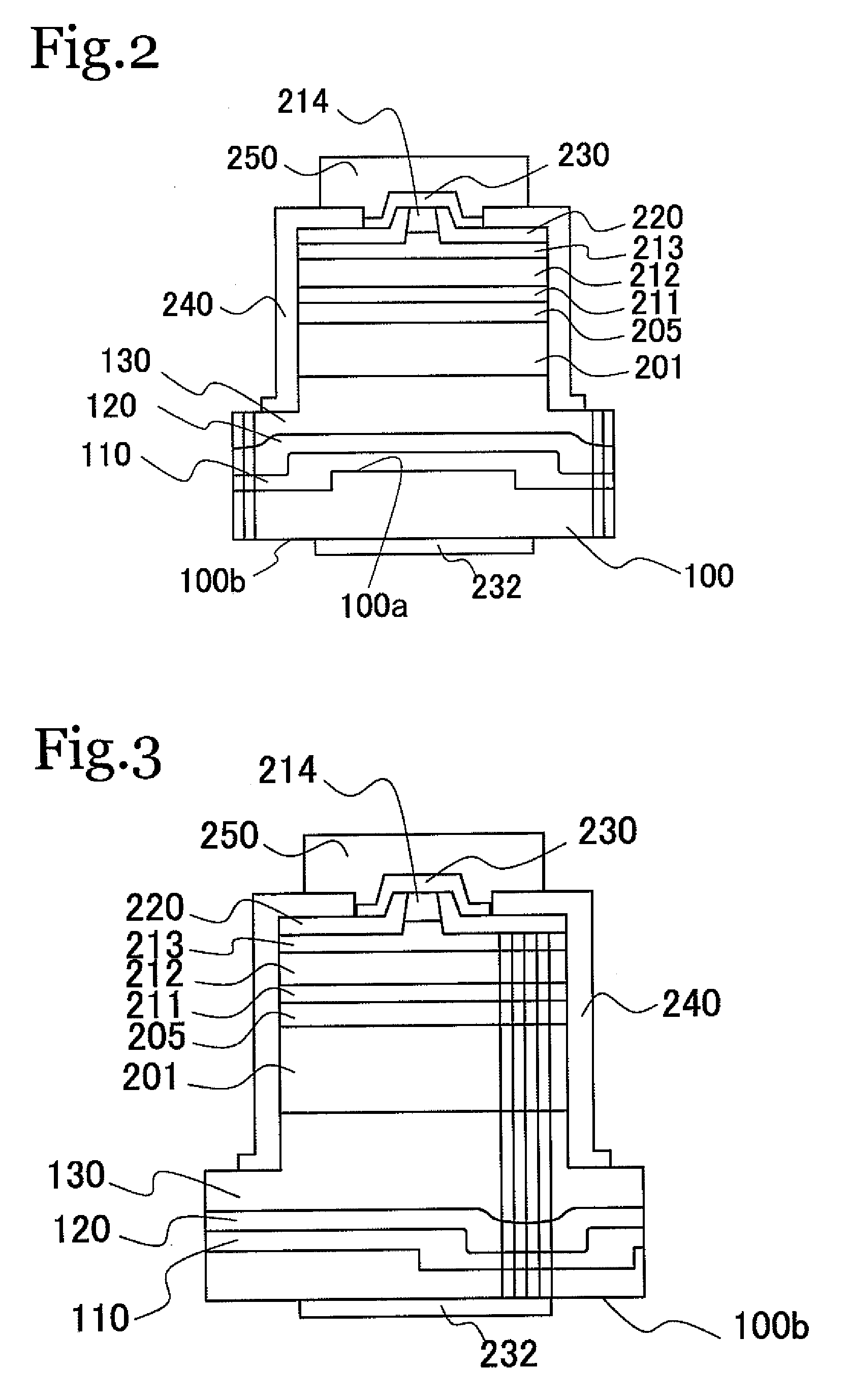

Nitride semiconductor laser element and method for manufacturing same

InactiveUS20080056322A1Tensile strain can be suppressedSuppress generationOptical wave guidanceLaser detailsIndiumGrown film

A nitride semiconductor laser element comprises a nitride semiconductor substrate and a nitride semiconductor layer laminated thereon, wherein the nitride semiconductor substrate has a high dislocation density region and a low dislocation density region containing lower dislocation than that of the high dislocation density region, and has at least one recess formed in at least the high dislocation density region, the nitride semiconductor layer has a first nitride semiconductor layer in which the grown film thickness in the lateral direction from the side faces of the recess in the substrate is greater than the grown film thickness in the heightwise direction from a region other than the recess, and a second nitride semiconductor layer that is disposed on the first nitride semiconductor layer and contains indium, and the first nitride semiconductor layer and second nitride semiconductor layer have recess over the recess in the nitride semiconductor substrate.

Owner:NICHIA CORP

Pneumatic tire

InactiveUS20090137718A1Avoid changeCrack generation can be suppressedSpecial tyresSilicon dioxideWear resistance

A pneumatic tire having excellent balance between low fuel consumption and grip property and capability of suppressing crack generation in a tread groove bottom while maintaining abrasion resistance is provided. The pneumatic tire has a tread formed from a rubber composition includes per parts by weight of a diene rubber, from 30 to 150 parts by weight of a reinforcing filler comprising at least one of carbon black and silica, and from 5 to 40 parts by weight of a terminally-amine modified liquid polybutadiene.

Owner:TOYO TIRE & RUBBER CO LTD

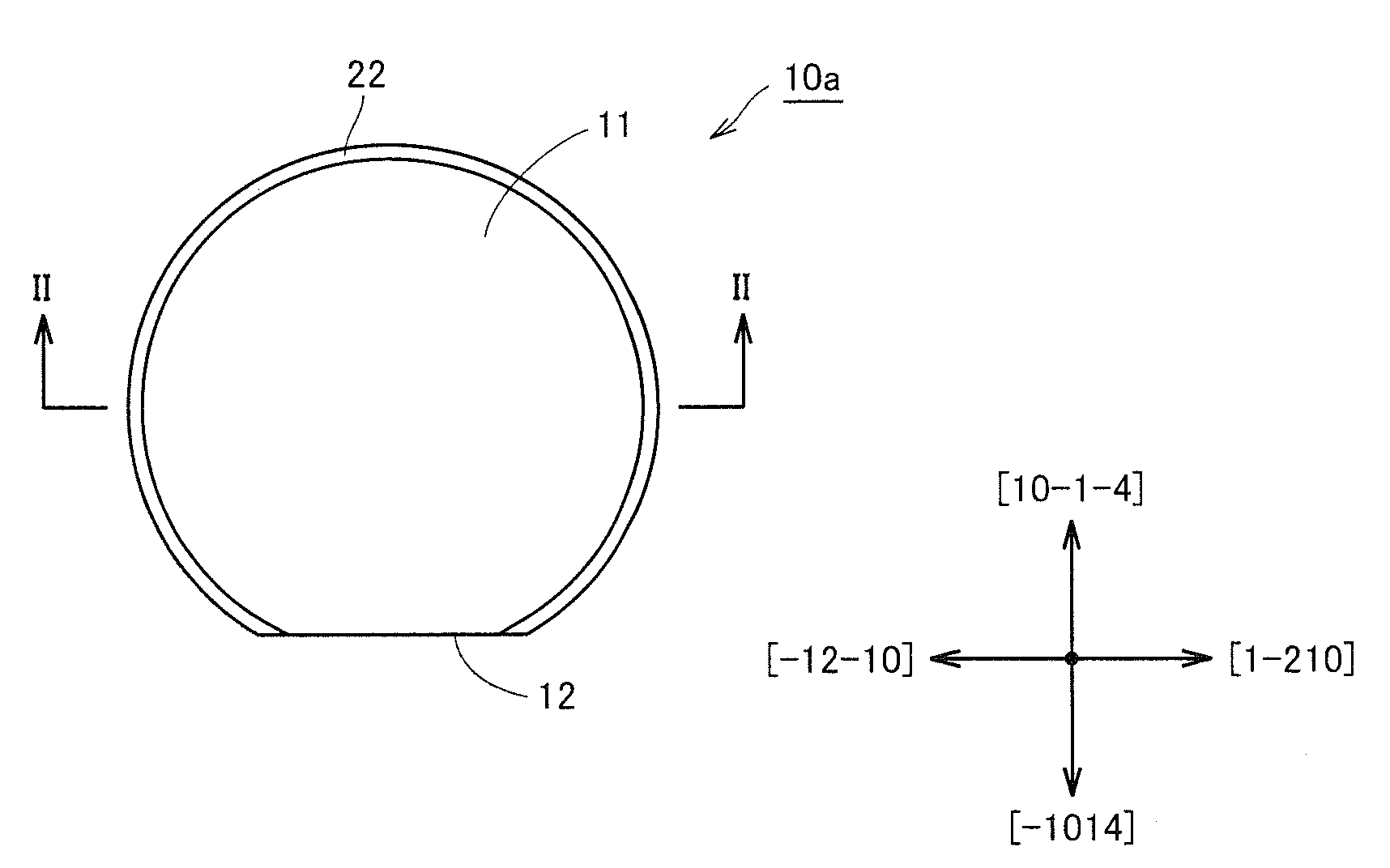

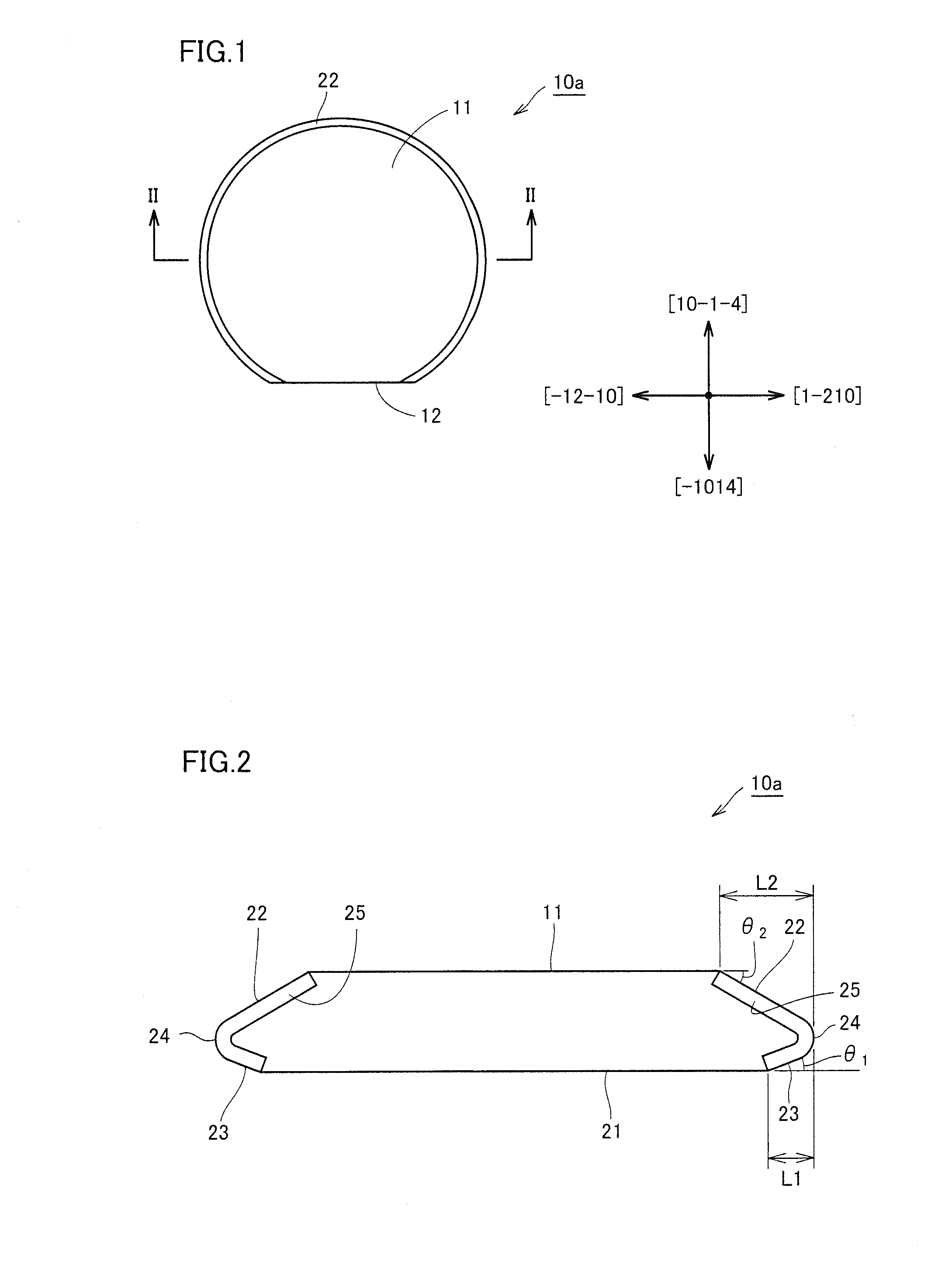

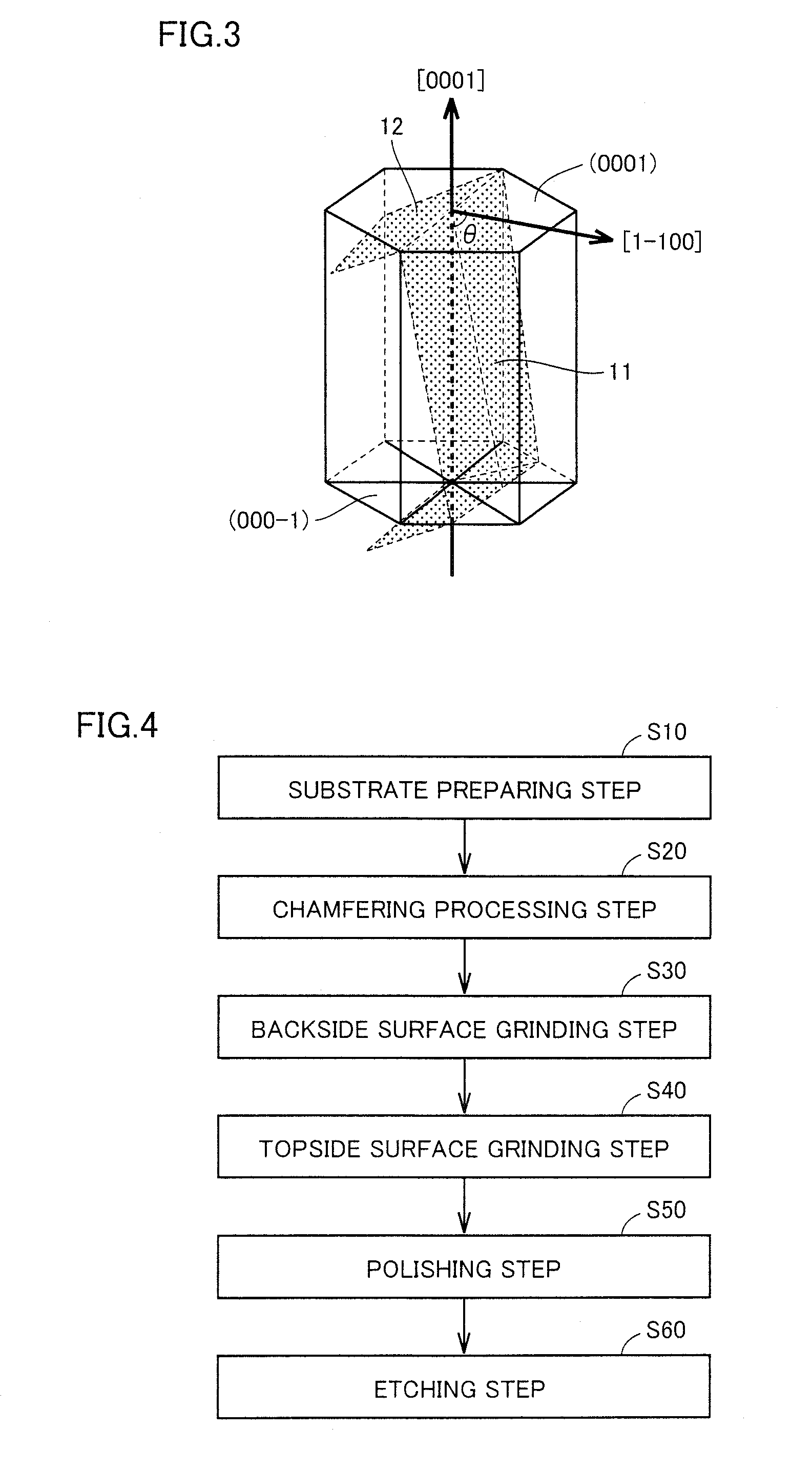

Nitride semiconductor substrate, semiconductor device, and methods for manufacturing nitride semiconductor substrate and semiconductor device

ActiveUS20110068434A1Effectively prevent crackingEffectively preventing chippingPolycrystalline material growthAfter-treatment detailsSemiconductor deviceNitride semiconductors

A nitride semiconductor substrate having a main surface serving as a semipolar plane and provided with a chamfered portion capable of effectively preventing cracking and chipping, a semiconductor device fabricated using the nitride semiconductor substrate, and a method for manufacturing the nitride semiconductor substrate and the semiconductor device are provided. The nitride semiconductor substrate includes a main surface inclined at an angle of 71° or more and 79° or less with respect to the (0001) plane toward the [1-100] direction or inclined at an angle of 71° or more and 79° or less with respect to the (000-1) plane toward the [−1100] direction; and a chamfered portion located at an edge of an outer periphery of the main surface. The chamfered portion is inclined at an angle θ1 or θ2 of 5° or more and 45° or less with respect to adjacent one of the main surface and a backside surface on a side opposite to the main surface. Accordingly, cracking and chipping occurring from the edge of the outer periphery of the nitride semiconductor substrate can be effectively suppressed.

Owner:SUMITOMO ELECTRIC IND LTD

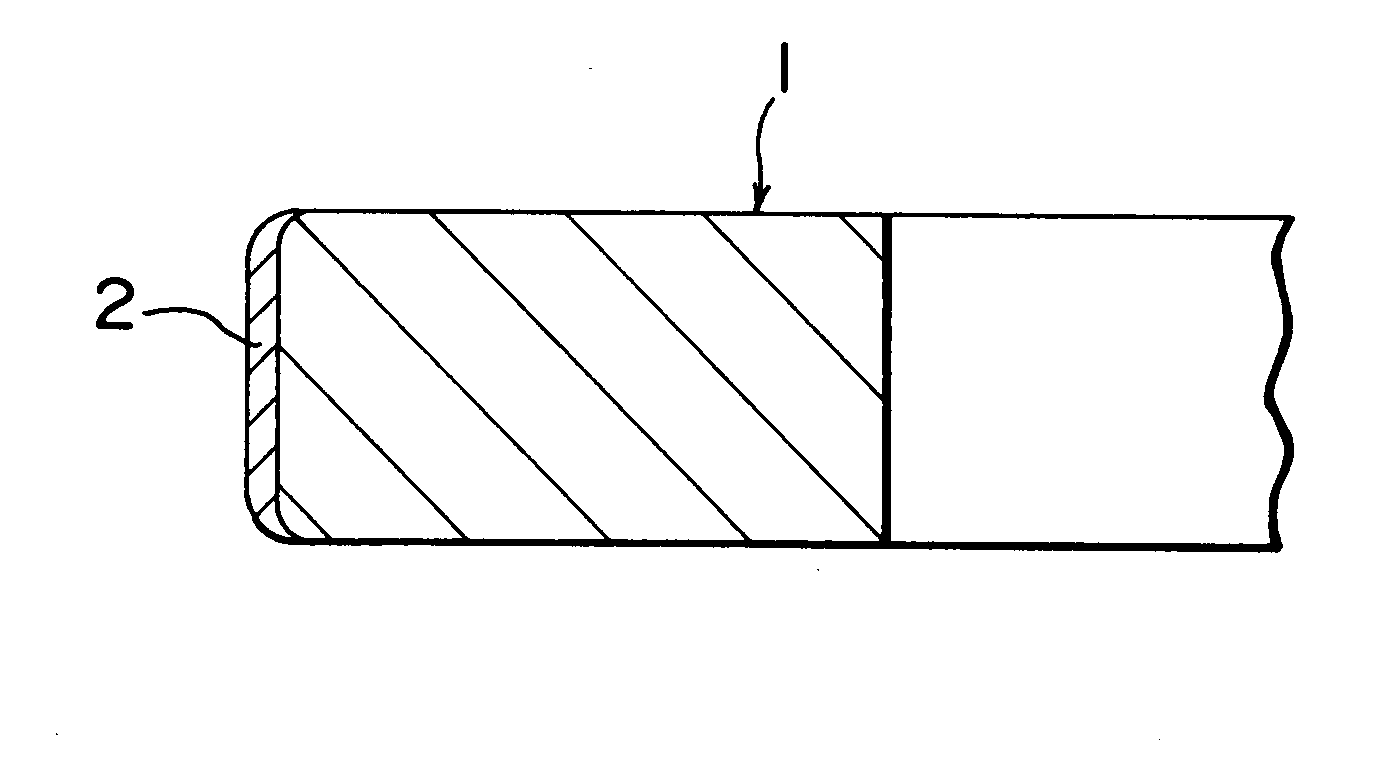

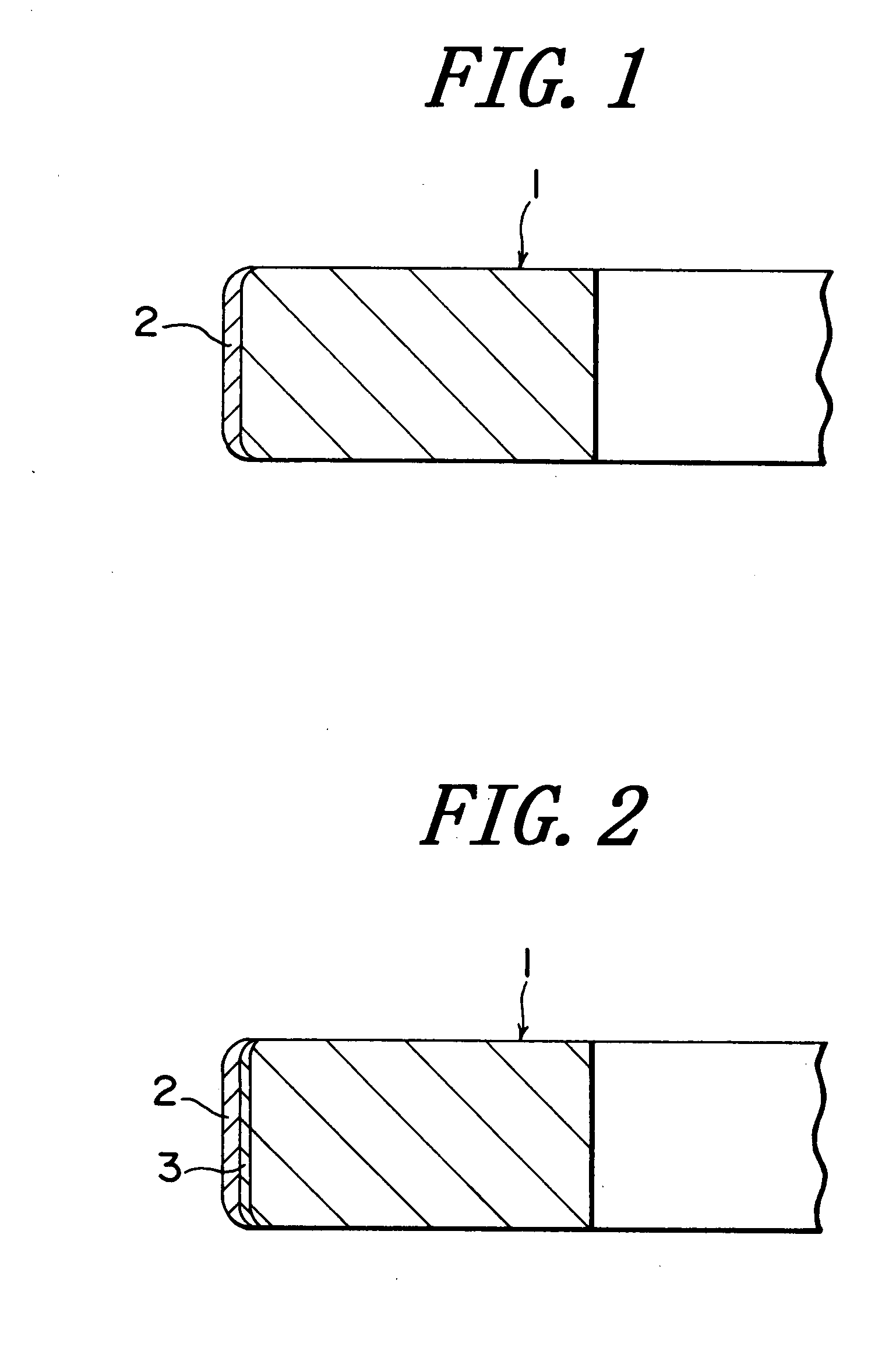

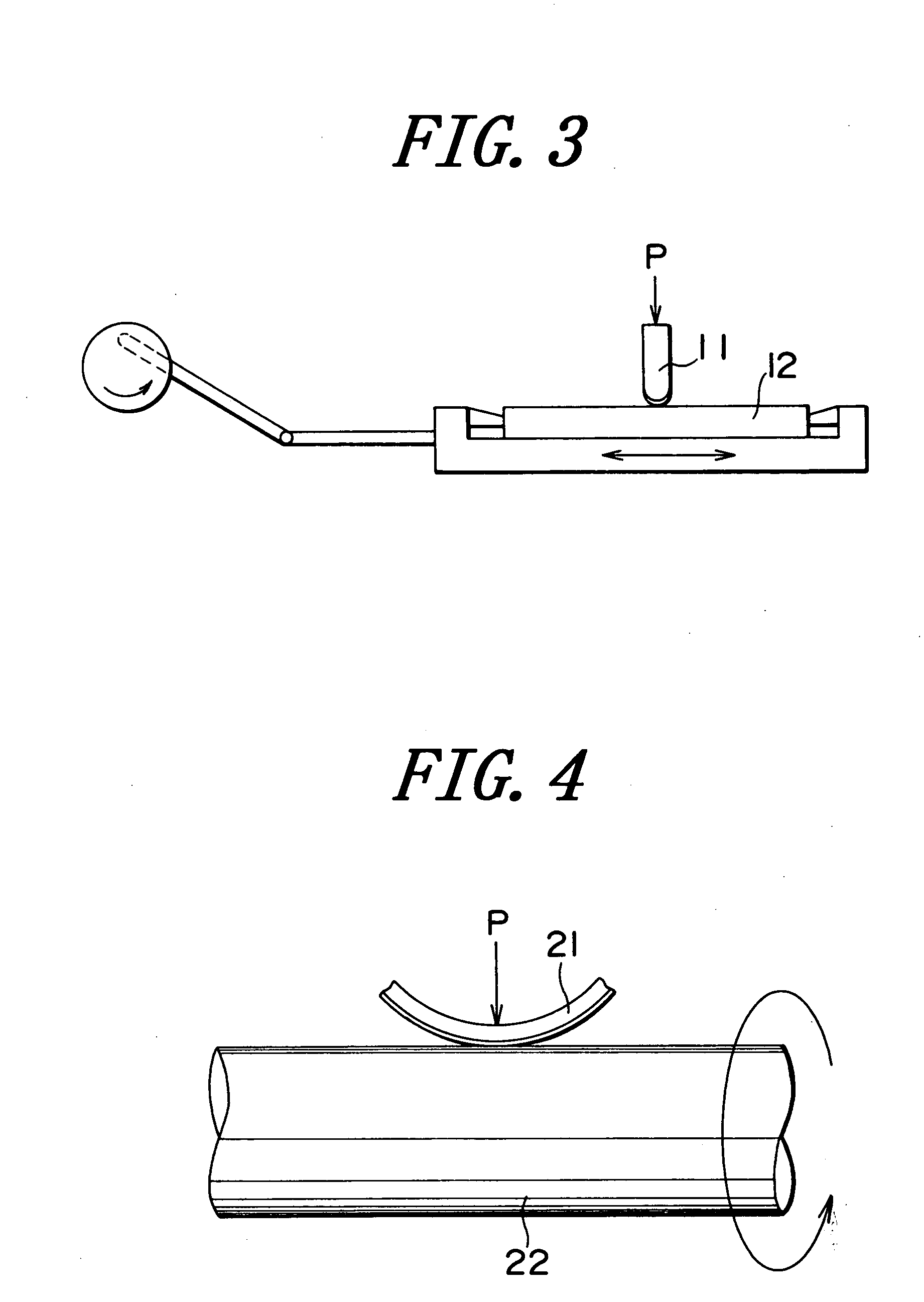

Piston ring for internal combustion engines

InactiveUS20080007006A1Reduced wear resistance requirementsReduced crack resistancePiston ringsVacuum evaporation coatingEngineeringOxygen

A piston ring 1 for internal combustion engines comprises a hard film 2 formed on at least an outer circumferential sliding surface of the piston ring 1. The hard film 2 includes chromium, nitrogen and silicon as structural elements and the same crystal structure as CrN, and is composed of a crystal phase where silicon is contained in a solid solution state in a crystal lattice at an atomic ratio between 1 and 9.5 percent. The hard film may be the following film. Namely, a hard film is composed of a mixed phase of a crystal phase and an amorphous phase; the crystal phase includes chromium, nitrogen and silicon as structural elements and the same crystal structure as CrN and moreover includes silicon contained in a solid solution state in a crystal lattice; the amorphous phase includes silicon, nitrogen and chromium as structural elements; the ratio of the amorphous phase in the hard film is 4.5 percent or less; and the silicon content in the hard film is between 1 and 9.5 percent at an atomic ratio. The hard film may include aluminum, vanadium, titanium, zirconium, boron, carbon, oxygen or fluorine.

Owner:TEIKOKU PISTON RING CO LTD

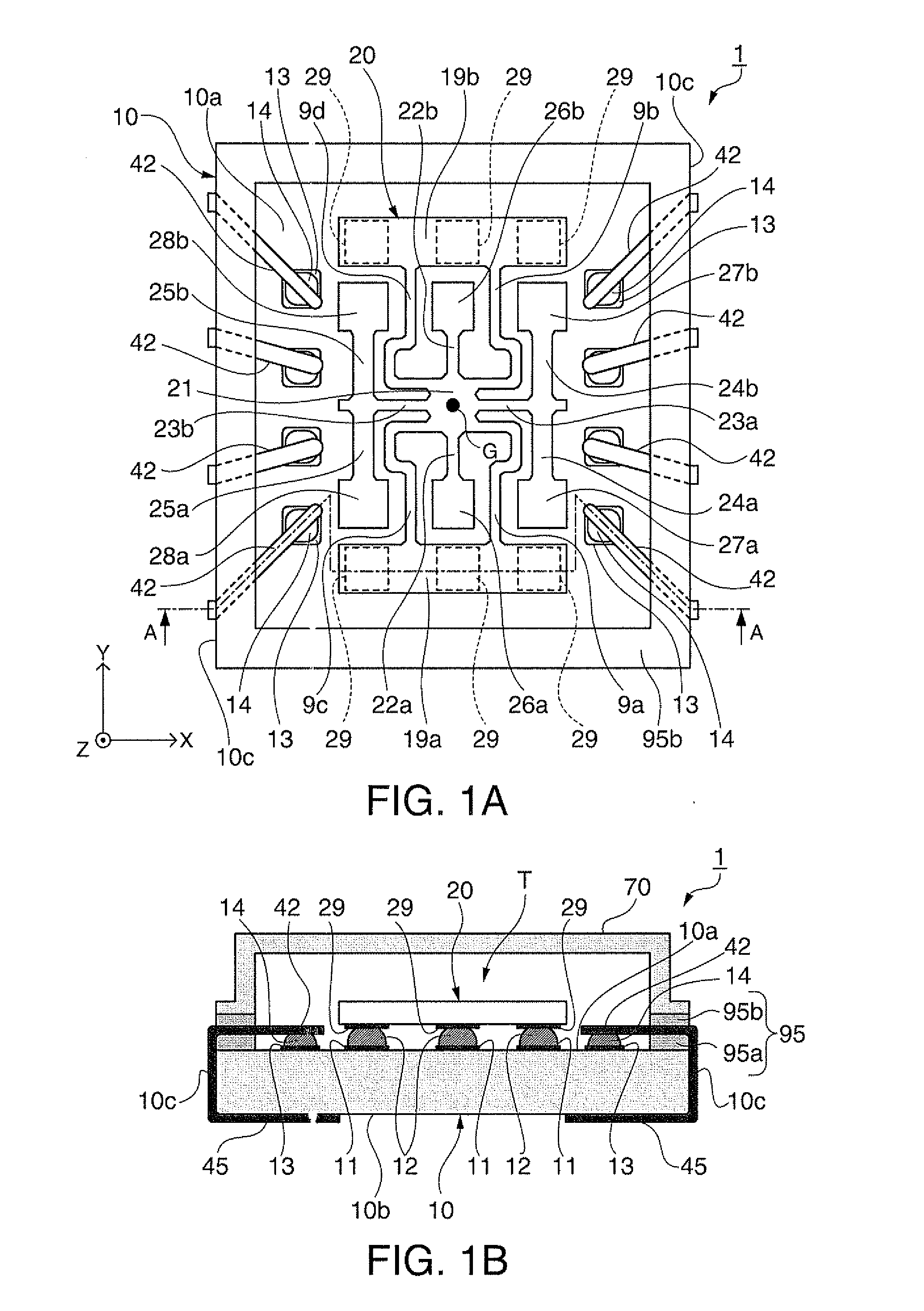

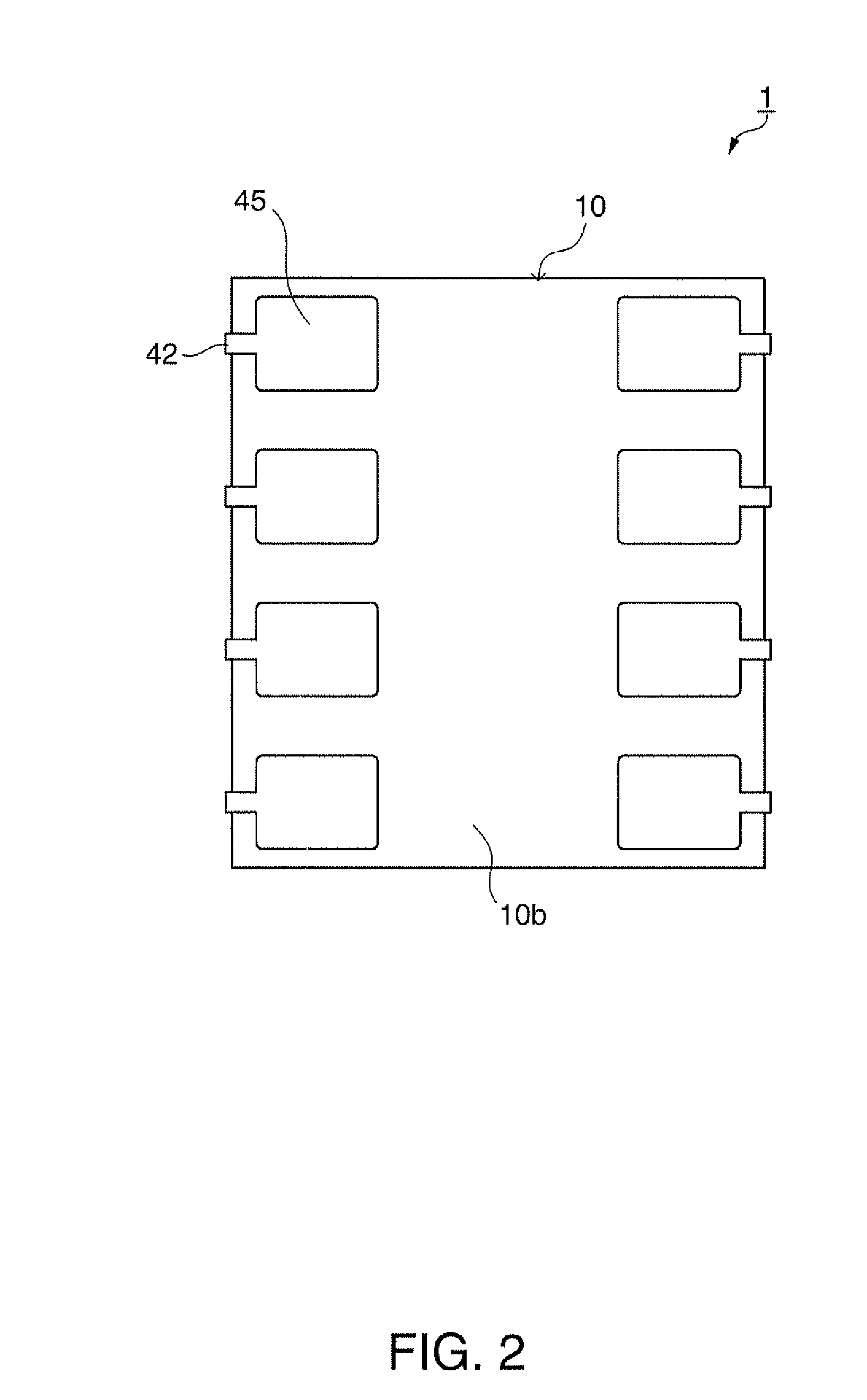

Sensor device and manufacturing method thereof

InactiveUS20120318059A1Relieve pressureSuppress cracksAcceleration measurement using interia forcesSemiconductor/solid-state device detailsBiomedical engineeringSemiconductor

A sensor device includes an IC chip as a semiconductor device having a first electrode and a second electrode on a first surface, a frame-like fixing member provided to surround the first electrode and the second electrode, a vibration gyro element as a vibrating piece electrically connected to the first electrode, a lid as a lid body bonded to the first surface via the fixing member and forming a space that covers the vibration gyro element, and a lead wire electrically connected to the second electrode and extending through inside (between an IC-side fixing member and a lid-side fixing member in the embodiment) of the fixing member to outside of the space.

Owner:SEIKO EPSON CORP

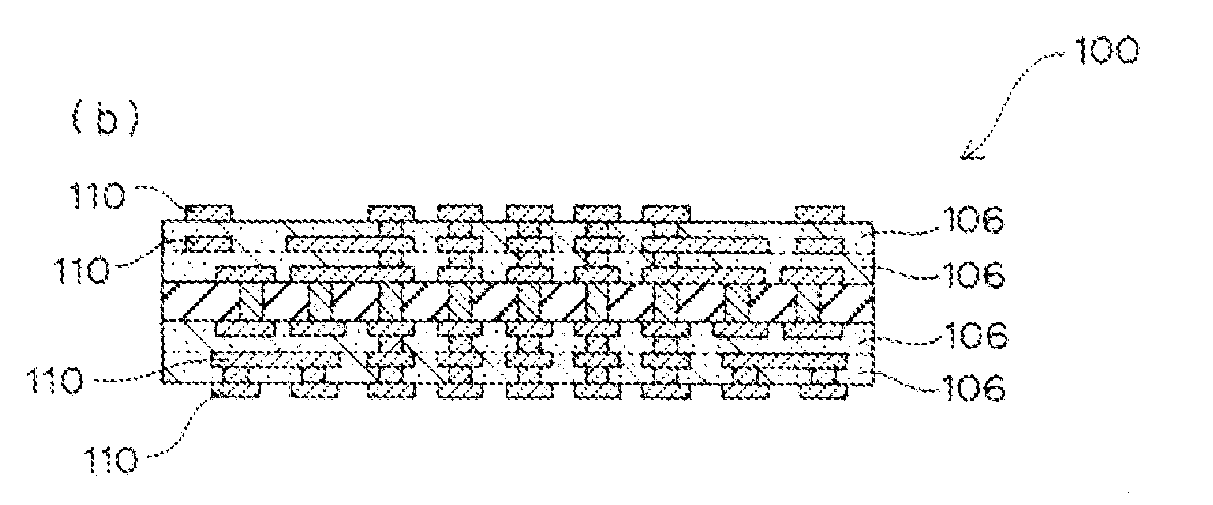

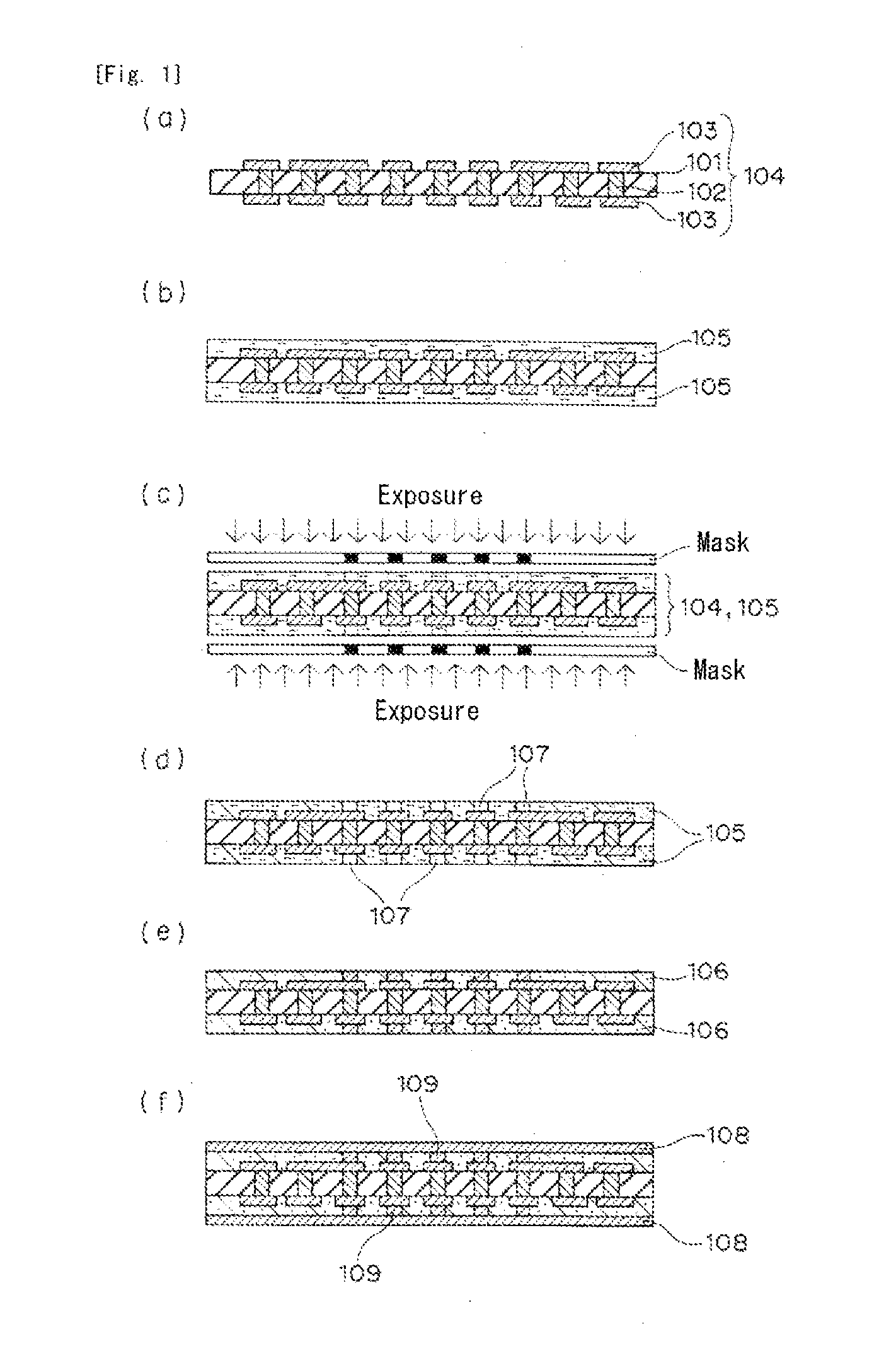

Built-up substrate, method for manufacturing same, and semiconductor integrated circuit package

ActiveUS20140124777A1Improve insulation reliabilityPrecise positioningDielectric materialsSemiconductor/solid-state device detailsEngineeringSemiconductor

A method for manufacturing a build-up substrate, the build-up substrate comprising an insulating layer and a wiring pattern layer stacked over a circuit substrate, said method comprising the steps of: (i) applying a photoactive metal oxide precursor material to one or both sides of the circuit substrate with a wiring pattern, and drying the applied photoactive metal oxide precursor material to form an insulating film; (ii) forming an opening for a via hole in the insulating film by exposure and development of the insulating film; (iii) applying a heat treatment to the insulating film to convert the insulating film into a metal oxide film, thereby forming a build-up insulating layer of the metal oxide film; and (iv) plating the build-up insulating layer to form via holes in the openings, forming a metal layer on the build-up insulating layer, and etching the metal layer to form a build-up wiring pattern; and (v) repeating the steps from (i) to (iv) at least one time.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com