Steam generator tube sheet with anti-corrosion layer and preparation method thereof

A technology of steam generator and anti-corrosion layer, which is applied in the direction of steam generation, steam boiler, steam boiler accessories, etc., can solve problems such as sag, and achieve the effects of easy preparation process, improved advancement, and reduced tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

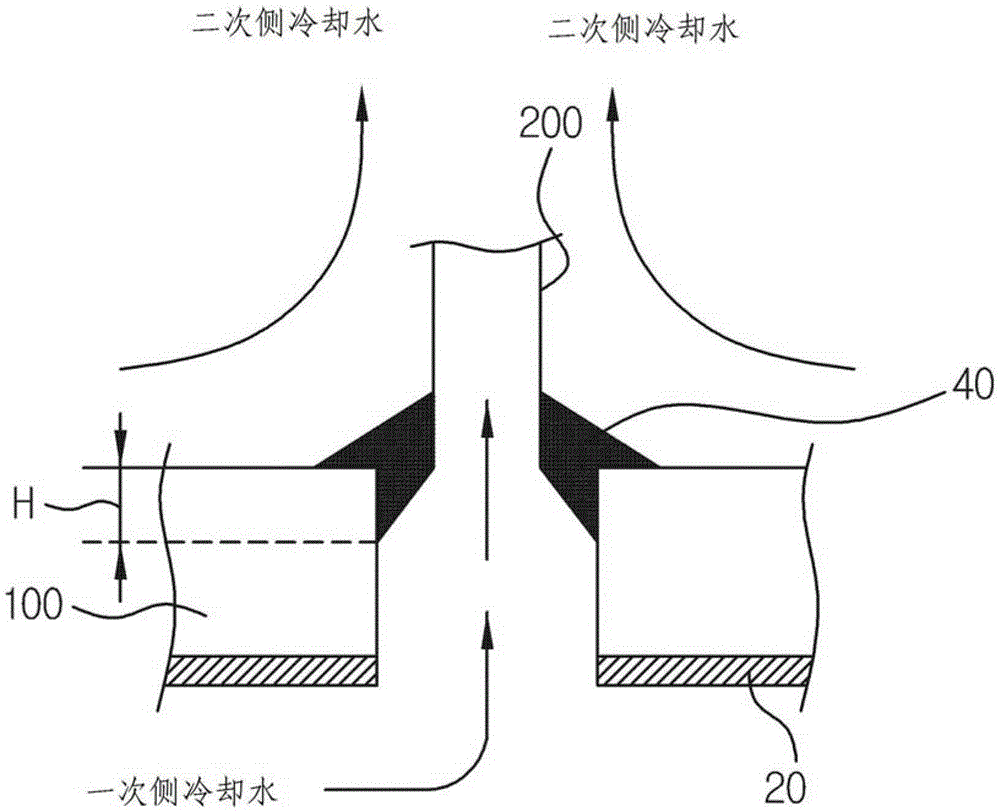

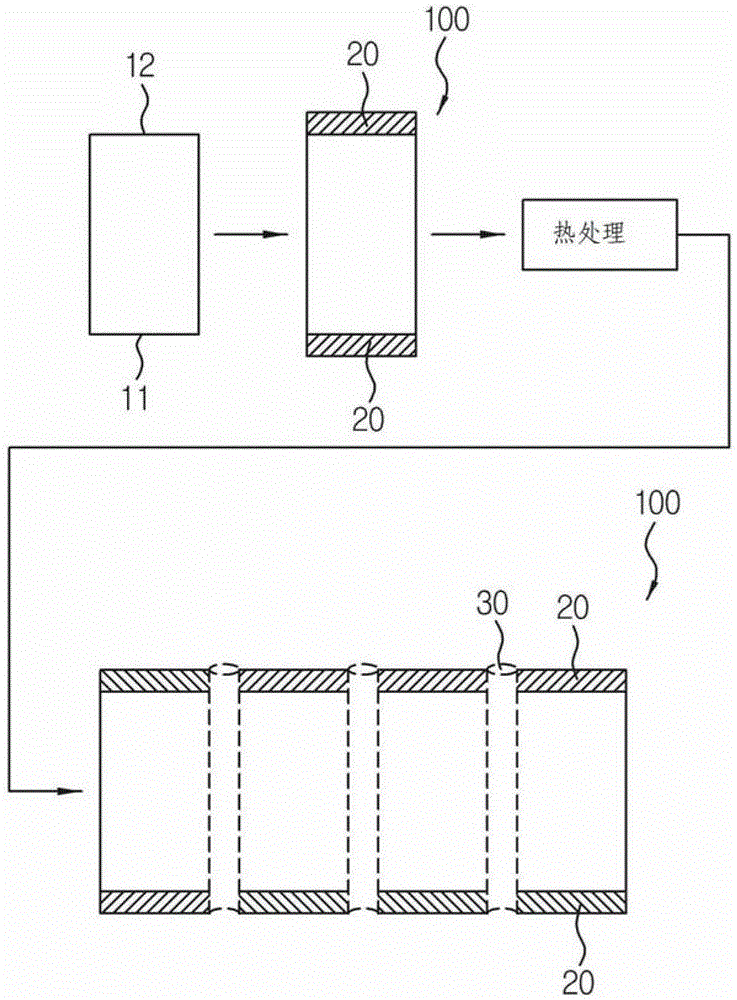

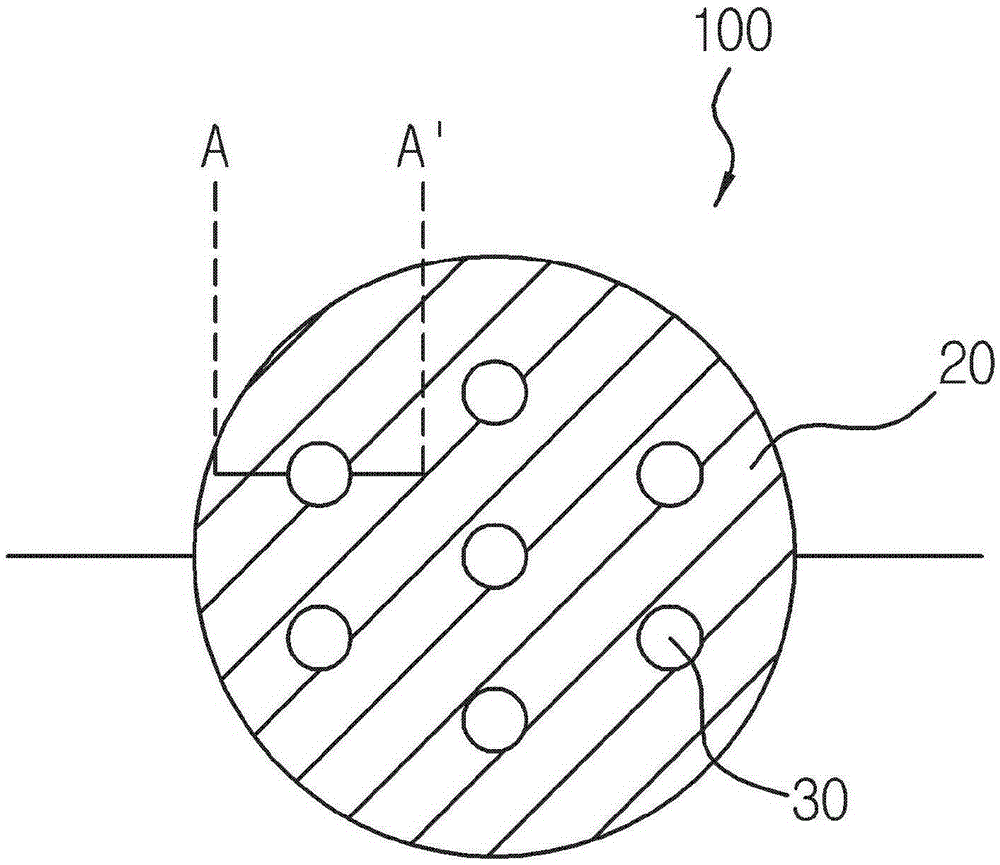

[0047] refer to figure 2 , the preparation method of the steam generator tube plate 100 is as follows, and the steam generator tube plate 100 supports the heat transfer tubes 200 of the steam generator. The method for the tube sheet 100 of the vaporizer having an anti-corrosion layer of the present invention comprises the following steps: providing a steam generator tube sheet 100 of a certain thickness; plating the primary side tube sheet surface 11 and the secondary side tube sheet surface with a corrosion-resistant metal 20 12. Perform heat treatment on the above-mentioned plated steam generator tube plate 100; drill holes to form heat transfer tube installation holes 30 on the above-mentioned heat-treated steam generator tube plate 100.

[0048] The preparation method of the steam generator tube sheet 100 with an anti-corrosion layer of the present invention is prepared through the following steps, that is, preparing a steam generator tube sheet 100 of a certain thickness...

Embodiment

[0060] Figure 5 ~ Figure 7 Alloy 690, one of the corrosion-resistant metals 20 used for plating, and SA508Cl. The result of the comparison. Figure 5 It is the result of measuring and comparing the electrochemical corrosion rates of alloy 690 and SA508Cl.3 when the pH of the test solution is 2; Image 6 It is the result of measuring and comparing the electrochemical corrosion rates of alloy 690 and SA508Cl.3 when the pH of the test solution is 7; Figure 7 It is the result of measuring and comparing the electrochemical corrosion rates of alloy 690 and SA508Cl.3 when the pH of the test solution is 12.

[0061] refer to Figure 5 It can be seen that when the pH of the test solution is 2, the electrochemical corrosion rate of alloy 690 is reduced to 1 / 145 compared with SA508Cl.3 which is the material of the conventional tube sheet 100 . refer to Image 6 It can be seen that when the pH of the test solution is 7, the electrochemical corrosion rate of alloy 690 is reduced to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com