Connecting method of pressure vessel connecting pipe and sealing head for reducing welding residual stress

A pressure vessel and residual stress technology, which is applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems that residual stress cannot be fully eliminated, consumes a lot of energy and time, and is inconvenient to operate, so as to achieve enhanced stress corrosion resistance Cracking ability, prevention of stress corrosion cracking, effect of improving structural integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The pressure vessel joint and head connection method for reducing welding residual stress includes the following steps:

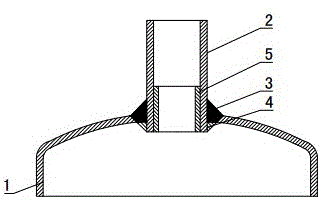

[0033] Such as figure 1 Shown as: a. Open the head of the pressure vessel 1, and process the connecting pipe 2 according to the size of the opening;

[0034] The materials of pressure vessel 1 head and connecting pipe 2 are 304 stainless steel. The thickness of the head of the pressure vessel 1 is 10mm, and the head type is an elliptical head. The head is drilled according to the GB150 pressure vessel manufacturing standard, and the hole is a single-side V-shaped groove. Process the connecting pipe 2 according to the size of the opening, the wall thickness of the connecting pipe 2 is 8mm, and the gap between the outer wall of the connecting pipe 2 and the inner wall of the opening is less than 1mm.

[0035] b. Pass one end of the connecting pipe 2 through the opening of the head and extend into the pressure vessel 1;

[0036] One end of the connec...

Embodiment 2

[0049] The pressure vessel joint and head connection method for reducing welding residual stress includes the following steps:

[0050] a. Open the head of the pressure vessel 1, and process the connecting pipe 2 according to the size of the opening;

[0051] The material of pressure vessel 1 head and connecting pipe 2 is Q345R. The thickness of the head of the pressure vessel 1 is 16mm, and the head type is an elliptical head. The head is drilled according to the GB150 pressure vessel manufacturing standard, and the hole is a K-shaped bevel. Process the connecting pipe 2 according to the size of the opening, the wall thickness of the connecting pipe 2 is 10mm, and the gap between the outer wall of the connecting pipe 2 and the inner wall of the opening is less than 1mm.

[0052] b. Pass one end of the connecting pipe 2 through the opening of the head and extend into the pressure vessel 1;

[0053] One end of the connecting pipe 2 is passed through the opening and deep into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com