A nuclear facility stainless steel cladding structure and construction technology

A construction technology, stainless steel technology, applied in covering/lining, building structure, construction, etc., can solve the problems of difficulty in ensuring the cleanliness of the back of the stainless steel cladding, economic loss, high dryness requirements, etc., and achieve long-term stability. , To ensure the quality of radiographic inspection, to ensure the effect of construction cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

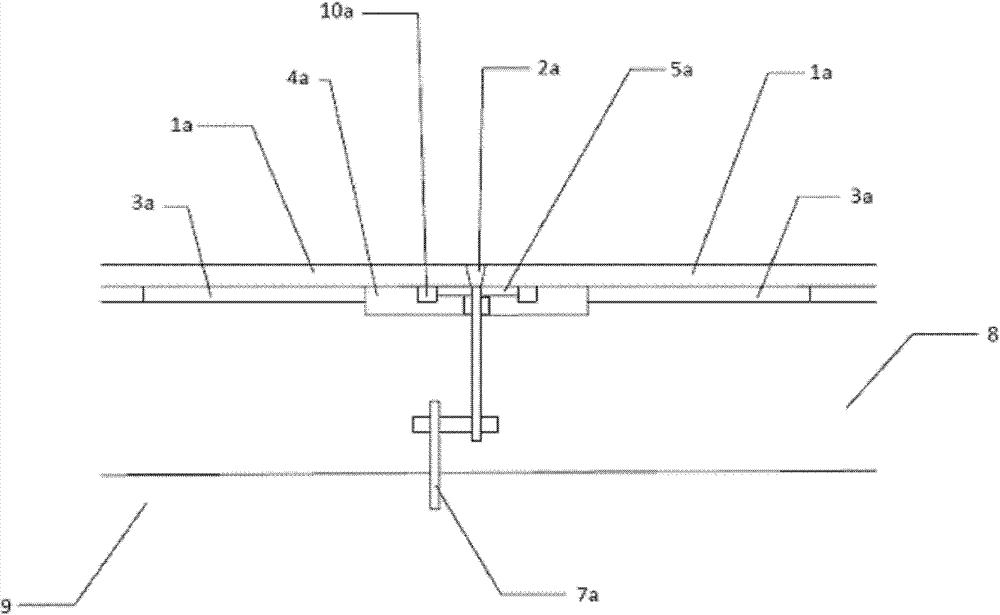

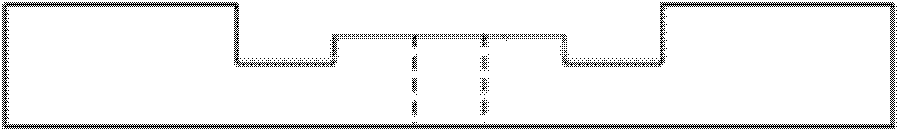

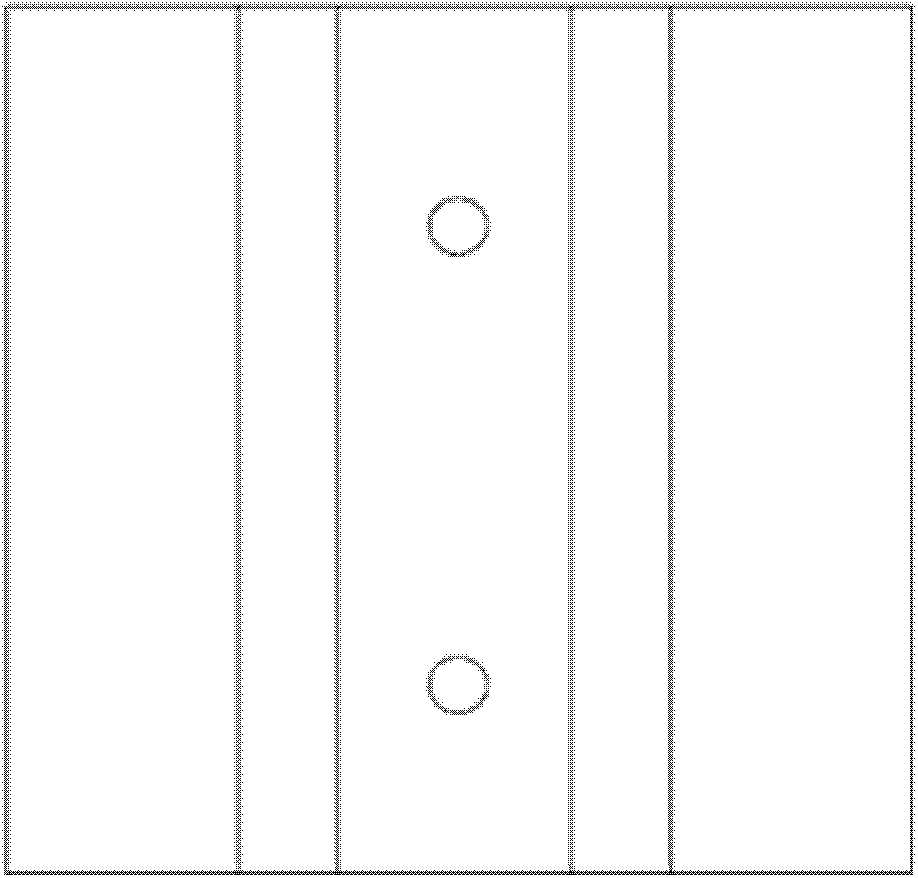

[0054] Such as figure 1 As shown, the nuclear facility stainless steel cladding structure provided in this embodiment includes a primary concrete foundation 9 and a secondary concrete 8, and a stainless steel cladding anchor 7a is installed on the primary concrete foundation 9, and the stainless steel cladding anchor 7a extends upward and passes through the secondary concrete. Concrete 8. The upper surface of the secondary concrete 8 is paved with ceramic components. The ceramic components are divided into common ceramic components 3a, ceramic components 4a at the lower part of the stainless steel cladding and spliced welds, and some special-shaped ceramic components. Ordinary ceramic components 3a are square, and special-shaped ceramic components can be laid on the corners of the pool or around the embedded parts of the pool as required. The structure of the ceramic member 4a at the bottom of the stainless steel cladding installation stitching weld is as follows figure 2...

Embodiment 2

[0062] Such as Figure 5 As shown, the nuclear facility stainless steel cladding structure provided in this embodiment includes a primary concrete foundation 9 and a secondary concrete 8. A stainless steel cladding anchor 7b is installed on the primary concrete foundation 9, and the stainless steel cladding anchor 7b extends upward and passes through the secondary concrete. Concrete 8. In this embodiment, the stainless steel cladding anchors 7b can be arranged in pairs. The upper surface of the secondary concrete 8 is paved with ceramic components. The ceramic components are divided into ordinary ceramic components 3b, ceramic components 4b at the lower part of the stainless steel cladding and spliced weld, and some ceramic components with special shapes suitable for special parts. Ordinary ceramic components 3b are square, and special-shaped ceramic components can be laid on the corners of the pool or around the embedded parts of the pool as required. The structure of the...

Embodiment 3

[0070] Such as Figure 9 As shown, the nuclear facility stainless steel cladding structure provided in this embodiment includes primary concrete foundation 9 and secondary concrete 8, and stainless steel cladding anchor 7c is installed on primary concrete foundation 9, and stainless steel cladding anchor 7c extends upward and passes through secondary concrete. Concrete 8. The upper surface of the secondary concrete 8 is paved with ceramic components. The ceramic components are divided into common ceramic components 3c, ceramic components 4c at the lower part of the stainless steel cladding and splicing welds, and some special-shaped ceramic components. Ordinary ceramic components 3c are square, and special-shaped ceramic components can be laid on the corners of the pool or around the embedded parts of the pool as required. The structure of the ceramic component 4c at the lower part of the stainless steel cladding installation stitching weld is as follows Figure 10 , Figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com