Patents

Literature

31results about How to "Prevents stress corrosion cracking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Reactor structural member and method of suppressing corrosion of the same

InactiveUS6940939B1Increase the concentration of hydrogenEffective preventionNuclear energy generationNuclear monitoringHydrogen concentrationNuclear reactor

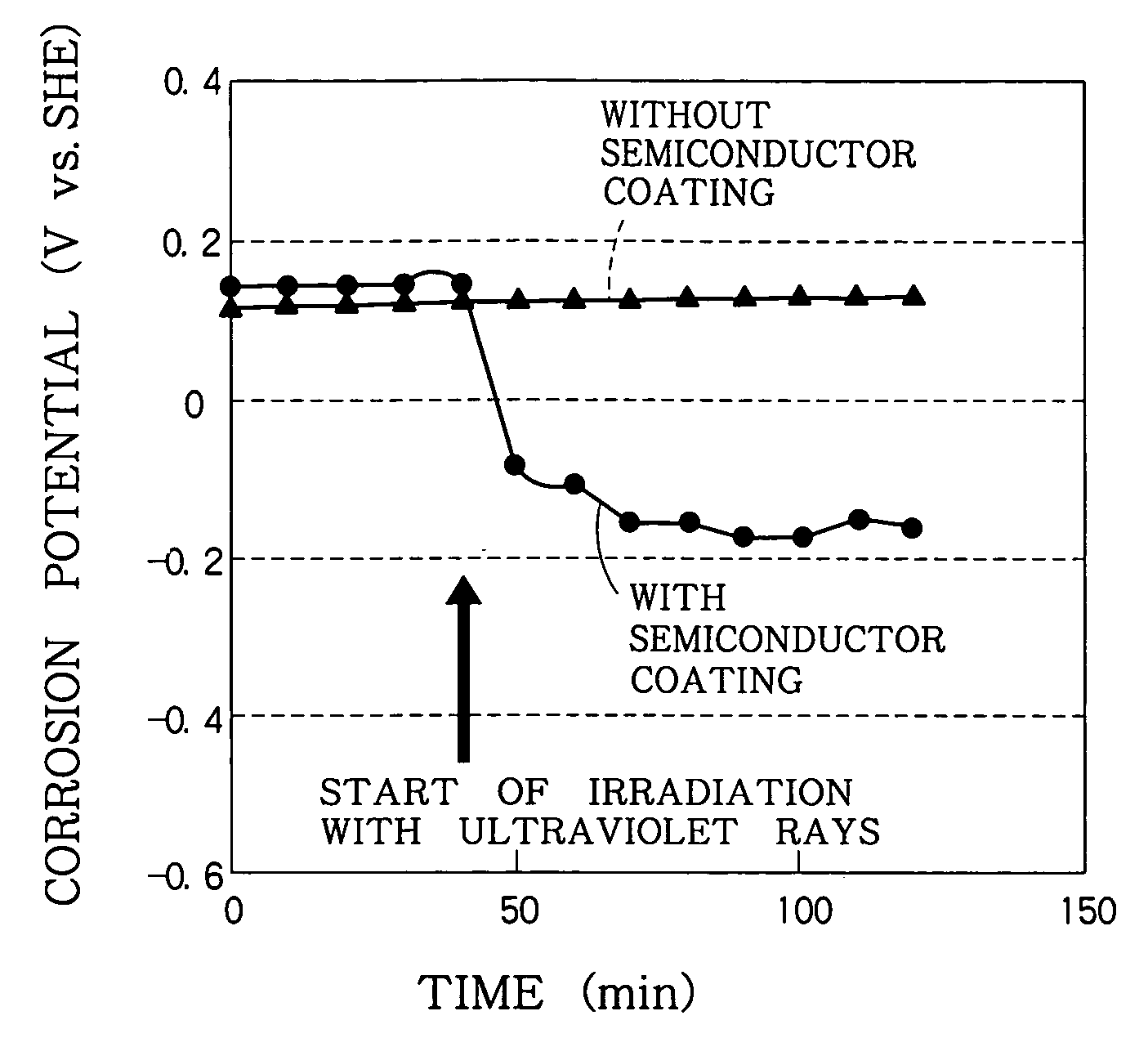

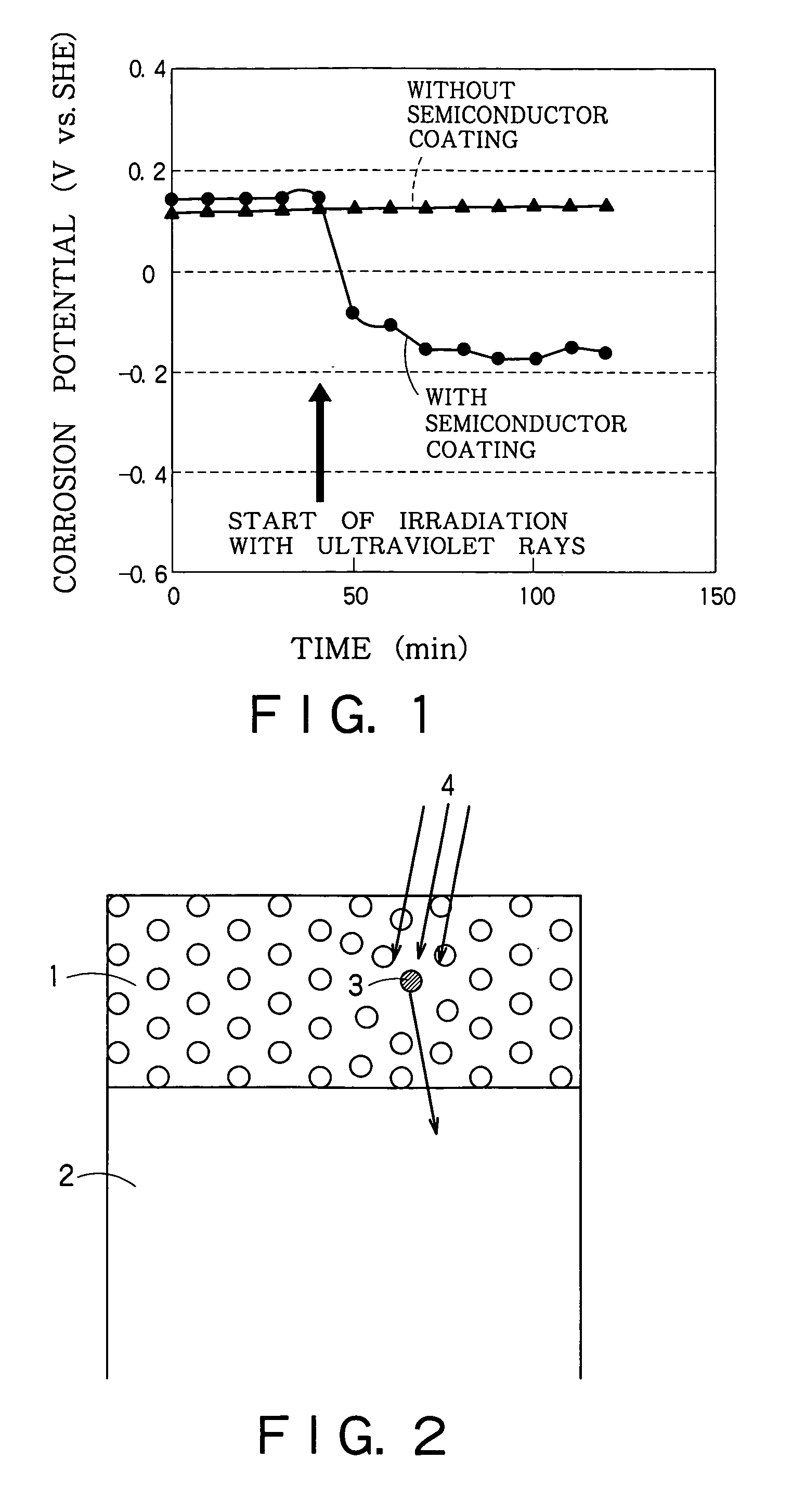

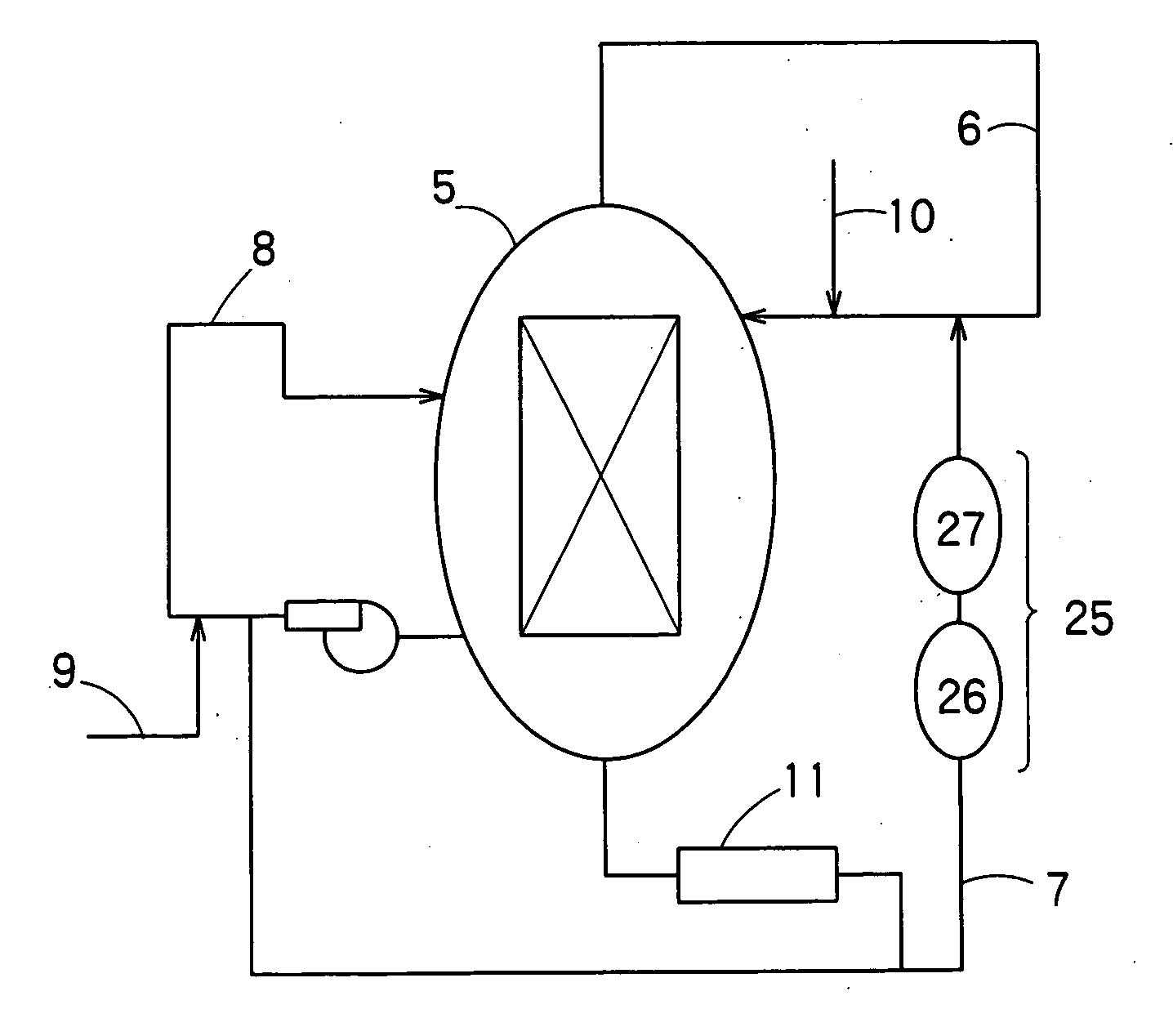

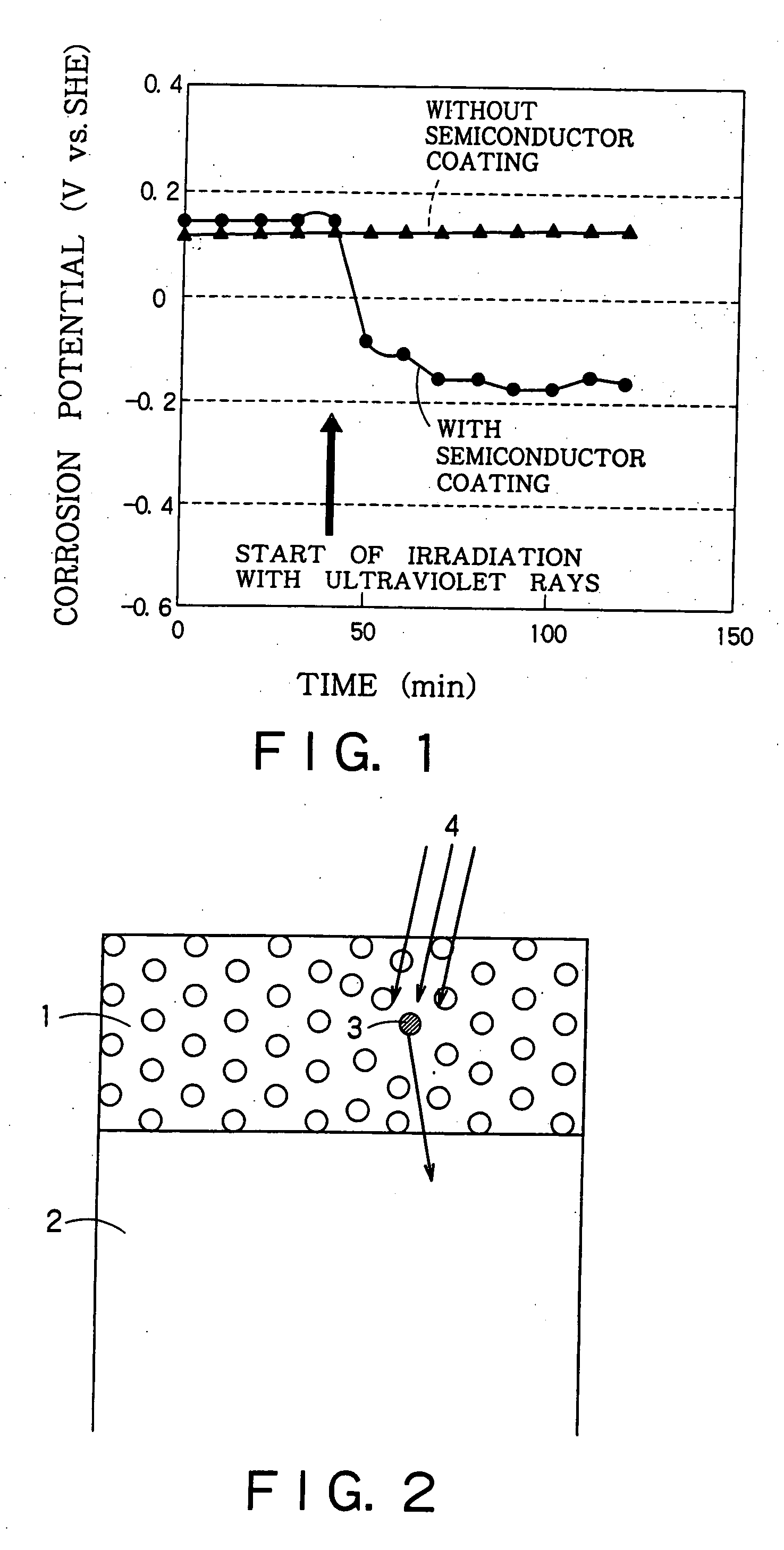

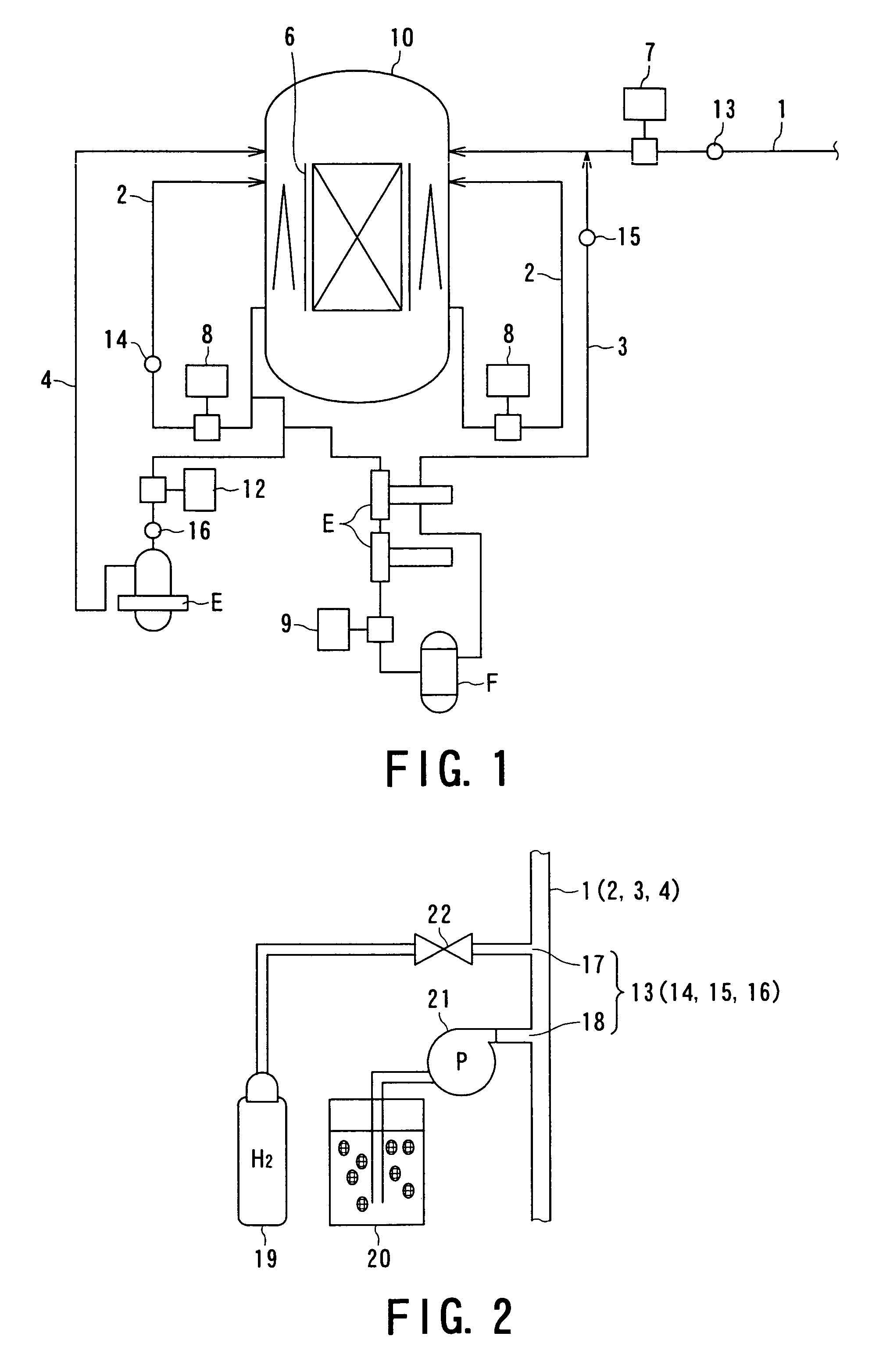

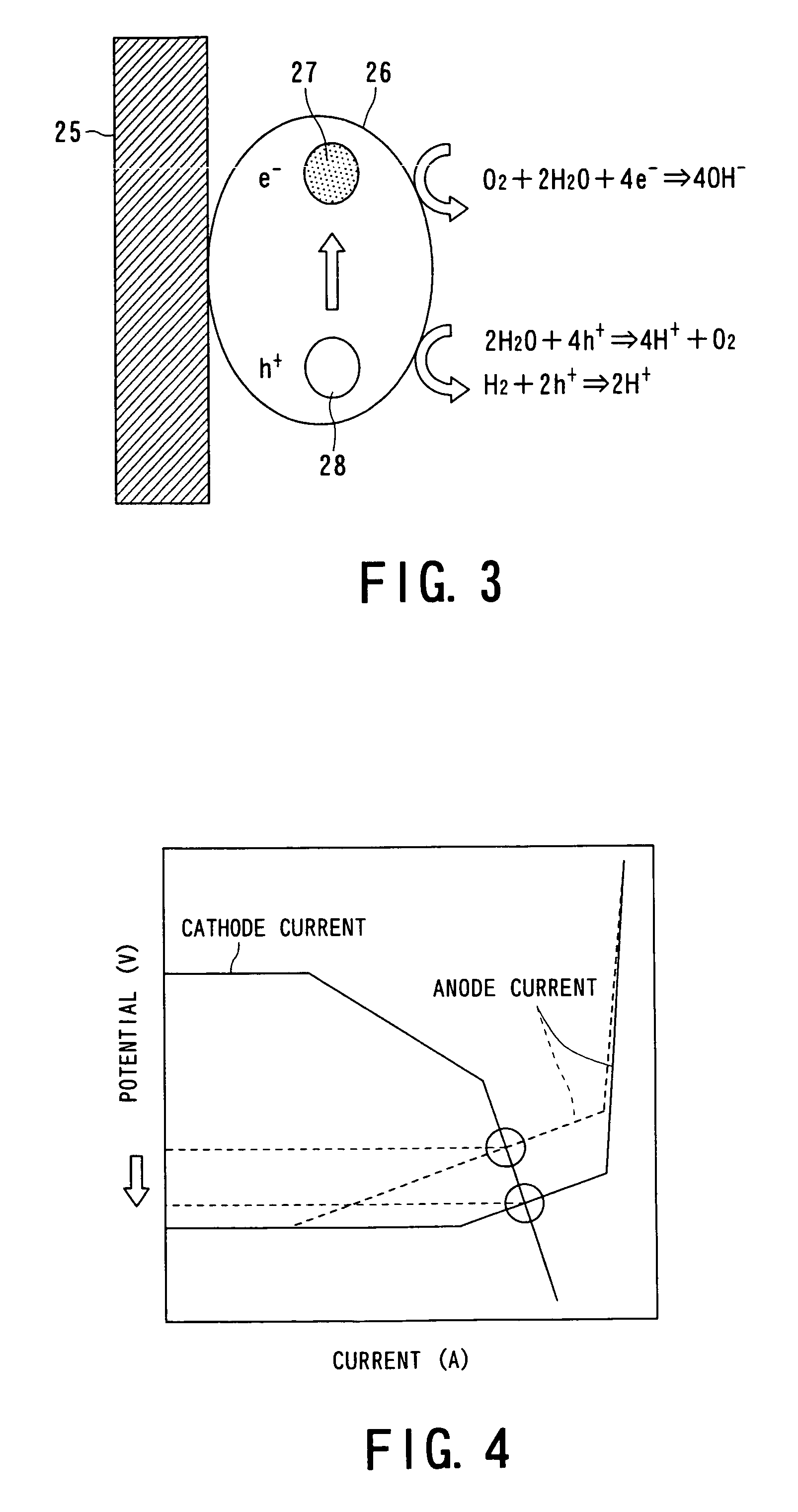

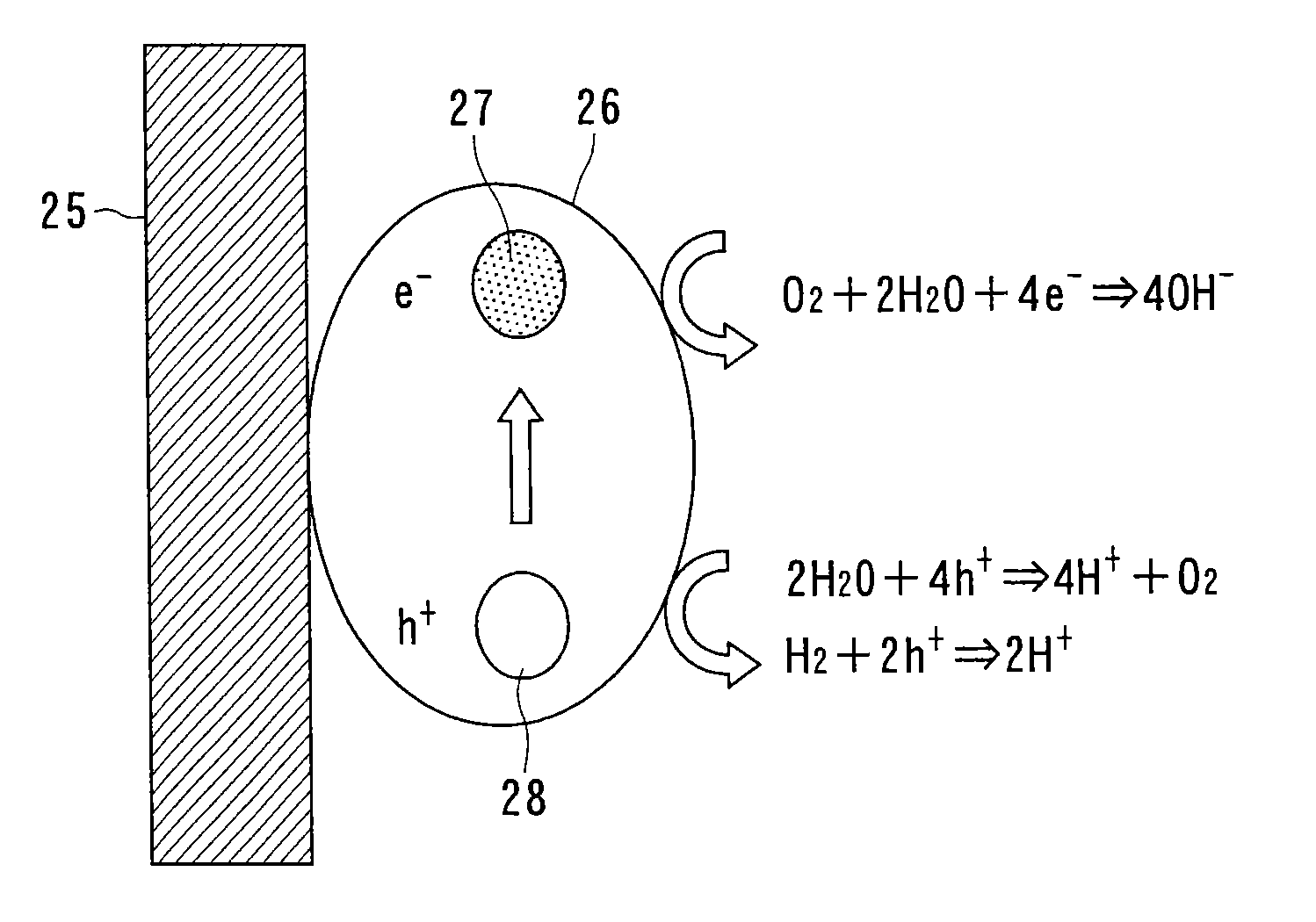

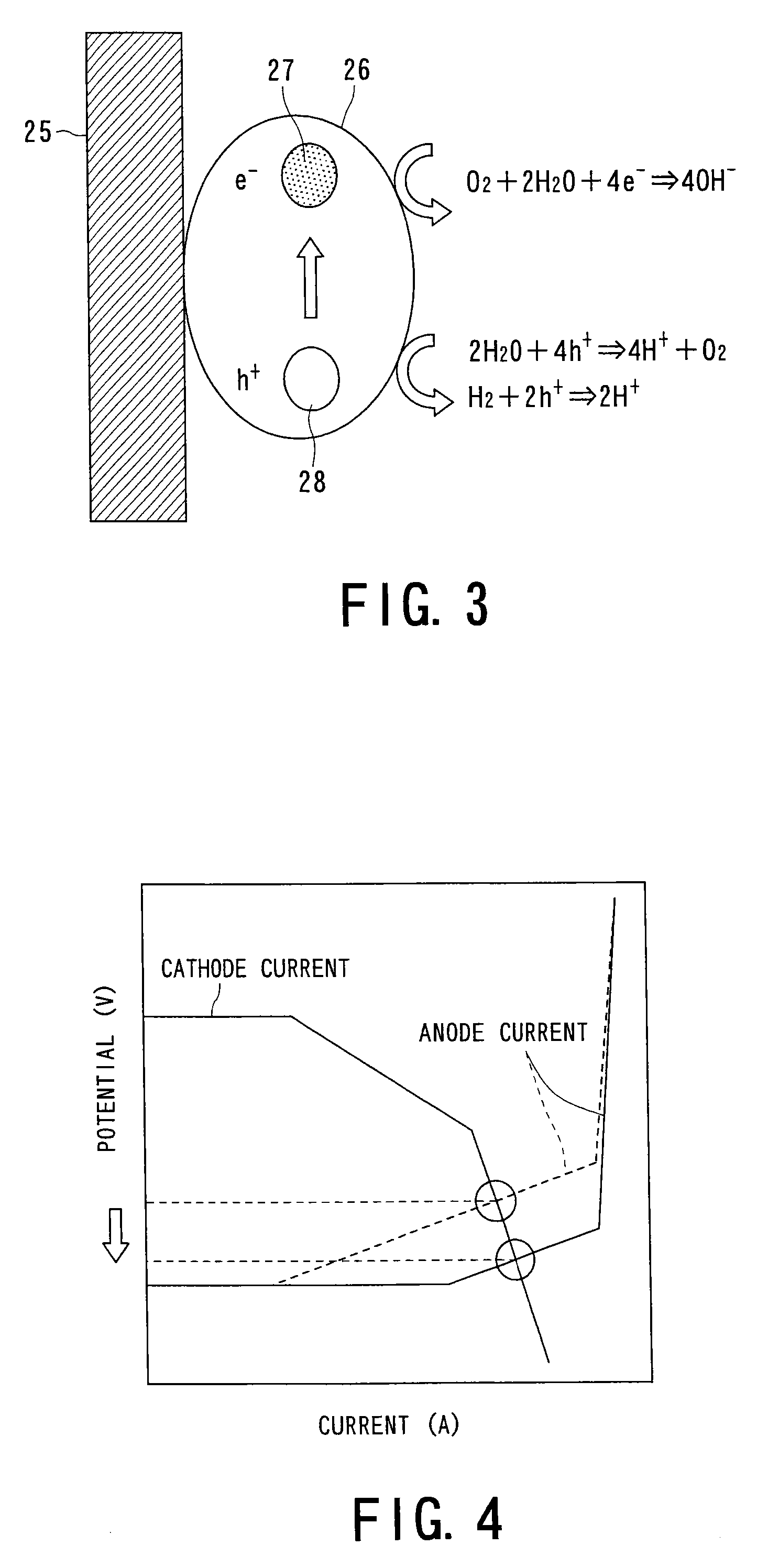

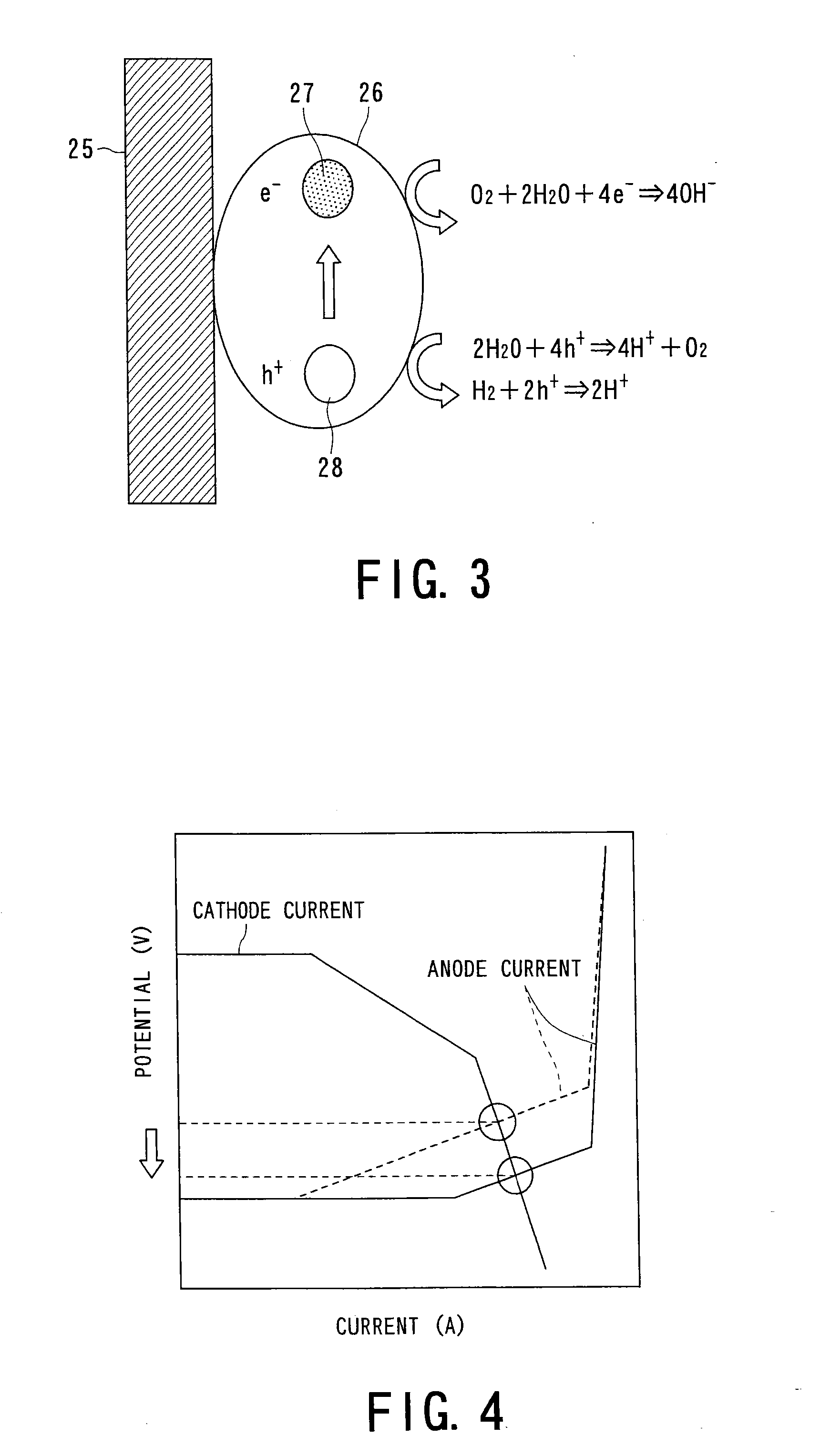

A photocatalytic substance having the properties of an n-type semiconductor is deposited on a surface of a metal base made of a stainless steel or Inconel. When necessary, the hydrogen concentration of the reactor water is increased. A current produced by the photocatalytic substance when the same is irradiated with light or radioactive rays in a nuclear reactor flows through the metal base to reduce corrosion current. When necessary, the photocatalytic substance is provided on its surface with at least one of Pt, Rh, Ru and Pd.

Owner:KK TOSHIBA

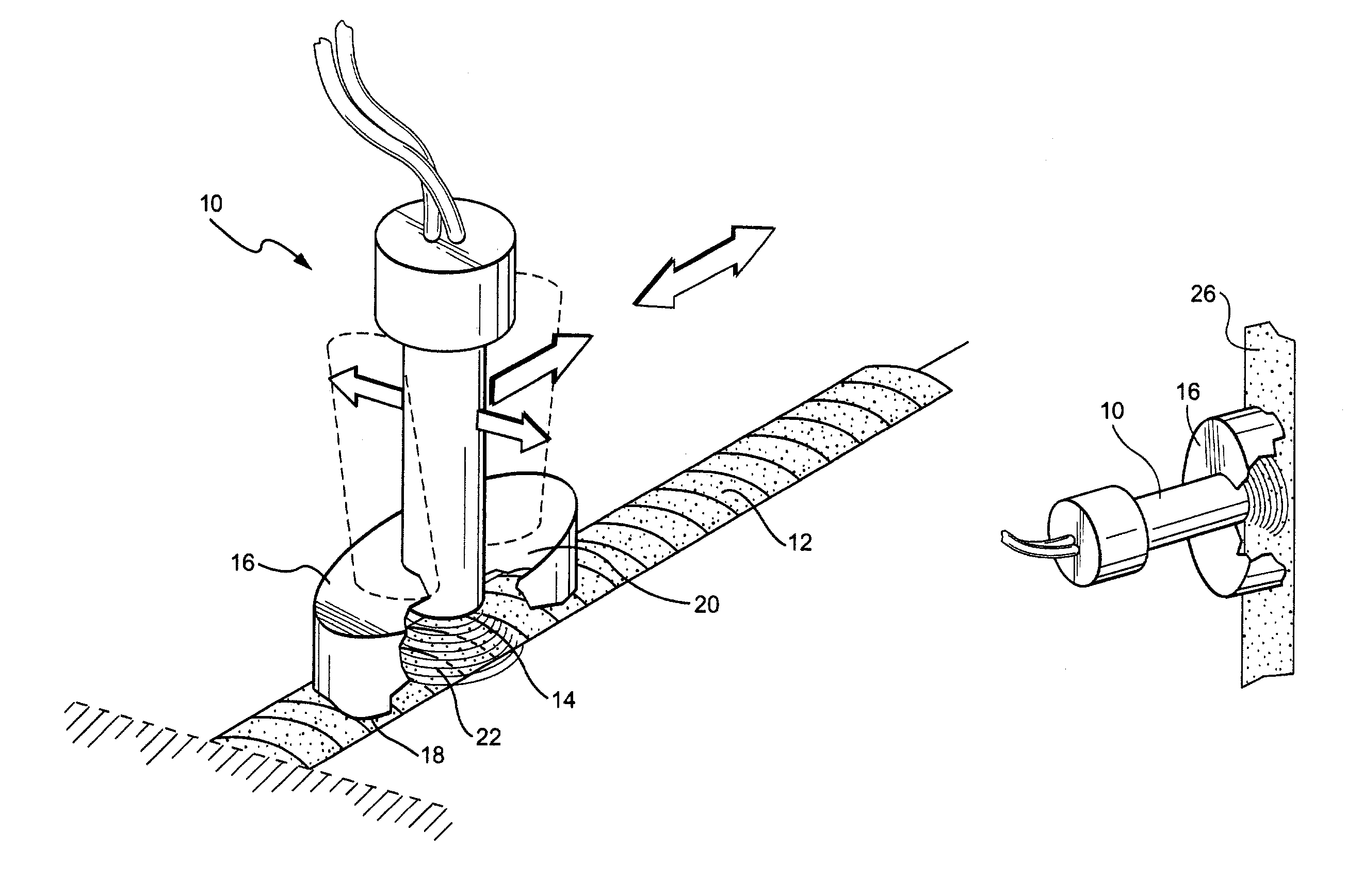

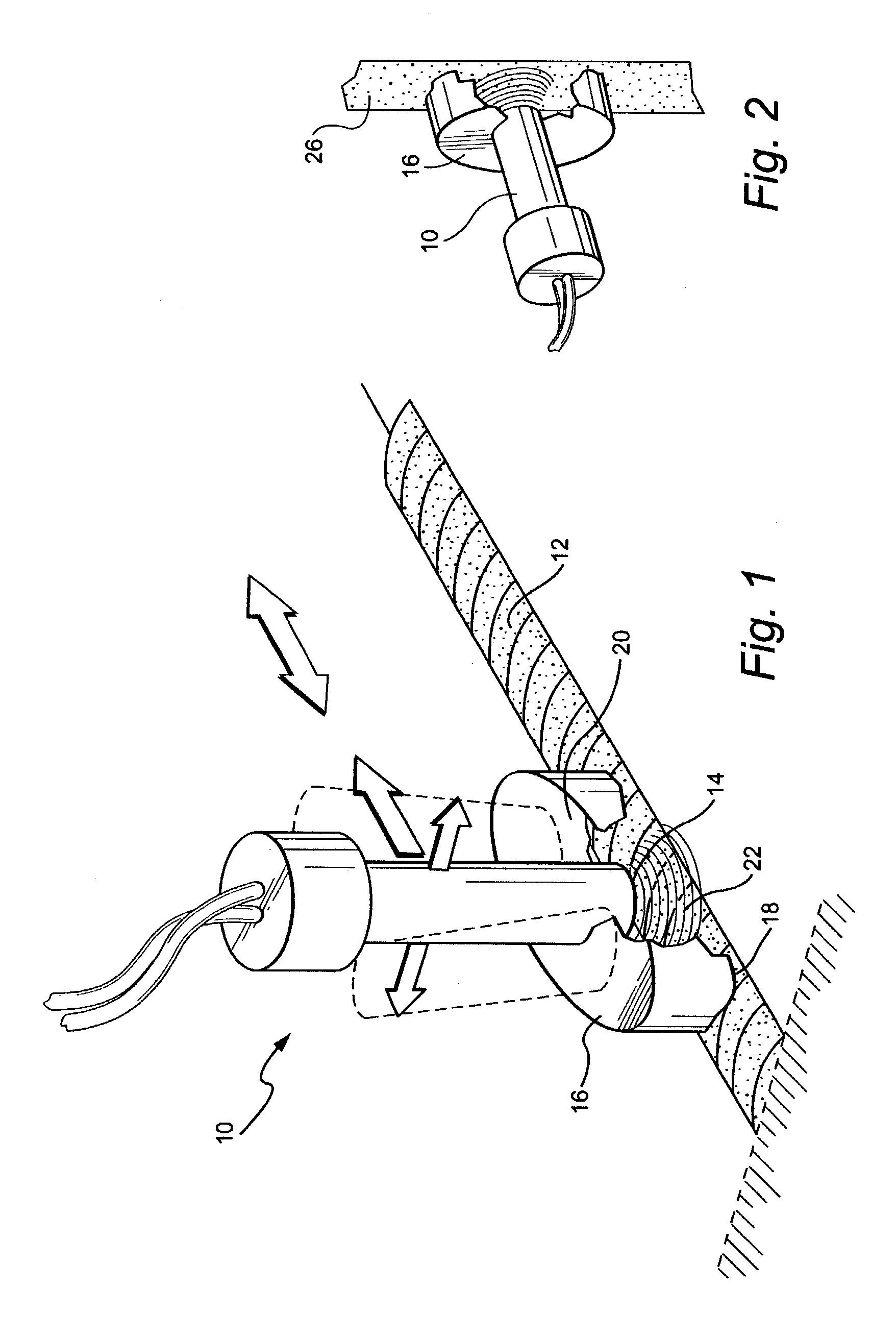

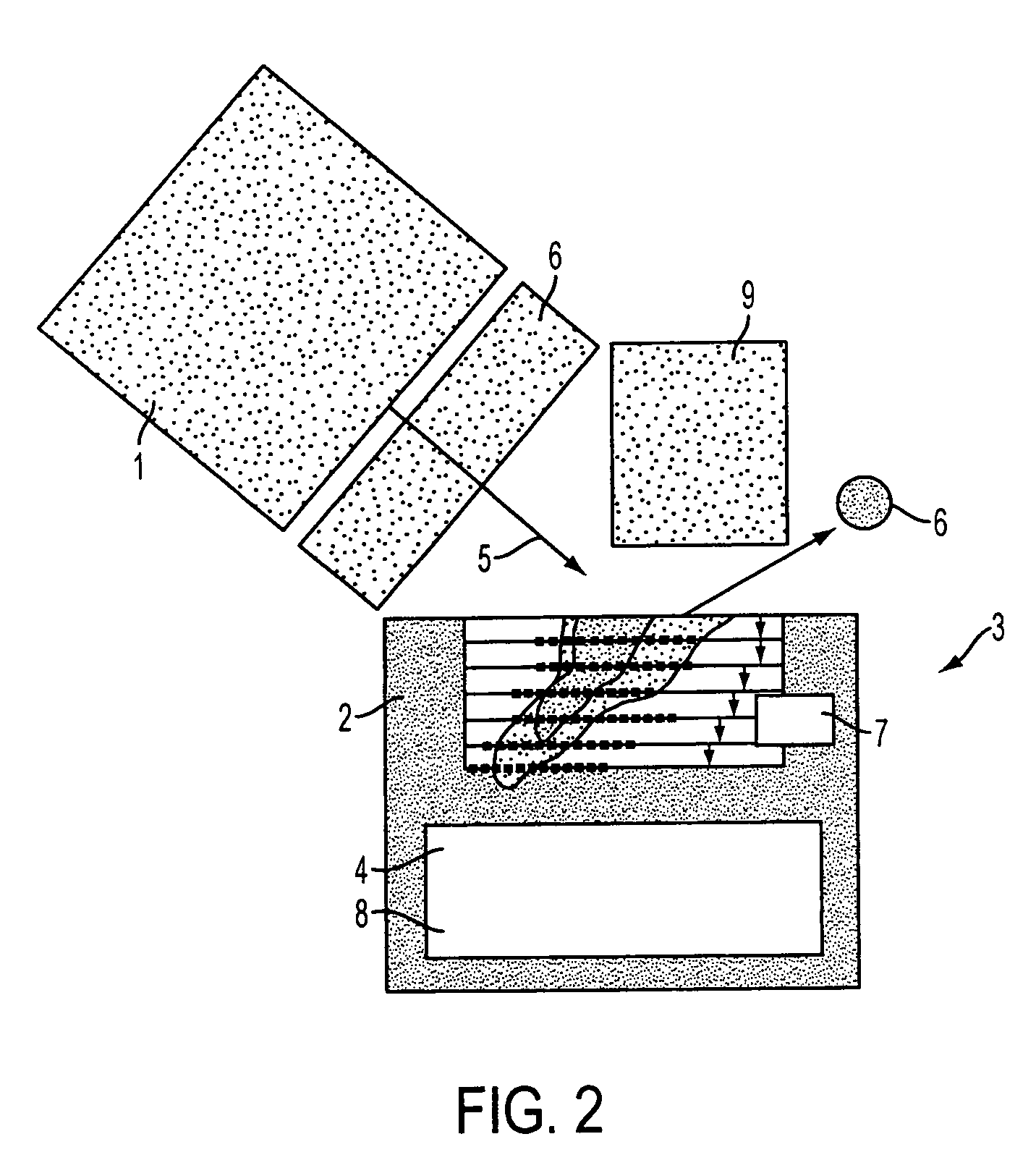

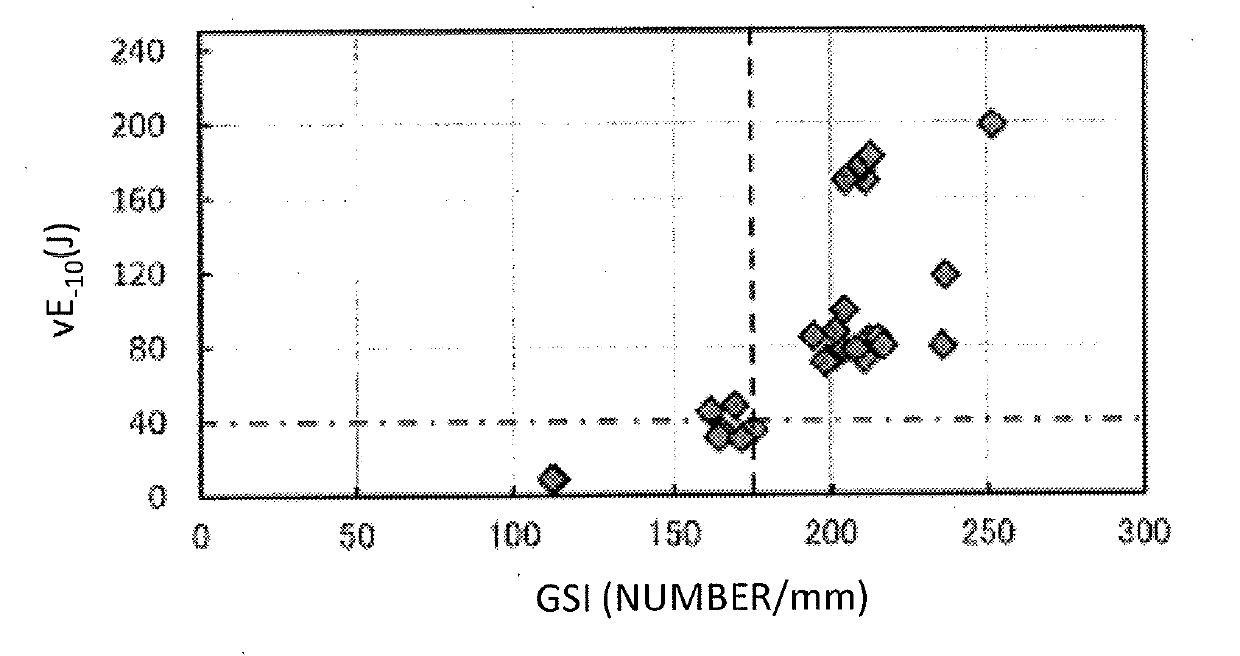

Methods for altering residual stresses using mechanically induced liquid cavitation

InactiveUS6993948B2Altering residual tensile stressEffectively water-hammeringBurnishing machinesForging press detailsCavitationTransducer

A mechanical transducer induces liquid cavitation, causing pressure waves in a liquid which are applied against a metal surface to afford localized elastic and plastic tensile microstrain. The pressure waves alter the surface tensile stresses in the treated metal by reducing the tensile stresses or forming surface compressive stresses. A boot is provided about the operating face of the transducer for confining a liquid through which compression waves are generated and applied to the metal surface, the boot sealing about the transducer and the surface undergoing treatment.

Owner:GENERAL ELECTRIC CO

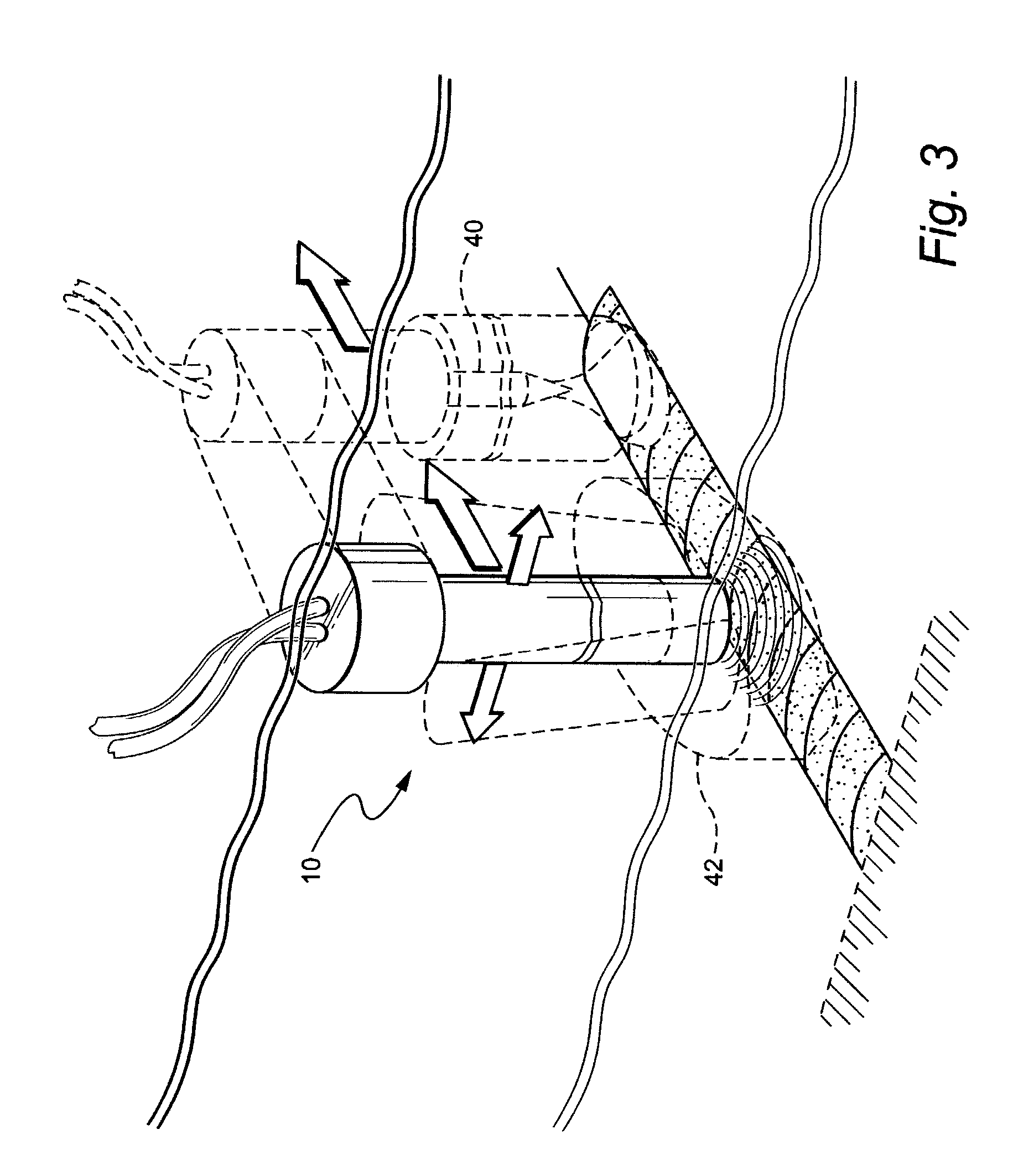

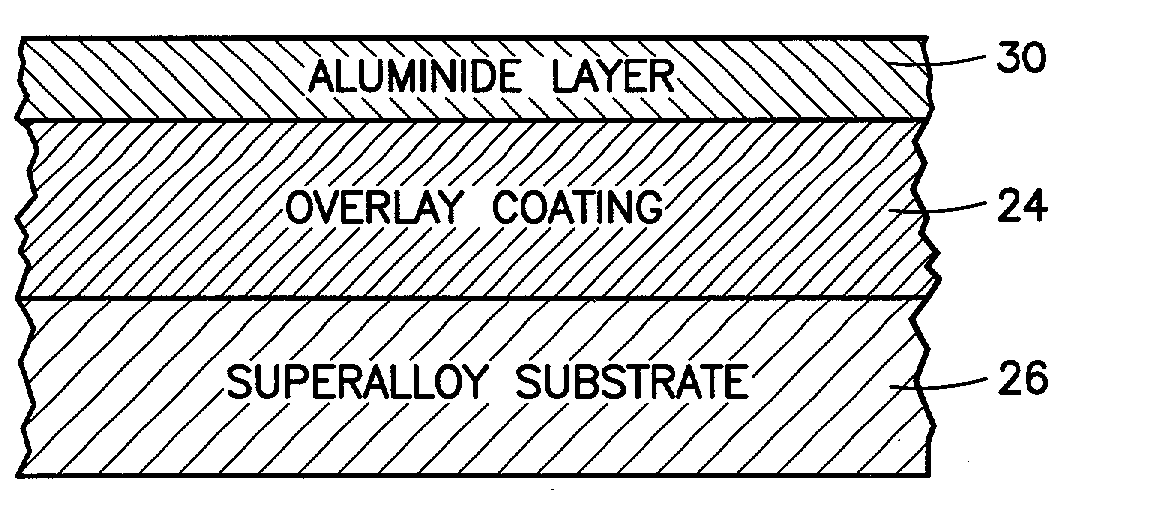

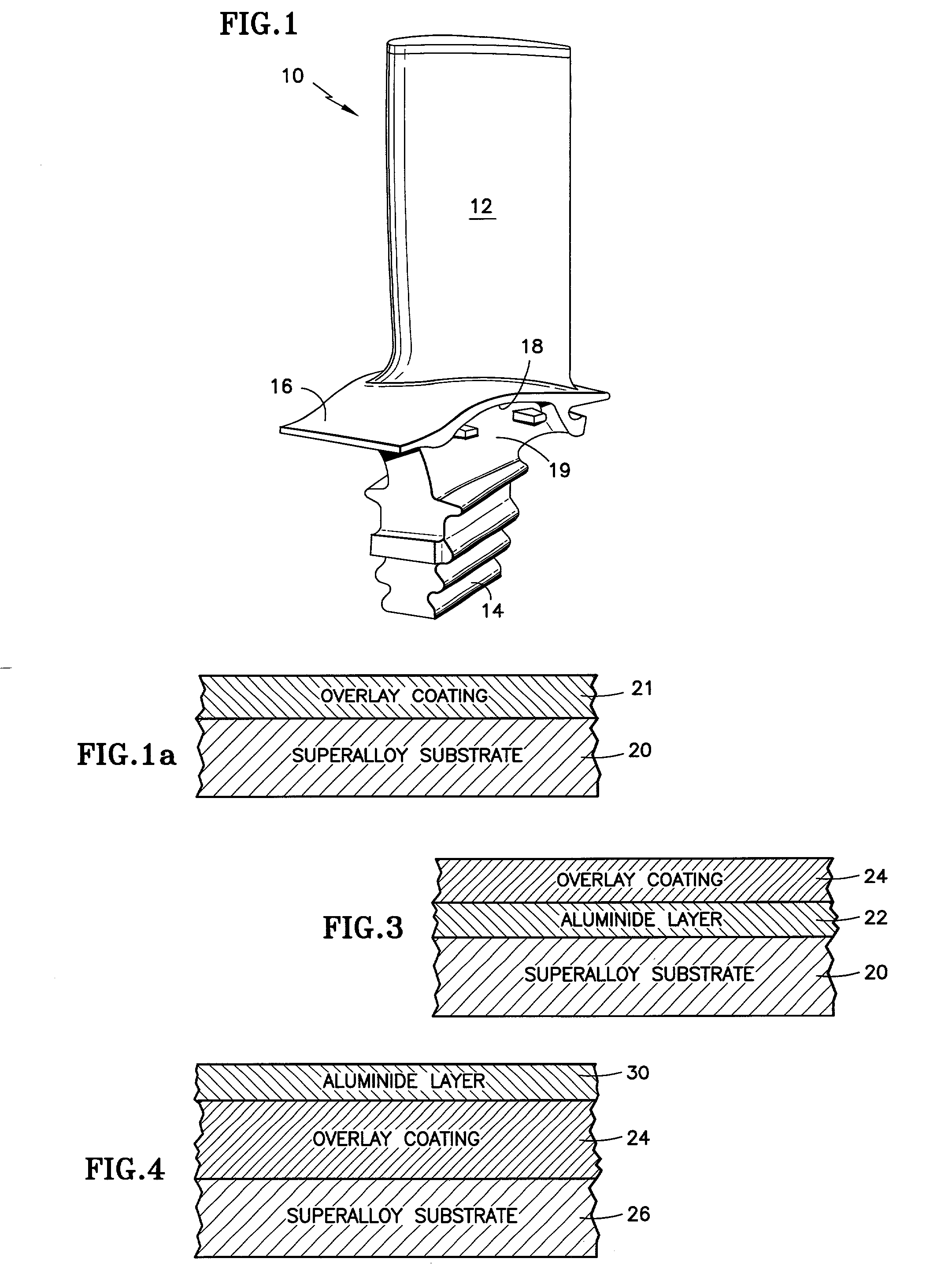

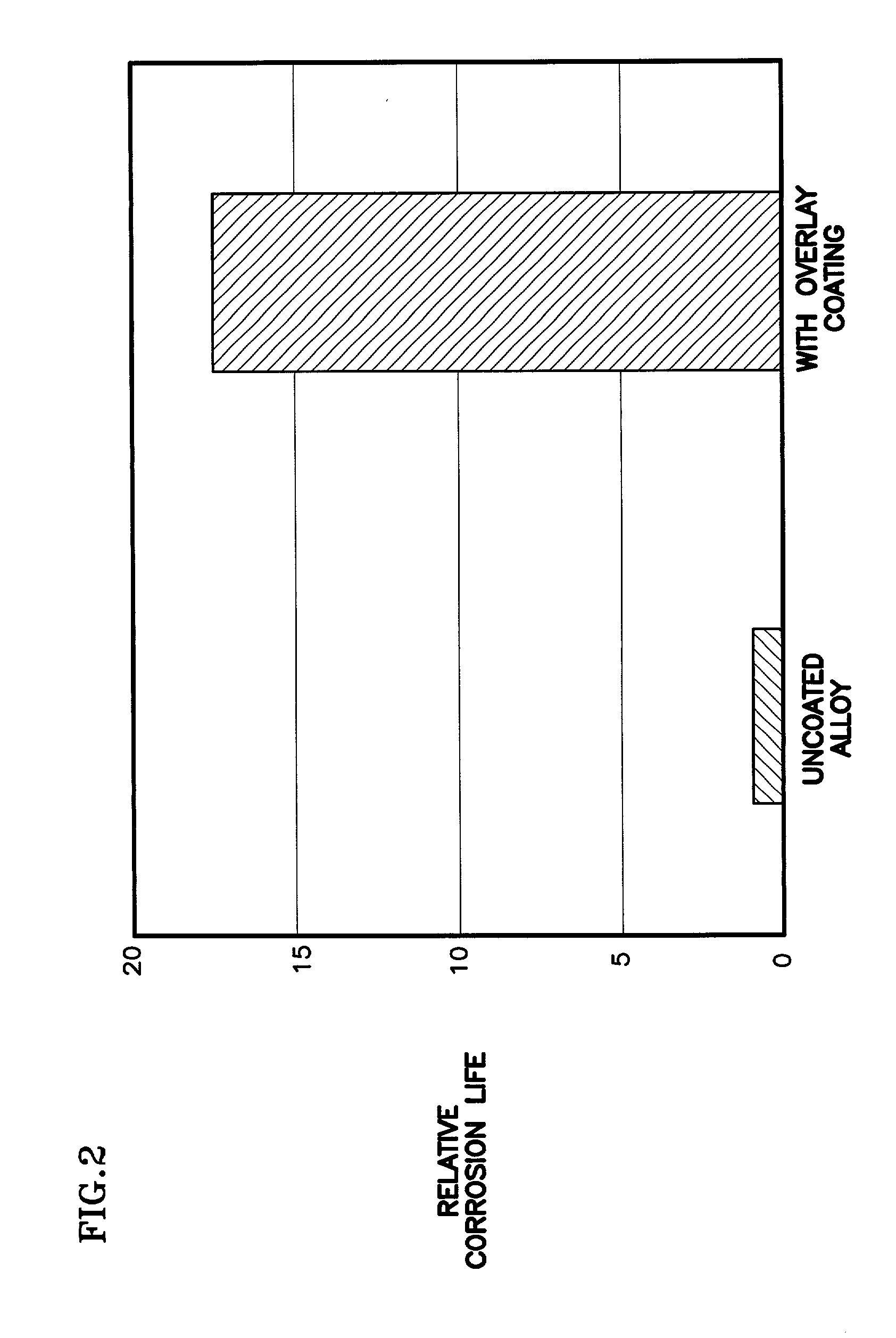

Methods of providing article with corrosion resistant coating and coated article

InactiveUS20020130047A1Increased durabilityMaximize protectionLiquid surface applicatorsMolten spray coatingCorrosion resistantAluminide

According to the invention, an article that is exposed to high temperature e.g., over 1000.degree. C. during operation is disclosed. In one embodiment, a method for a gas turbine engine includes a directionally solidifed metallic substrate, e.g., a superalloy, which defines an airfoil, a root and a platform located between the blade and root. The platform has an underside adjacent the root, and a corrosion resistant overlay coating such as an MCrAlY or a noble metal containing aluminide or corrosion inhibiting ceramic is located on portions or the blade not previously covered with such coatings, e.g., the underside of the platform and the neck. The applied coating prevents corrosion and stress corrosion cracking of blade in these regions. Where the airfoil is also created, the airfoil coating may have a composition different from that of the coating on the underplatform surfaces.

Owner:UNITED TECH CORP

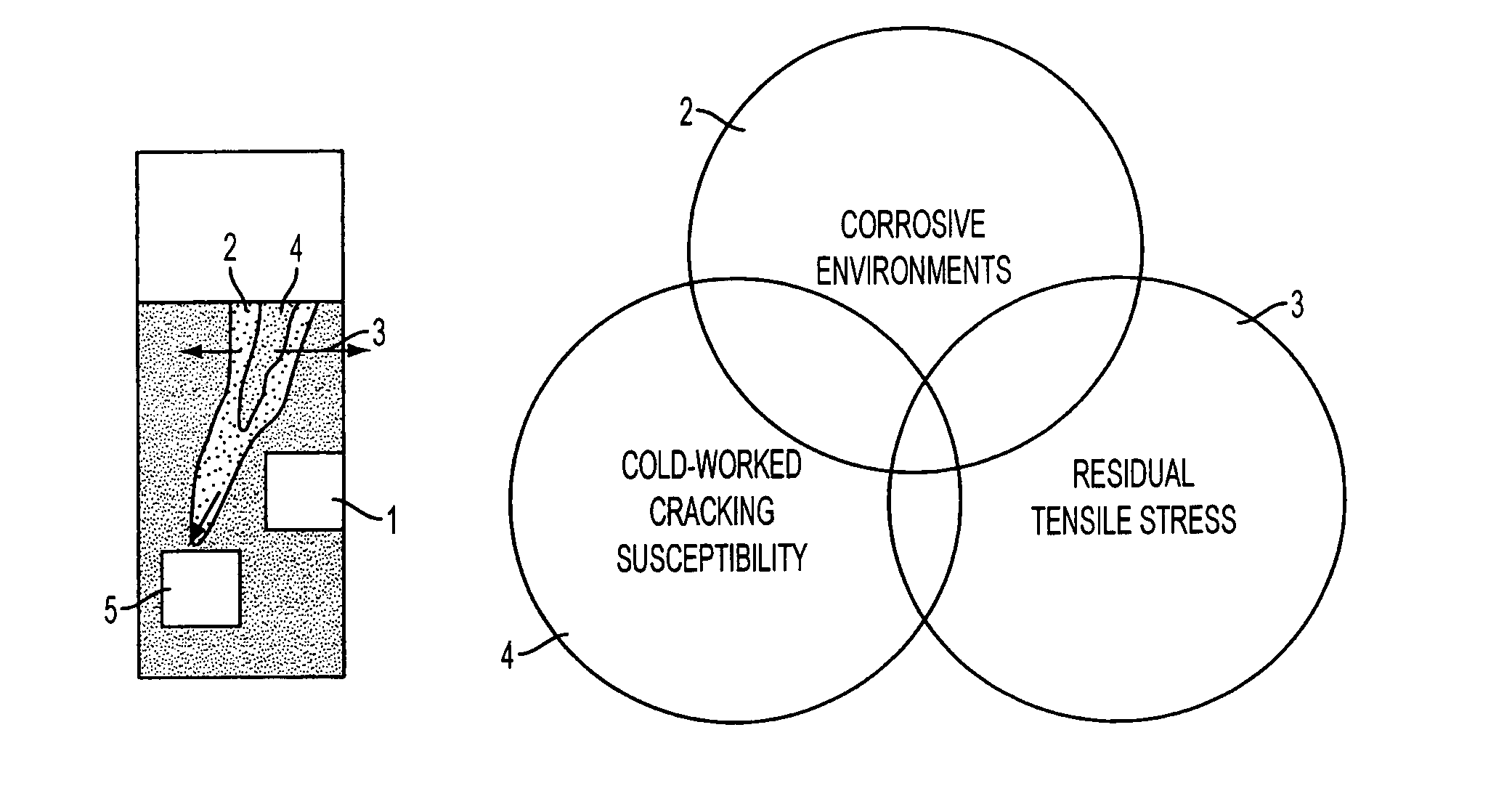

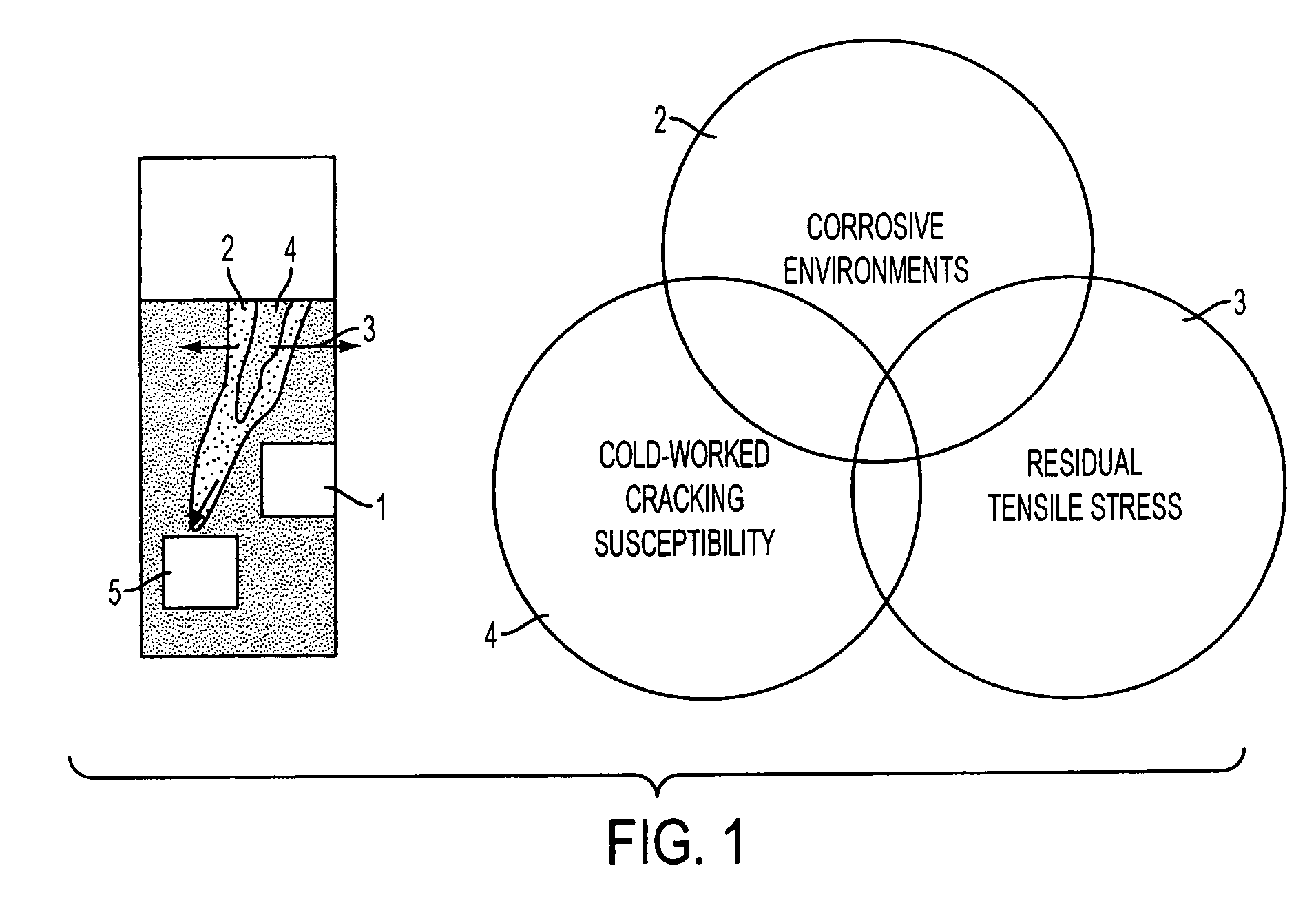

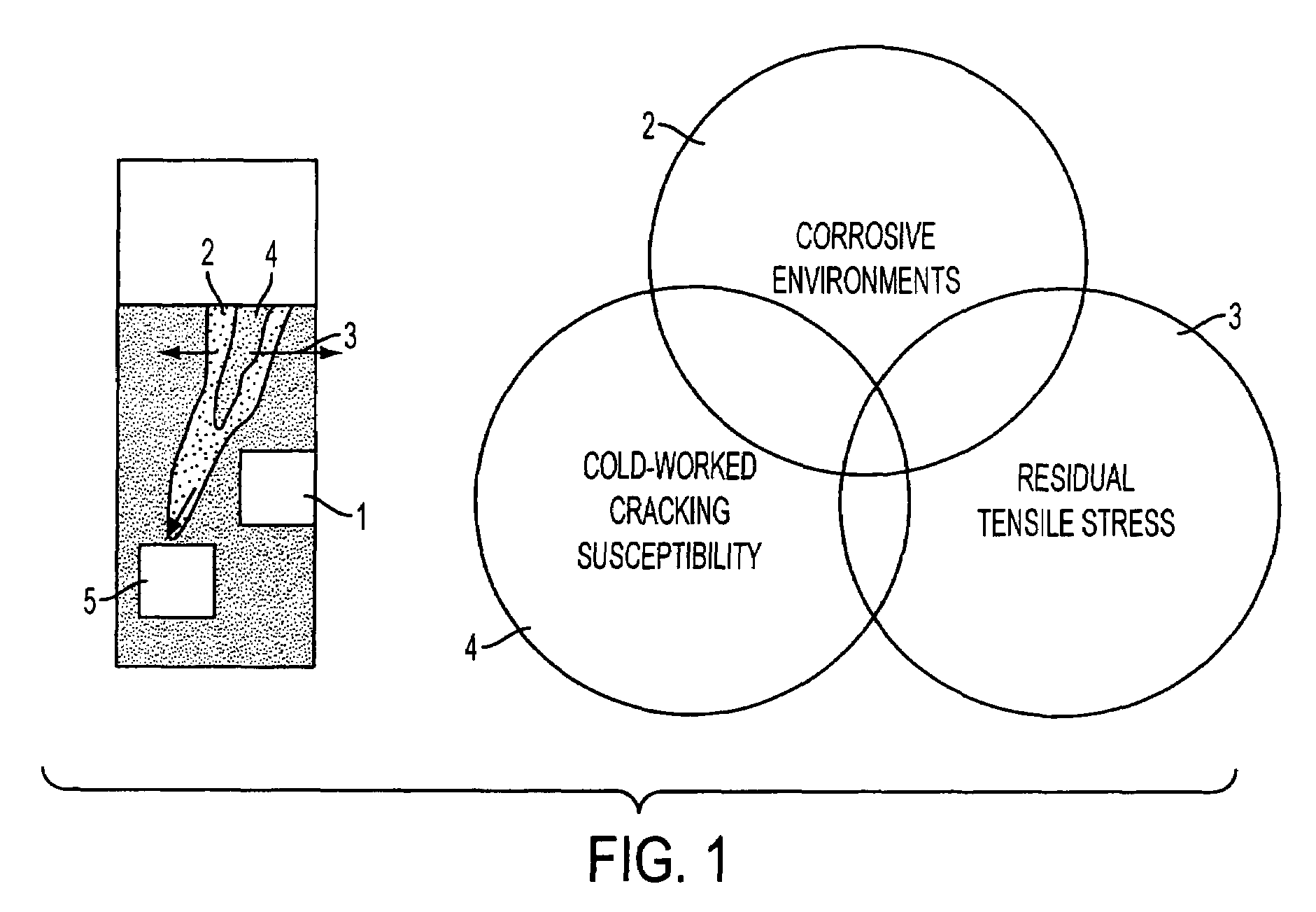

Method of an ultra-short femtosecond pulse and KW class high average-power laser for preventing cold-worked stress corrosion cracking in iron steels and alloyed steel including stainless steels

InactiveUS20060048867A1Preventing cold-worked stress corrosion crackingFree from risk of damageWelding/soldering/cutting articlesLaser beam welding apparatusNuclear reactorSurface layer

The method of preventing cold-worked stress corrosion cracking in the iron steels and alloyed steels including stainless steels comprises removing a residual tensile stressed layer, optionally generating residual compression, through the impact of irradiation with the ultra-short femtosecond pulse and kW class high average-power laser, and removing a hardened surface layer extremely susceptible to stress corrosion cracking, whereby this susceptible hardened surface layer with many concentrated dislocation defects and the likes is removed without generating or introducing any of such hardened layer in the process of its removal. The method is free from the risk of damaging other equipment by peening with steel balls or other shaped shots, is almost unlimited in actual environment, effectiveness, work, place and other conditions for application, is inexpensive, and functions continuously for a much longer period than an ordinary nuclear reactor's service lifetimes.

Owner:JAPAN ATOM ENERGY RES INST

Reactor structural member and method of suppressing corrosion of the same

InactiveUS20060050833A1Simple structurePrevents stress corrosion crackingNuclear energy generationNuclear monitoringHydrogen concentrationNuclear reactor

A photocatalytic substance having the properties of an n-type semiconductor is deposited on a surface of a metal base made of a stainless steel or Inconel. When necessary, the hydrogen concentration of the reactor water is increased. A current produced by the photocatalytic substance when the same is irradiated with light or radioactive rays in a nuclear reactor flows through the metal base to reduce corrosion current. When necessary, the photocatalytic substance is provided on its surface with at least one of Pt, Rh, Ru and Pd.

Owner:KK TOSHIBA

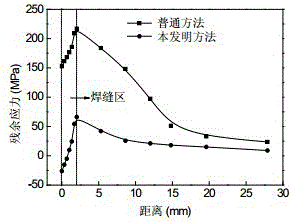

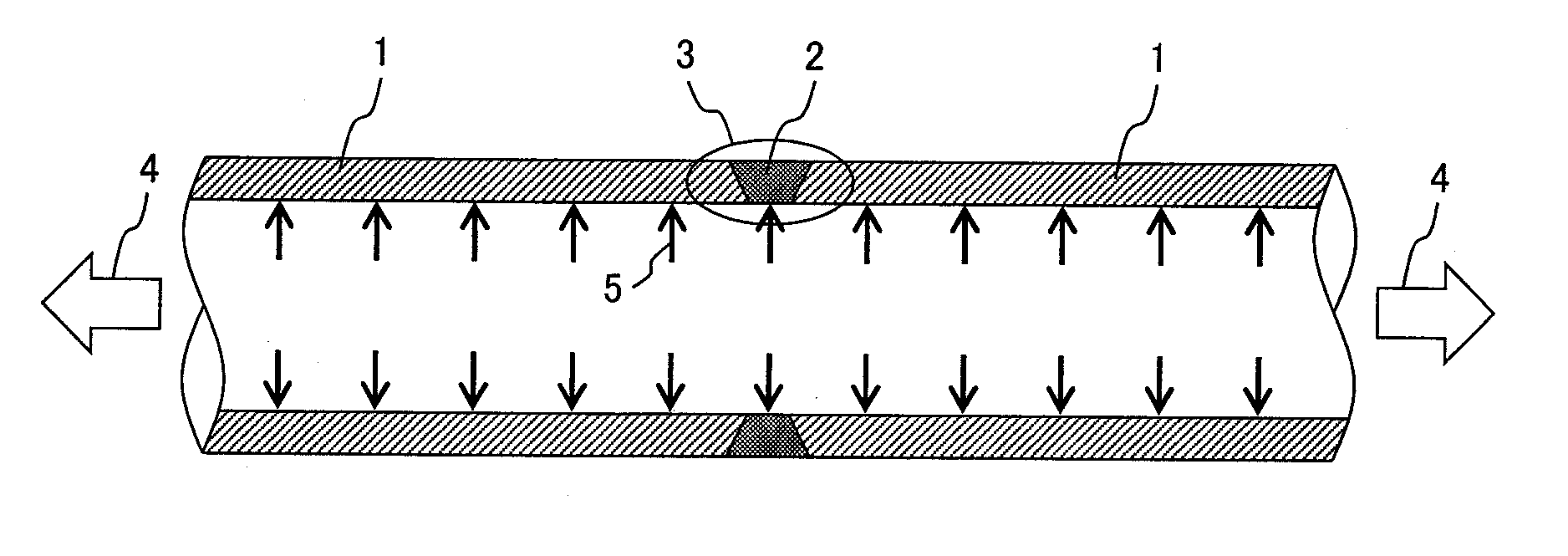

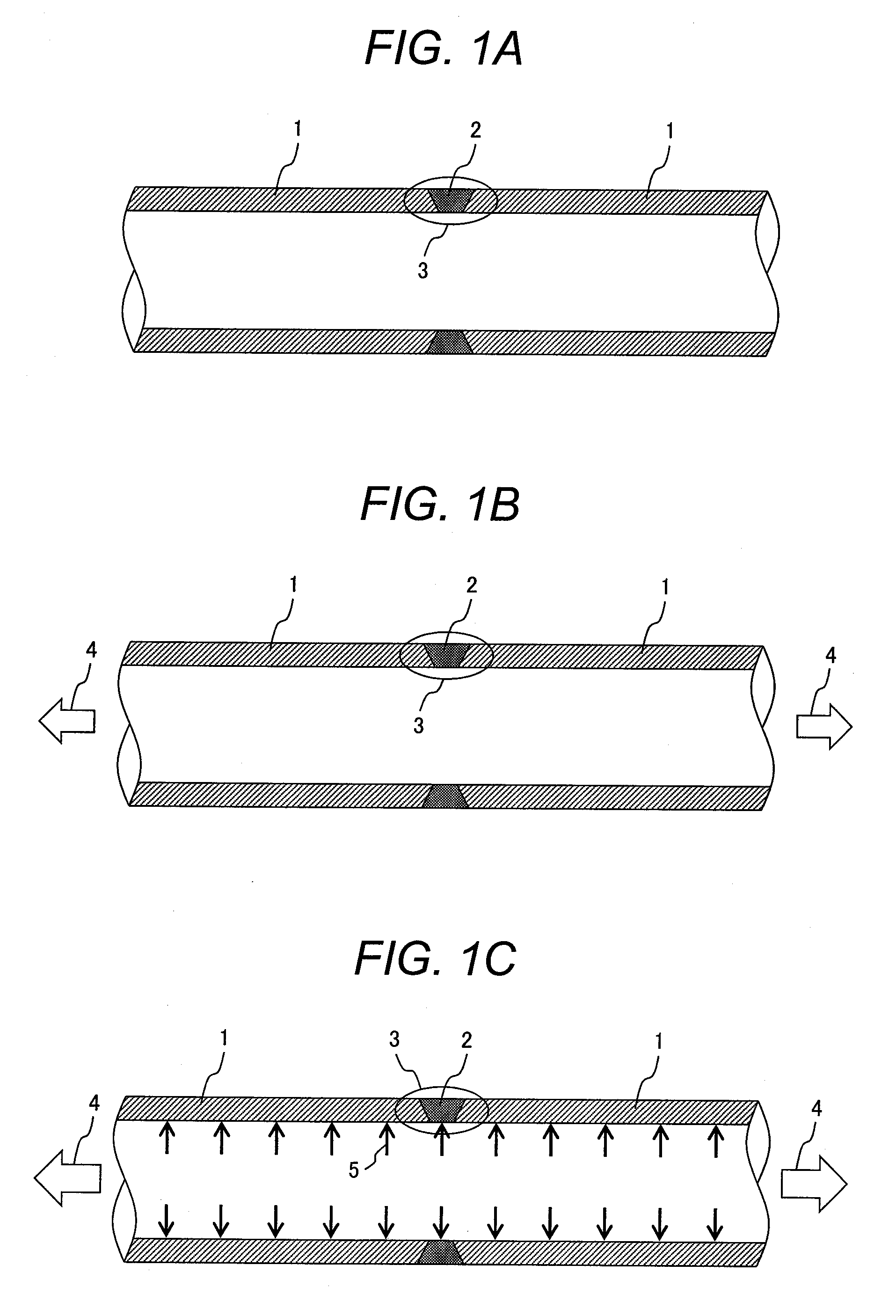

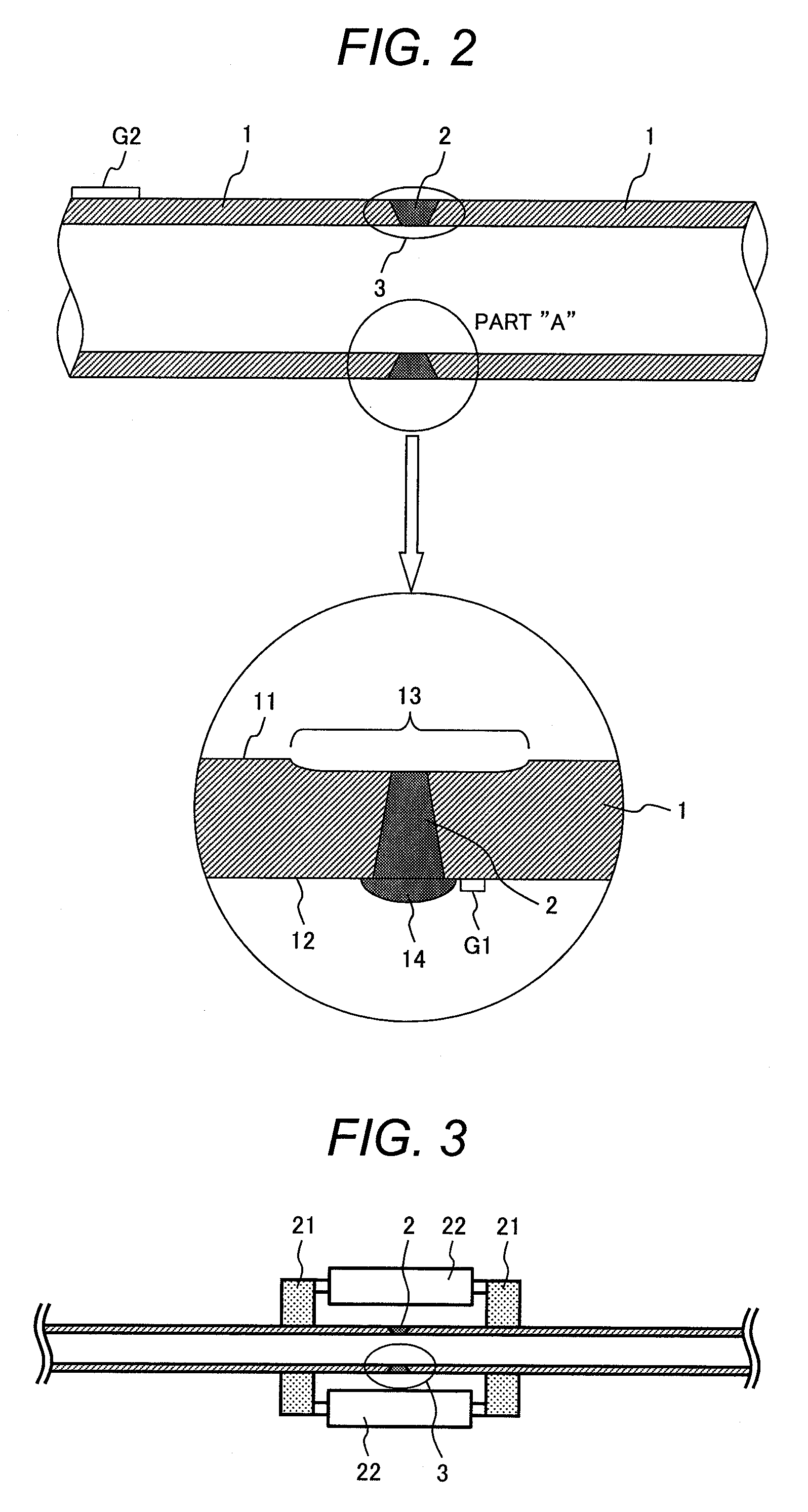

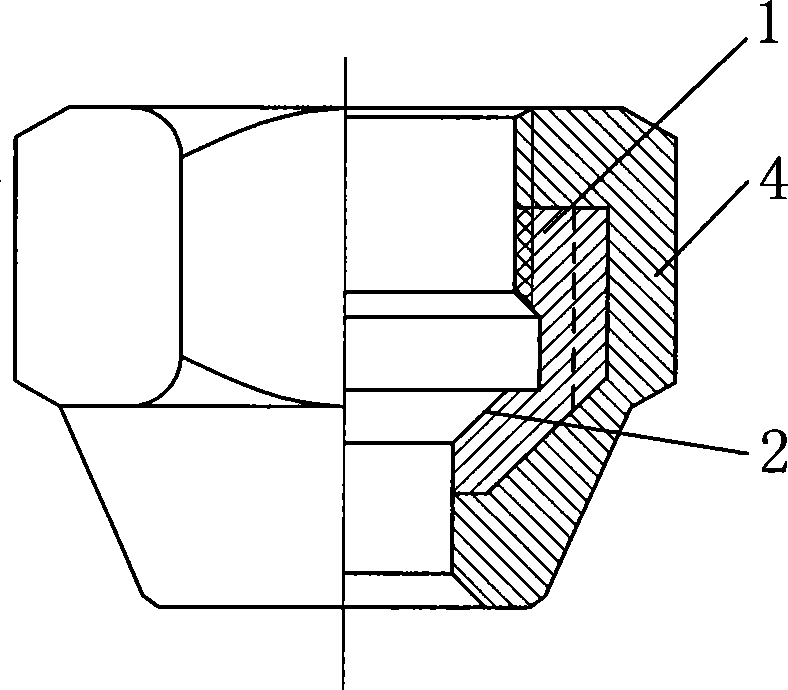

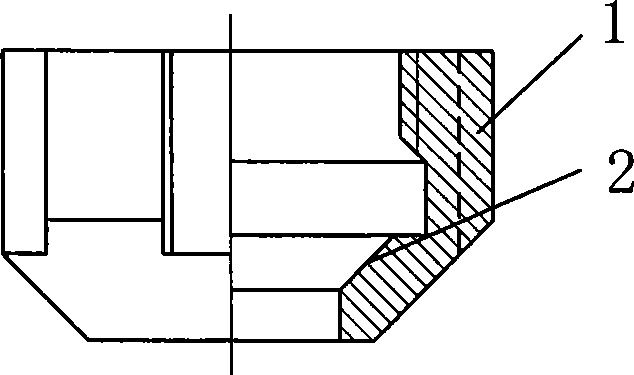

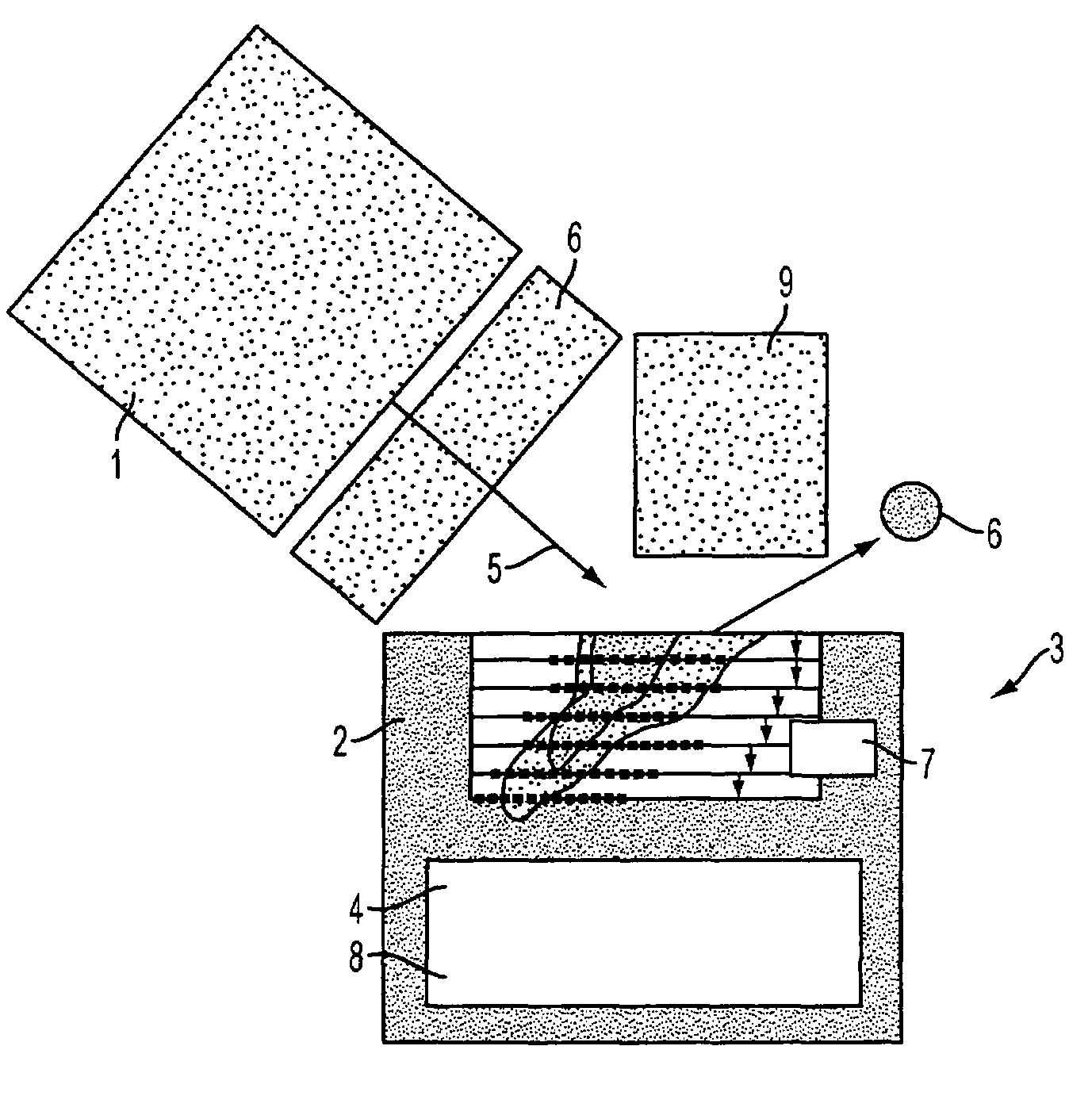

Connecting method of pressure vessel connecting pipe and sealing head for reducing welding residual stress

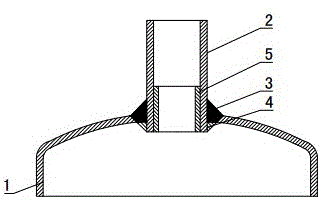

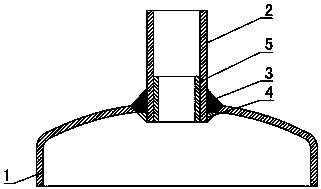

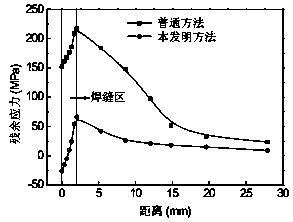

ActiveCN106112225APrevents stress corrosion crackingEnhanced resistance to stress corrosion crackingWelding/cutting auxillary devicesArc welding apparatusWeld seamWelding residual stress

The invention relates to a connecting method of a pressure vessel connecting pipe and a sealing head for reducing welding residual stress, which belongs to the technical field of sealing container processing and manufacturing. The connecting method is characterized by comprising the following steps of (a) opening the sealing head, and processing the connecting pipe (2); (b) extending one end of the connecting pipe (2) into a pressure vessel (1); (c) welding the sealing head and the connecting pipe (2); (d) preheating one side, which is positioned in the pressure vessel (1), of a welding seam (3), and then performing overlay welding on the root of the connecting pipe (2) in the pressure vessel (1); (e) preheating the inner wall of the connecting pipe (2), and then performing overlay welding on the inner wall of the connecting pipe (2); (f) cutting the connecting pipe (2) in the pressure vessel (1); (g) tempering the sealing head. According to the connecting method of the pressure vessel connecting pipe and the sealing head for reducing the welding residual stress, the welding residual stress is reduced in the manufacturing process of the pressure vessel, so that the structural integrity of the pressure vessel is increased, and the stress corrosion cracking resistant capability of a welding connector of the pressure vessel connecting pipe is enhanced.

Owner:江苏格兰环境科技有限公司

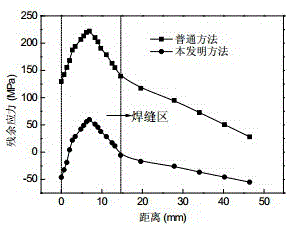

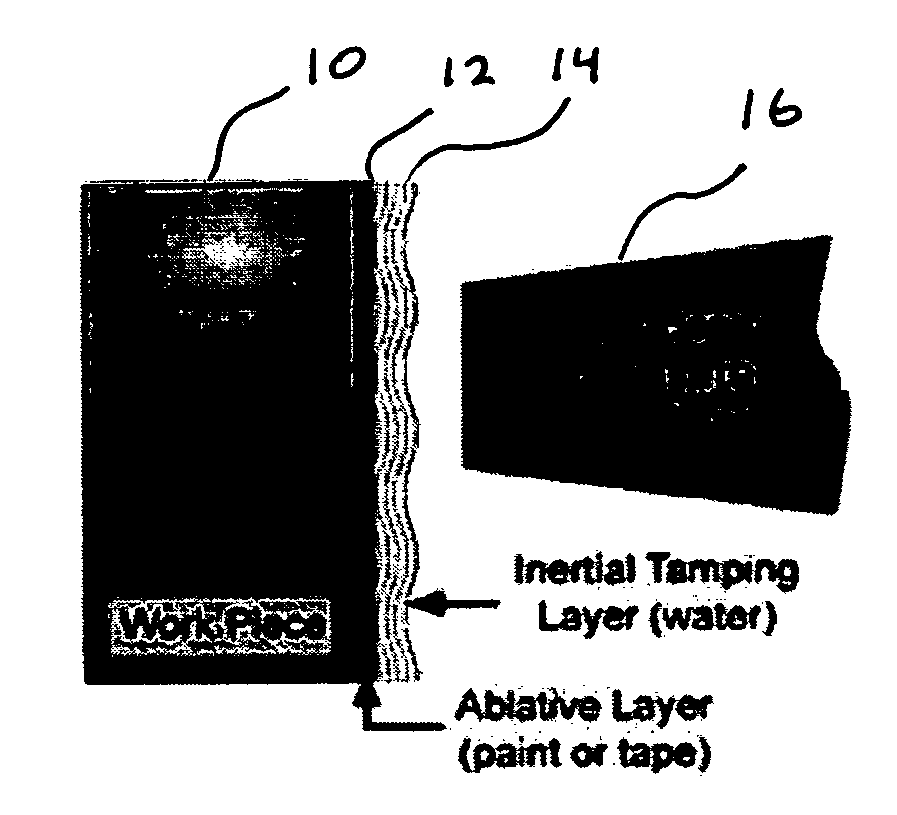

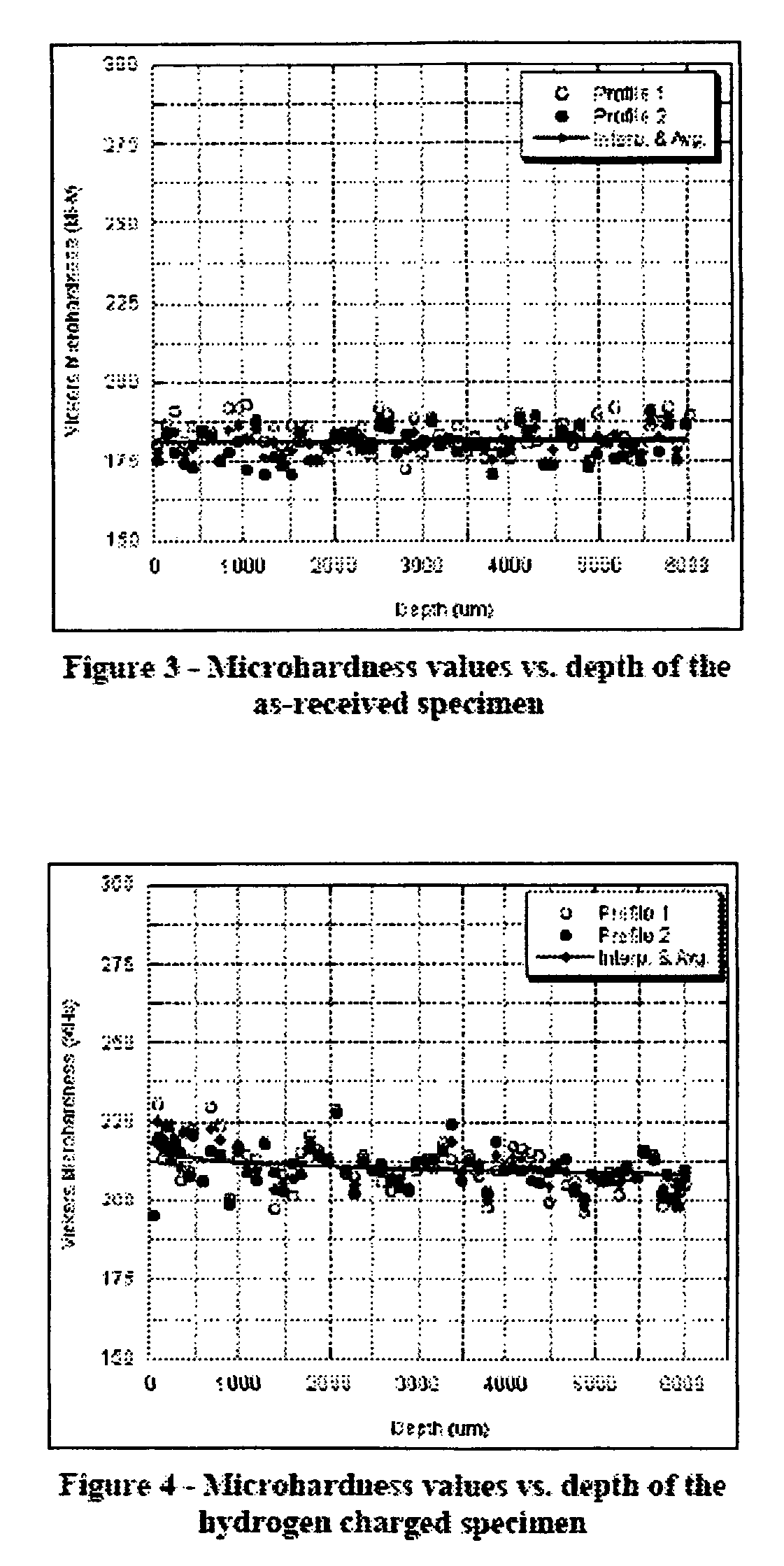

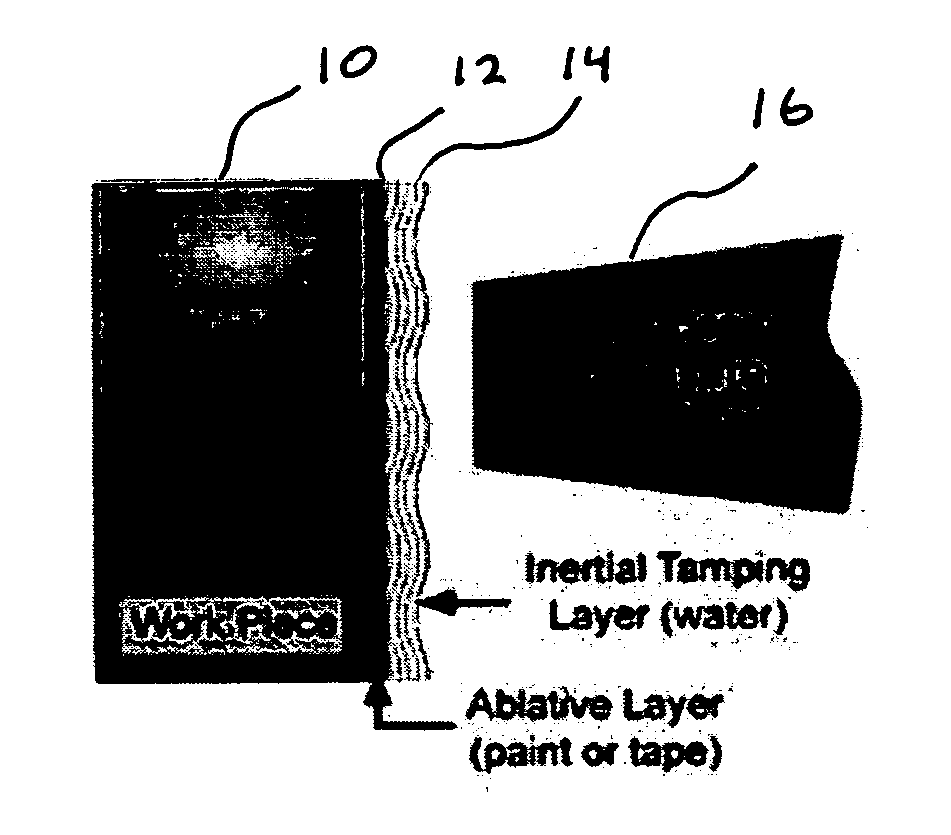

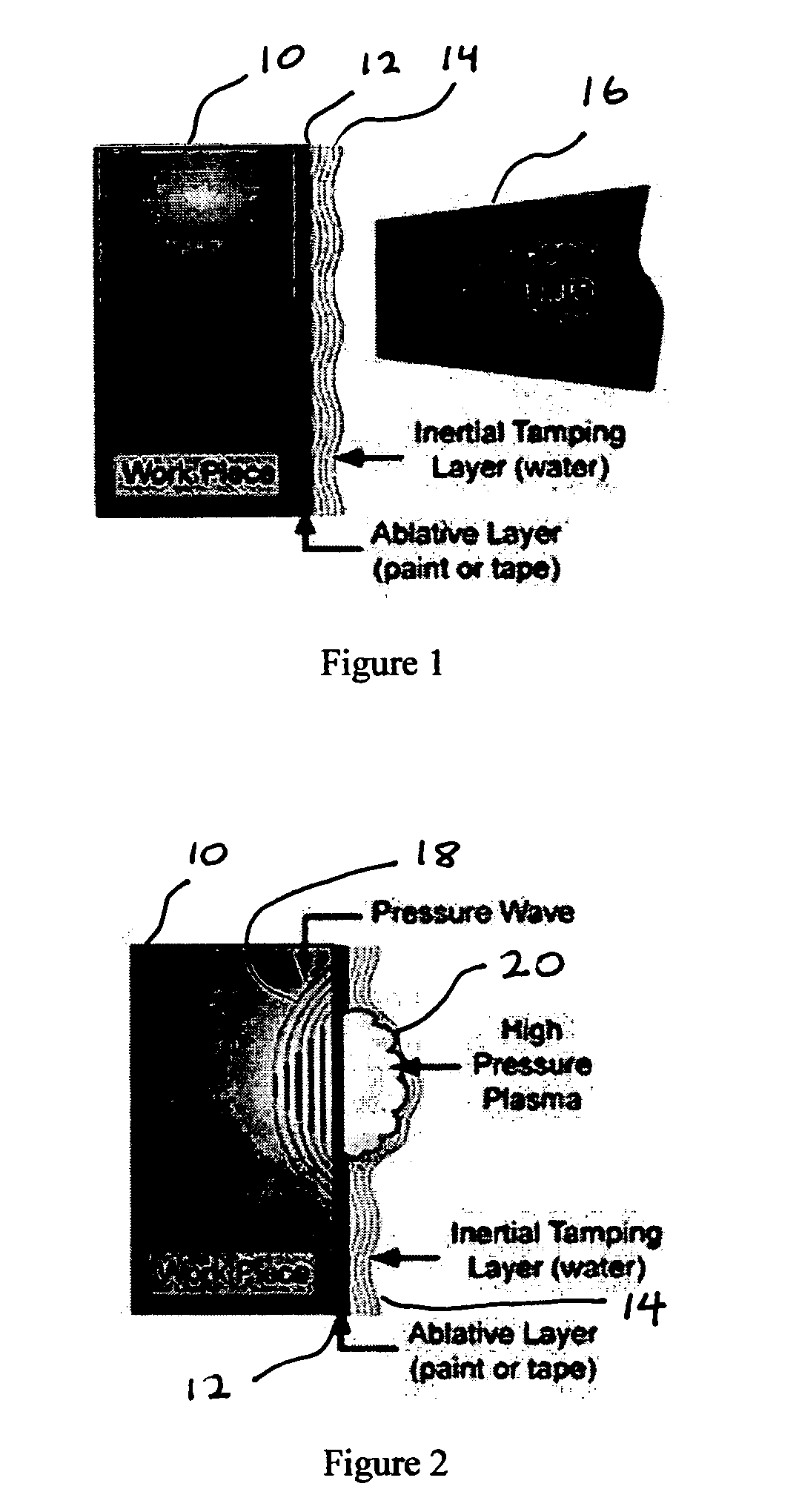

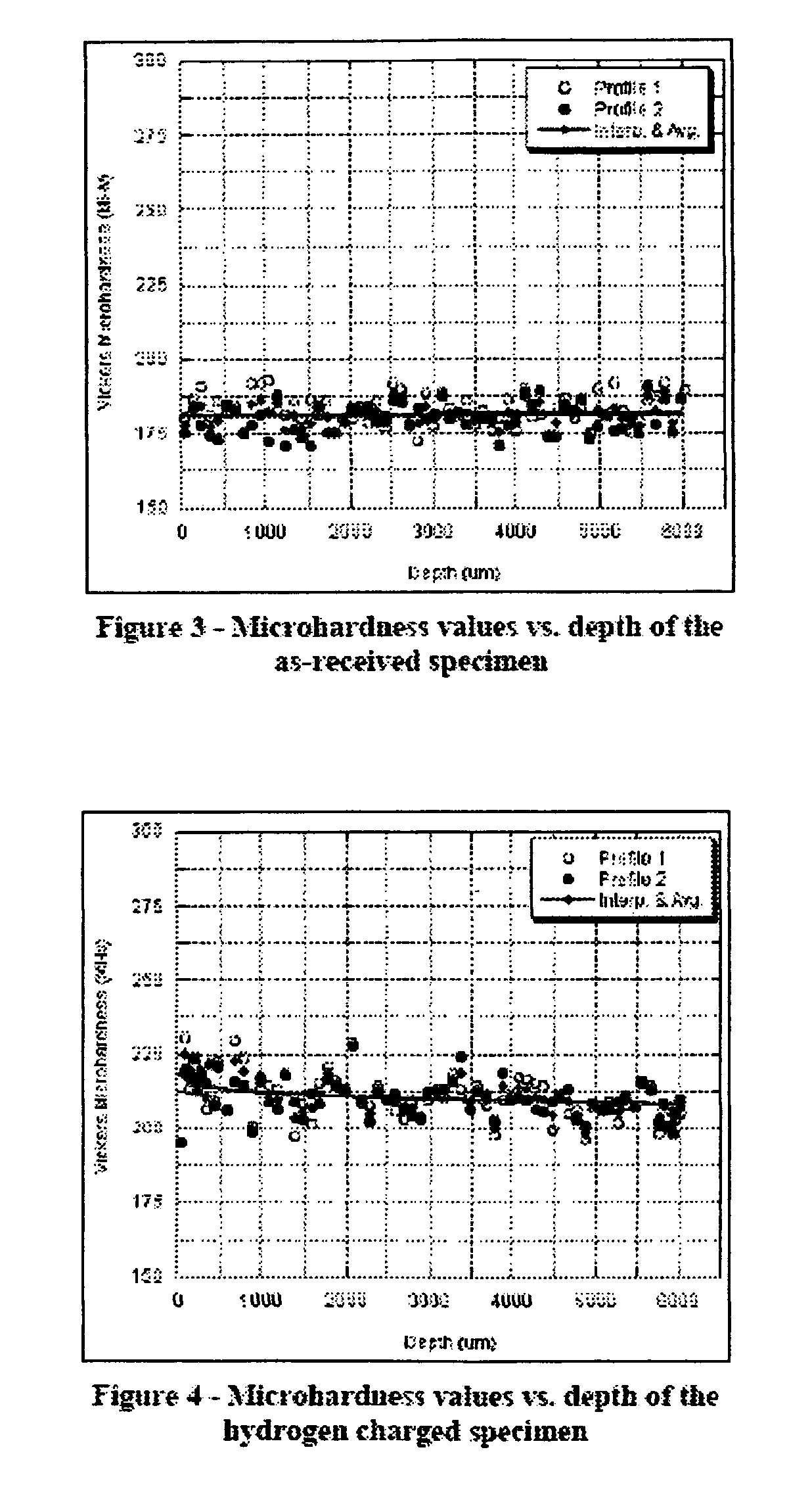

Laser peening for reducing hydrogen embrittlement

ActiveUS7723643B2Simple methodExtended service lifeLaser beam welding apparatusOptoelectronicsLaser peening

A laser peening process for the densification of metal surfaces and sub-layers and for changing surface chemical activities provides retardation of the up-take and penetration of atoms and molecules, particularly Hydrogen, which improves the lifetime of such laser peened metals. Penetration of hydrogen into metals initiates an embrittlement that leaves the material susceptible to cracking.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC +1

Laser peening for reducing hydrogen embrittlement

ActiveUS20070221641A1Reduce transmissionReduce effectLaser beam welding apparatusEmbrittlementOptoelectronics

A laser peening process for the densification of metal surfaces and sub-layers and for changing surface chemical activities provides retardation of the up-take and penetration of atoms and molecules, particularly Hydrogen, which improves the lifetime of such laser peened metals. Penetration of hydrogen into metals initiates an embrittlement that leaves the material susceptible to cracking.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC +1

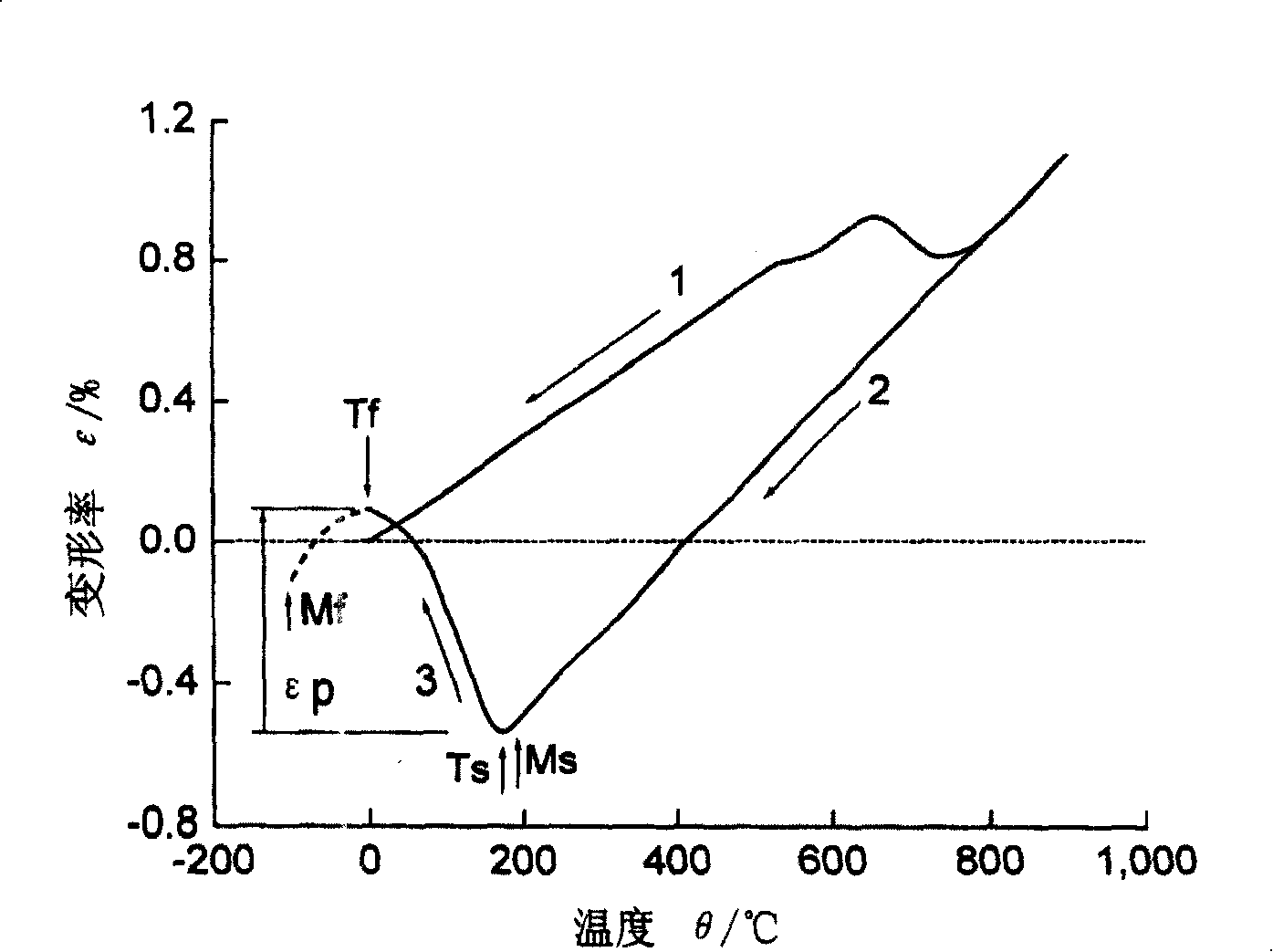

Residual stress improving method for pipe

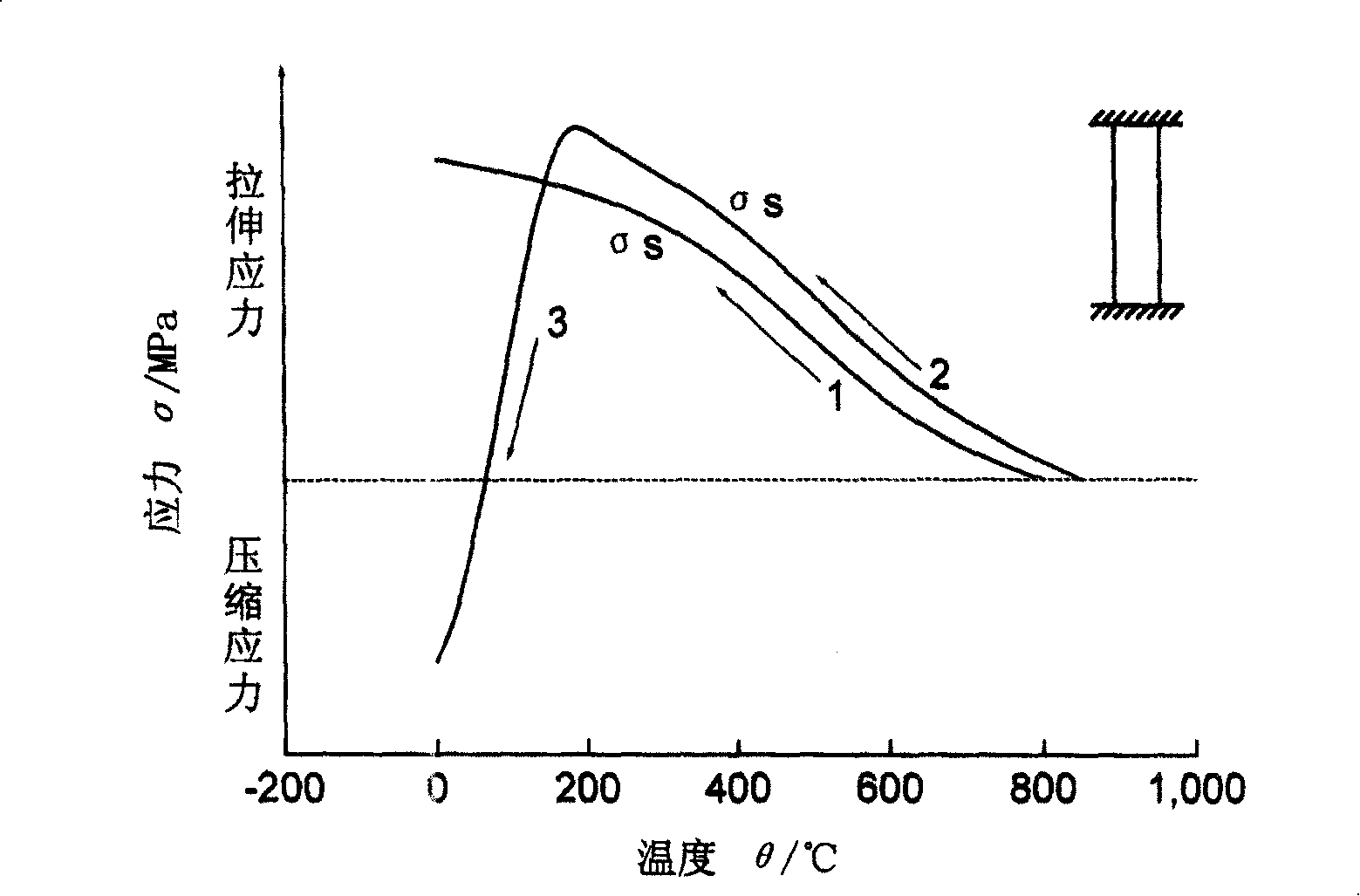

InactiveUS20110155289A1Increase overall stressPrevents stress corrosion crackingFurnace typesMetal working apparatusInternal pressureHeat-affected zone

It is an object to provide a residual stress improving method for a pipe by imparting larger compressive residual stress on the pipe to sufficiently reduce tensile residual stress in order to prevent the stress corrosion cracking. With respect to a stress improving region where the residual stress of a pipe is to be improved, a load in the axial direction of the pipe is made such stress making axial strain of the outer surface of the pipe 0% or above and being yield stress of the pipe or below, and internal pressure of the pipe is raised. The pipe is plastically deformed and is expanded in the radial direction by the internal pressure. After the internal pressure is raised to the degree the pipe is plastically deformed, the internal pressure and the axial load are removed, and thereby compressive residual stress is imparted to a welding section and a heat affected zone which are the stress improving region of the inner surface of the pipe.

Owner:HITACHI LTD

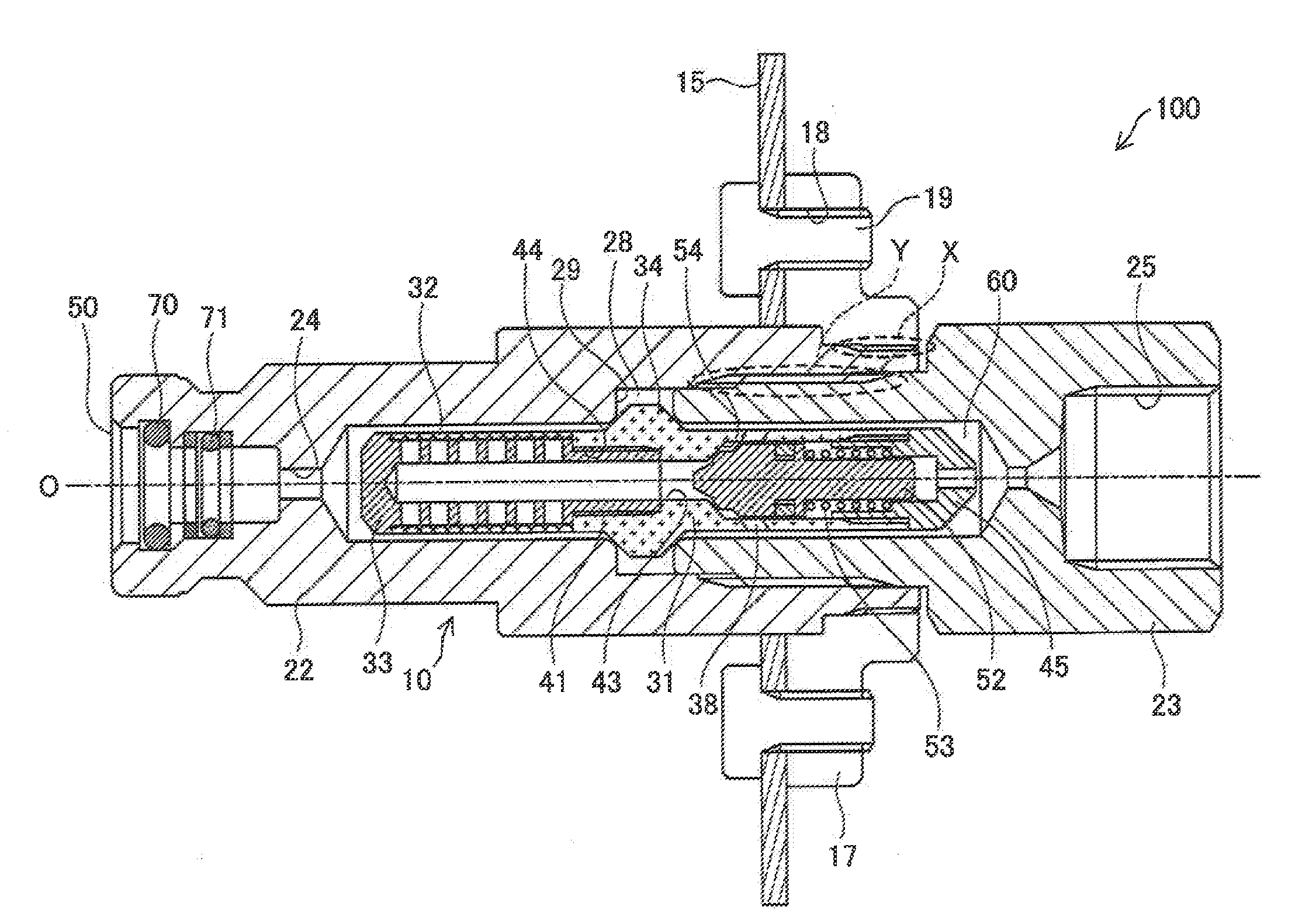

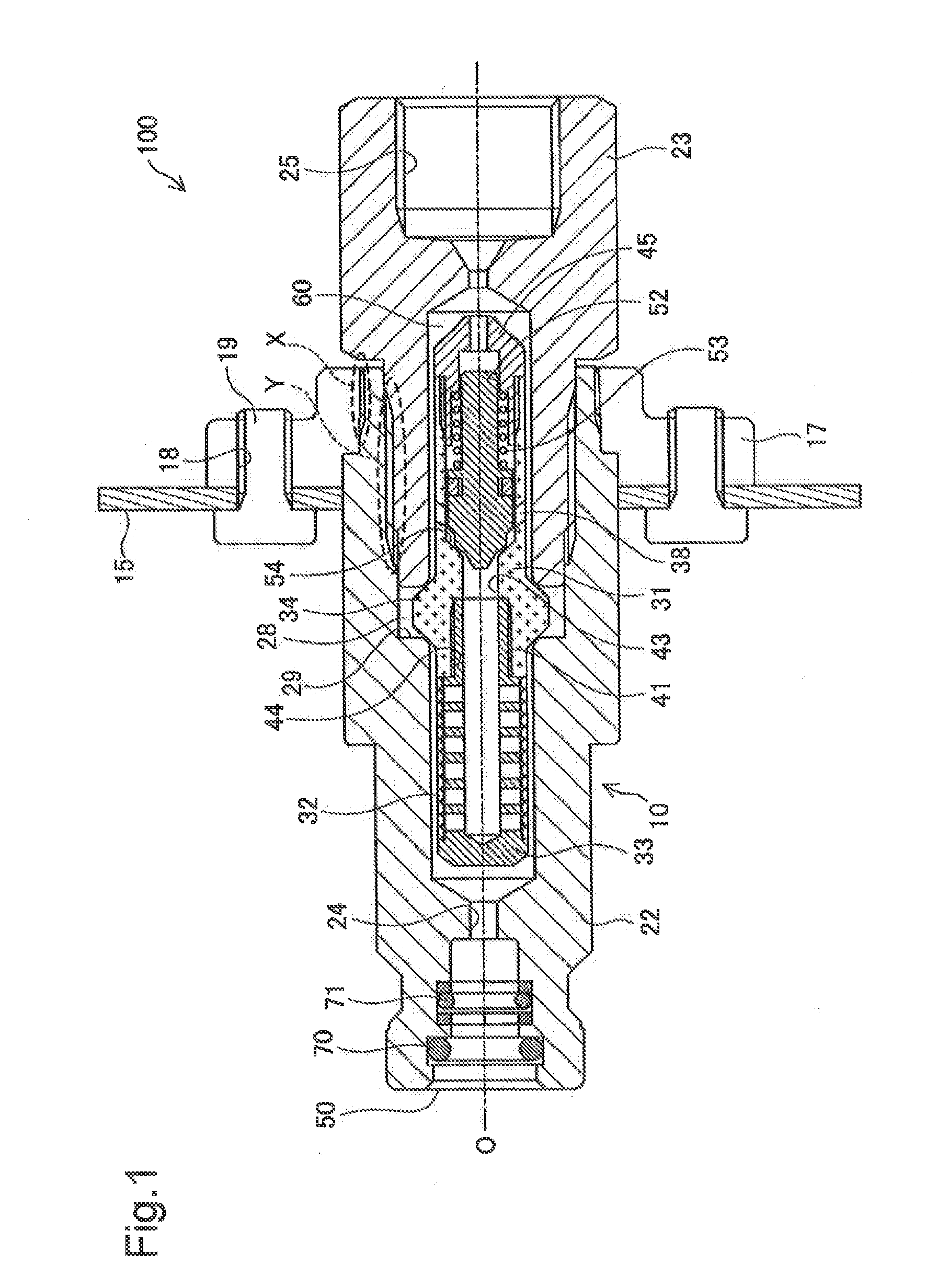

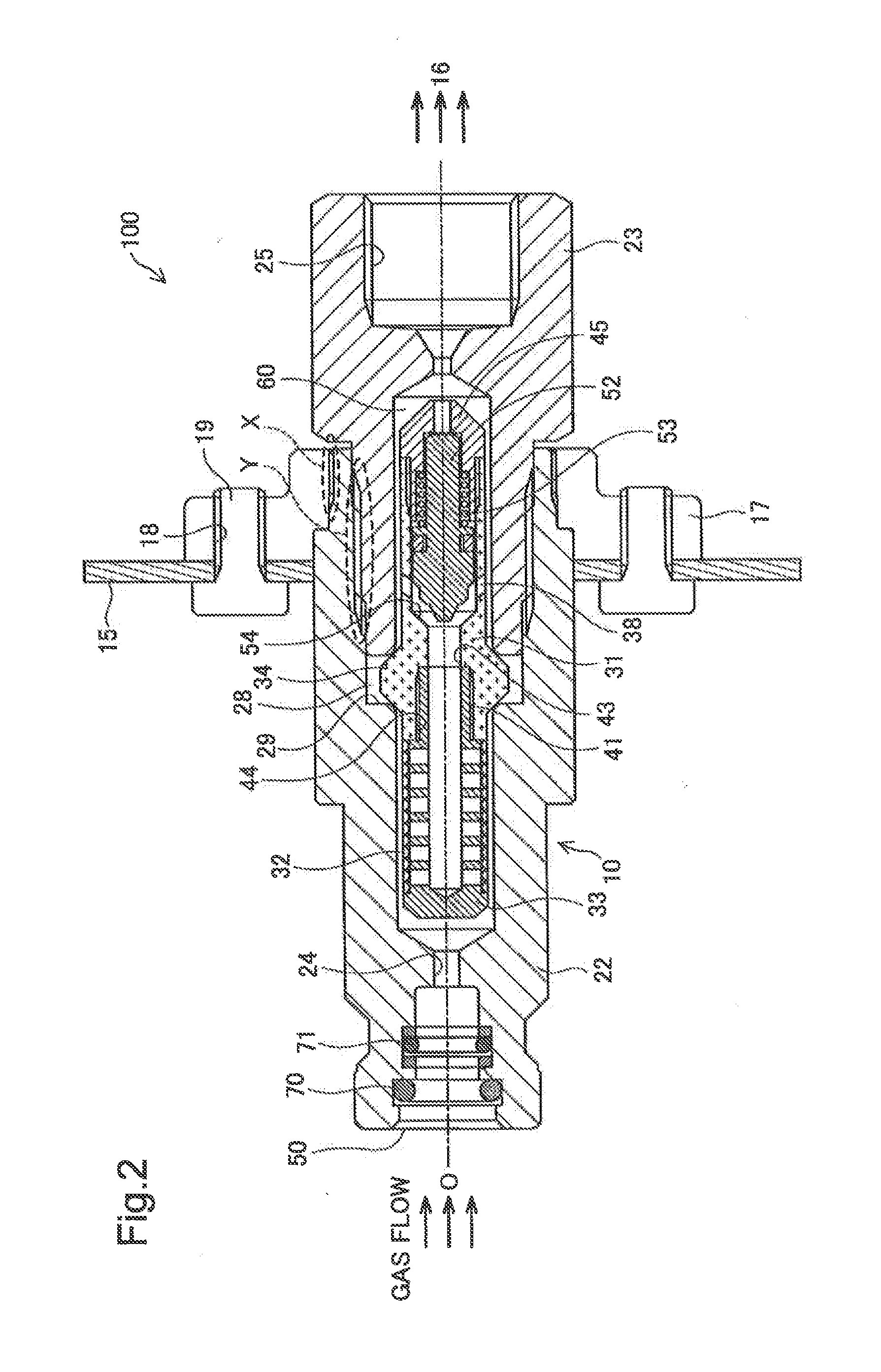

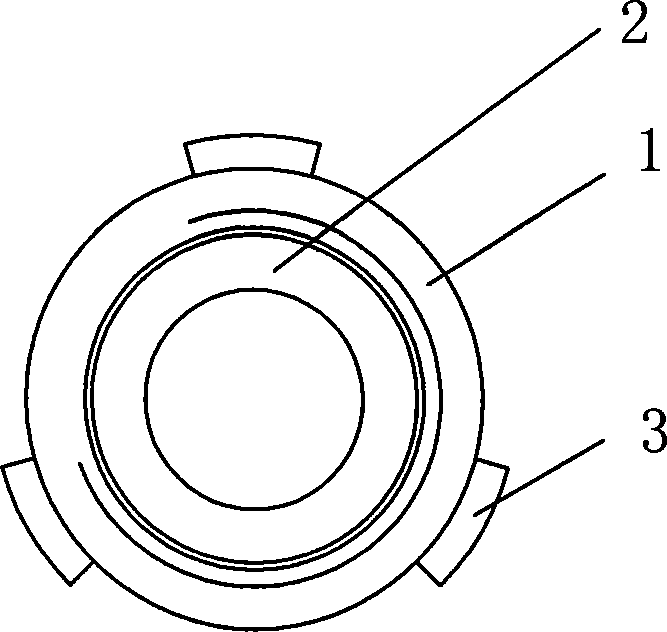

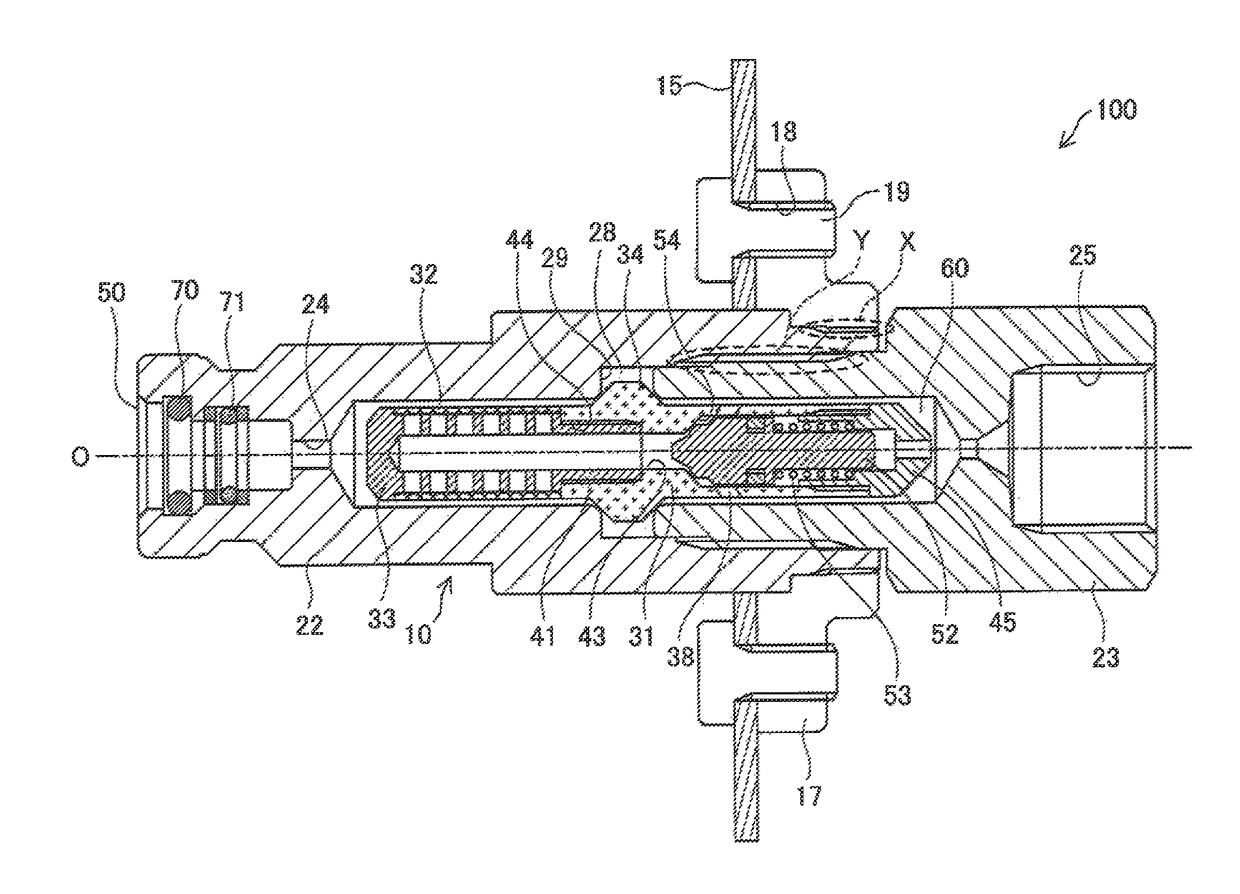

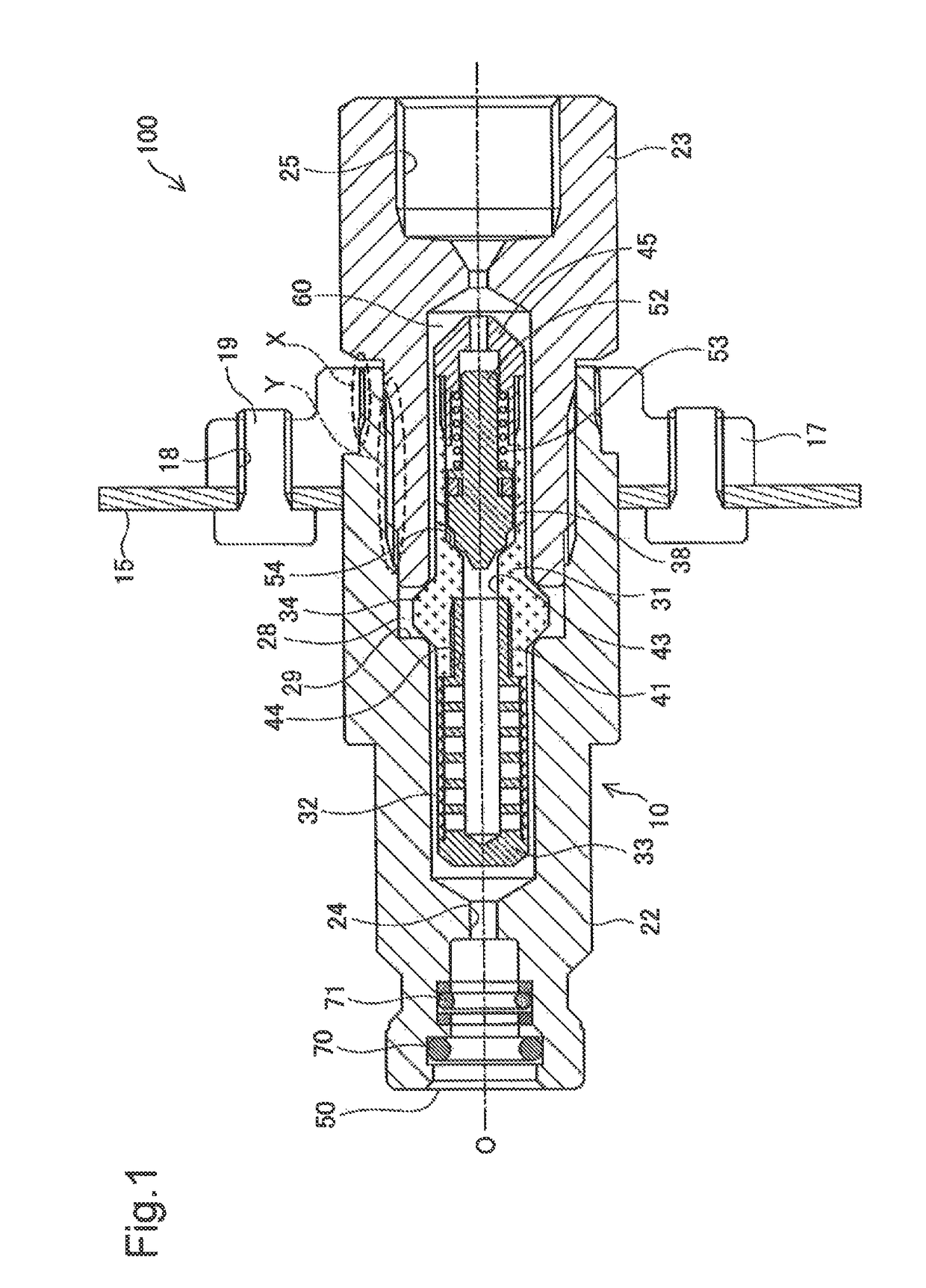

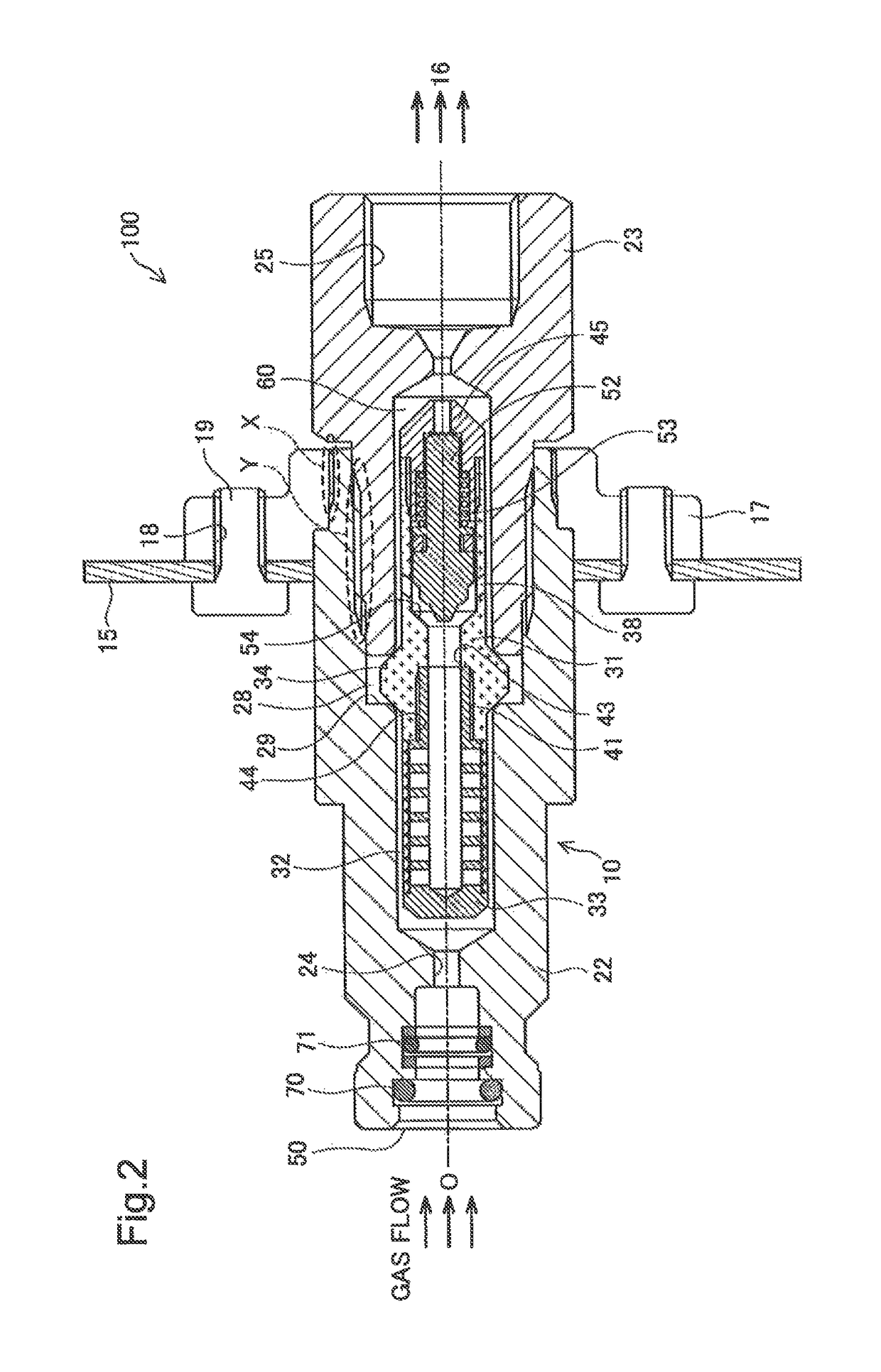

Check valve and receptacle structure

ActiveUS20160131273A1Simplify manufacturing processImprove durabilityContainer filling methodsCheck valvesPipingCheck valve

In order to reduce a pressure loss in a check valve and simplify a manufacturing process, a check valve (10) configured to be disposed in piping of fluid is provided, which includes a valve housing (31) including a valve element (52) and a valve seat (54) therein, a casing (20) that is configured to place the valve housing therein, in which a casing flow path (60) is provided between the casing and the valve housing to make a flow of the fluid in an axial direction of the valve housing. In the valve housing, a communicating hole (38) and sealing portion (34) are formed. The communicating hole that is formed through the valve housing in a thickness direction thereof introduces the fluid, which flows through between the valve element and the valve seat at the open position of the check valve, into the casing flow path. The sealing portion that is provided on an outer surface of the valve housing upstream of the communicating hole in a flow direction of the fluid in the casing flow path, is configured to come into contact with an inner surface of the casing to seal the casing flow path and position the valve housing in a radial direction perpendicular to the axial direction relative to the casing.

Owner:TOYOTA JIDOSHA KK +1

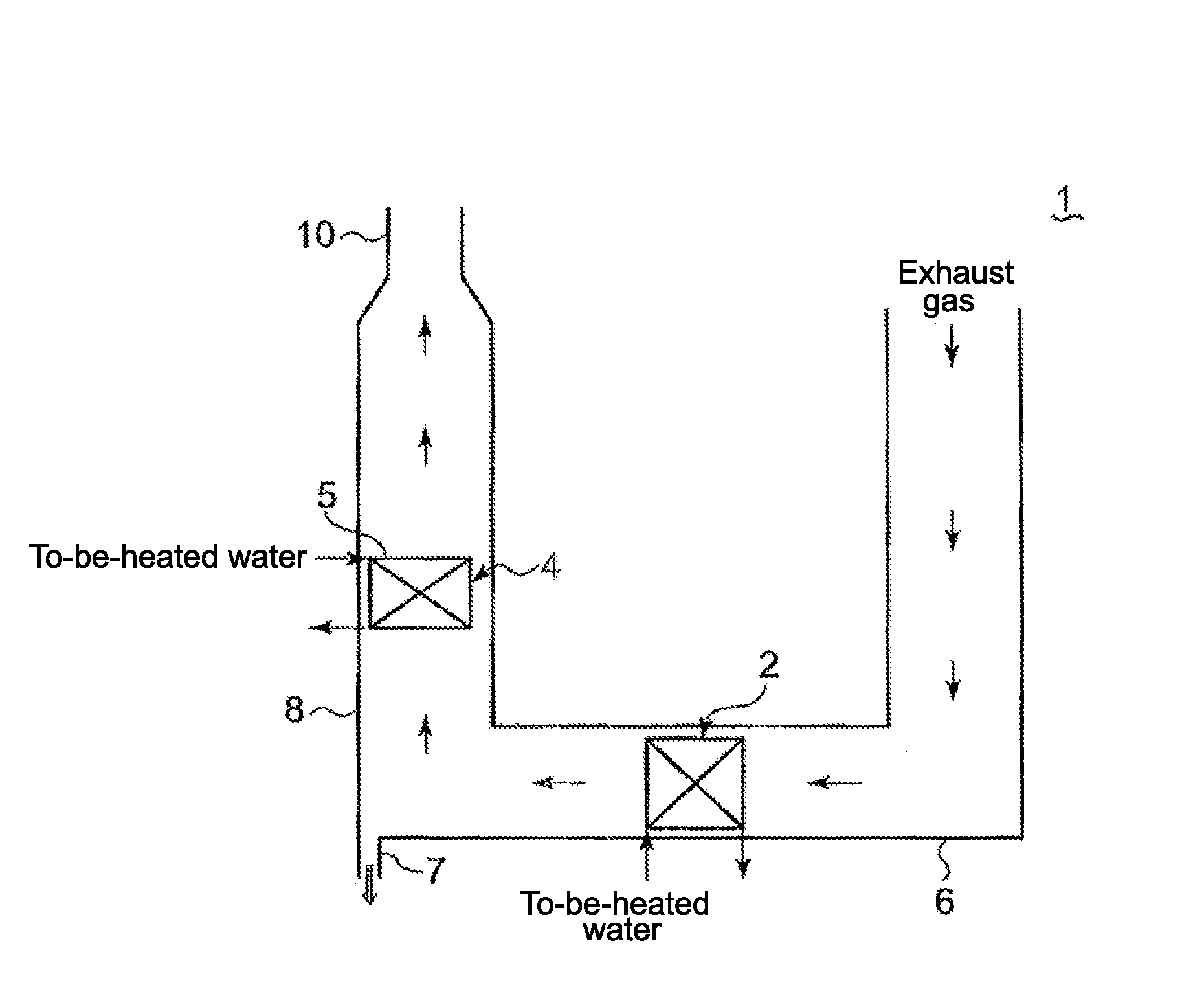

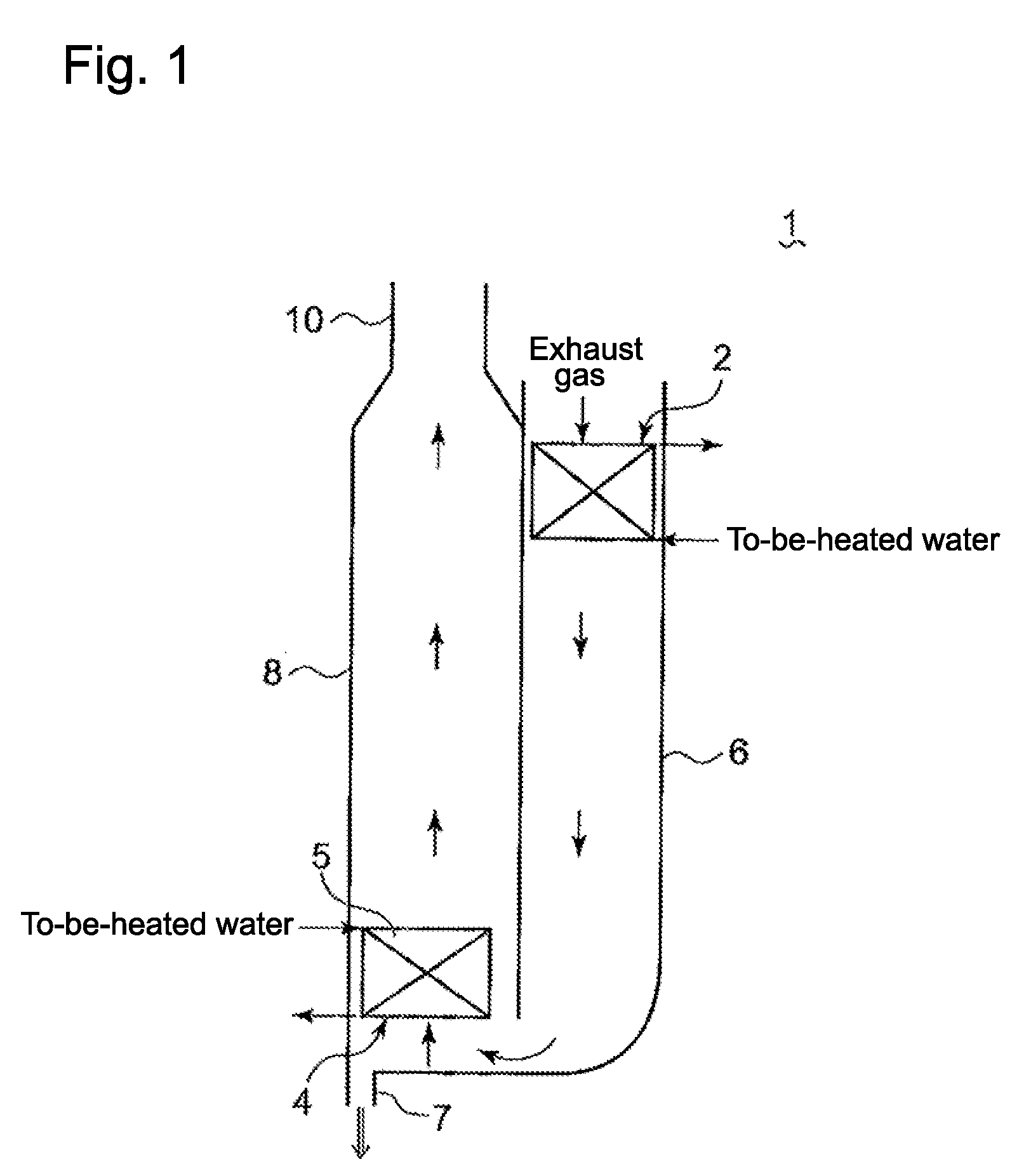

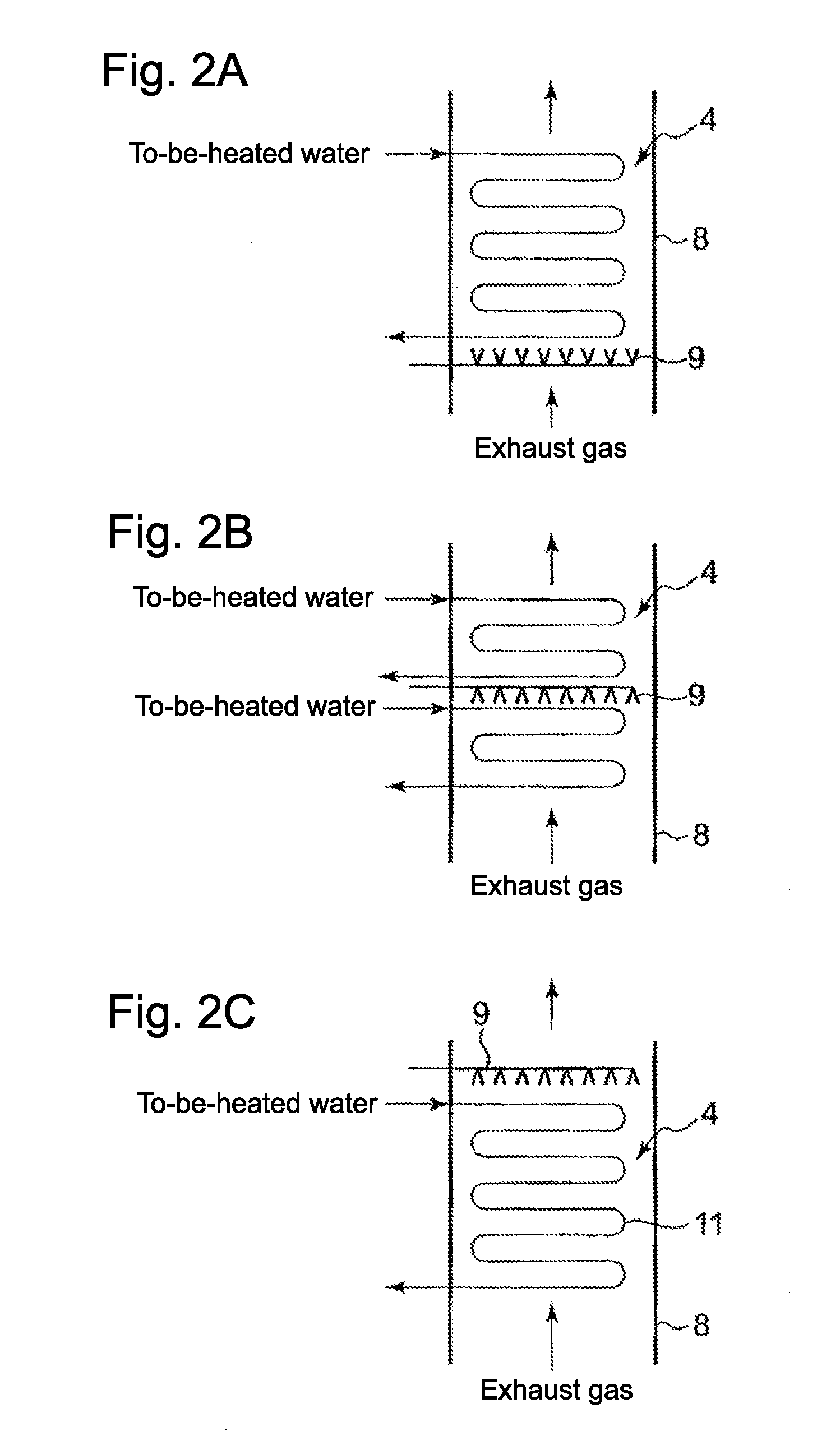

Device for recovering residual heat from exhaust gas

InactiveUS20130125841A1Improve heat recovery efficiencyImprove recycling efficiencyHeat recoveryWaste gas energyAtmospheric airExhaust fumes

A device for recovering residual heat from exhaust gas includes: a dry economizer which heats to-be-heated water by utilizing sensible heat of the exhaust gas, the dry economizer being provided in a duct extending to a funnel through which the exhaust gas is emitted to atmosphere; and a condensation economizer which heats to-be-heated water by utilizing latent heat of condensation of the exhaust gas, the condensation economizer being provided on a downstream side of the dry economizer. The duct includes an upstream duct in which the dry economizer is provided and a downstream duct connected to the upstream duct and directing the exhaust gas to flow upwardly. The condensation economizer is arranged in the downstream duct so that temperature of the exhaust gas amounts to condensation temperature at a vicinity of an upper part of the condensation economizer.

Owner:MITSUBISHI HEAVY IND LTD

Metal plastic compound screw cap

InactiveCN101245802APrevents stress corrosion crackingTightly boundJoints with sealing surfacesNutsStress corrosion crackingScrew thread

The invention discloses a metal plastic composite screw cap, belonging to the connecting part field. The metal plastic composite screw cap comprises a metal insert; the internal surface of the metal insert is provided with a thread; the external surface of the metal insert is provided with a clamping fin; a plastic layer is covered outside the metal insert. The metal plastic composite screw cap can avoid the problems of stress corrosion and crack and can obviously reduce cost.

Owner:杨光磊 +1

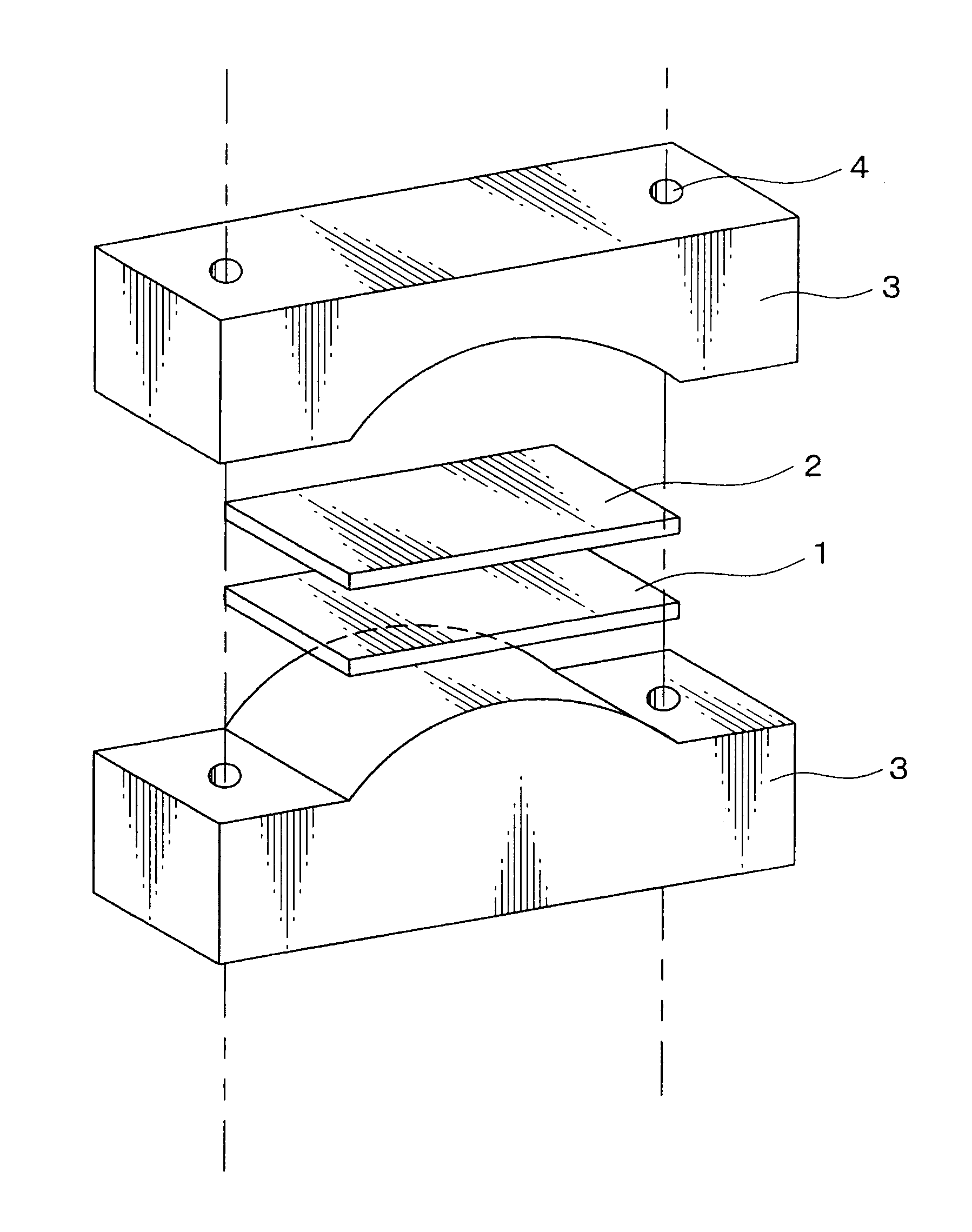

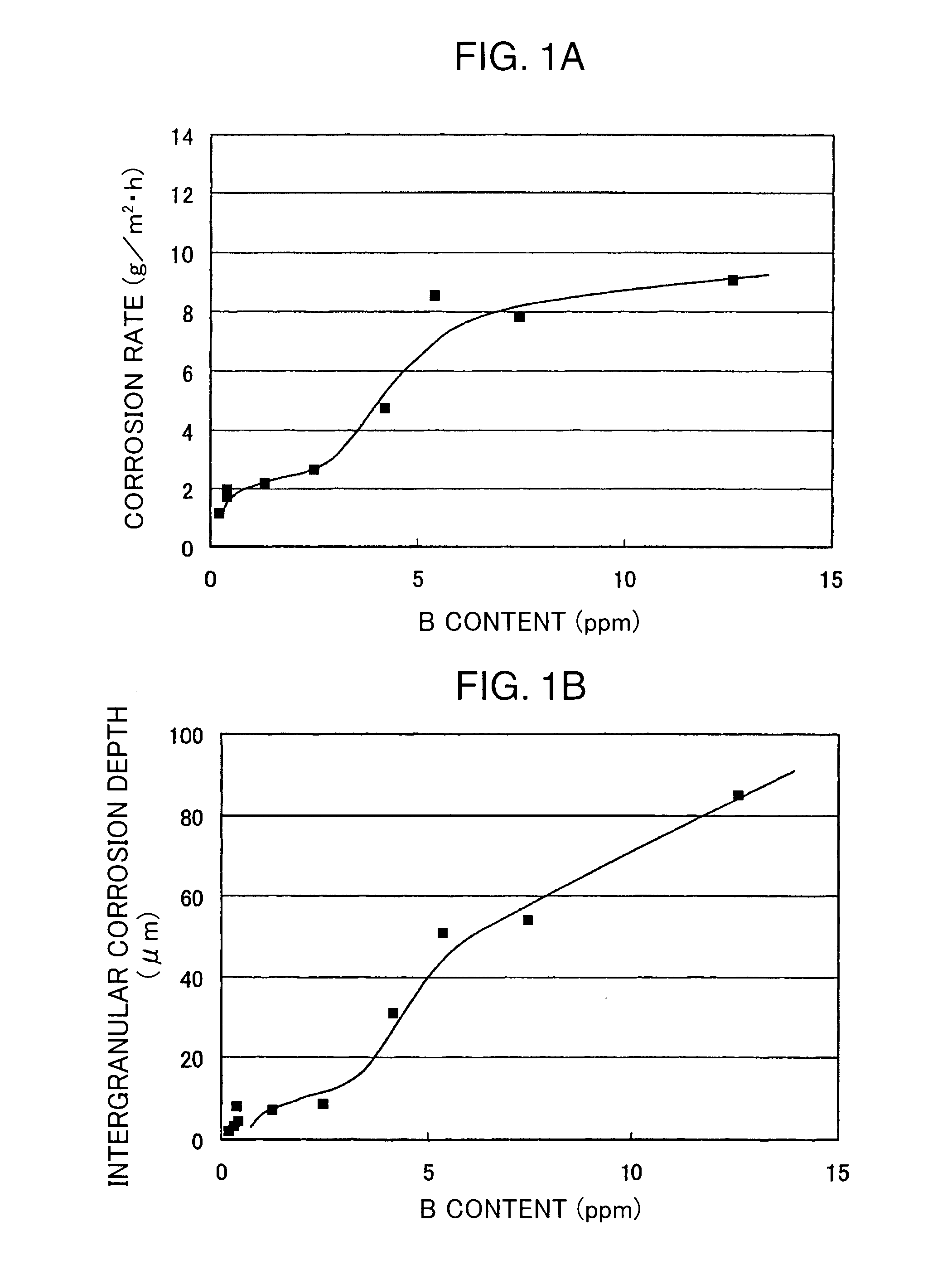

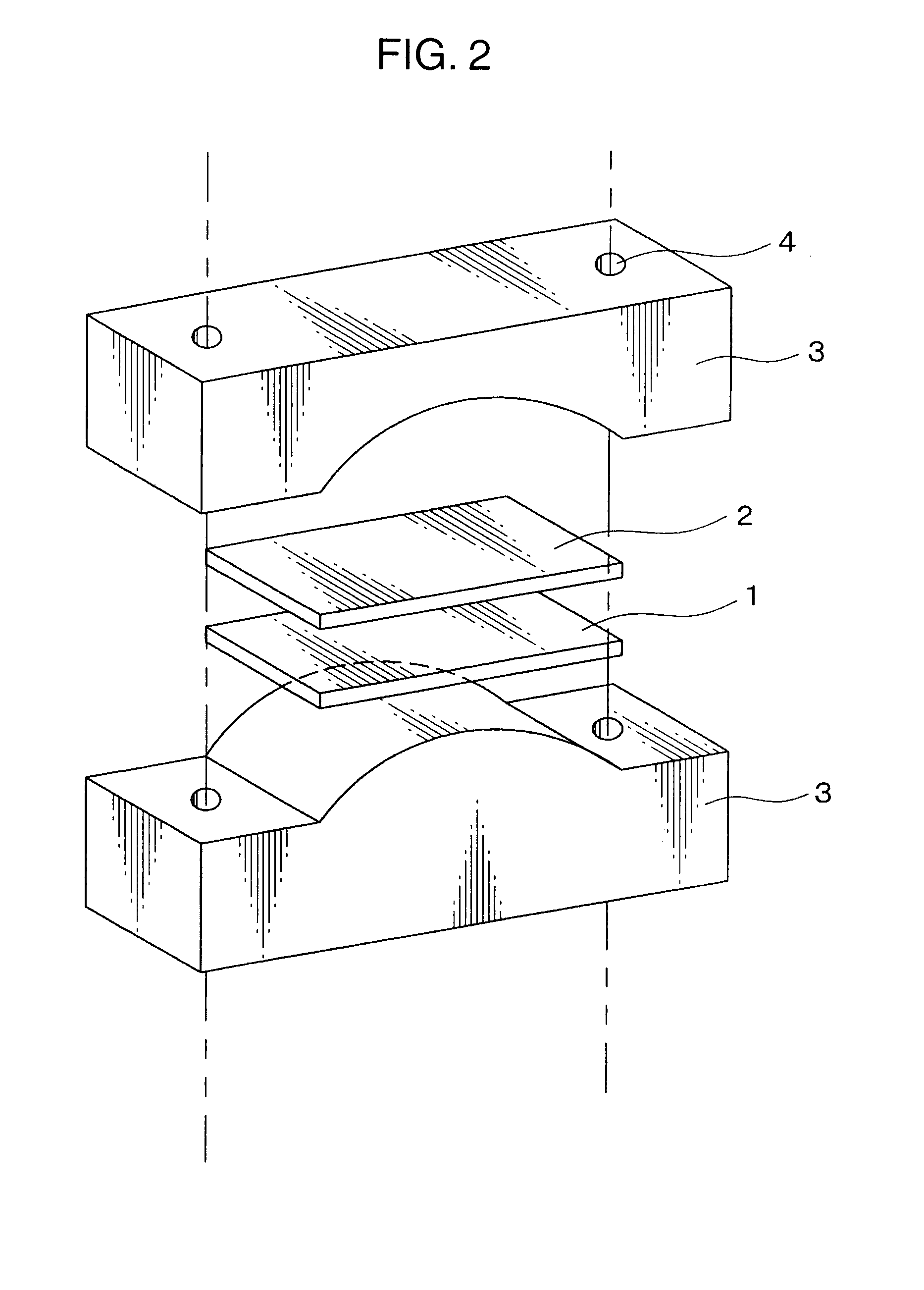

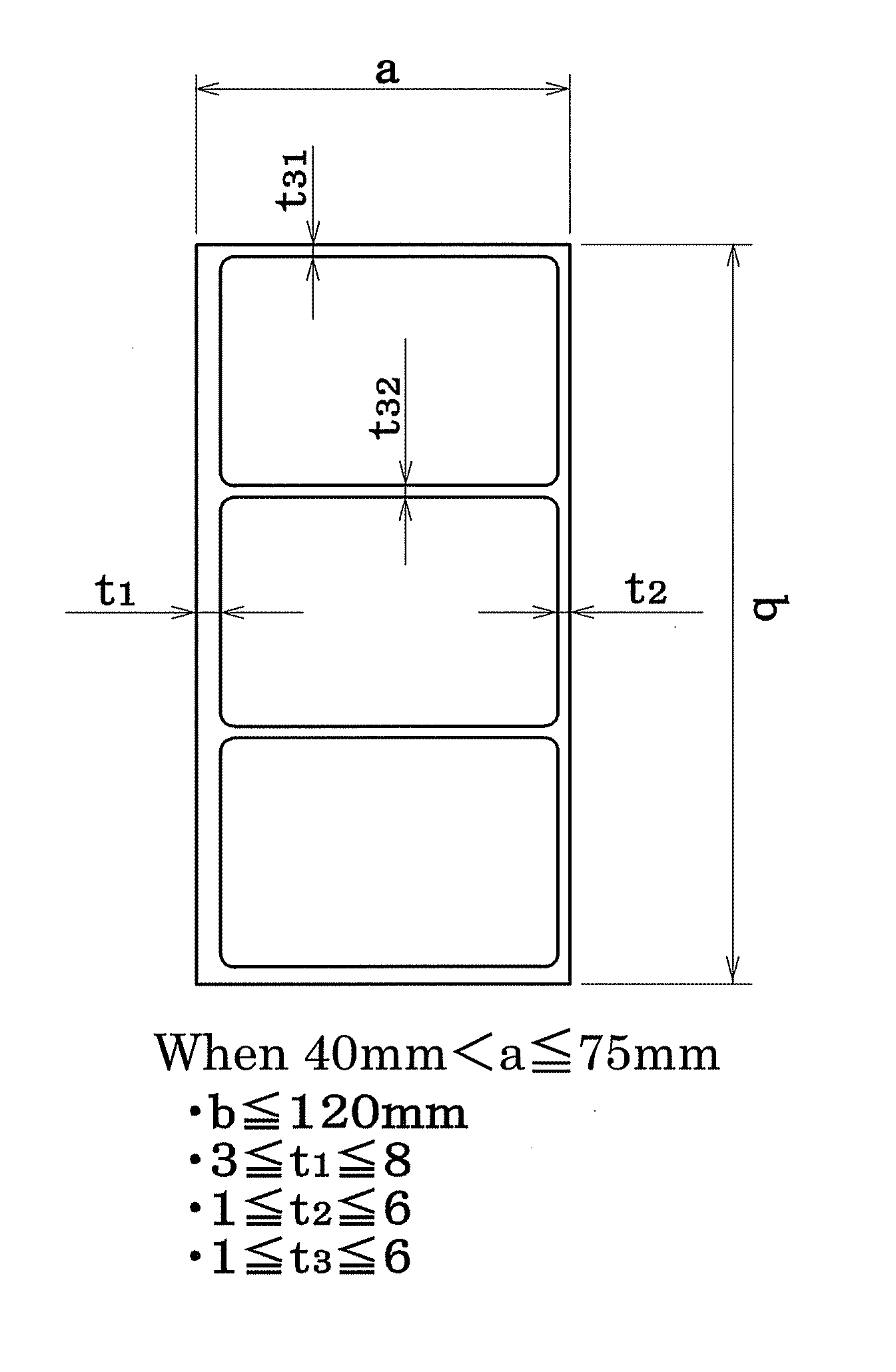

Austenitic stainless steel excellent in intergranular corrosion resistance and stress corrosion cracking resistance, and method for producing austenitic stainless steel material

InactiveUS20100116382A1Avoid problemsExcellent in intergranular corrosion resistanceAustenitic stainless steelMetallurgy

An austenitic stainless steel excellent in intergranular corrosion resistance and stress corrosion cracking resistance, comprising: C: 0.005 wt % or less; Si: 0.5 wt % or less; Mn: 0.5 wt % or less; P: 0.005 wt % or less; S: 0.005 wt % or less; Ni: 15.0 to 40.0 wt %, Cr: 20.0 to 30.0 wt %, N: 0.01 wt % or less; O: 0.01 wt % or less; and the balance of Fe and inevitable impurities, wherein the content of B included in the inevitable impurities is 3 wt ppm or less.

Owner:KOBELCO RES INST +1

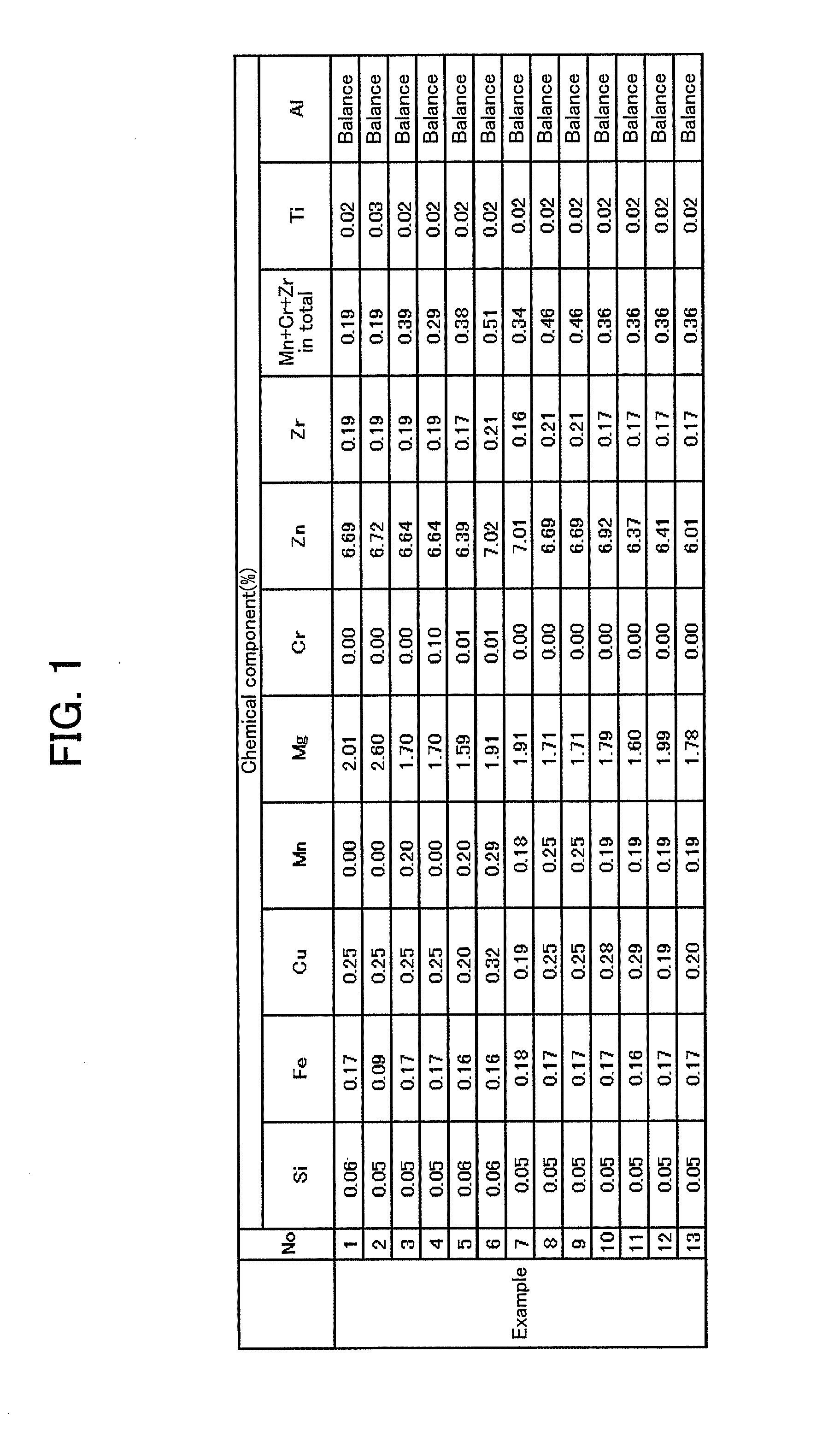

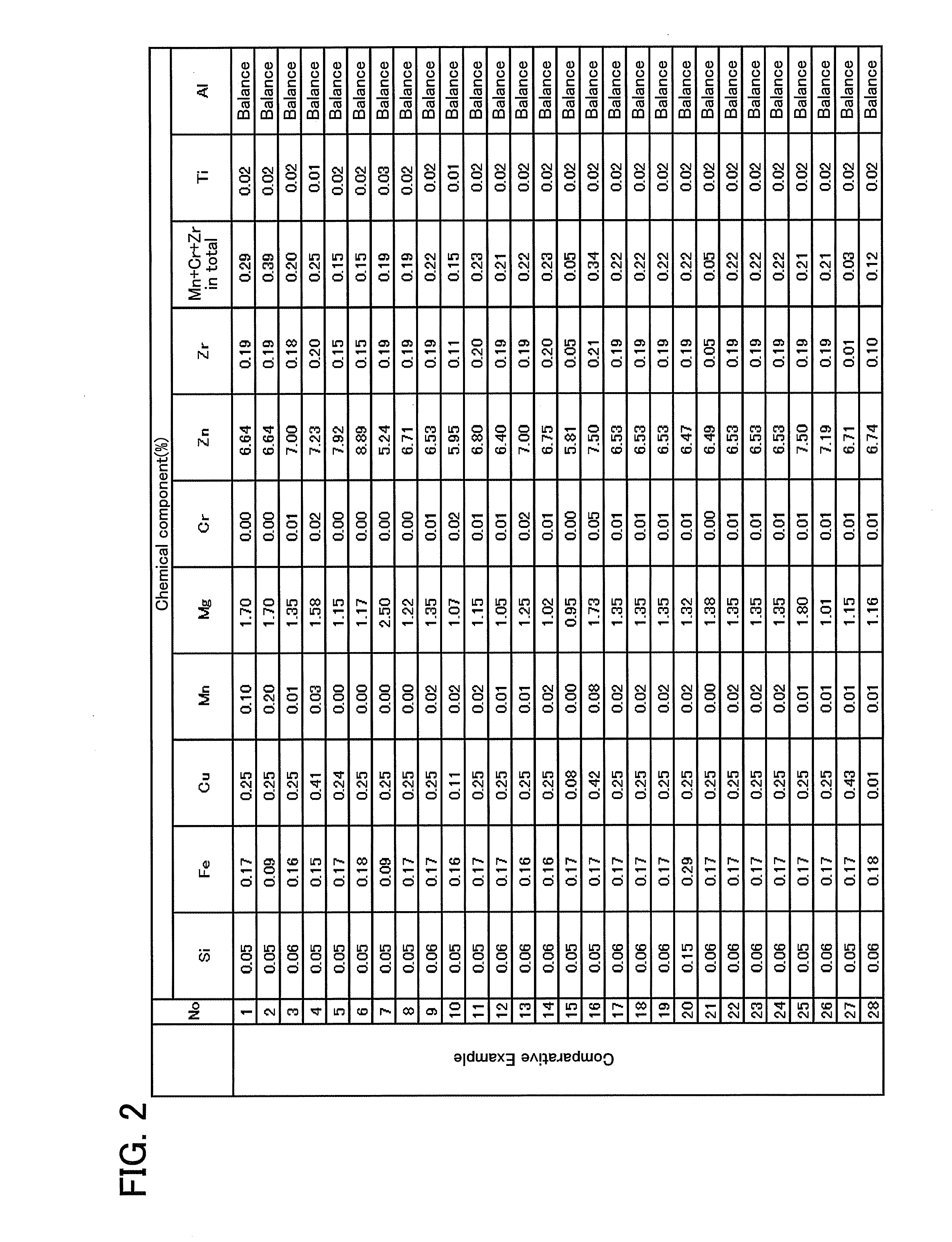

Aluminum alloy and method of manufacturing extrusion using same

ActiveUS20140102601A1Improve the extrusion effectHigh strengthVehicular safety arrangmentsSiluminHigh intensity

A high-strength aluminum alloy exhibiting excellent stress corrosion cracking resistance and excellent extrudability, and a method for producing an extruded shape using the same are disclosed. The aluminum alloy includes 1.6 to 2.6 mass % of Mg, 6.0 to 7.0 mass % of Zn, 0.5 mass % or less of Cu, and 0.01 to 0.05 mass % of Ti, with the balance being Al and unavoidable impurities.

Owner:AISIN KEIKINZOKU CO LTD

Method of an ultra-short femtosecond pulse and KW class high average-power laser for preventing cold-worked stress corrosion cracking in iron steels and alloyed steels including stainless steels

InactiveUS7651576B2Prevents stress corrosion crackingFree from risk of damageWelding/soldering/cutting articlesLaser beam welding apparatusSurface layerNuclear reactor

The method of preventing cold-worked stress corrosion cracking in the iron steels and alloyed steels including stainless steels comprises removing a residual tensile stressed layer, optionally generating residual compression, through the impact of irradiation with the ultra-short femtosecond pulse and kW class high average-power laser, and removing a hardened surface layer extremely susceptible to stress corrosion cracking, whereby this susceptible hardened surface layer with many concentrated dislocation defects and the likes is removed without generating or introducing any of such hardened layer in the process of its removal. The method is free from the risk of damaging other equipment by peening with steel balls or other shaped shots, is almost unlimited in actual environment, effectiveness, work, place and other conditions for application, is inexpensive, and functions continuously for a much longer period than an ordinary nuclear reactor's service lifetimes.

Owner:JAPAN ATOM ENERGY RES INST

Method of reducing corrosion of nuclear reactor structural material

ActiveUS8295426B1Simple structurePrevents stress corrosion crackingNuclear energy generationNuclear monitoringNuclear reactor coreHydrogen concentration

Owner:IHI CORP +2

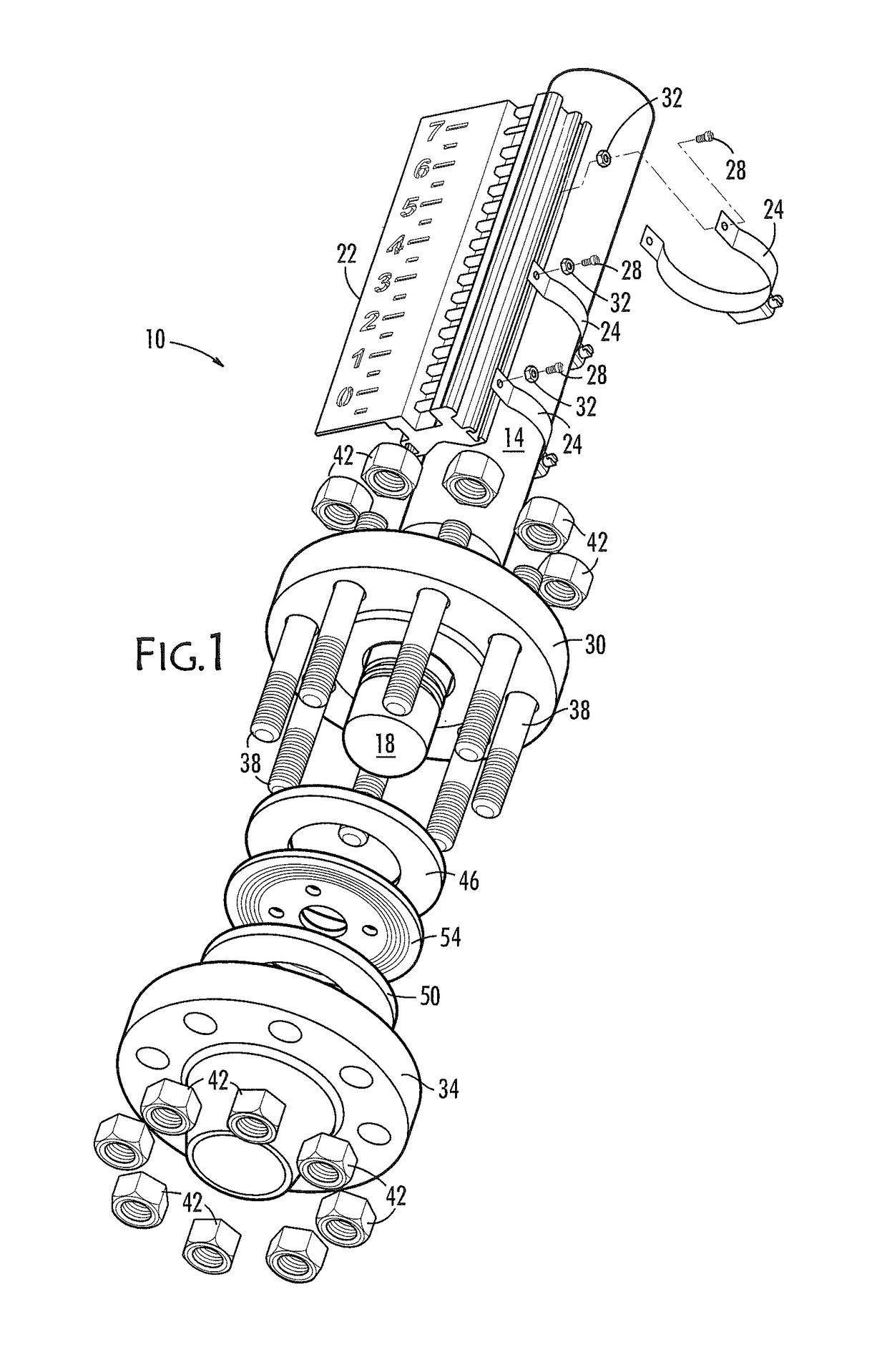

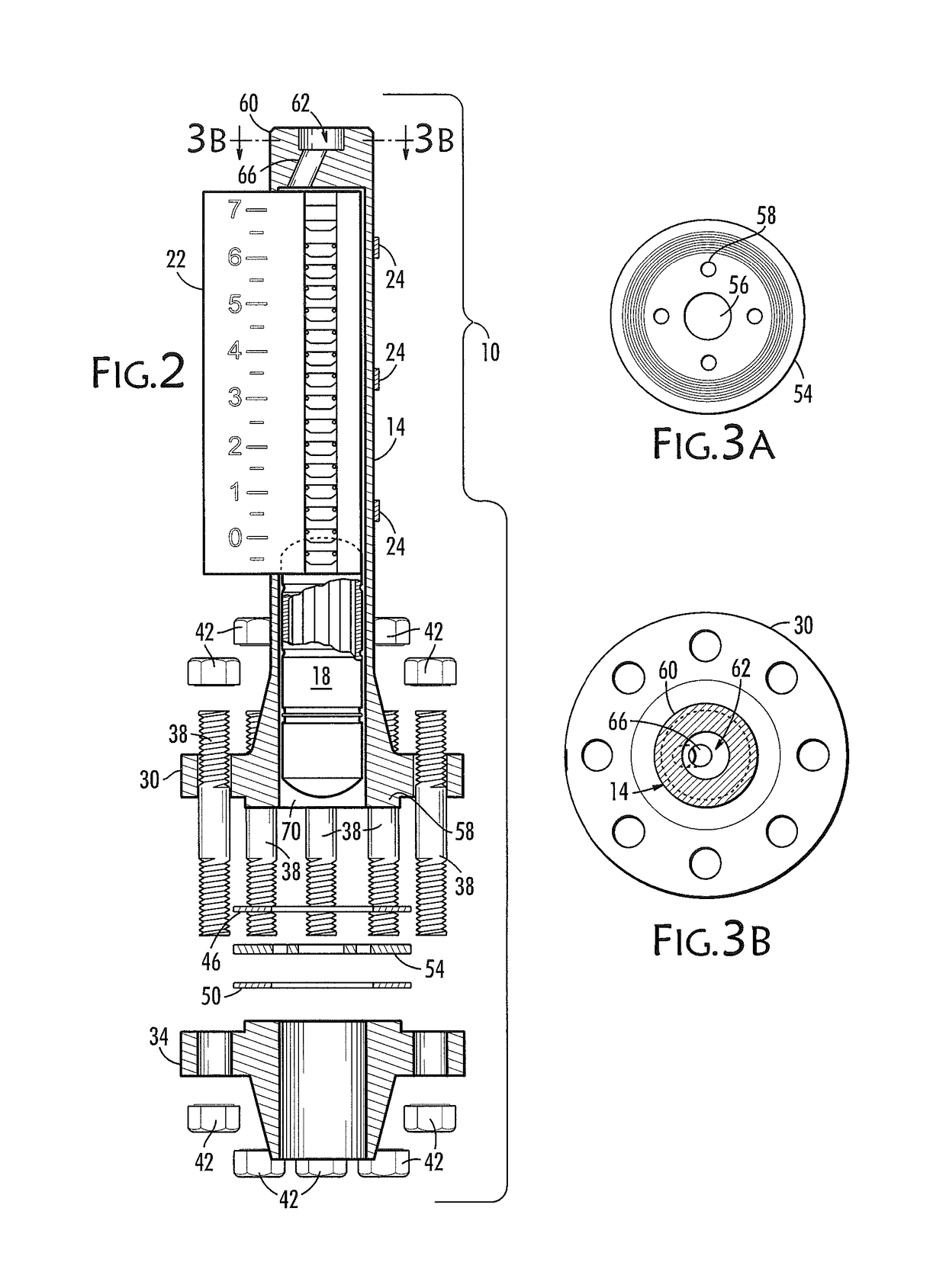

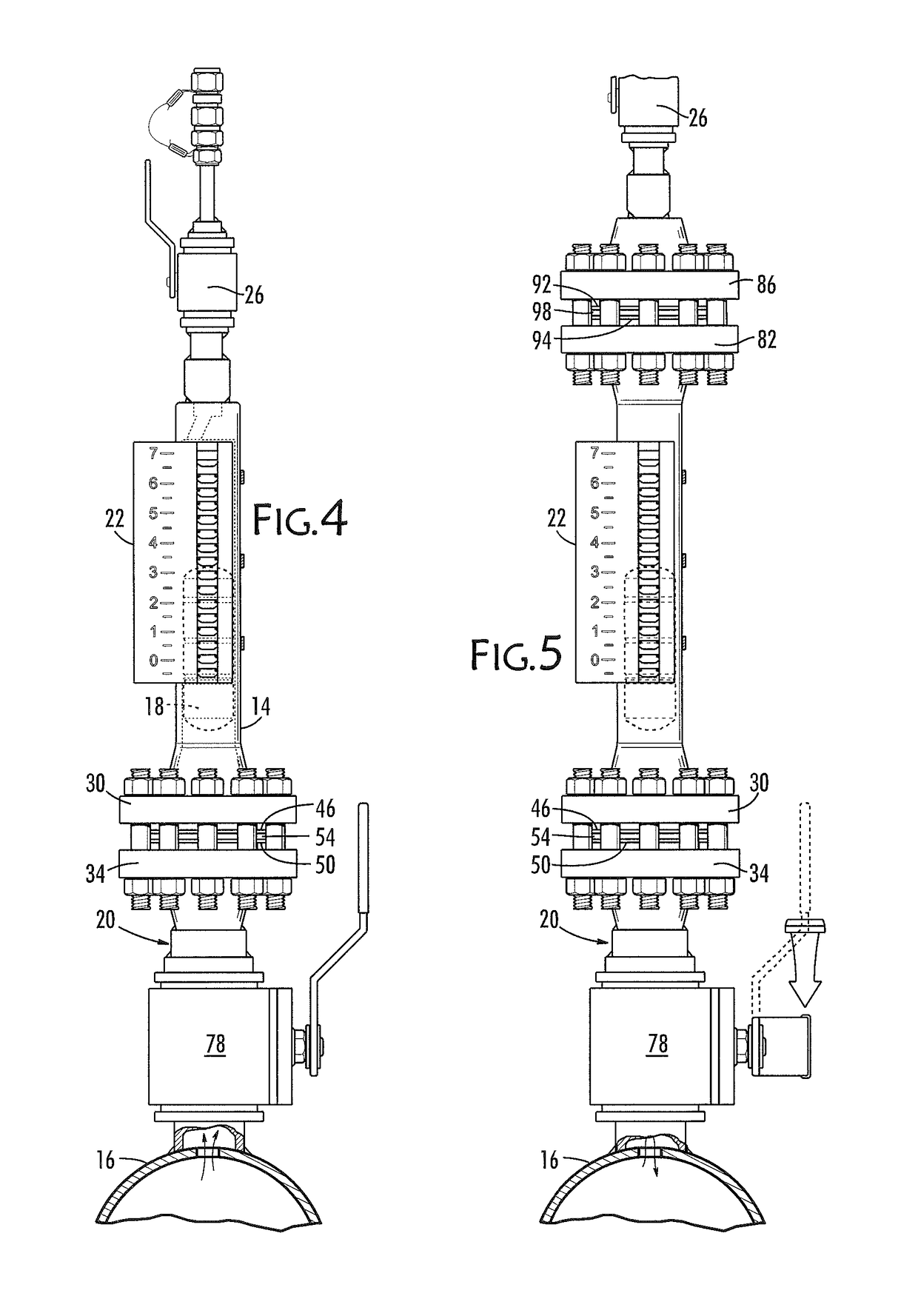

Nuclear grade air accumulating, isolating, indicating and venting device

ActiveUS10157688B2Prevents stress corrosion crackingImprove serviceabilityNuclear energy generationNuclear monitoringNuclear gradeIsolation valve

Owner:NUCCORP

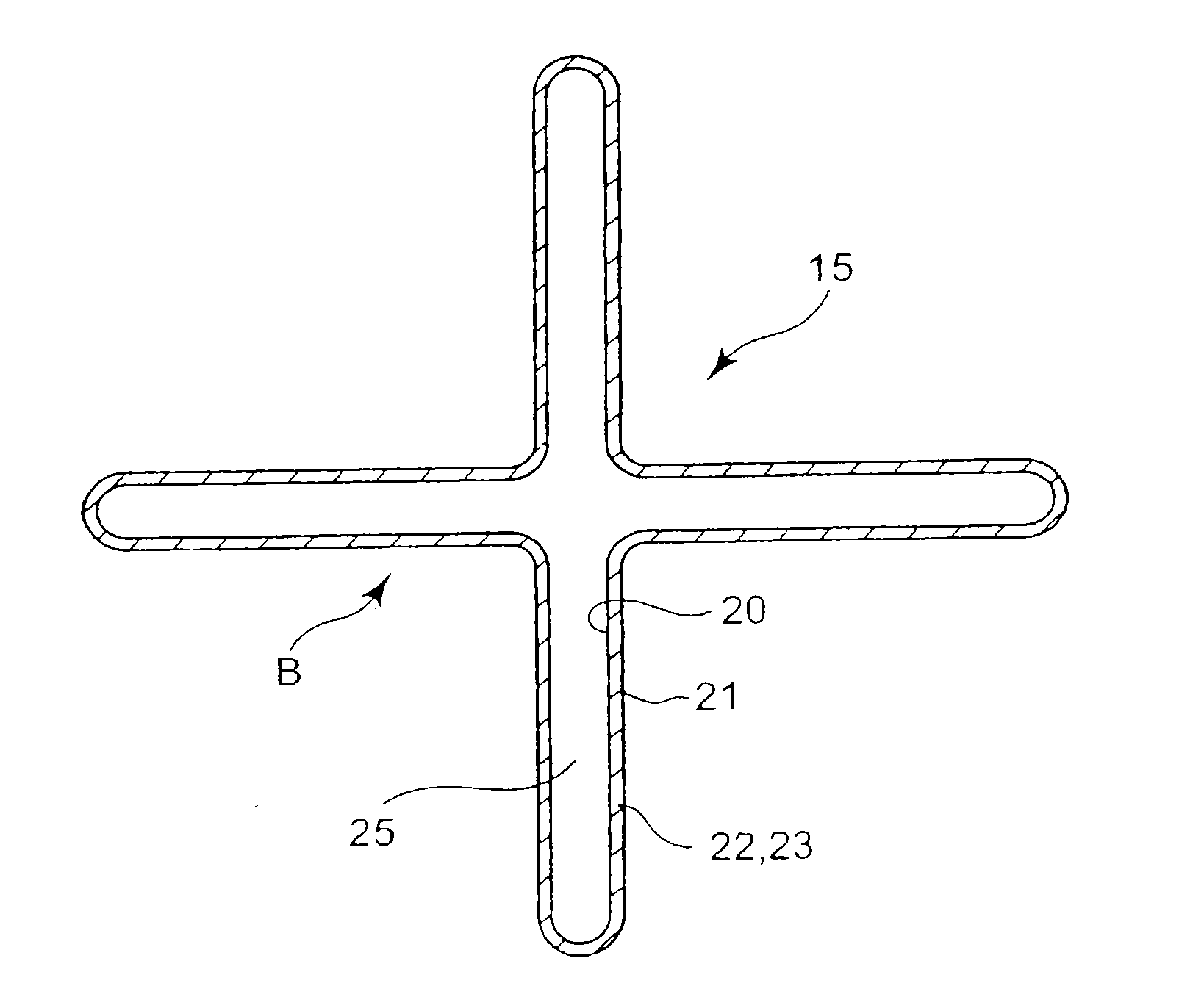

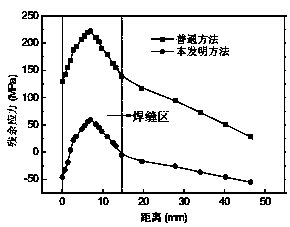

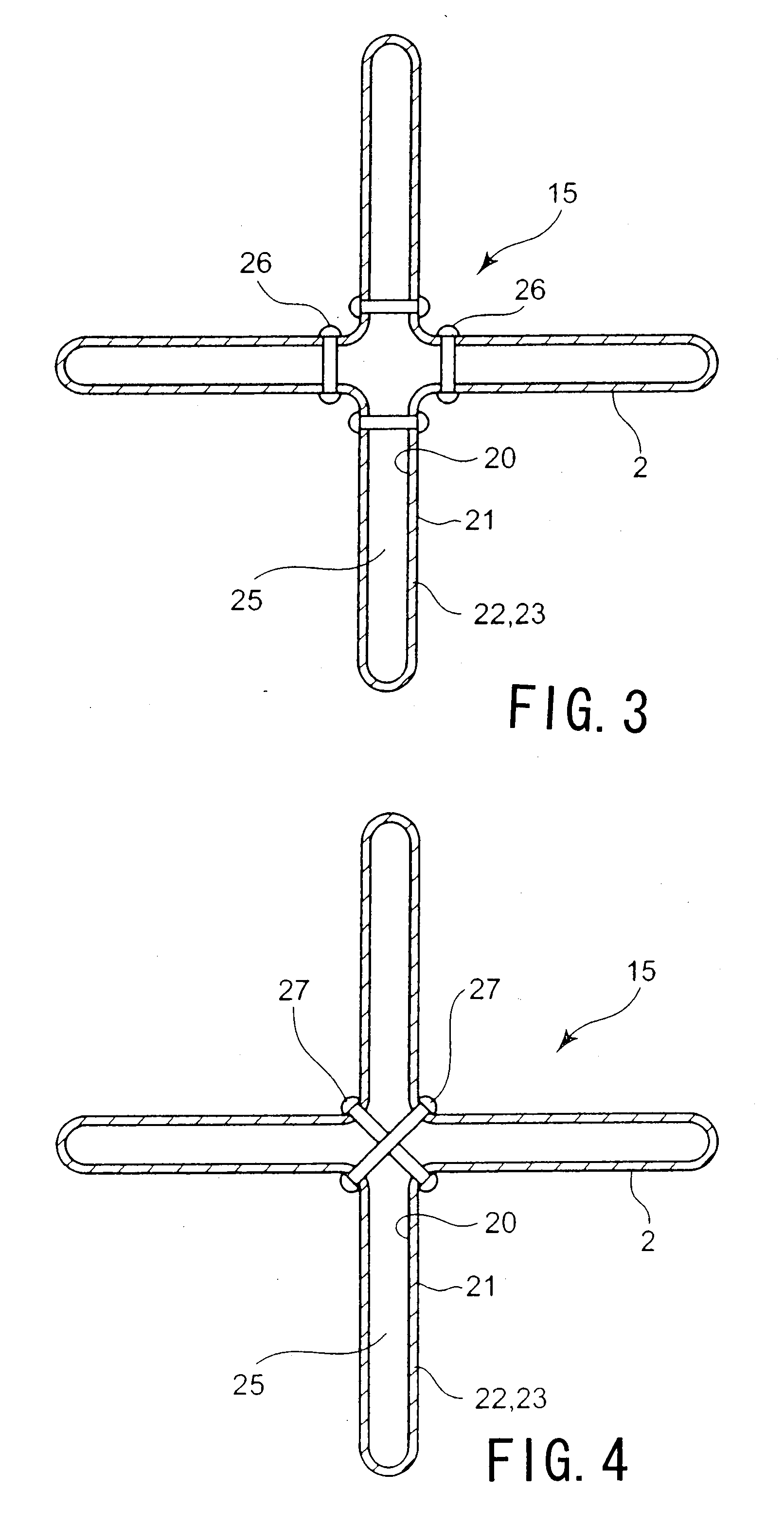

Control rod for nuclear reactor and method of manufacturing control rod

InactiveUS20140098925A1Prevents stress corrosion crackingReduce activationNuclear energy generationReactors manufactureNuclear reactor coreNuclear reactor

A control rod for nuclear reactors includes four wings including neutron absorbers containing hafnium, a front end structural member which has a cross shape in cross section and includes brackets bonded to the leading ends of the wings, and a terminal end structural member which has a cross shape in cross section and includes brackets bonded to the tailing ends of the wings. The four wings are bonded to a wing-bonding member including a cross-shaped center shaft so as to form a cross shape. The front end structural member and the wing-bonding member are made of a zirconium alloy. The wings include neutron-absorbing plates having neutron-absorbing portions and each have an outer surface which is opposed to a fuel assembly and at which a hafnium-zircaloy composite member covered with zircaloy is disposed. The neutron-absorbing plates are opposed to each other with trap spaces disposed therebetween.

Owner:KK TOSHIBA

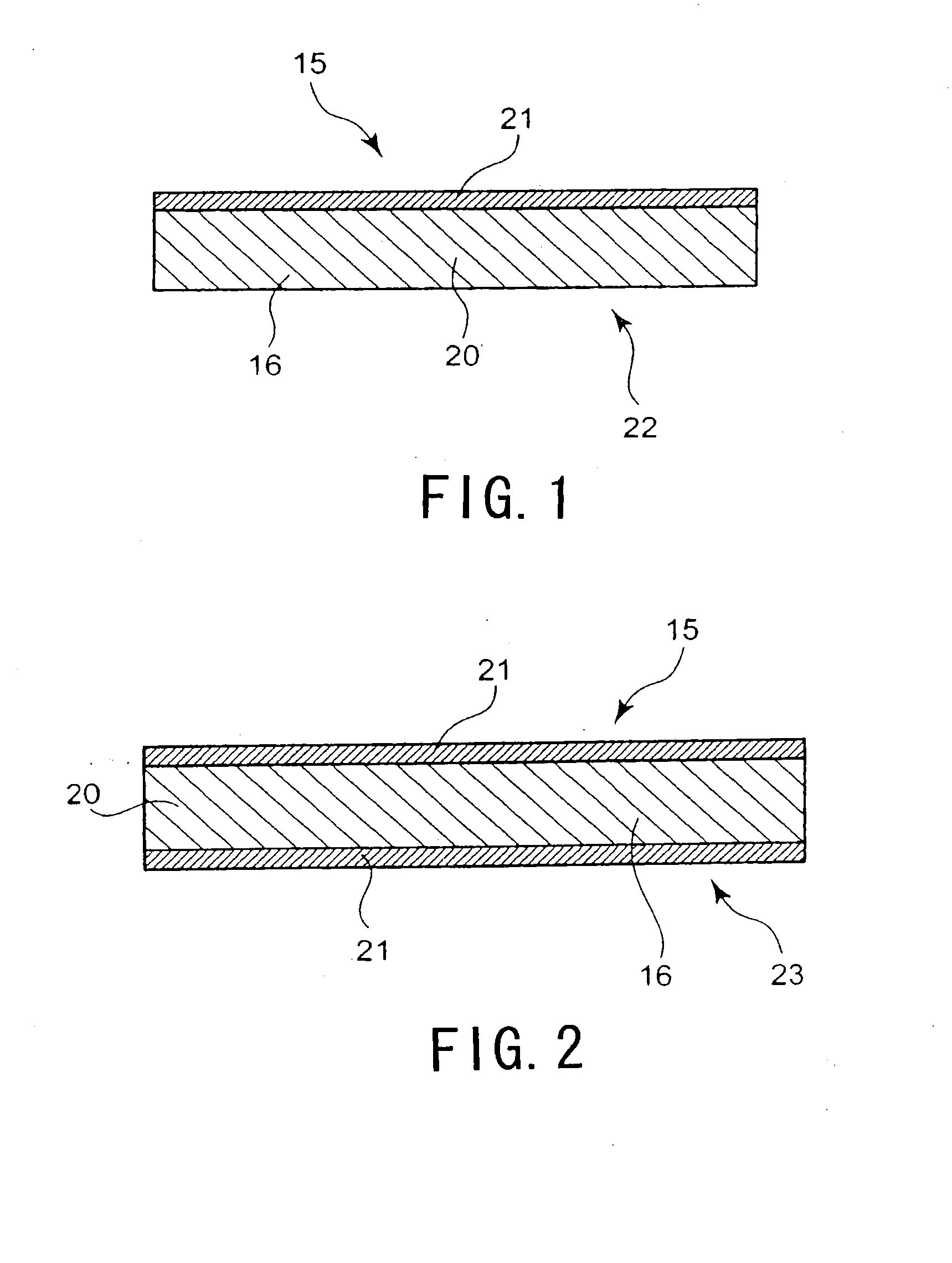

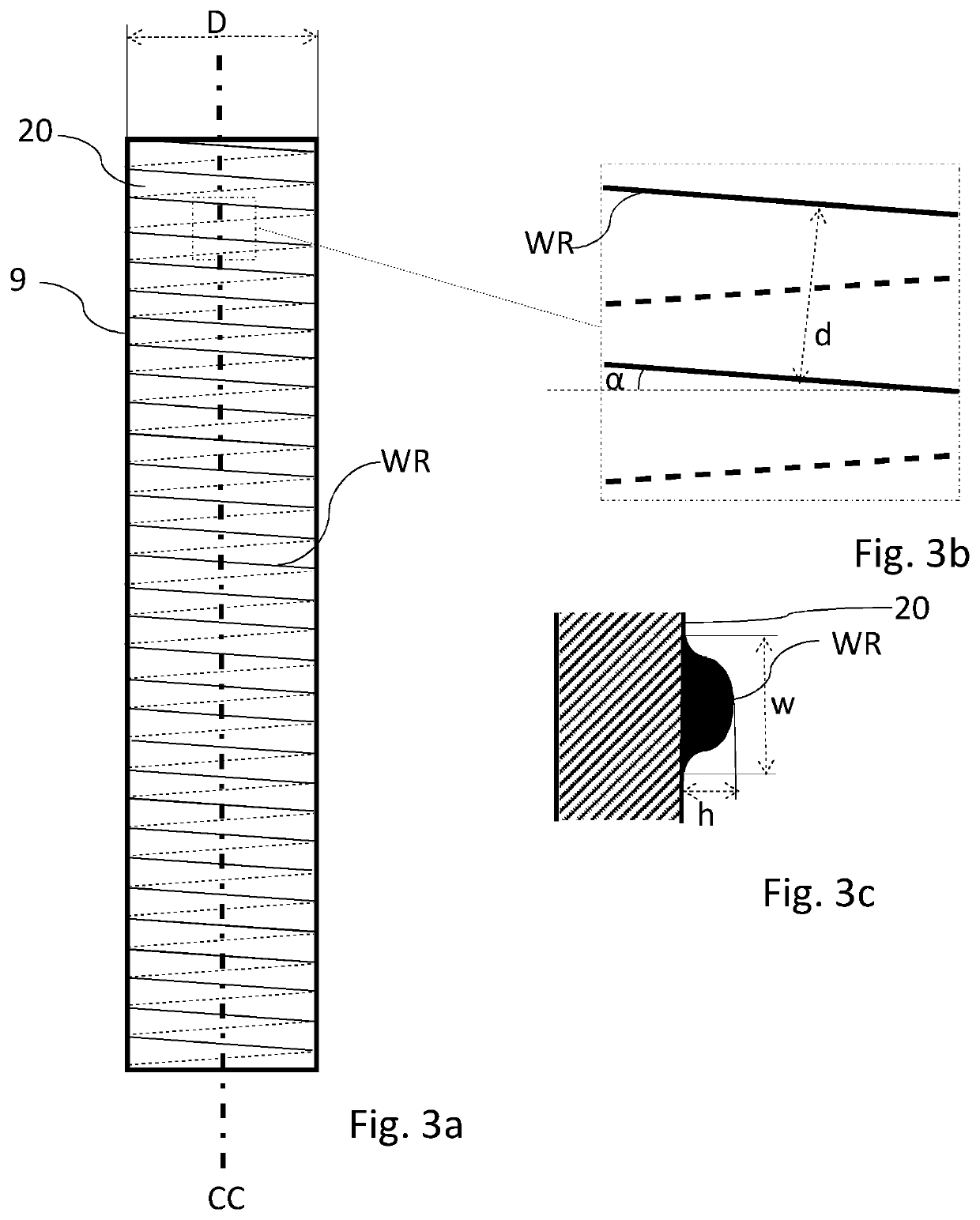

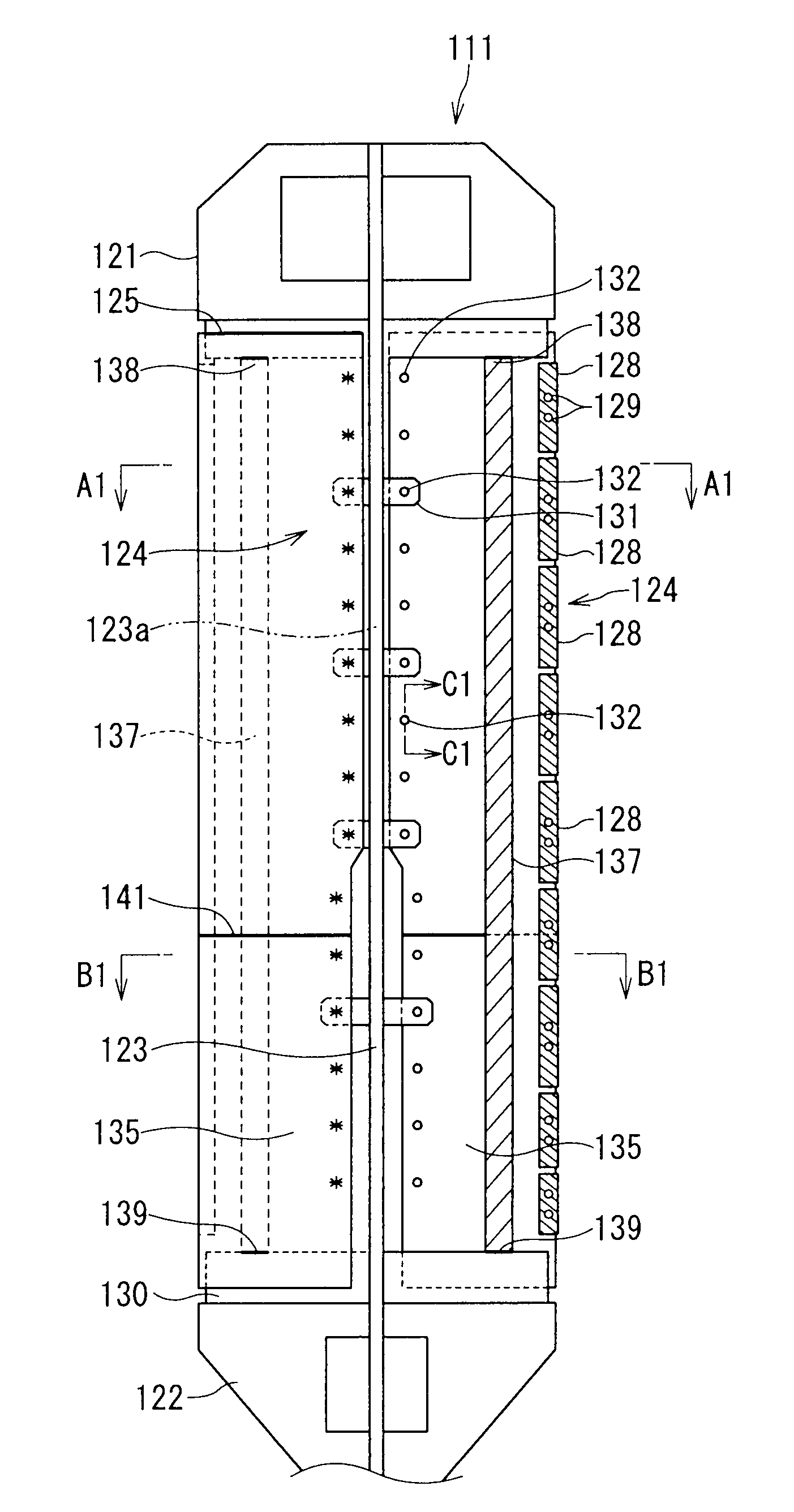

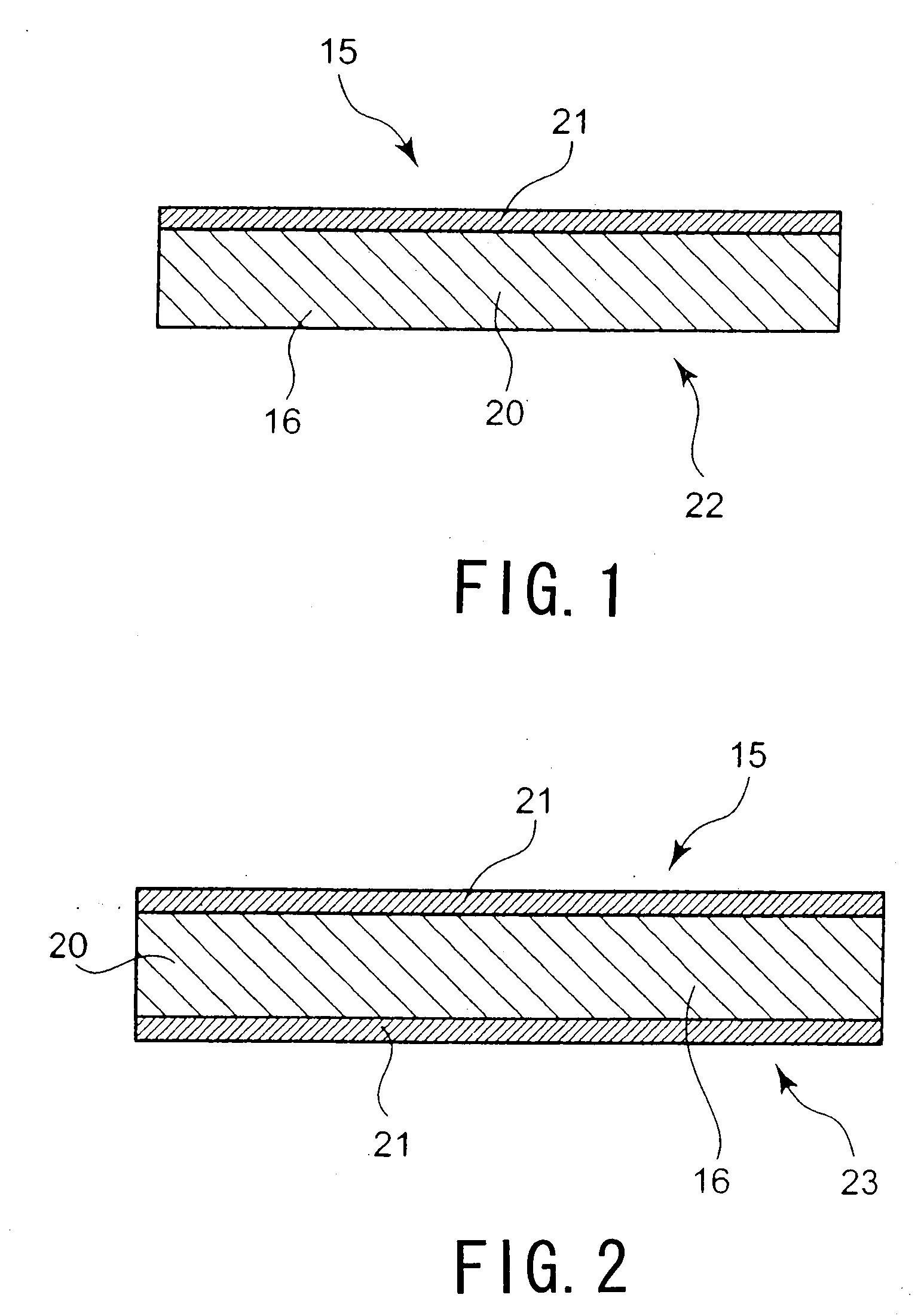

Heat transfer tube and method for manufacturing a heat transfer tube

ActiveUS20190366228A1Taller in heightIncrease distanceStationary conduit assembliesStationary tubular conduit assembliesEvaporationAlloy

The invention relates to a heat transfer tube (9) for falling film evaporation having a heating medium surface (21) to be heated by a heating medium, a falling film surface (20) to have spent liquor passing over it, and being made from an iron based high alloy stainless steel material with an alloy content above 16.00% for Chromium and above 1% for Nickel. The falling film surface of the heat transfer tube is equipped with at least one weld ridge (WR; WR1, WR2), said weld ridge having a height (h; h2) in the range 0.3 to 5.0 mm, a width (w; w2) in the range 0.5-15 mm, and an inclination angle (α; α1, α2) versus a plane orthogonal to a longitudinal axis (CC) of the heat transfer tube in a range of 0-70 degrees so that each weld ridge is inclined and extends helically along at least a portion of the heat transfer tube or extend within a plane orthogonal to the longitudinal axis of the heat transfer tube and forms well ridge portions on the falling film surface such that the distance along the longitudinal axis of the heat transfer tube between adjacent weld ridge portions is within the range of 0 to 250 mm. The invention also relates to a method for manufacturing said heat transfer tube.

Owner:VALMET AB

Check valve and receptacle structure

ActiveUS10030783B2Simple structureReduce total pressure lossVessel mounting detailsContainer filling methodsEngineeringCheck valve

In order to reduce a pressure loss in a check valve and simplify a manufacturing process, a check valve (10) configured to be disposed in piping of fluid is provided, which includes a valve housing (31) including a valve element (52) and a valve seat (54) therein, a casing (20) that is configured to place the valve housing therein, in which a casing flow path (60) is provided between the casing and the valve housing to make a flow of the fluid in an axial direction of the valve housing. In the valve housing, a communicating hole (38) and sealing portion (34) are formed. The communicating hole that is formed through the valve housing in a thickness direction thereof introduces the fluid, which flows through between the valve element and the valve seat at the open position of the check valve, into the casing flow path. The sealing portion that is provided on an outer surface of the valve housing upstream of the communicating hole in a flow direction of the fluid in the casing flow path, is configured to come into contact with an inner surface of the casing to seal the casing flow path and position the valve housing in a radial direction perpendicular to the axial direction relative to the casing.

Owner:TOYOTA JIDOSHA KK +1

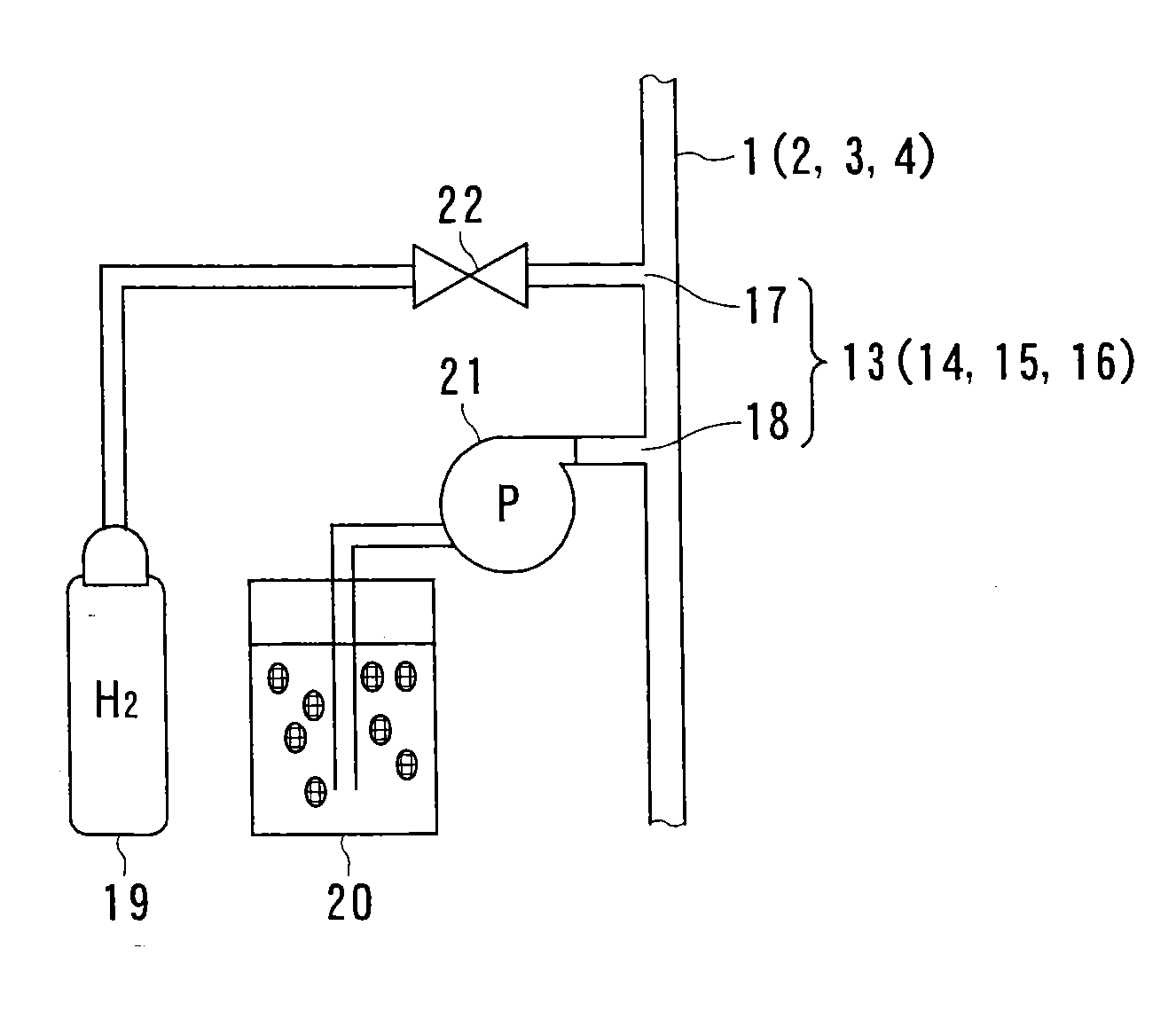

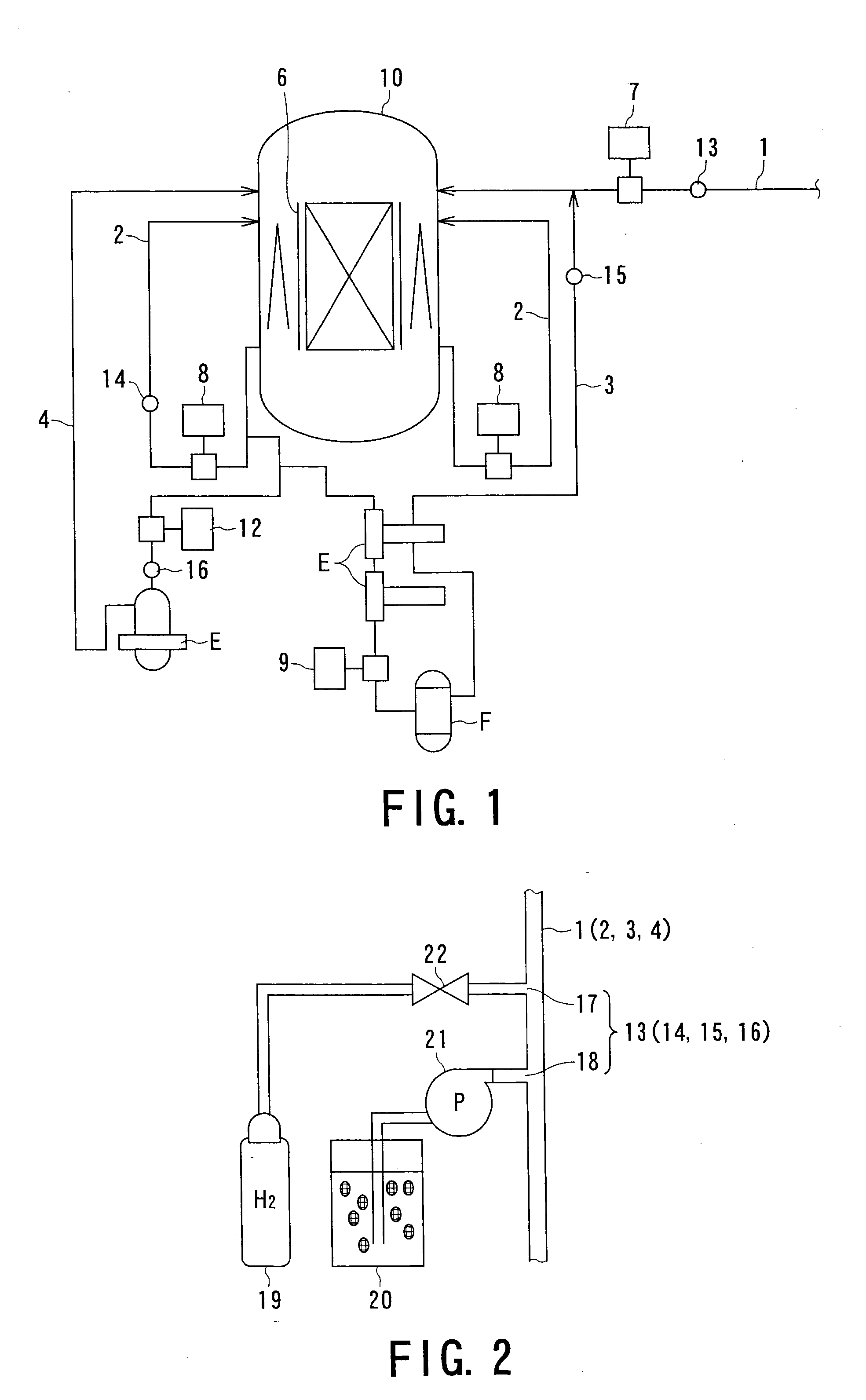

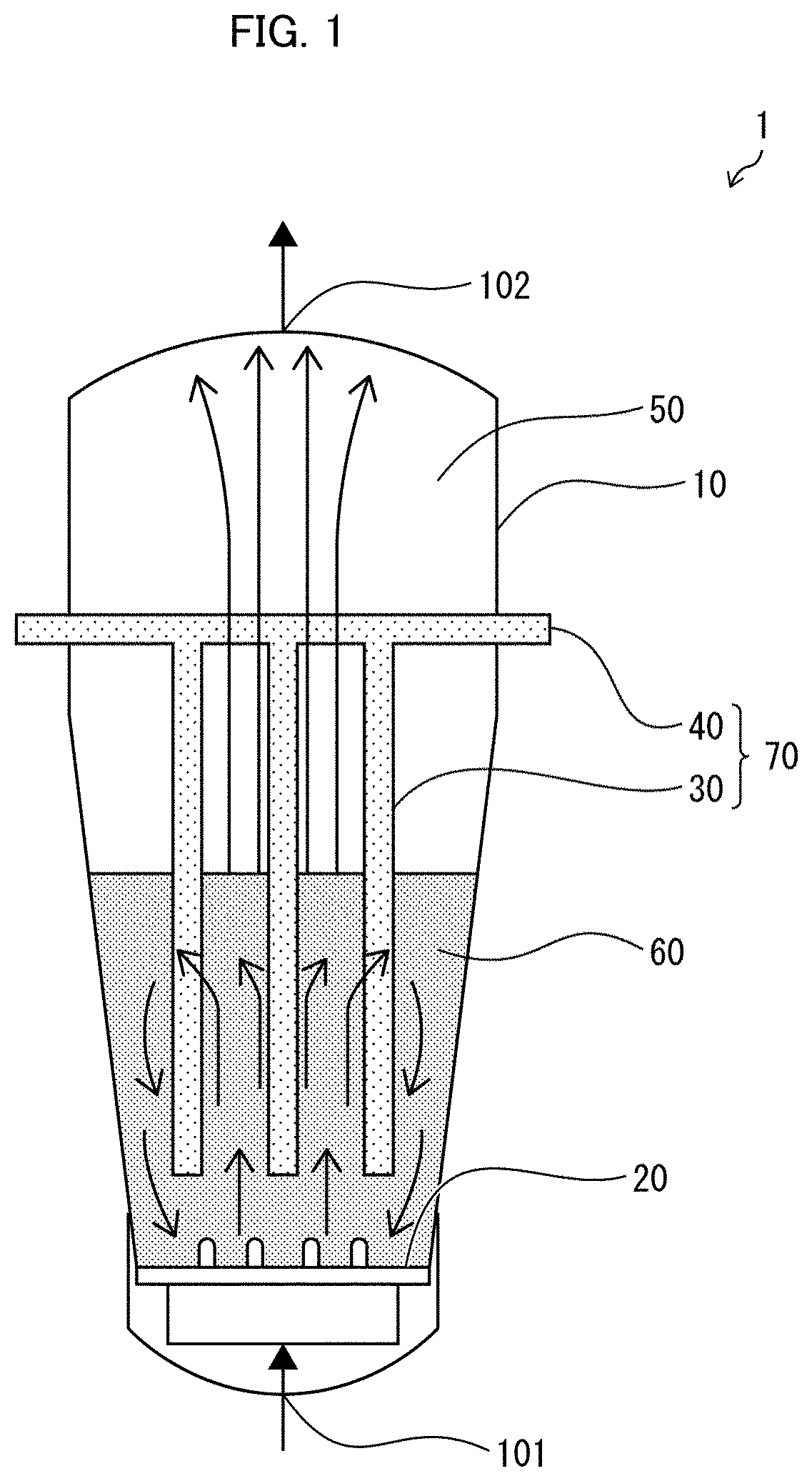

Method of reducing corrosion of nuclear reactor structural material

ActiveUS8731131B2Simple structurePrevents stress corrosion crackingOptical rangefindersPlant parameters regulationNuclear reactor coreHydrogen concentration

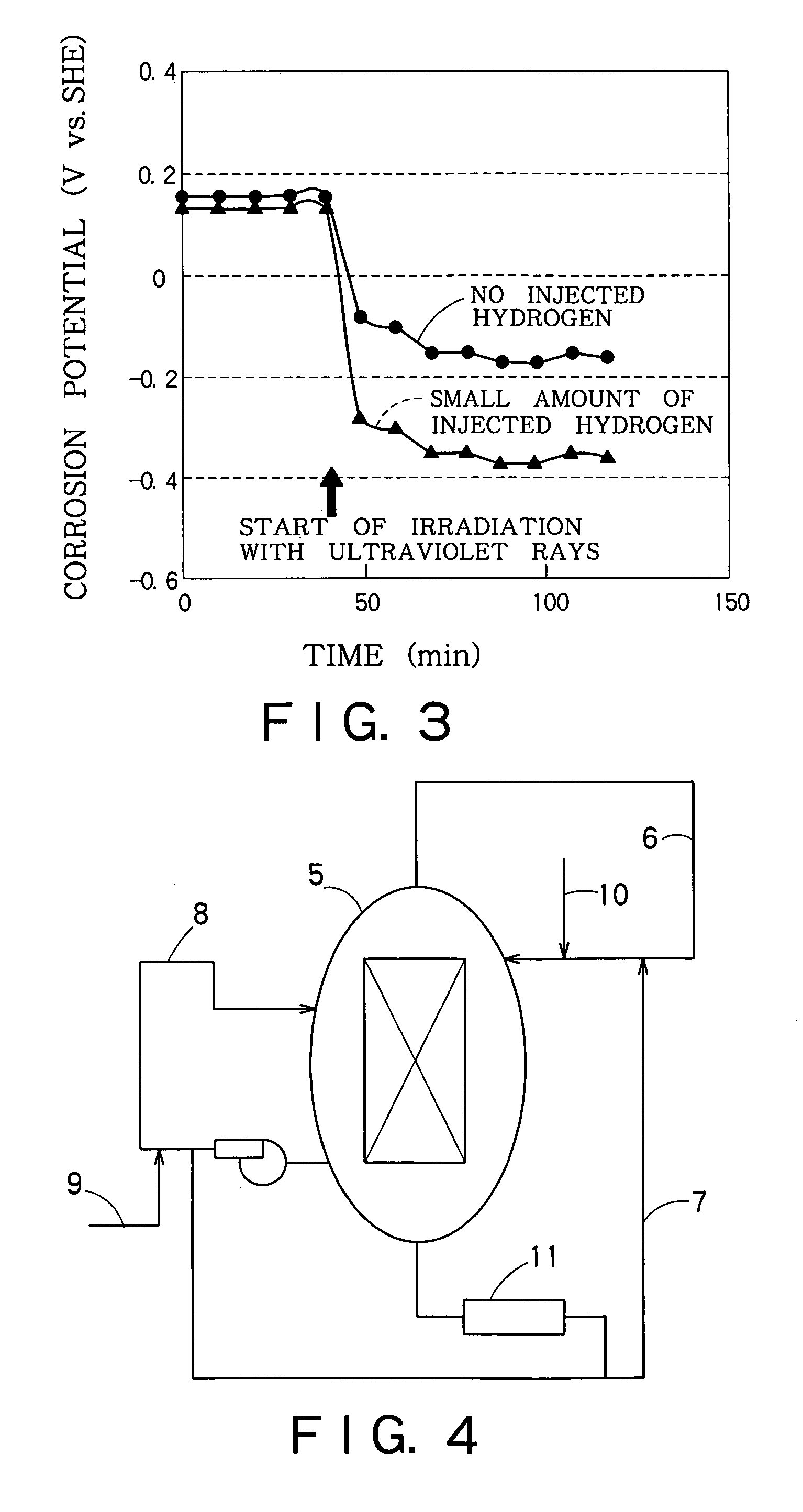

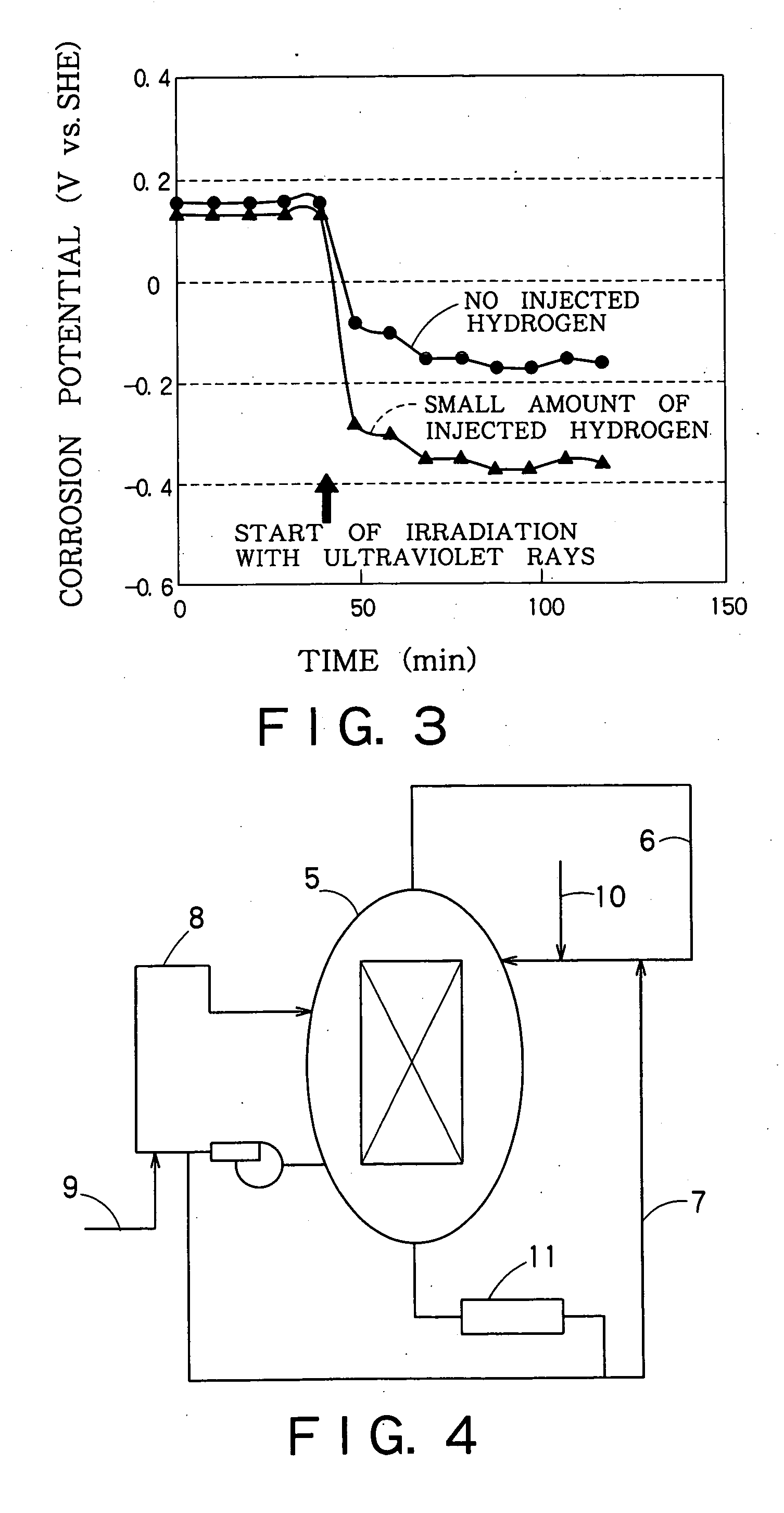

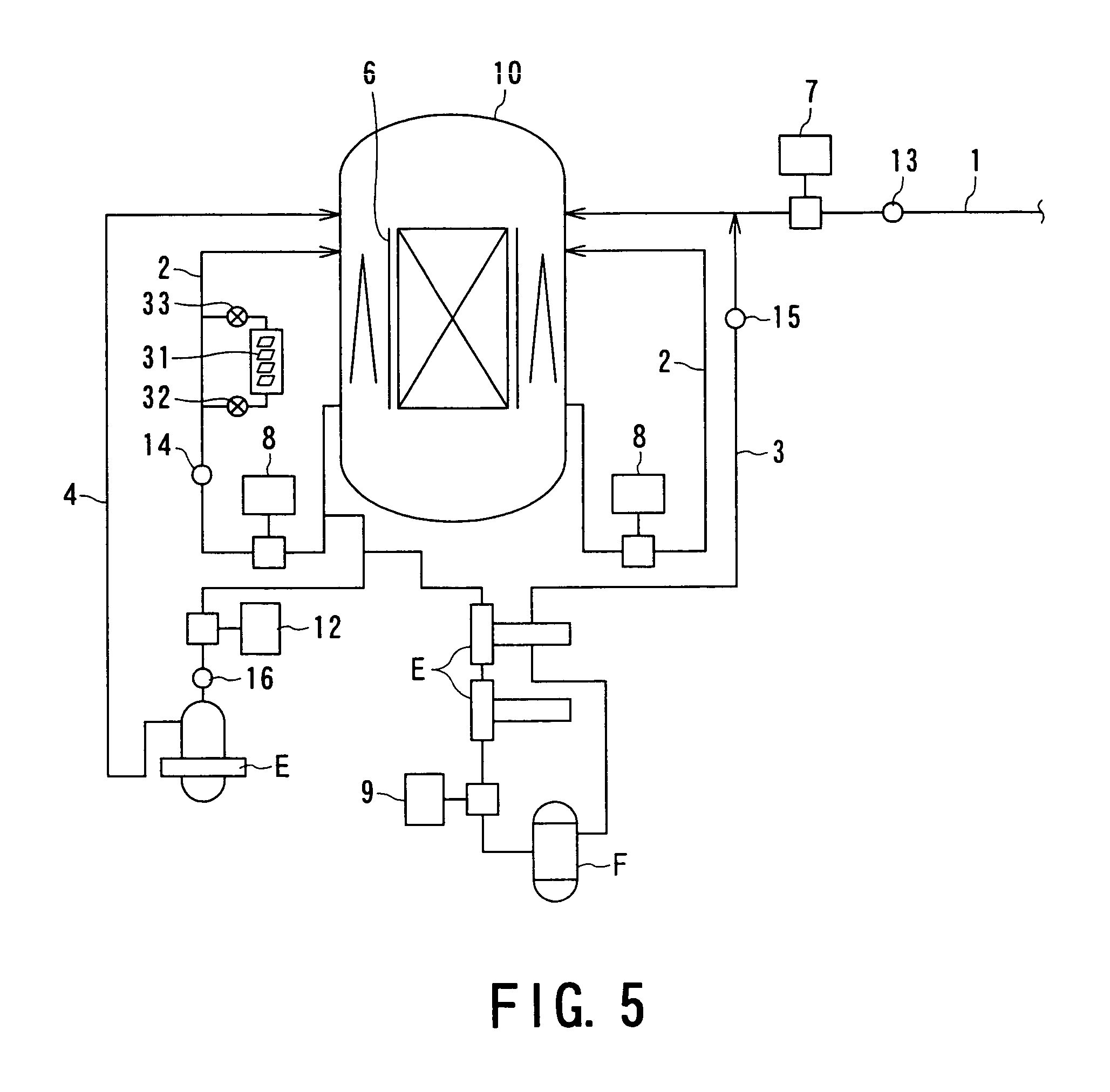

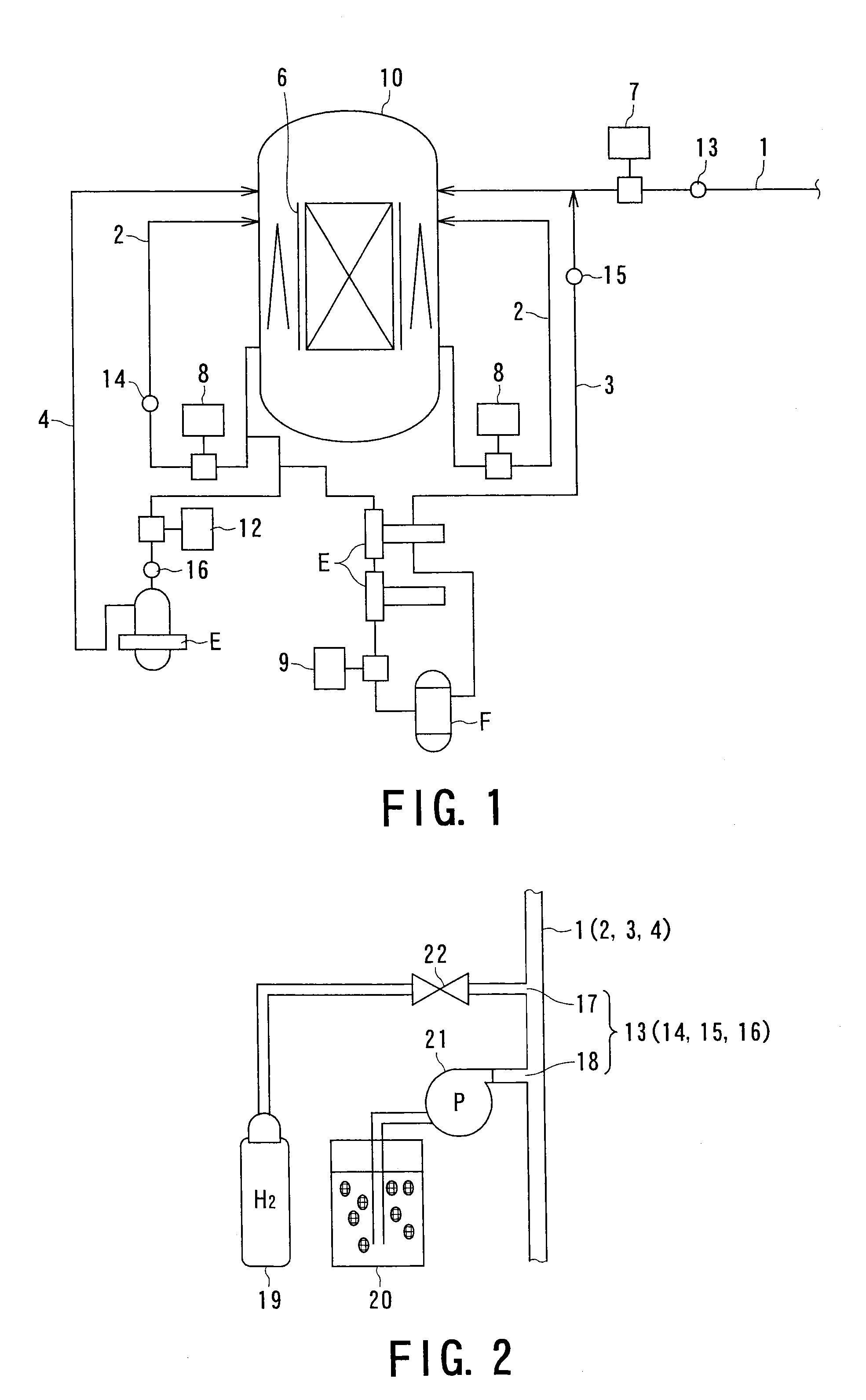

In a method of reducing corrosion of a material constituting a nuclear reactor structure, an electrochemical corrosion potential is controlled by injecting a solution or a suspension containing a substance generating an excitation current by an action of at least one of radiation, light, and heat existing in a nuclear reactor, or a metal or a metallic compound forming the substance generating the excitation current under the condition in the nuclear reactor to allow the substance generating the excitation current to adhere to the surface of the nuclear reactor structural material, and by injecting hydrogen in cooling water of the nuclear reactor while controlling the hydrogen concentration in a feed water.

Owner:TOSHIBA ENERGY SYST & SOLUTIONS CORP

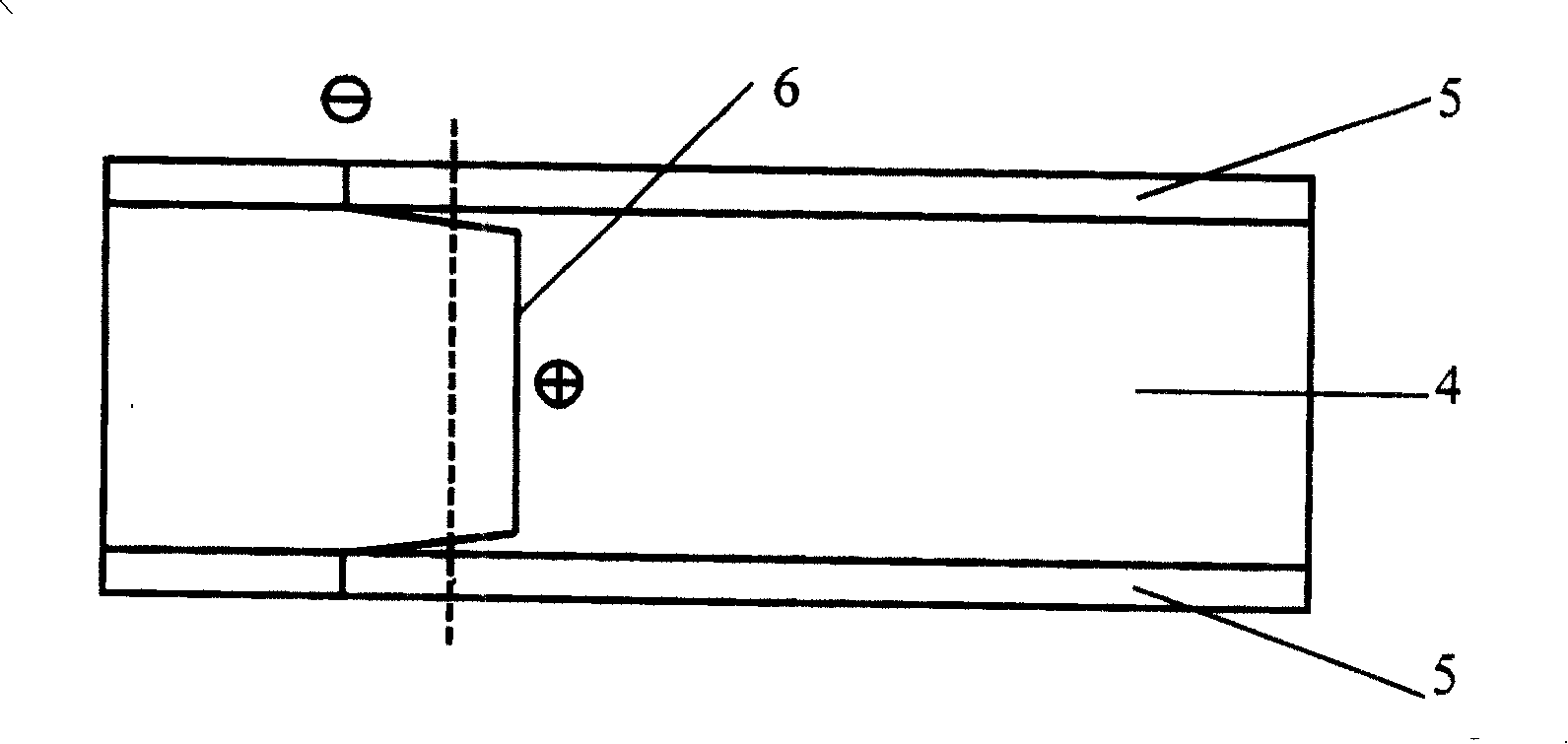

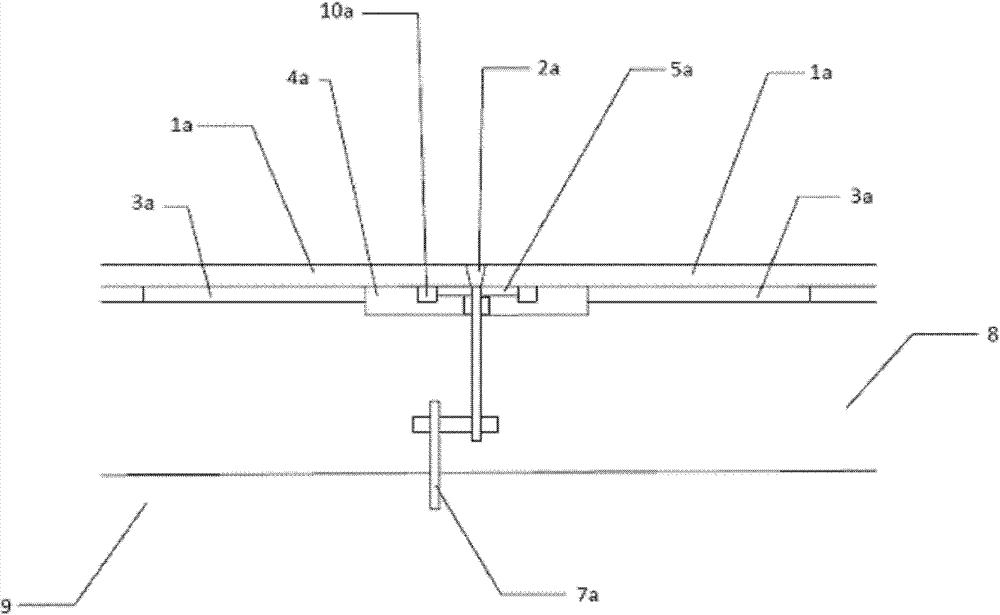

A connection method of pressure vessel nozzle and head to reduce welding residual stress

ActiveCN106112225BEnhanced resistance to stress corrosion crackingImproves Structural IntegrityWelding/cutting auxillary devicesArc welding apparatusManufacturing technologyWelding residual stress

The invention discloses a method for connecting a pressure vessel nozzle and a head for reducing welding residual stress, and belongs to the technical field of sealing vessel processing and manufacturing. It is characterized in that it includes the following steps: a. drilling the head and processing the connecting pipe (2); b. extending one end of the connecting pipe (2) into the pressure vessel (1); c. welding the sealing head and the connecting pipe (2); d. Preheat the welding seam (3) on one side of the pressure vessel (1), and then surfacing welding at the root of the connecting pipe (2) in the pressure vessel (1); e. After preheating the inner wall of the connecting pipe (2) Then surfacing welding on the inner wall of the connecting pipe (2); f, cutting the connecting pipe (2) in the pressure vessel (1); g, tempering the head. The pressure vessel nozzle and head connection method for reducing welding residual stress reduces the welding residual stress during the pressure vessel manufacturing process, improves the structural integrity of the pressure vessel, and enhances the stress corrosion cracking resistance of the pressure vessel nozzle welded joint.

Owner:JIANGSU GELAN ENVIRONMENTAL TECH CO LTD

Control rod for nuclear reactor and method of manufacturing control rod

ActiveUS20080205574A1Prevents stress corrosion crackingReduce activationNuclear energy generationReactors manufactureNuclear reactor coreNuclear reactor

A control rod for nuclear reactors includes four wings including neutron absorbers containing hafnium, a front end structural member which has a cross shape in cross section and includes brackets bonded to the leading ends of the wings, and a terminal end structural member which has a cross shape in cross section and includes brackets bonded to the tailing ends of the wings. The four wings are bonded to a wing-bonding member including a cross-shaped center shaft so as to form a cross shape. The front end structural member and the wing-bonding member are made of a zirconium alloy. The wings include neutron-absorbing plates having neutron-absorbing portions and each have an outer surface which is opposed to a fuel assembly and at which a hafnium-zircaloy composite member covered with zircaloy is disposed. The neutron-absorbing plates are opposed to each other with trap spaces disposed therebetween.

Owner:KK TOSHIBA

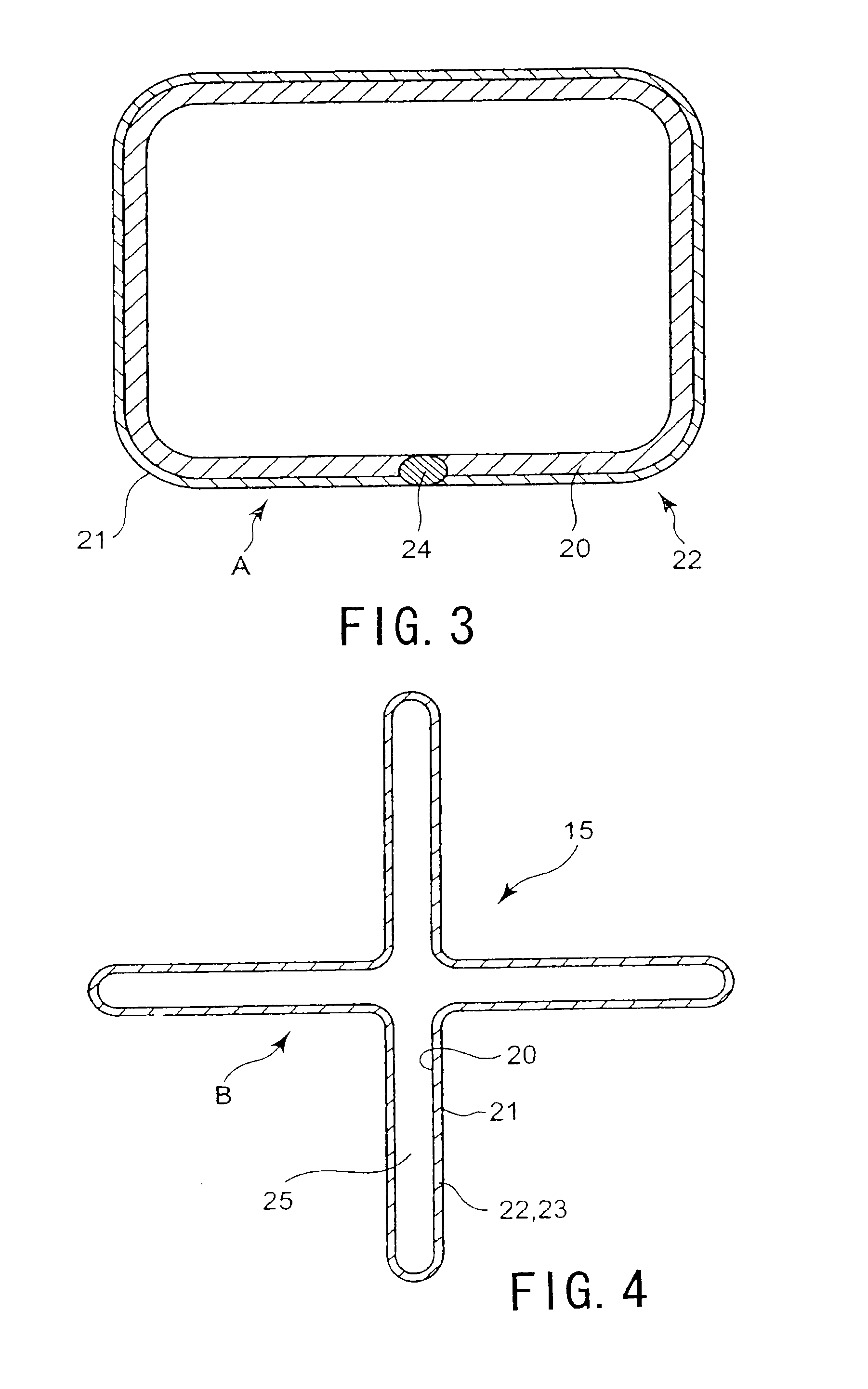

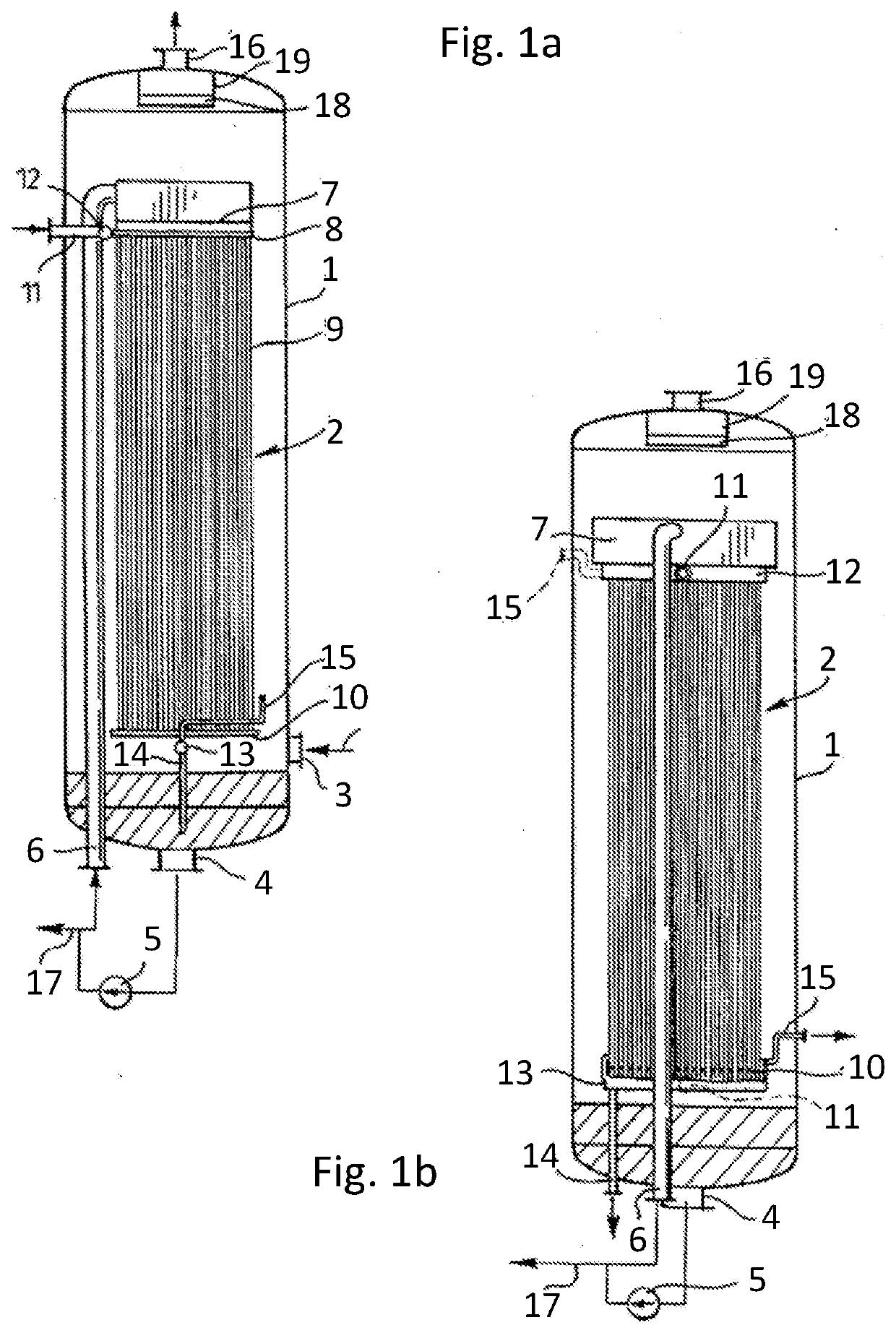

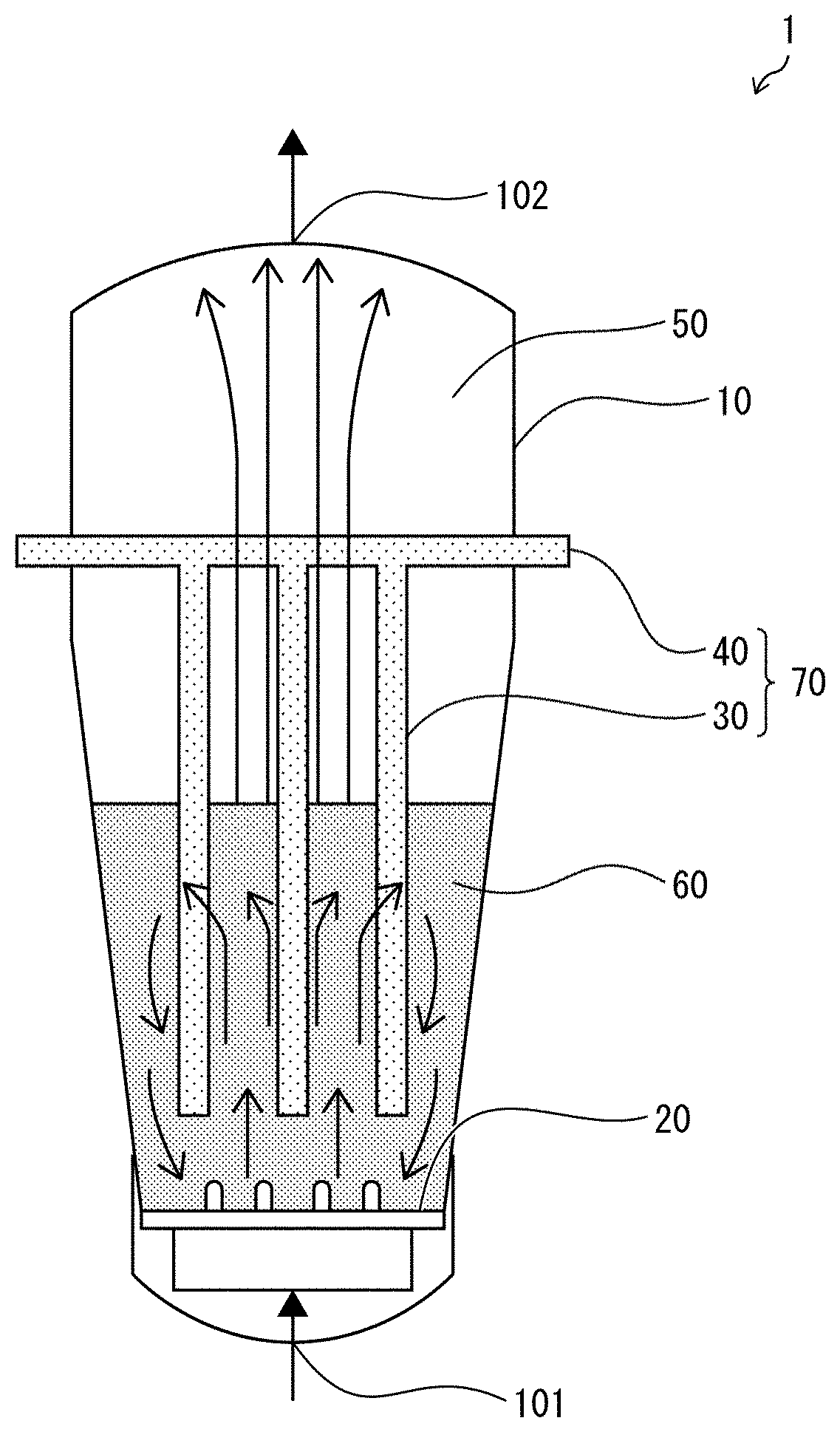

Reactor and production method of trichlorosilane

ActiveUS11241666B2Prevents stress corrosion crackingChemical/physical/physico-chemical processesHalogenated silanesFluidized bedPhysical chemistry

An object of the present invention is to prevent stress-corrosion cracking of a header (40) of a reactor. A reactor for producing trichlorosilane by causing metal silicon powder and a hydrogen chloride gas to react with each other includes a cooler (70), the cooler including a plurality of heat transfer medium pipes (30) and a header (40), the plurality of heat transfer medium pipes being provided in a fluid bed (60) inside the reactor, the header being provided in a freeboard section (50) inside the reactor, the header being comprised of a corrosion-resistant material.

Owner:TOKUYAMA CORP

Method of reducing corrosion of nuclear reactor structural material

ActiveUS20130070888A1Simple structurePrevents stress corrosion crackingPlant parameters regulationOptical rangefindersNuclear reactor coreHydrogen concentration

In a method of reducing corrosion of a material constituting a nuclear reactor structure, an electrochemical corrosion potential is controlled by injecting a solution or a suspension containing a substance generating an excitation current by an action of at least one of radiation, light, and heat existing in a nuclear reactor, or a metal or a metallic compound forming the substance generating the excitation current under the condition in the nuclear reactor to allow the substance generating the excitation current to adhere to the surface of the nuclear reactor structural material, and by injecting hydrogen in cooling water of the nuclear reactor while controlling the hydrogen concentration in a feed water.

Owner:TOSHIBA ENERGY SYST & SOLUTIONS CORP

Dual-phase stainless steel, and method of production thereof

ActiveUS20190211416A1High strengthProduction cost be reduceFurnace typesHeat treatment furnacesSulfide stress crackingAustenitic stainless steel

Provided herein is a dual-phase stainless steel having excellent carbon dioxide corrosion resistance, excellent sulfide stress corrosion cracking resistance, and excellent sulfide stress cracking resistance. The dual-phase stainless steel contains, in mass %, C: 0.03% or less, Si: 1.0% or less, Mn: 0.10 to 1.5%, P: 0.030% or less, S: 0.005% or less, Cr: 20.0 to 30.0%, Ni: 5.0 to 10.0%, Mo: 2.0 to 5.0%, Cu: 2.0 to 6.0%, N: less than 0.07%, and the balance Fe and unavoidable impurities, and has a structure that is 20 to 70% austenite phase, and 30 to 80% ferrite phase in terms of a volume fraction.

Owner:JFE STEEL CORP

Reactor and production method of trichlorosilane

ActiveUS20200306714A1Prevents stress corrosion crackingChemical/physical/physico-chemical processesHalogenated silanesFluidized bedPhysical chemistry

An object of the present invention is to prevent stress-corrosion cracking of a header (40) of a reactor. A reactor for producing trichlorosilane by causing metal silicon powder and a hydrogen chloride gas to react with each other includes a cooler (70), the cooler including a plurality of heat transfer medium pipes (30) and a header (40), the plurality of heat transfer medium pipes being provided in a fluid bed (60) inside the reactor, the header being provided in a freeboard section (50) inside the reactor, the header being comprised of a corrosion-resistant material.

Owner:TOKUYAMA CORP

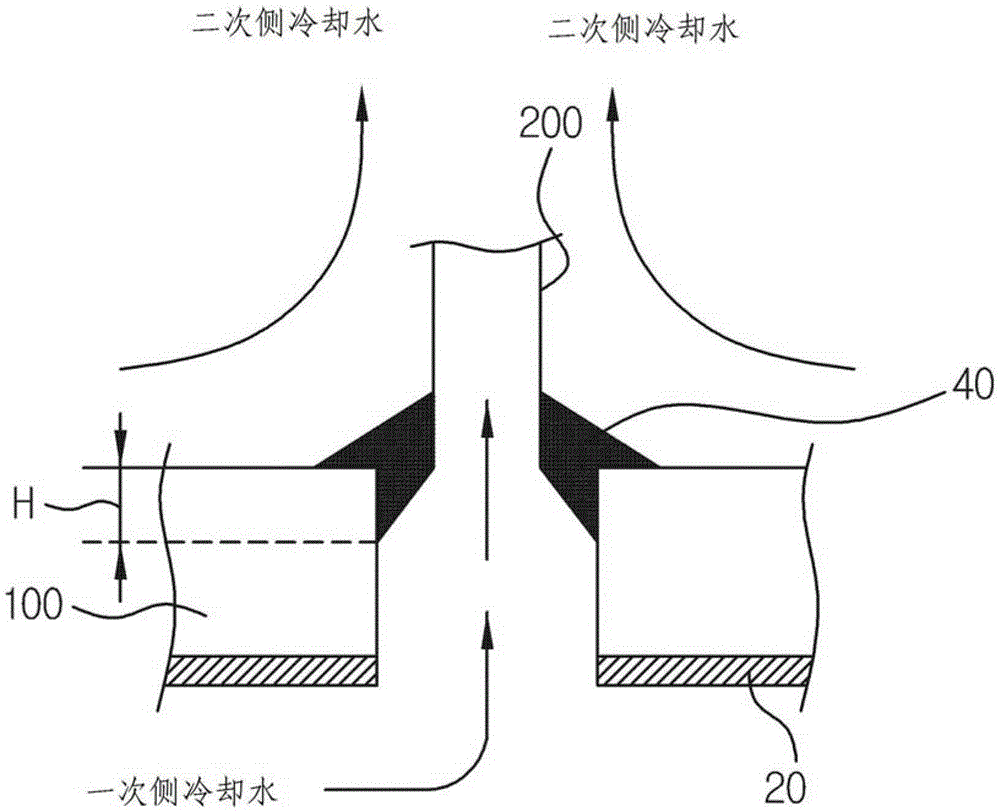

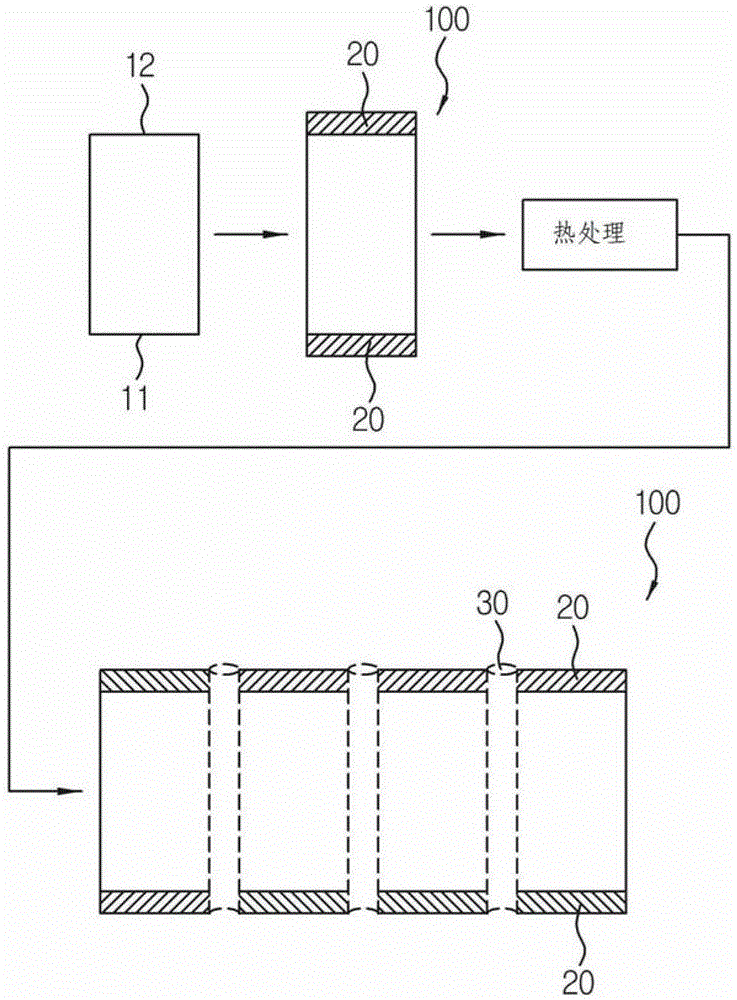

Steam generator tube sheet with anti-corrosion layer and preparation method thereof

InactiveCN103629655BAvoid corrosionPrevents stress corrosion crackingBoiler supporting/setting arrangementsNuclear energy generationBiochemical engineeringEngineering

The invention relates to a tube plate of a steam generator and a preparation method thereof. The tube plate of the steam generator supports heat transfer tubes of the steam generator. In particular, it relates to a steam generator tube plate with an anti-corrosion layer and a preparation method thereof. Specifically, the steam generator tube sheet with an anti-corrosion layer includes: a steam generator tube sheet, which supports the heat transfer tube of the vaporizer; and a corrosion-resistant metal, which is plated on the surface of the primary side tube sheet and the surface of the secondary side tube sheet superior. In addition, a method for preparing a steam generator tube sheet with an anti-corrosion layer includes the steps of: coating the surface of the primary side tube sheet and the surface of the secondary side tube sheet with a corrosion-resistant metal; heat-treating the above-mentioned coated tube sheet; and drilling holes, forming heat transfer tube mounting holes on the heat-treated tube sheet; thereby inhibiting the corrosion of the surface of the primary side tube sheet and the surface of the secondary side tube sheet, and preventing the depression and stress corrosion cracking of the heat transfer tube, thereby improving The reliability of the steam generator.

Owner:KOREA HYDRO & NUCLEAR POWER CO LTD +1

A nuclear facility stainless steel cladding structure and construction technology

ActiveCN104018637BPrevents stress corrosion crackingReduced seal does not leakCovering/liningsQuality levelMaterials science

The invention belongs to the field of building structures, and in particular relates to a nuclear facility stainless steel cladding structure and a construction process. The stainless steel cladding structure includes stainless steel cladding, connectors, anchors, ceramic components and concrete, wherein the ceramic components are located between the stainless steel cladding and the concrete for use. The stainless steel cladding and concrete are isolated from each other. After adopting the nuclear facility stainless steel cladding structure of the present invention, the construction process can be simplified, the construction quality level can be improved, the construction period of the nuclear facility stainless steel cladding can be shortened, and the corrosion leakage of the stainless steel cladding can be reduced.

Owner:CHINA NUCLEAR POWER ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com