A connection method of pressure vessel nozzle and head to reduce welding residual stress

A pressure vessel, residual stress technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of insufficient elimination of residual stress, large energy and time consumption, inconvenient operation, etc., to enhance the resistance to stress corrosion. Cracking ability, prevent stress corrosion cracking, improve the effect of structural integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The pressure vessel joint and head connection method for reducing welding residual stress includes the following steps:

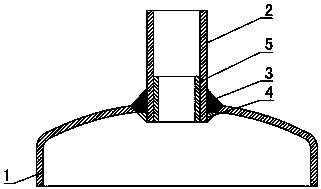

[0033] Such as figure 1 Shown as: a. Open the head of the pressure vessel 1, and process the connecting pipe 2 according to the size of the opening;

[0034] The materials of pressure vessel 1 head and connecting pipe 2 are 304 stainless steel. The thickness of the head of the pressure vessel 1 is 10mm, and the head type is an elliptical head. The head is drilled according to the GB150 pressure vessel manufacturing standard, and the hole is a single-side V-shaped groove. Process the connecting pipe 2 according to the size of the opening, the wall thickness of the connecting pipe 2 is 8mm, and the gap between the outer wall of the connecting pipe 2 and the inner wall of the opening is less than 1mm.

[0035] b. Pass one end of the connecting pipe 2 through the opening of the head and extend into the pressure vessel 1;

[0036] One end of the connec...

Embodiment 2

[0049] The pressure vessel joint and head connection method for reducing welding residual stress includes the following steps:

[0050] a. Open the head of the pressure vessel 1, and process the connecting pipe 2 according to the size of the opening;

[0051] The material of pressure vessel 1 head and connecting pipe 2 is Q345R. The thickness of the head of the pressure vessel 1 is 16mm, and the head type is an elliptical head. The head is drilled according to the GB150 pressure vessel manufacturing standard, and the hole is a K-shaped bevel. Process the connecting pipe 2 according to the size of the opening, the wall thickness of the connecting pipe 2 is 10mm, and the gap between the outer wall of the connecting pipe 2 and the inner wall of the opening is less than 1mm.

[0052] b. Pass one end of the connecting pipe 2 through the opening of the head and extend into the pressure vessel 1;

[0053] One end of the connecting pipe 2 is passed through the opening and deep into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com