Patents

Literature

70results about How to "Improved stress crack resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

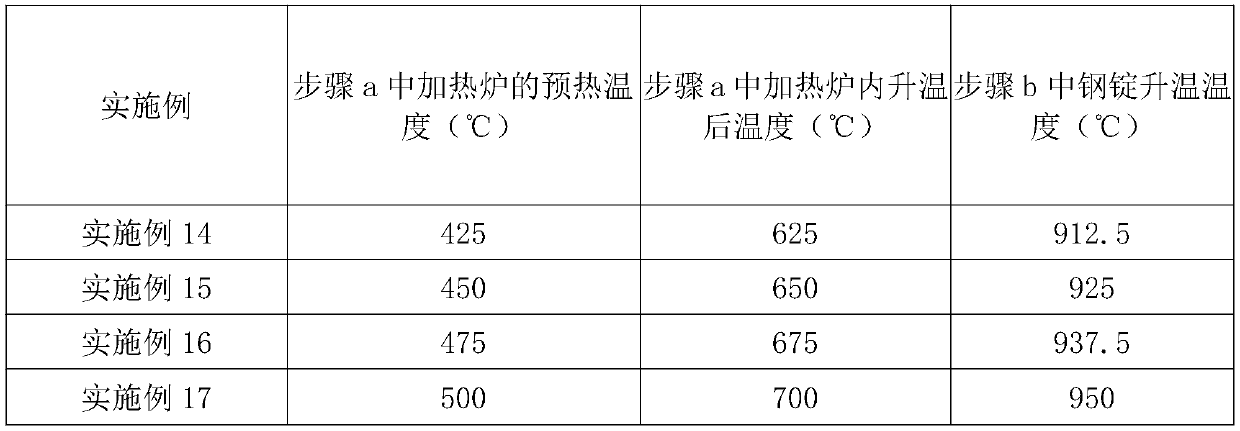

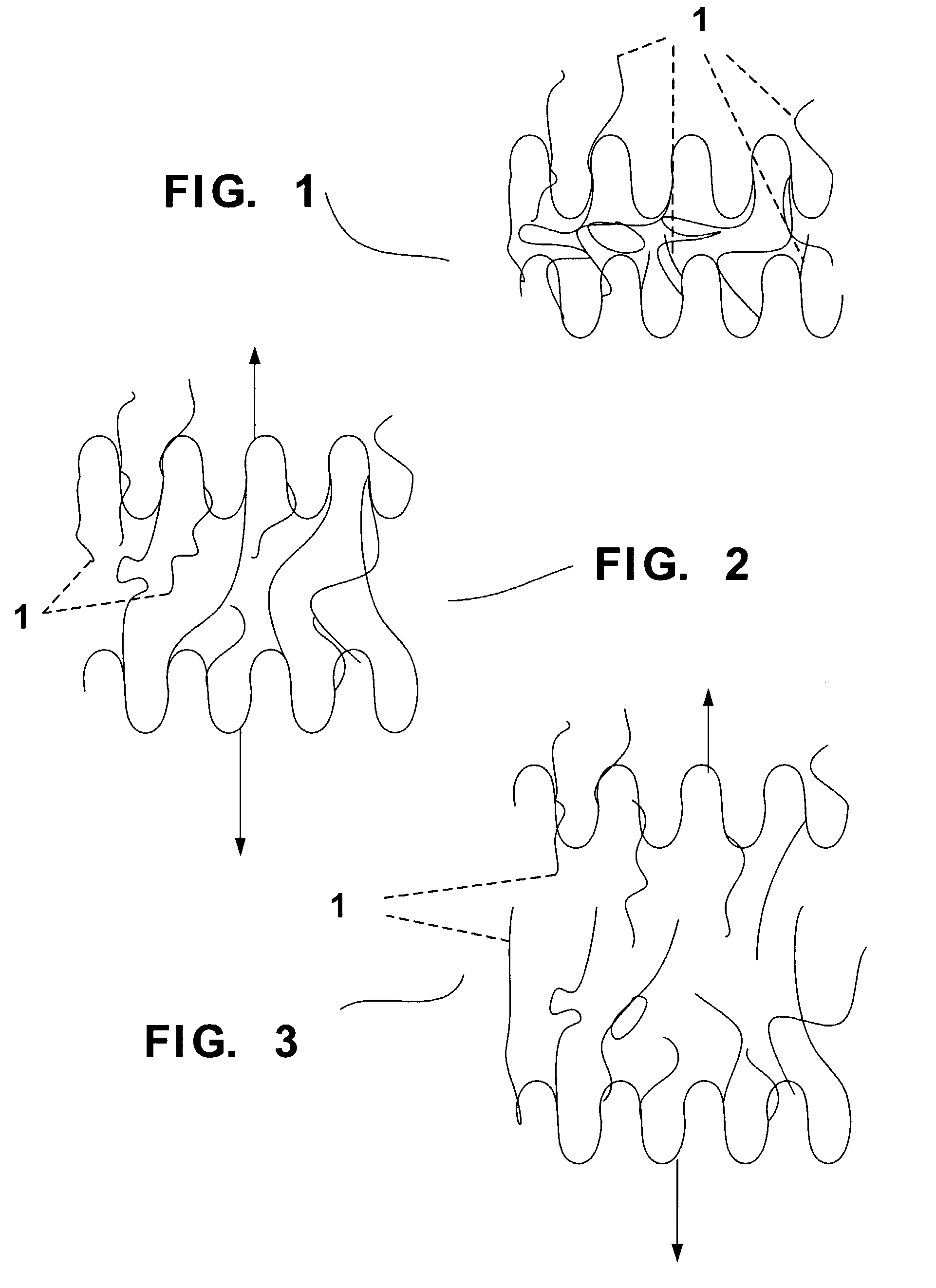

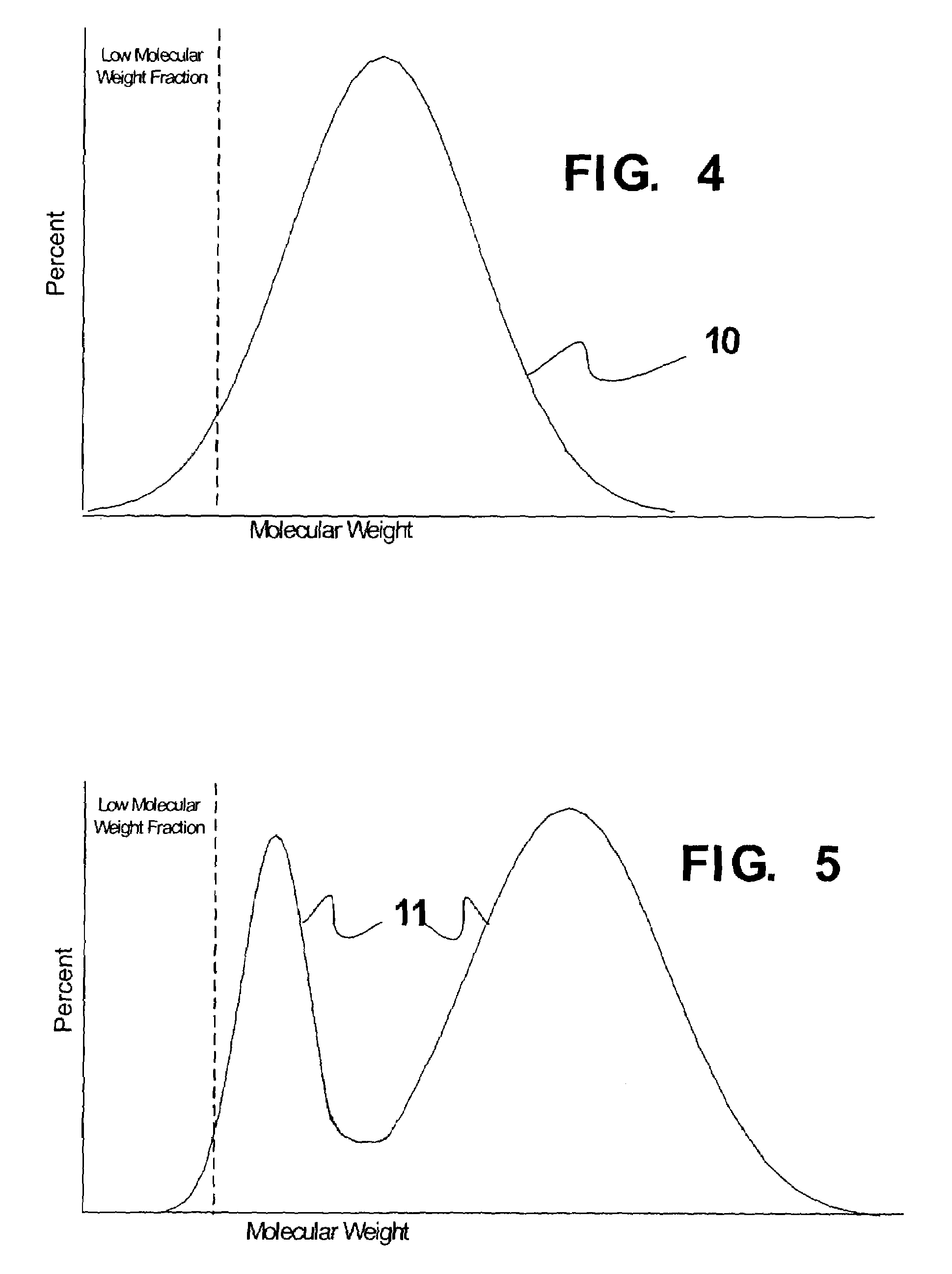

Melt blended high density polyethylene compositions with enhanced properties and method for producing the same

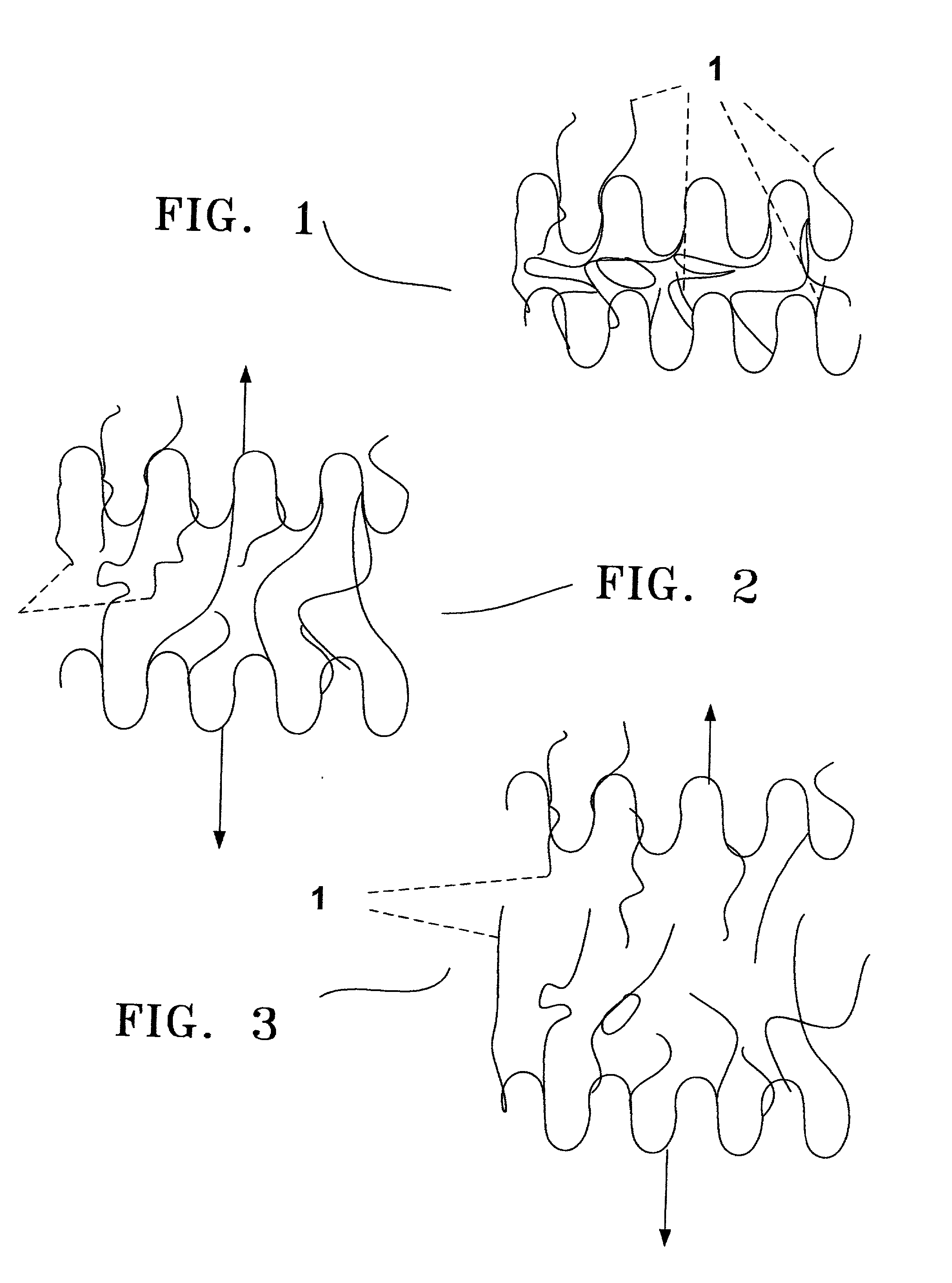

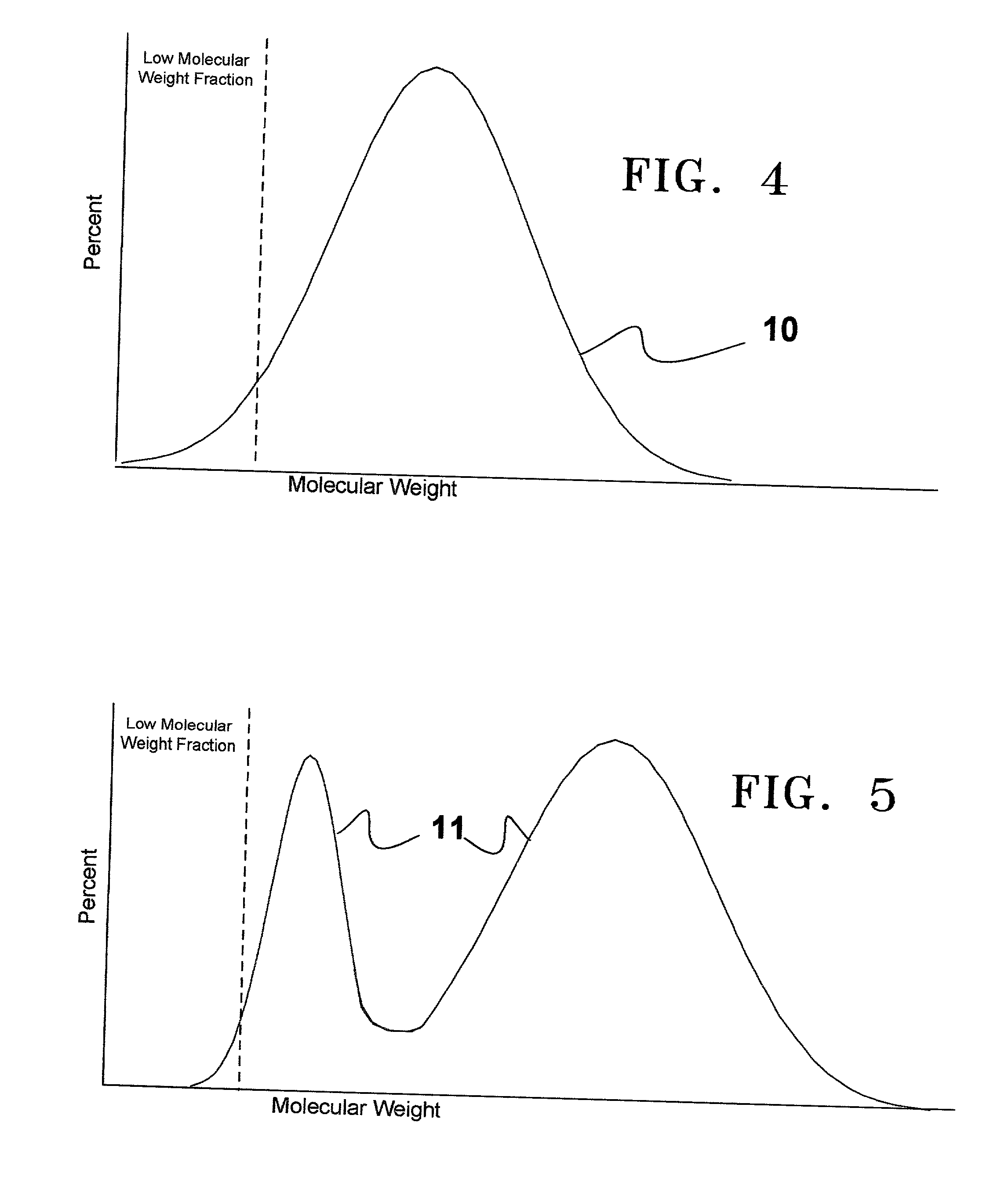

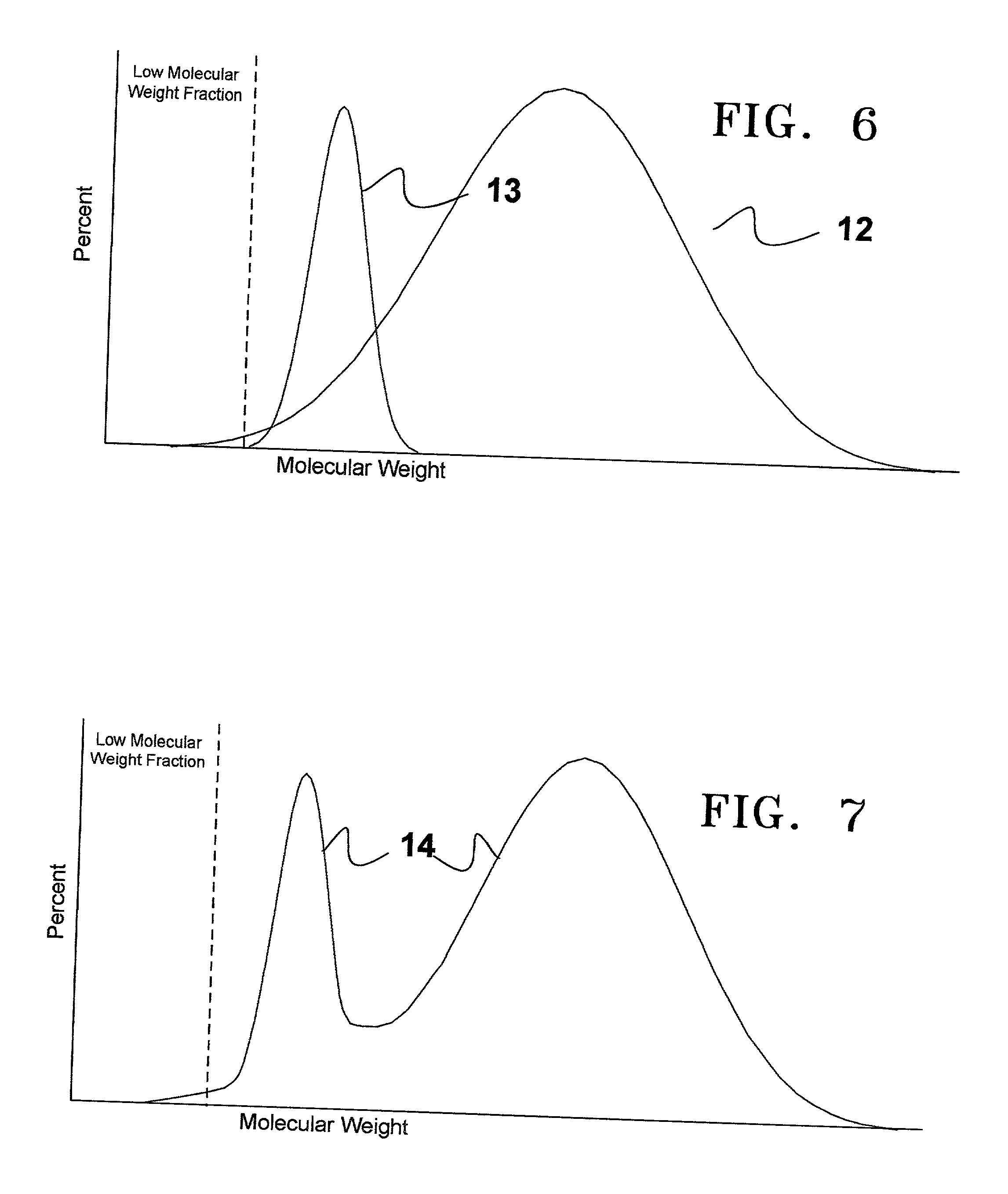

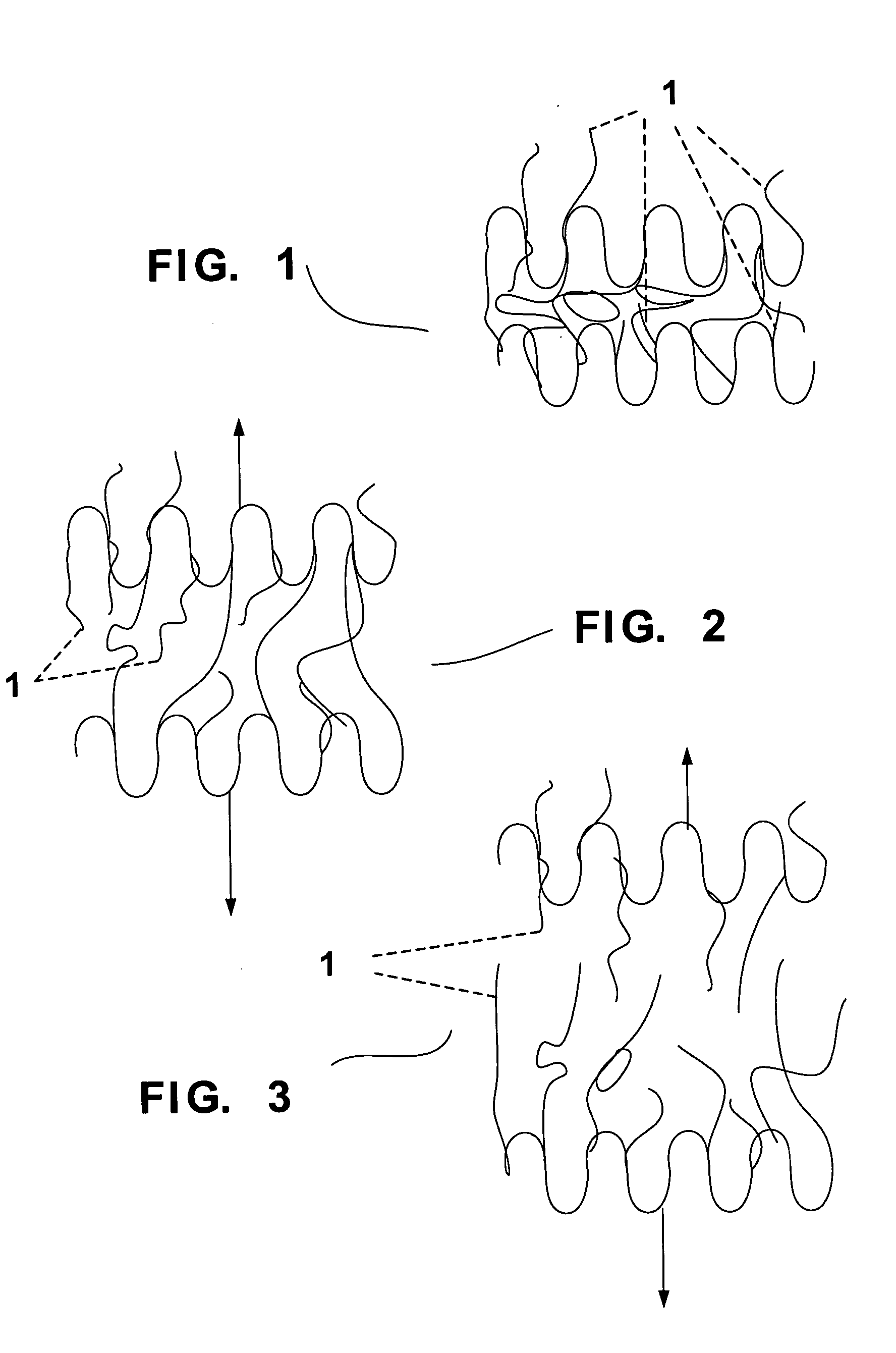

Melt blended HDPE compositions for single and dual wall corrugated HDPE pipe and associated fabricated and molded fittings and accessories with enhanced physical properties and processing and environmental stress crack resistance (ESCR) characteristics and associated blend methods are disclosed in which virgin or recycled homopolymer and / or copolymer HDPE resin components are blended. The invention discloses methods for 1) selecting and determining the relative weight fractions of the HDPE blending components that provide specific physical properties and processability of HDPE blended compositions associated with density and melt index respectively and specific values of environmental stress crack resistance (ESCR) associated with specific molecular parameters and 2) for determining from molecular parameters, the ESCR of linear polyethylene resins and blended compositions within a class having similar densities. The invention reduces the cost of raw materials to corrugated HDPE pipe manufacturers by enabling the use of virgin prime commodity HDPE resins and / or wide and off specification prime HDFE resins in place of single stream specialty HDPE resins and favorably impacts the environment by providing the capability of utilizing recycled HDPE resins in place of prime HDPE resins in the manufacture of corrugated HDPE pipe.

Owner:CORRUGATEDD POLYETHYLENE PIPE

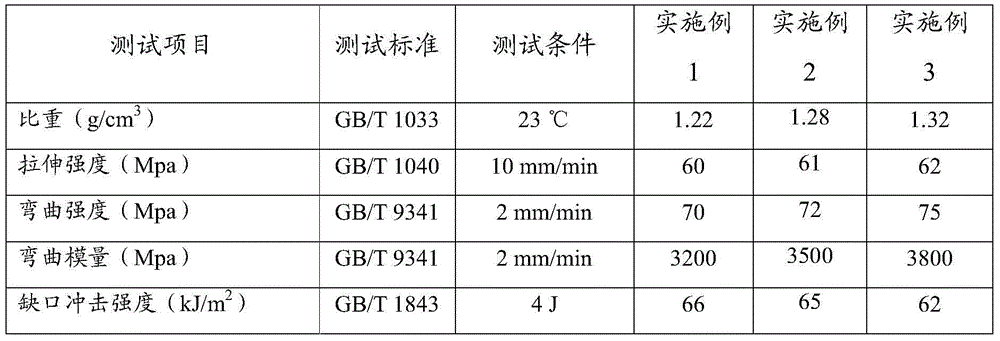

Polycarbonate/acrylonitrile-styrene-acrylate copolymer alloy material and preparation method thereof

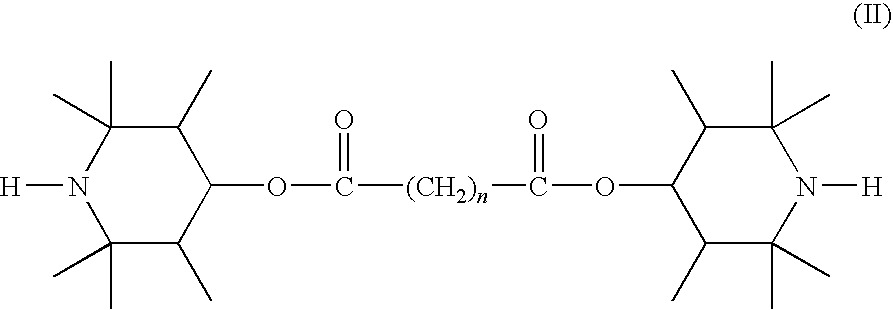

InactiveCN102399424AImprove processing fluidityImproved stress crack resistanceAcrylonitrileUltraviolet lights

The invention relates to a polycarbonate / acrylonitrile-styrene-acrylate copolymer alloy material and a preparation method thereof. The polycarbonate / acrylonitrile-styrene-acrylate copolymer alloy material is prepared mainly from 40 to 70 parts by weight of polycarbonate (PC), 20 to 50 parts by weight of acrylonitrile-styrene-acrylate copolymer (ASA), 2 to 10 parts by weight of a compatilizer, 3 to 15 parts by weight of a flexibilizer, 0.1 to 0.8 parts by weight of anti-oxidants, 0.5 to 5 parts by weight of a lubricant, 0.2 to 1 part by weight of an ultraviolet light absorber and 0.2 to 1.5 parts by weight of teflon through melt blending extrusion. The polycarbonate / acrylonitrile-styrene-acrylate copolymer alloy material obtained by the preparation method has good comprehensive mechanical properties, processing properties and weatherability, and is especially suitable for manufacture of interior and exterior trim parts of automobiles.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Composition with increased stress cracking resistance

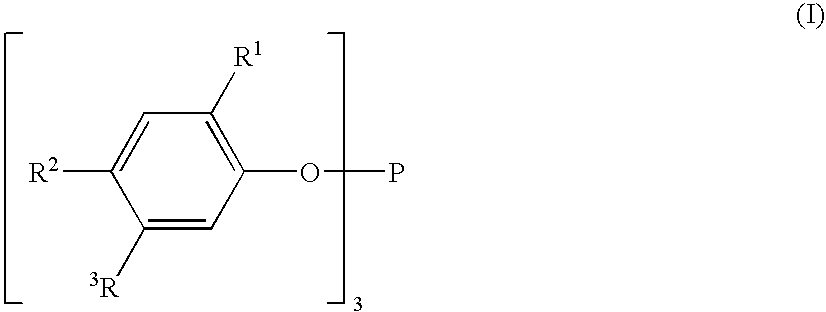

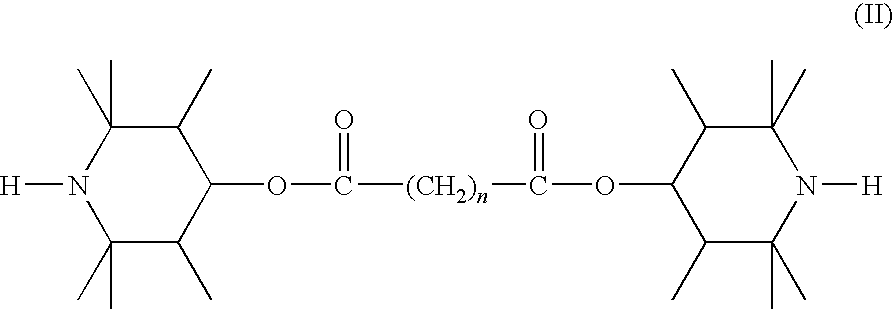

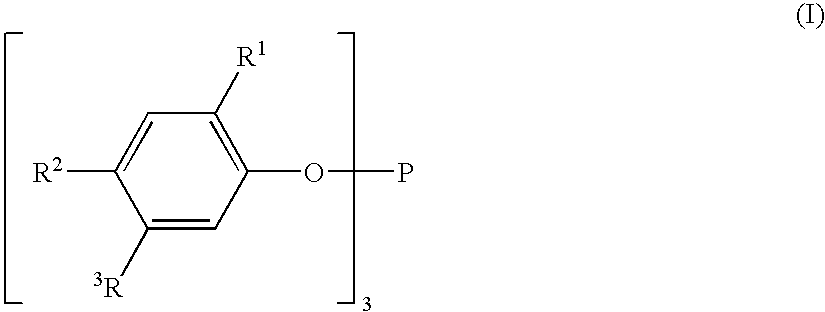

InactiveUS20100174022A1Improved stress crack resistanceImprove heat deformation resistanceInksOrganic dyesMeth-Crack resistance

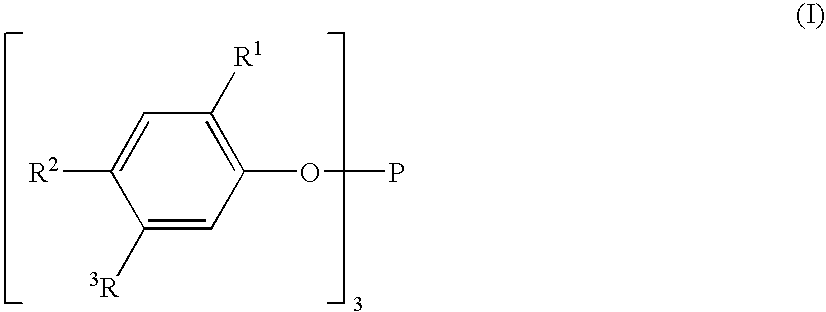

Composition containing, based in each case on its total weight,A) 50.0% by weight to 99.5% by weight of at least one (meth)acrylate (co)polymer andB) 0.5% by weight to 50.0% by weight of at least one copolymer obtainable by polymerisation of a monomer mixture comprisingi. 70% by weight to 92% by weight of a vinylaromatic monomer andii. 8% by weight to 30% by weight of acrylonitrile or methacrylonitrile or mixtures thereof andiii. 0% by weight to 22% by weight of at least one further monomer, the composition having a haze according to ASTM D1003 of less than 2.0% at 23° C. and a haze according to ASTM D1003 of less than 4.0% at 40° C. and the composition containing at least one (meth)acrylate (co)polymer a) having a solution viscosity in chloroform at 25° C. (ISO 1628—part 6) of greater than 55 ml / g.The mouldings obtainable from the composition are distinguished in particular by improved stress cracking resistance and are suitable in particular for coverings, finishes or films.

Owner:EVONIK ROEHM GMBH

Coloured composition with increased stress cracking resistance

InactiveUS20100148401A1Improved stress crack resistanceImprove heat deformation resistanceOrganic dyesCeramic shaping apparatusCrack resistanceMeth-

The invention relates to a composition containing, in relation to the total weight of said composition, A) between 50.0% by weight and 99.5% by weight of at least one (meth)acrylate (co)polymer and B) between 0.5% by weight and 50.0% by weight of at least one copolymer, obtained by the polymerisation of a monomer mixture consisting of i. between 70% by weight and 92% by weight of a vinyl aromatic monomer and ii. between 8% by weight and 30% by weight of acryl nitrile or methacryl nitrile or mixtures thereof iii. between 0% by weight and 22% by weight of at least one other monomer, the composition having at 50° C. a ΔE of less than 0.15, ΔE being defined according to the relationship (1): (1) in which ΔL*: the modification of the colour co-ordinates L* compared with the colour co-ordinates L* at 23° C., Δa*: the modification of the colour co-ordinates a* compared with the colour co-ordinates a* at 23° C., Δb*: the modification of the colour co-ordinates b* compared to the colour co-ordinates b* at 23° C., and the composition contains at least one (meth)acrylate (co)polymer a) with a solution viscosity in chloroform at 25° C. (ISO 1628 part 6) greater than 55 ml / g. The moulded bodies that can be obtained from the composition are characterised in particular by improved stress cracking resistance and are suitable in particular for use in coatings, paints or films.

Owner:EVONIK ROEHM GMBH

Melt blended high-density polyethylene compositions with enhanced properties and method for producing the same

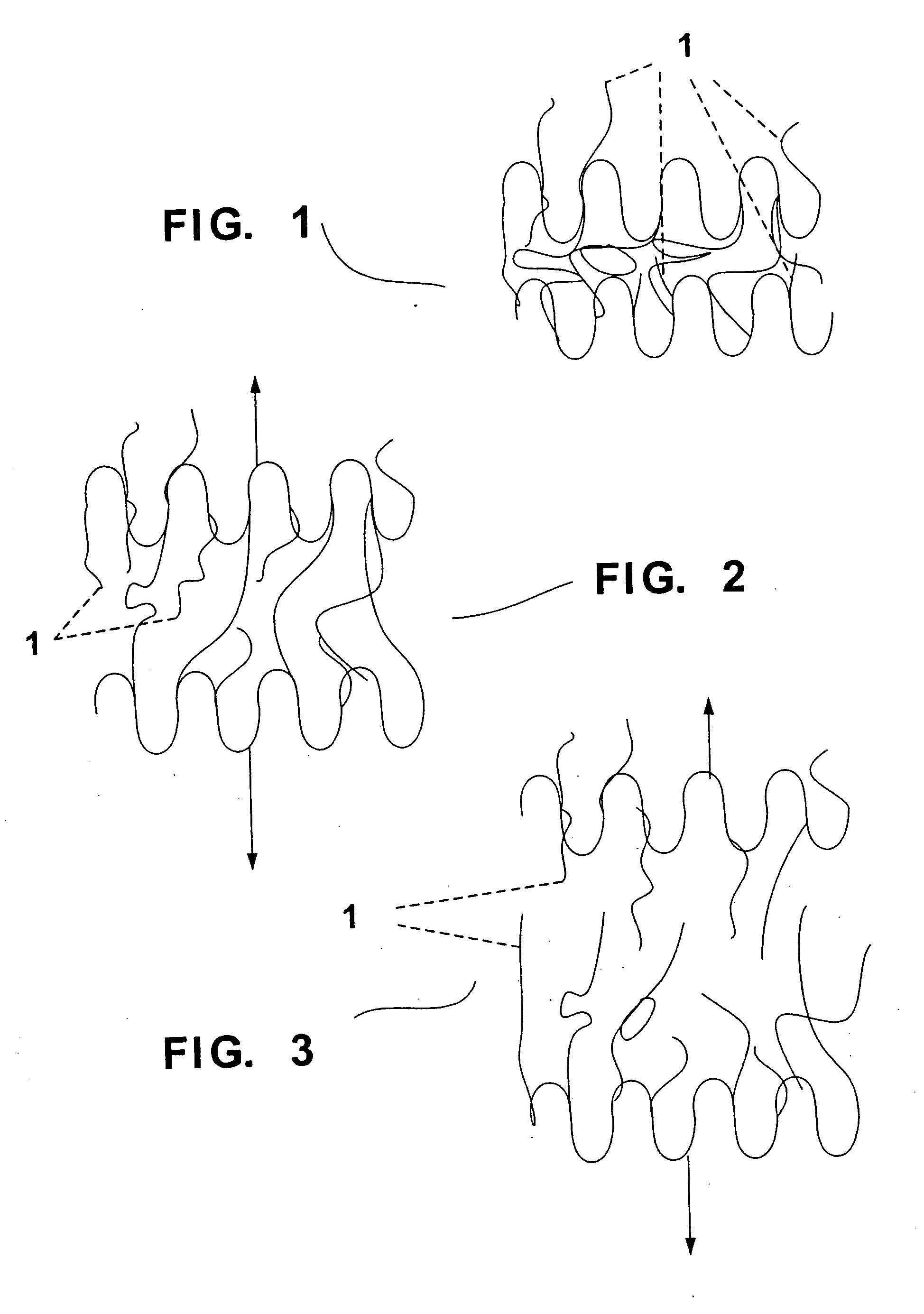

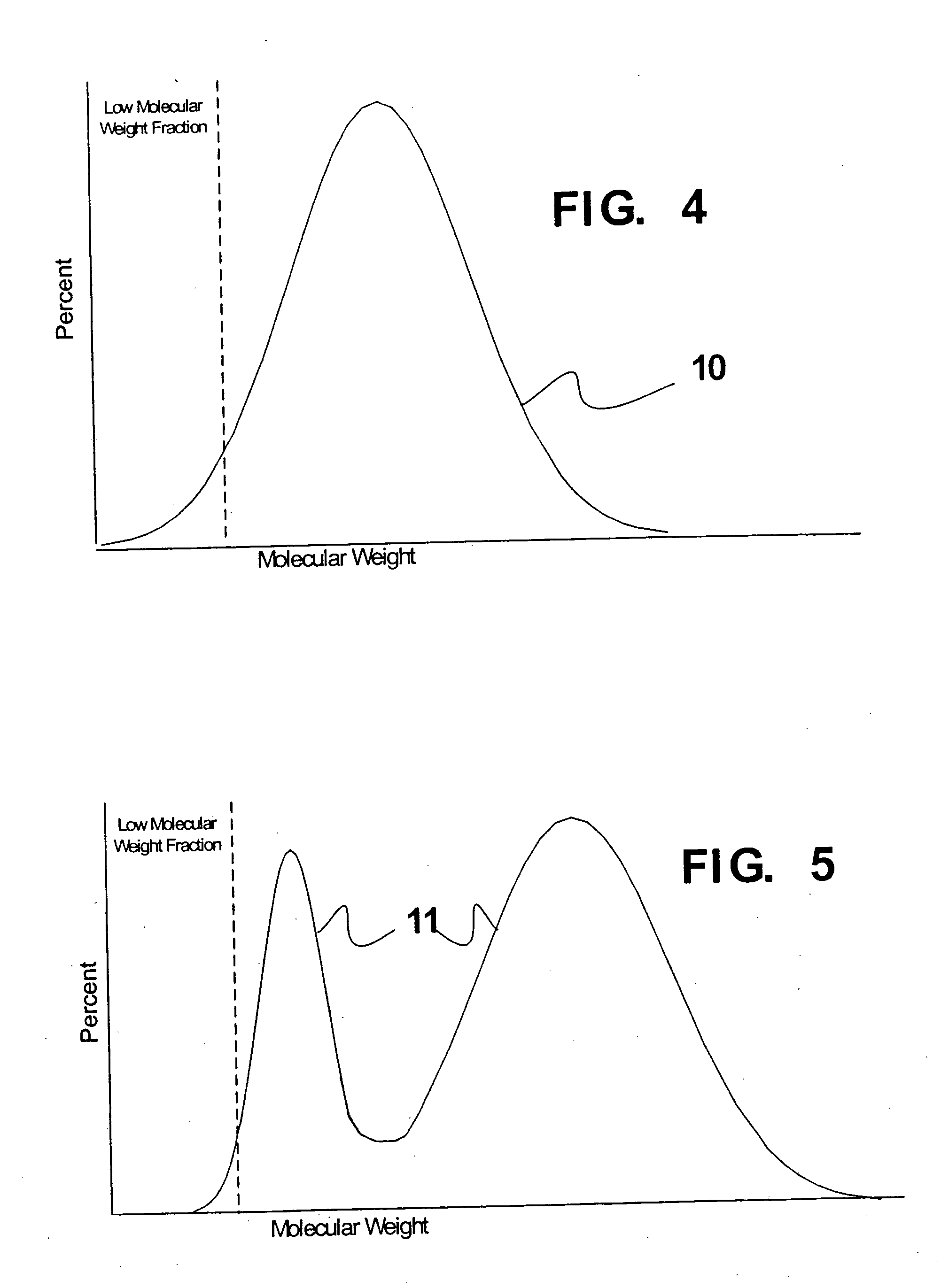

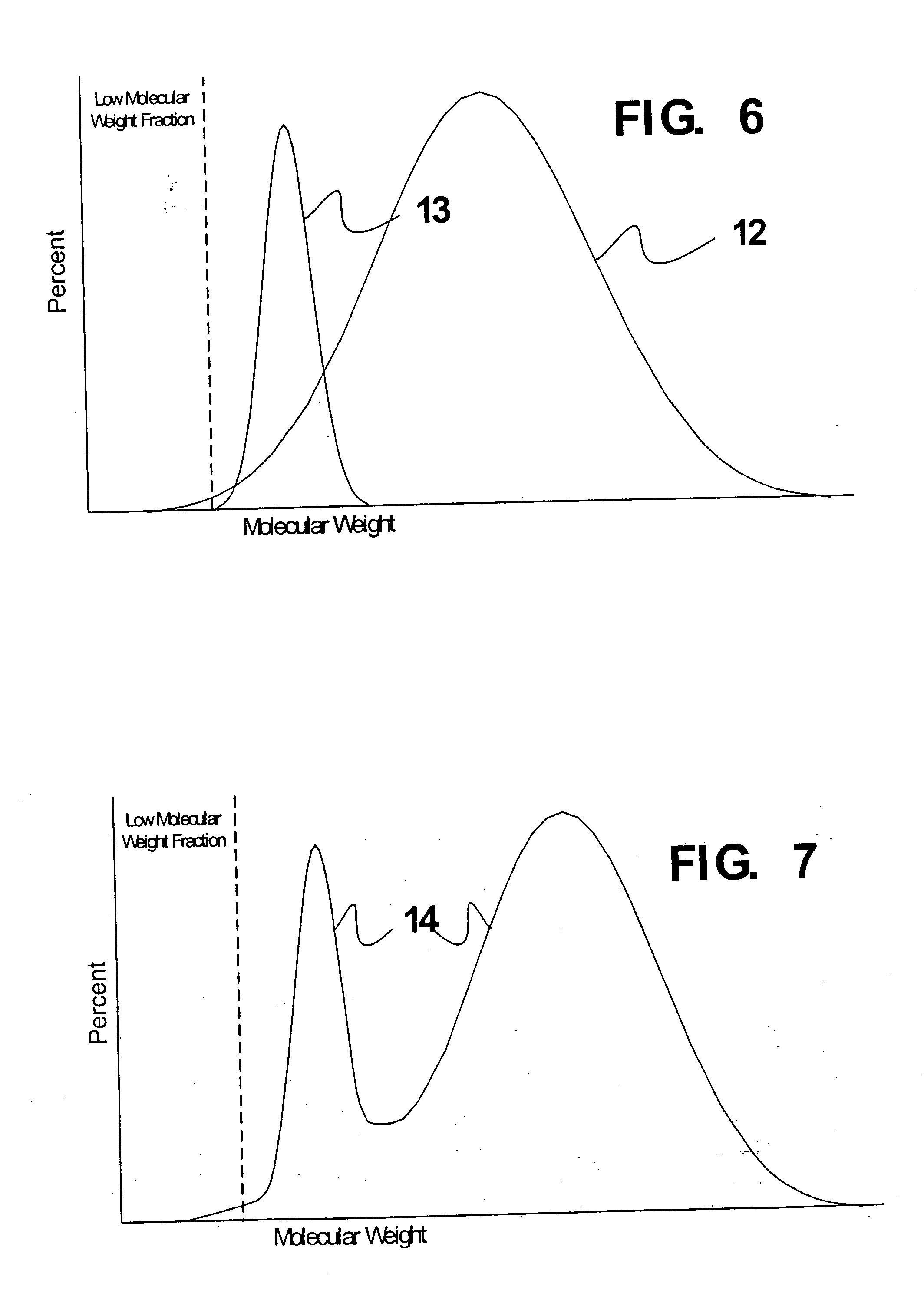

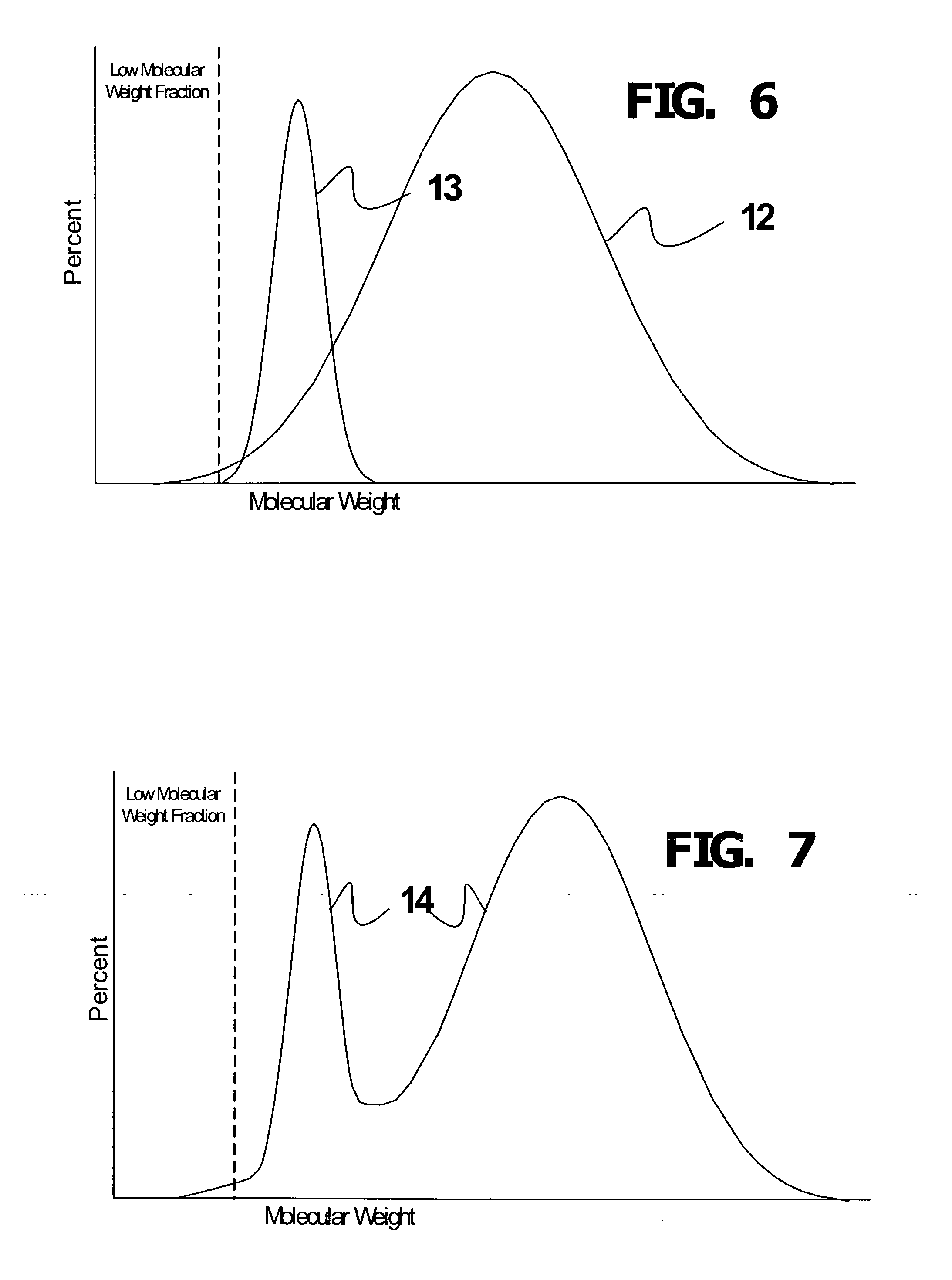

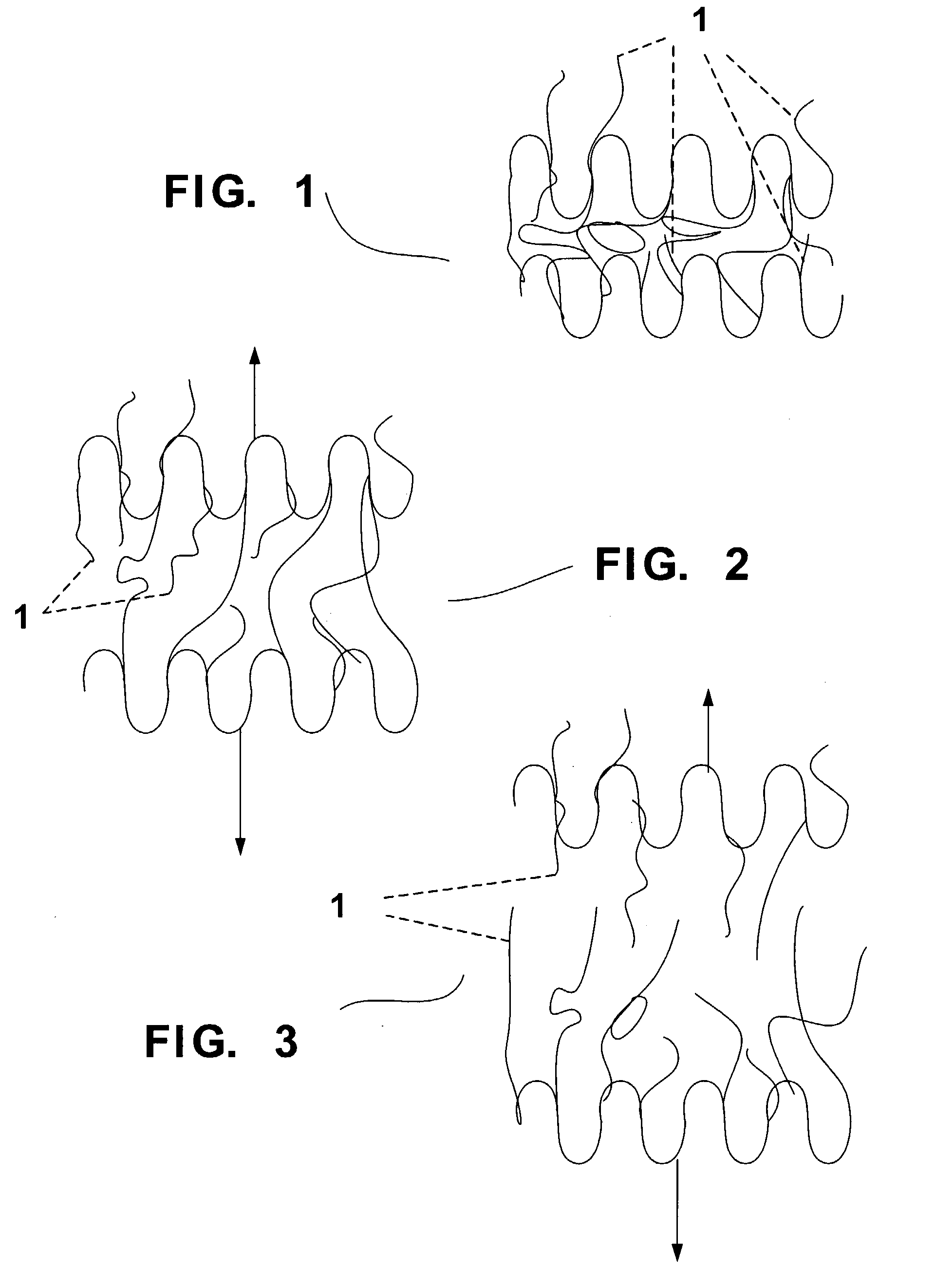

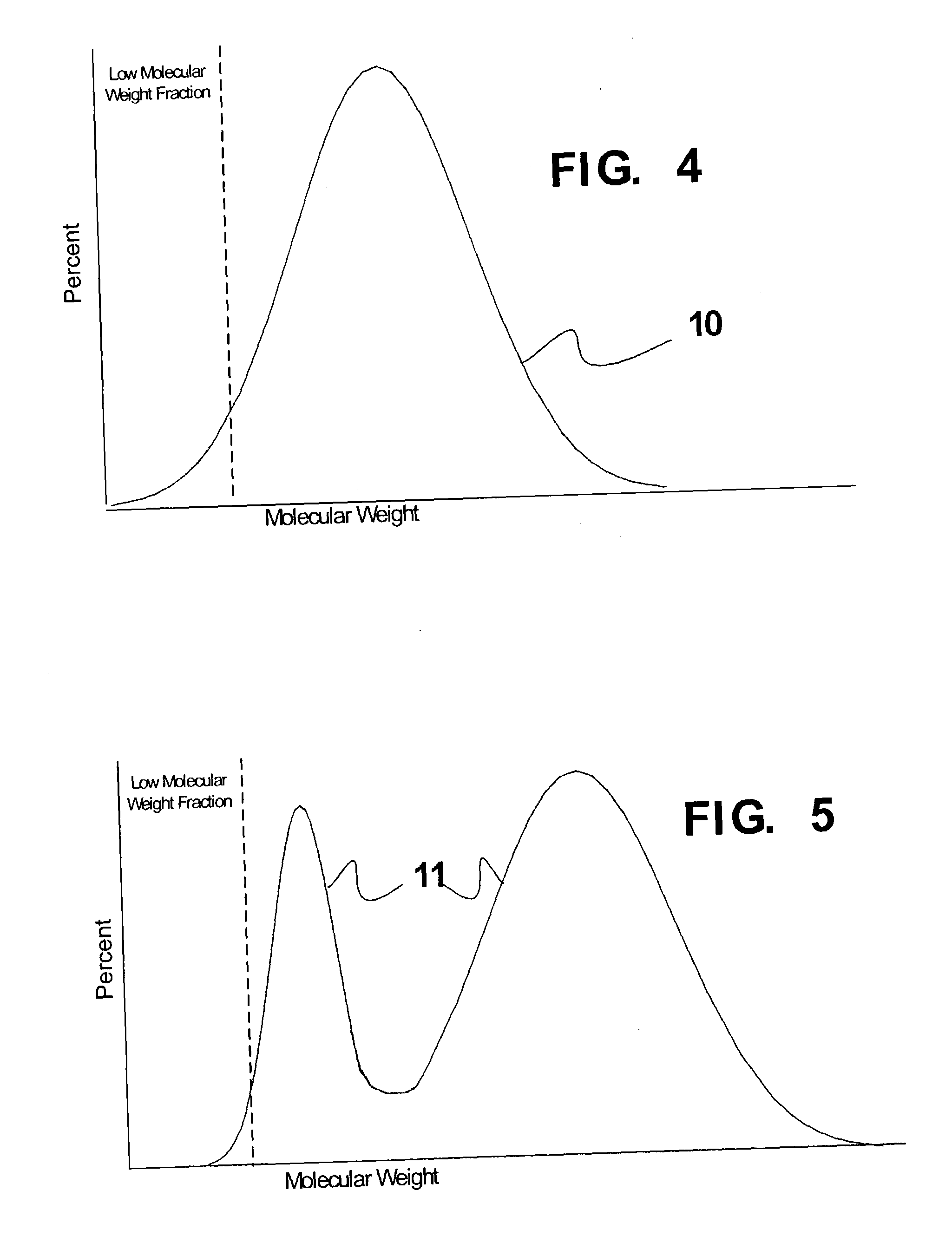

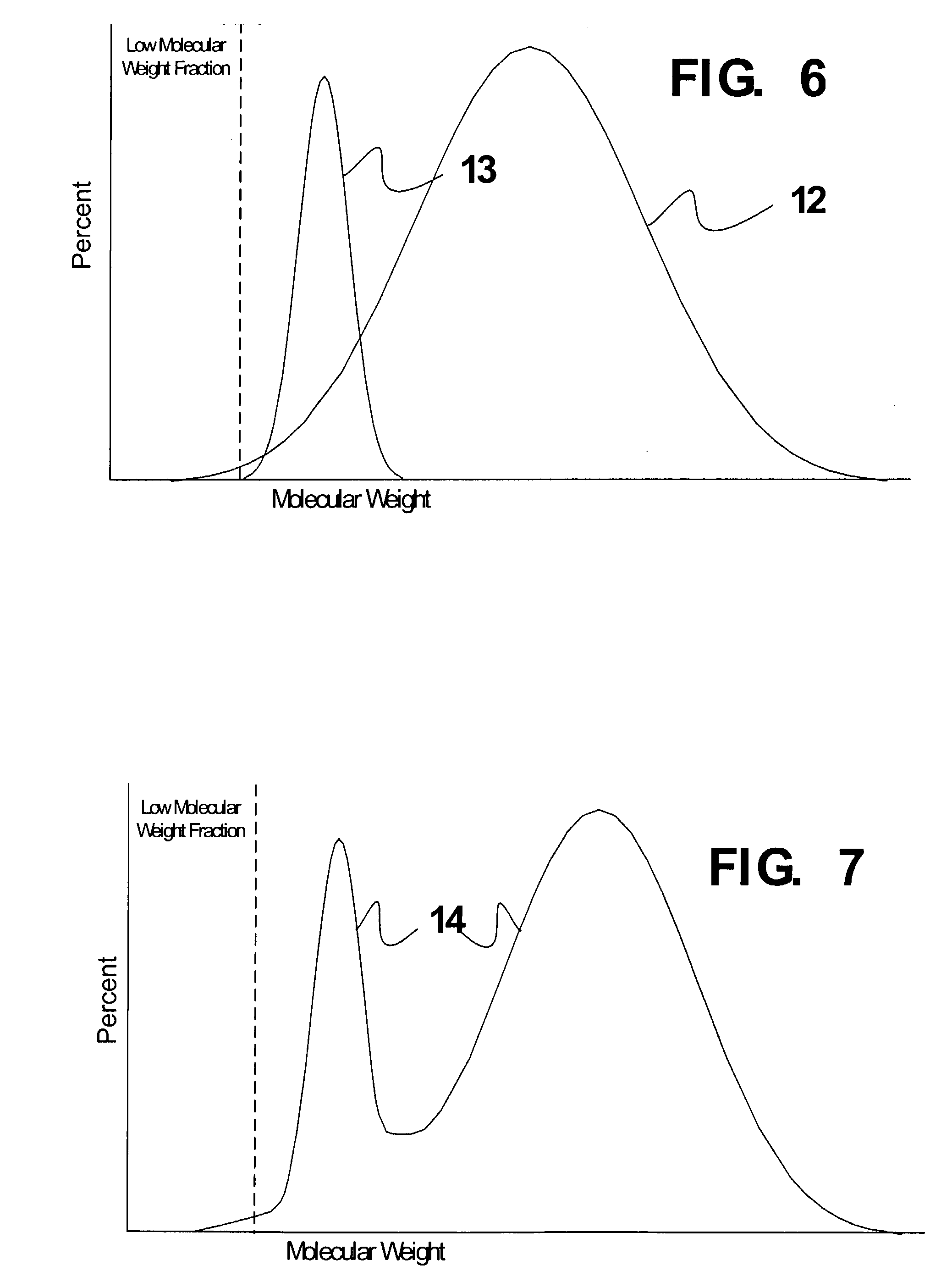

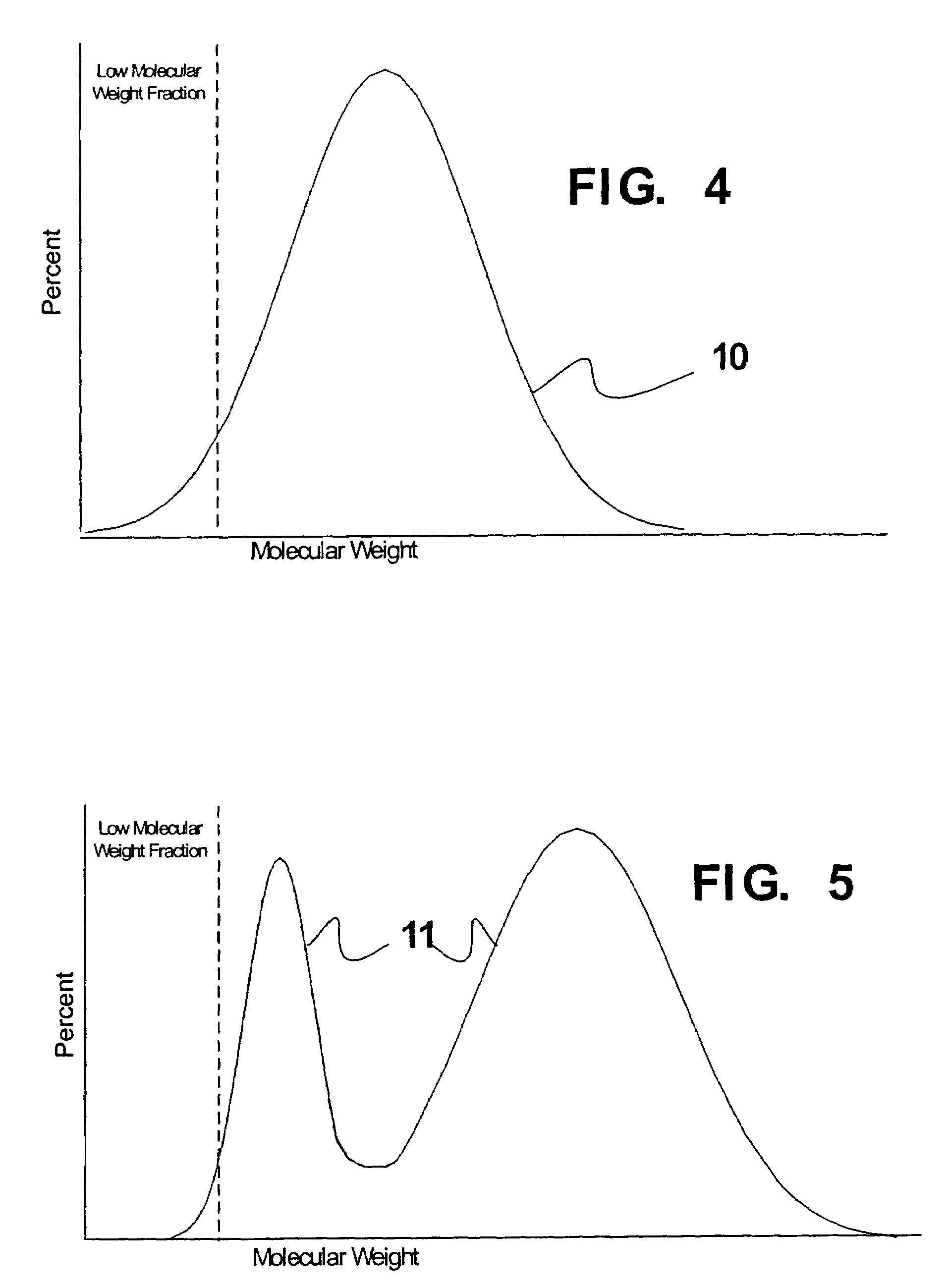

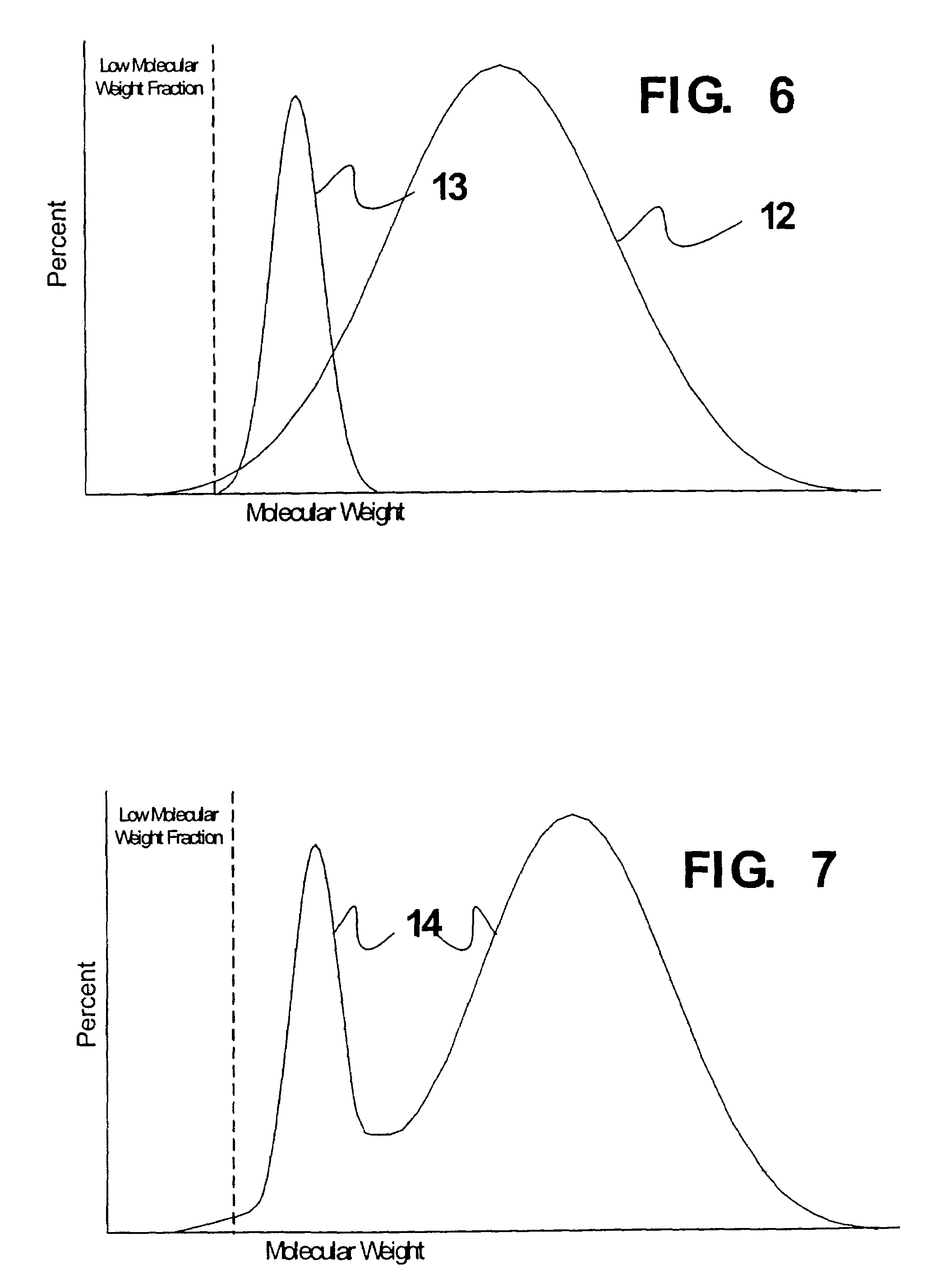

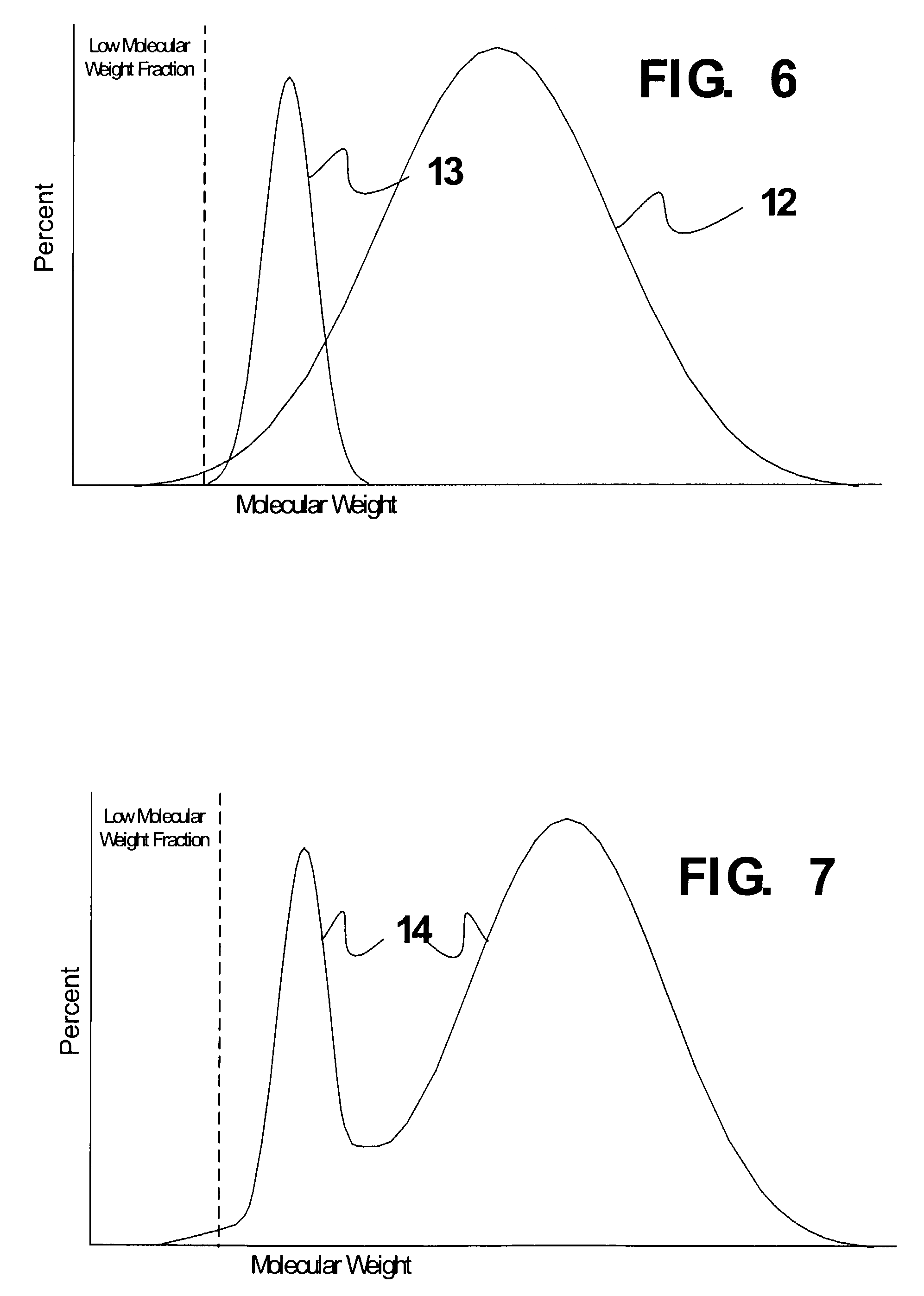

InactiveUS6749914B2Improved stress crack resistanceIncrease the number ofLayered productsThin material handlingPolymer scienceHigh density

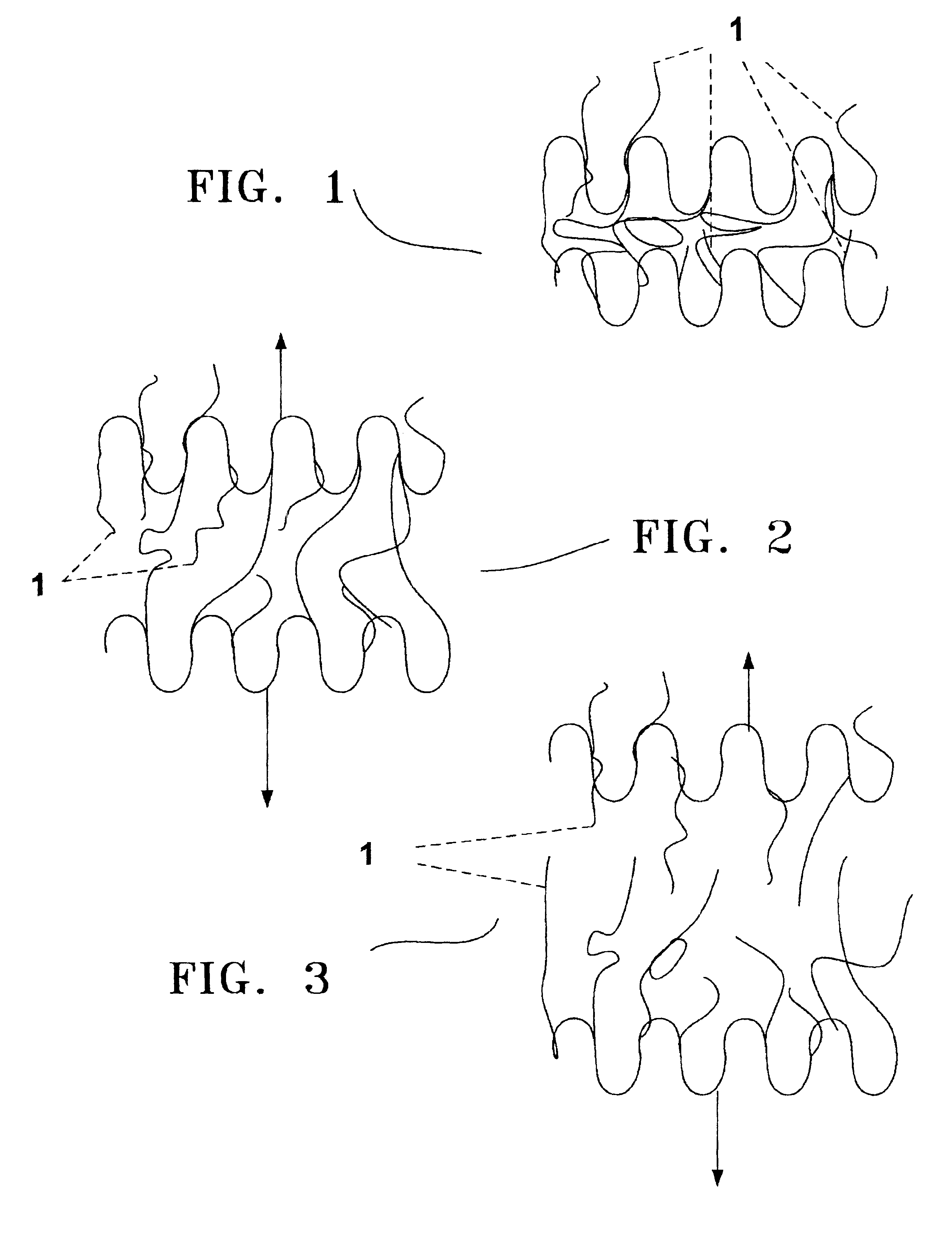

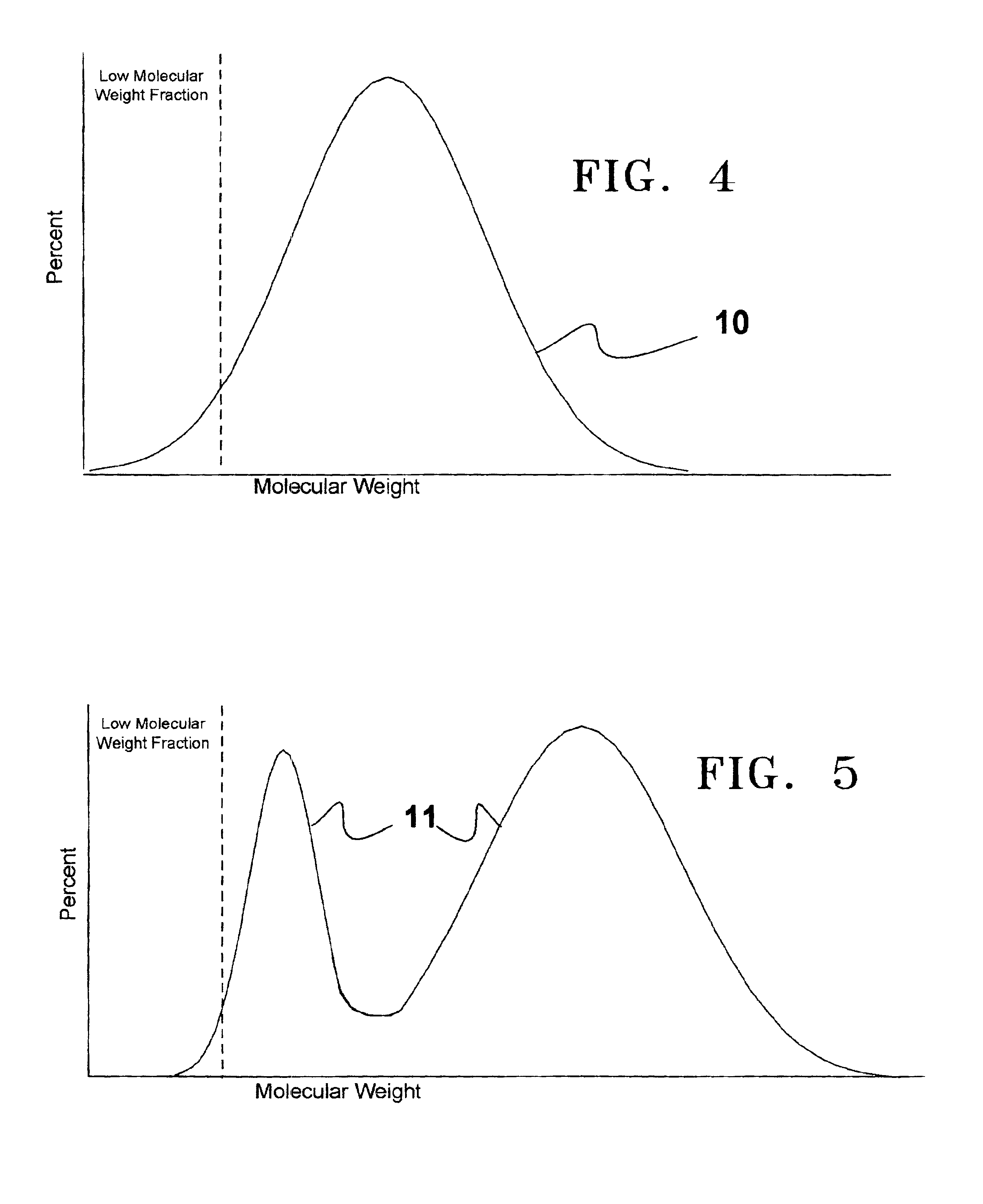

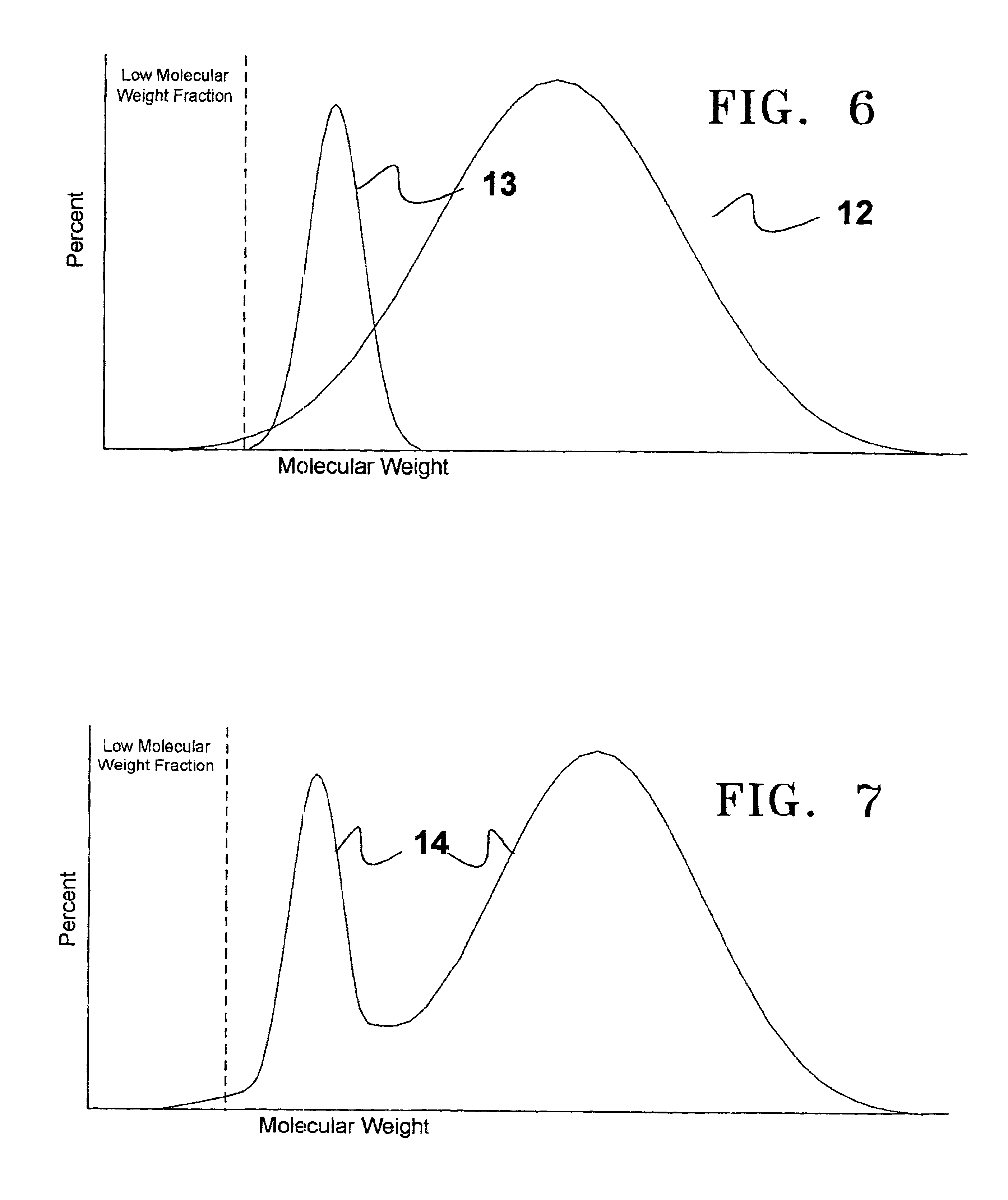

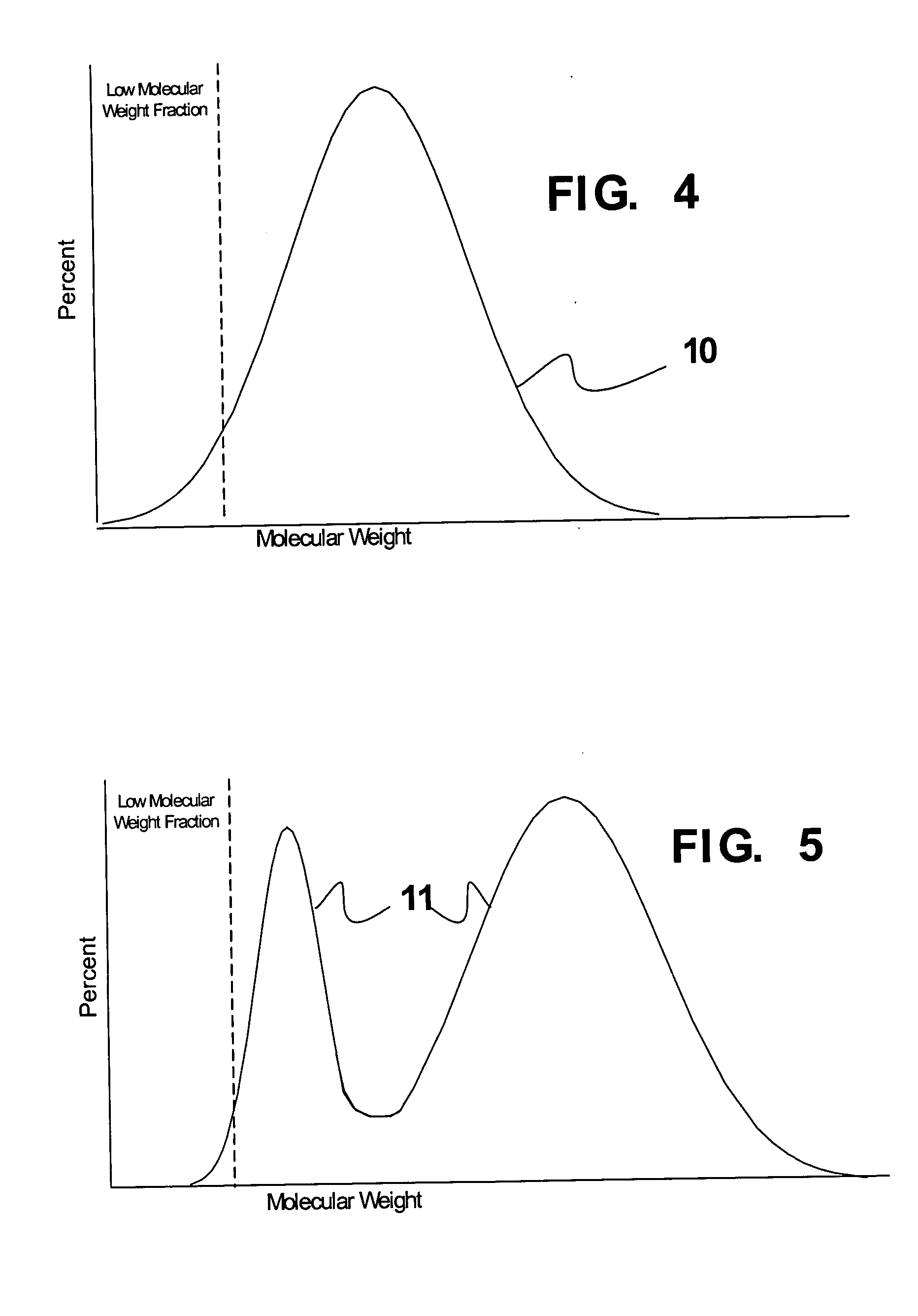

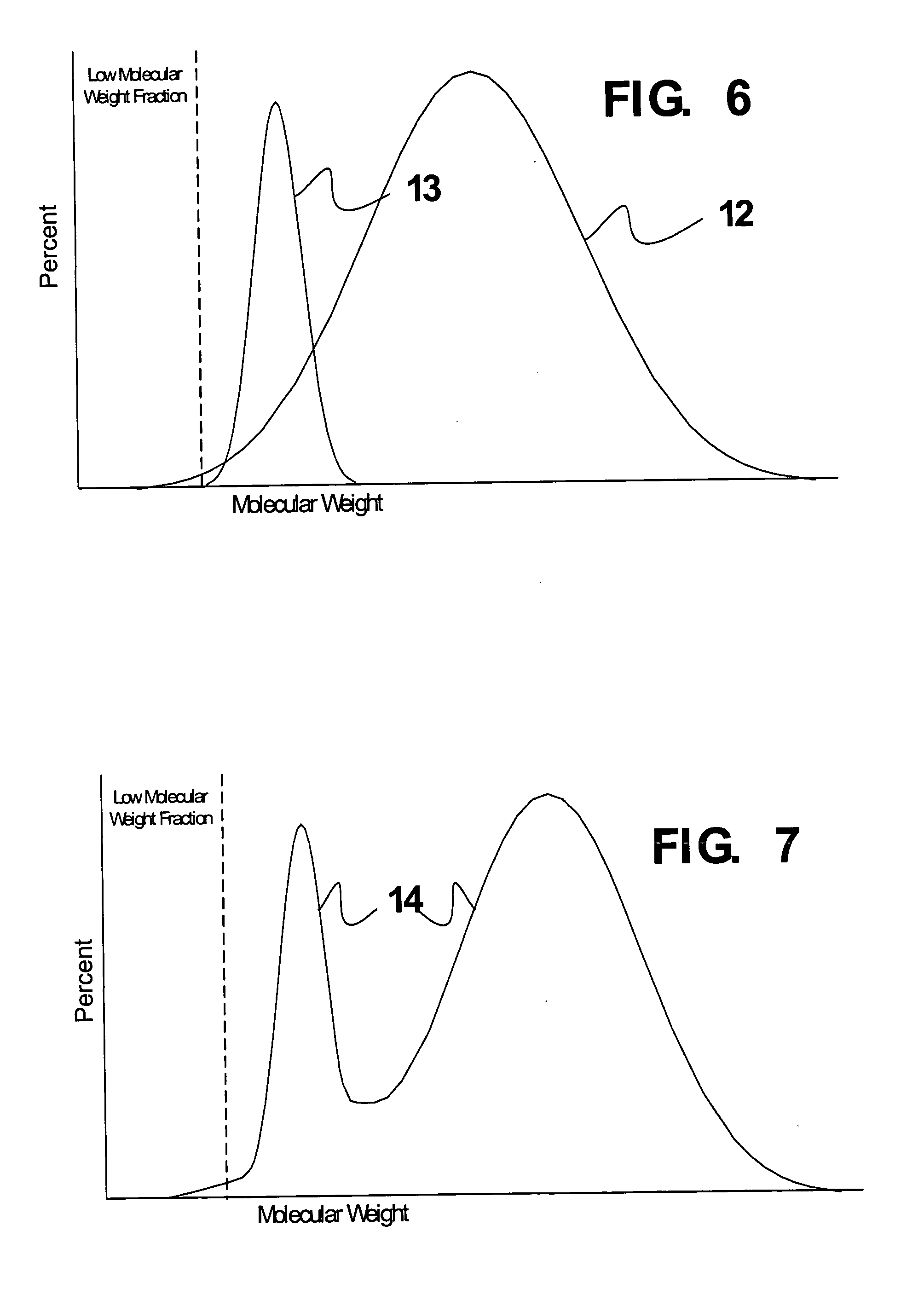

Melt blended HDPE for pipe and fitting material having a density in the range of 0.945 to 0.955 grams per cubic centimeter, values of melt flow index according to ASTM D1238 less than 0.4 with enhanced physical properties and process characteristics and blend methods are described in which virgin, reprocessed, wide specification, flake or regrind HMW homopolymer and copolymer HDPE (5 to <50%) are included as a minor component and HMW HDPE (>50 to 95%) is the major component. The method of selecting and blending the HMW HDPE copolymer, LMW HDPE homopolymer and LMW HDPE copolymer provides the corrugated HDPE pipe manufacturer with enhanced HDPE compositions and the means to independently design physical properties and enhance processability while exceeding AASHTO's standard for ESCR.

Owner:CORRUGATED POLYETHYLENE PIPE

Melt blended high-density polyethylene compositions with enhanced properties and method for producing the same

InactiveUS20030114594A1Easy to processDecreasing ESCRLayered productsThin material handlingHigh densityMelt flow index

Melt blended HDPE for pipe and fitting material having a density in the range of 0.945 to 0.955 grams per cubic centimeter, values of melt flow index according to ASTM D1238 less than 0.4 with enhanced physical properties and process characteristics and blend methods are described in which virgin, reprocessed, wide specification, flake or regrind HMW homopolymer and copolymer HDPE (5 to <50%) are included as a minor component and HMW HDPE (>50 to 95%) is the major component. The method of selecting and blending the HMW HDPE copolymer, LMW HDPE homopolymer and LMW HDPE copolymer provides the corrugated HDPE pipe manufacturer with enhanced HDPE compositions and the means to independently design physical properties and enhance processability while exceeding AASHTO's standard for ESCR.

Owner:CORRUGATED POLYETHYLENE PIPE

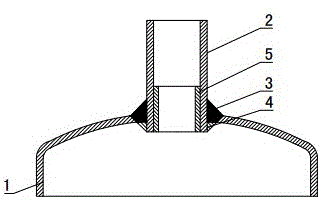

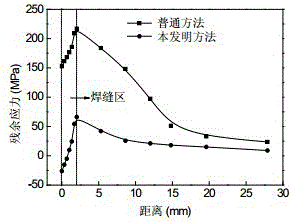

Connecting method of pressure vessel connecting pipe and sealing head for reducing welding residual stress

ActiveCN106112225APrevents stress corrosion crackingEnhanced resistance to stress corrosion crackingWelding/cutting auxillary devicesArc welding apparatusWeld seamWelding residual stress

The invention relates to a connecting method of a pressure vessel connecting pipe and a sealing head for reducing welding residual stress, which belongs to the technical field of sealing container processing and manufacturing. The connecting method is characterized by comprising the following steps of (a) opening the sealing head, and processing the connecting pipe (2); (b) extending one end of the connecting pipe (2) into a pressure vessel (1); (c) welding the sealing head and the connecting pipe (2); (d) preheating one side, which is positioned in the pressure vessel (1), of a welding seam (3), and then performing overlay welding on the root of the connecting pipe (2) in the pressure vessel (1); (e) preheating the inner wall of the connecting pipe (2), and then performing overlay welding on the inner wall of the connecting pipe (2); (f) cutting the connecting pipe (2) in the pressure vessel (1); (g) tempering the sealing head. According to the connecting method of the pressure vessel connecting pipe and the sealing head for reducing the welding residual stress, the welding residual stress is reduced in the manufacturing process of the pressure vessel, so that the structural integrity of the pressure vessel is increased, and the stress corrosion cracking resistant capability of a welding connector of the pressure vessel connecting pipe is enhanced.

Owner:江苏格兰环境科技有限公司

Melt blended high density polyethylene compositions with enhanced properties and method for producing the same

Melt blended HDPE compositions for single and dual wall corrugated HDPE pipe and associated fabricated and molded fittings and accessories having a density in the range of 0.951 to 0.954 grams per cubic centimeter, values of melt flow index according to ASTM D1238 in the range of about 0.15 to 0.35 with enhanced physical properties, process and environmental stress crack resistance (ESCR) characteristics and associated blend methods are disclosed in which virgin or recycled homopolymer and / or copolymer HDPE resin components are blended. The invention discloses a method selecting and determining the relative weight fractions of the HDPE blending components that provides specific physical properties and processability of HDPE blended compositions associated with density and melt index respectively and specific values of environmental stress crack resistance (ESCR) associated with specific molecular parameters. The principal benefits of this invention include cost reduction of raw materials to the corrugated HDPE pipe manufacturers by use of virgin prime commodity HDPE resins and / or wide and off specification prime HDPE resins in place of single stream specialty HDPE resins and favorable impact on the environment by providing the capability of utilizing billions of pounds of recycled HDPE resins in place of prime HDPE resins in the manufacture of corrugated HDPE pipe.

Owner:CORRUGATED POLYETHYLENE PIPE

Melt blended high density polyethylene compositions with enhanced properties and method for producing the same

InactiveUS20030171492A1Improved ESCRReduce in quantityRigid pipesPolymer scienceEnvironmental stress cracking

Melt blended HDPE compositions for single and dual wall corrugated HDPE pipe and associated fabricated and molded fittings and accessories with enhanced physical properties and processing and environmental stress crack resistance (ESCR) characteristics and associated blend methods are disclosed in which virgin or recycled homopolymer and / or copolymer HDPE resin components are blended. The invention discloses methods for 1) selecting and determining the relative weight fractions of the HDPE blending components that provide specific physical properties and processability of HDPE blended compositions associated with density and melt index respectively and specific values of environmental stress crack resistance (ESCR) associated with specific molecular parameters and 2) for determining from molecular parameters, the ESCR of linear polyethylene resins and blended compositions within a class having similar densities. The invention reduces the cost of raw materials to corrugated HDPE pipe manufacturers by enabling the use of virgin prime commodity HDPE resins and / or wide and off specification prime HDPE resins in place of single stream specialty HDPE resins and favorably impacts the environment by providing the capability of utilizing recycled HDPE resins in place of prime HDPE resins in the manufacture of corrugated HDPE pipe.

Owner:CORRUGATED POLYETHYLENE PIPE

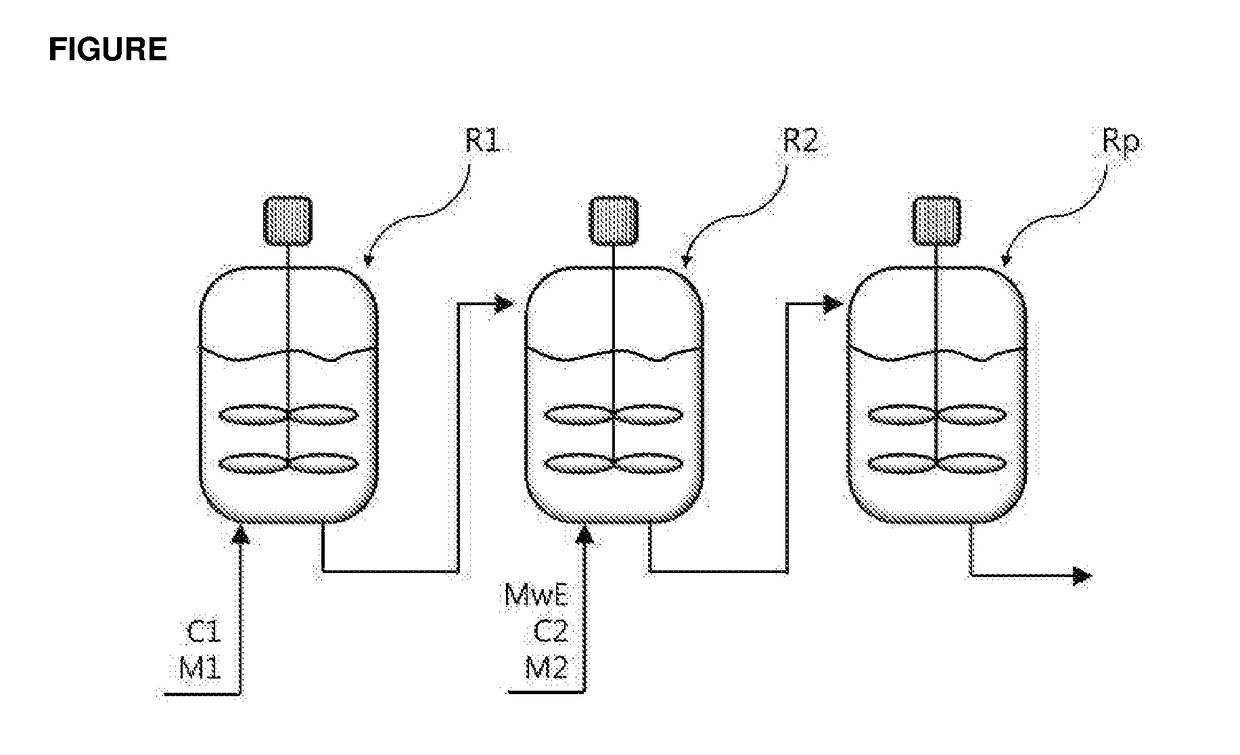

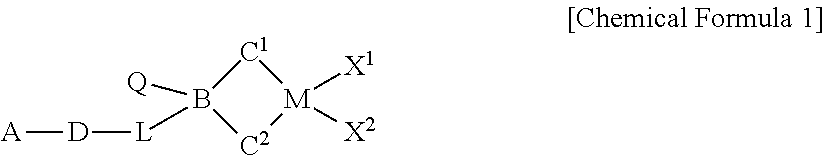

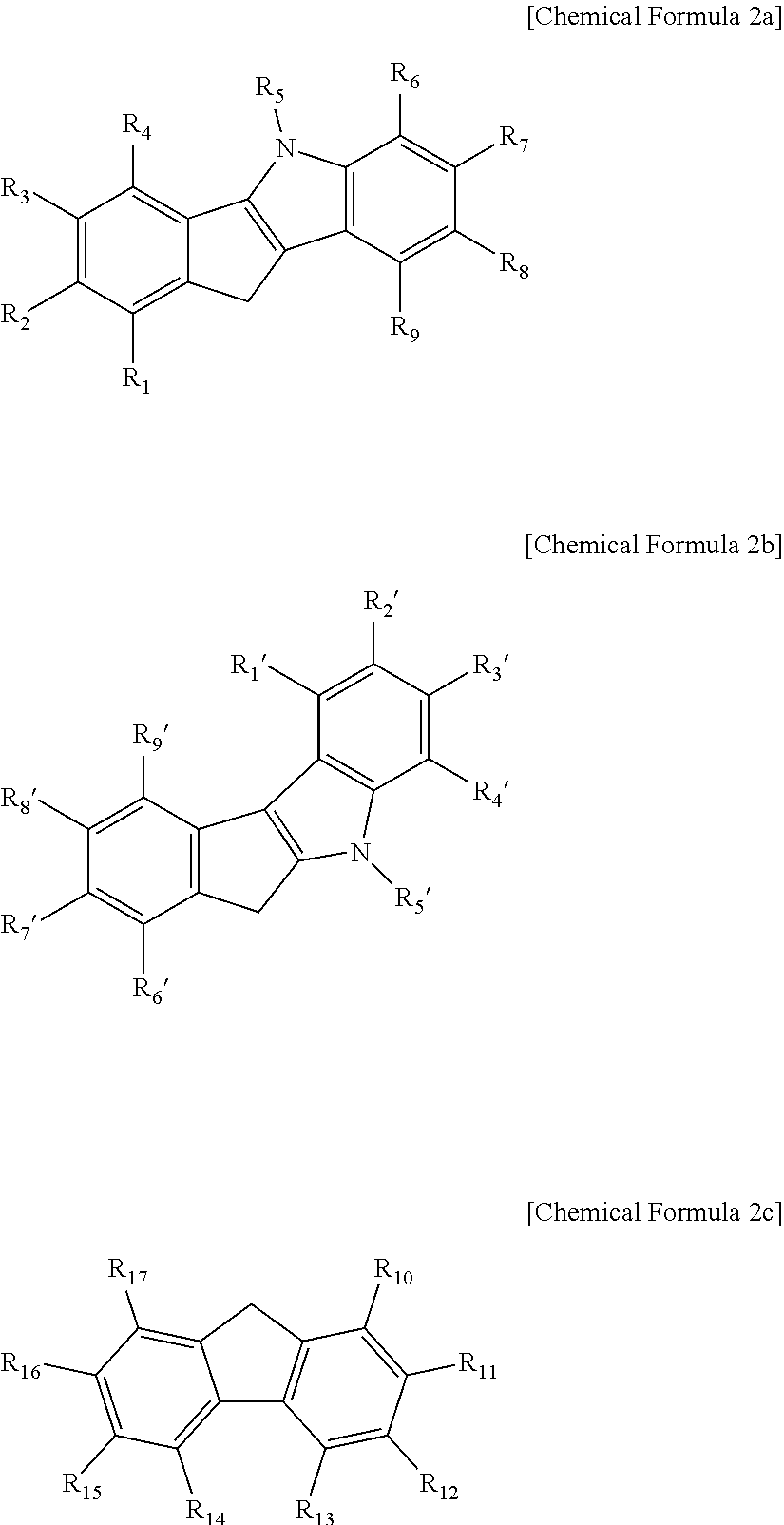

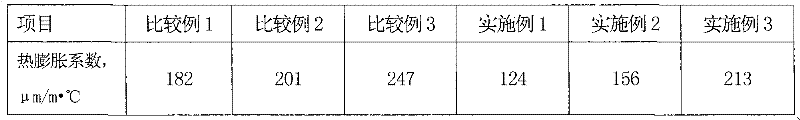

HYBRID SUPPORTED METALLOCENE CATALYST AND POLYOLEFIN PREPARATION METHOD USING SAME (As Amended)

The present invention relates to a hybrid supported metallocene catalyst and a polyolefin preparation method using the same. Using the hybrid supported metallocene catalyst can not only significantly reduce the amount of wax produced when polymerizing olefin monomers, but can also enhance the stress cracking resistance of the polyolefin that is prepared.

Owner:LG CHEM LTD

Cracking resistant fiber reinforced epoxy paint for ship ballast tank and preparation method thereof

InactiveCN102443338AExcellent anti-corrosion performanceGood corrosion resistanceEpoxy resin coatingsSolventCorrosion

The invention relates to the field of paint and specifically provides a cracking resistant fiber reinforced epoxy paint for a ship ballast tank and a preparation method thereof to solve a problem of easily cracked or spalled ballast tank coating in a prior art. The cracking resistant fiber reinforced epoxy paint for the ship ballast tank comprises the following two ingredients, by weight: an ingredient one containing epoxy resin, petroleum resin, crack resistant material, coloring pigment, extender pigment, auxiliary agent and solvent; an ingredient two containing solvent and curing agent. The ingredient one is added into the ingredient two, uniformly stirred, applied to a base material and solidified for 5 min to 15 days at 10-120 DEG C, so as to form the cracking resistant fiber reinforced epoxy paint for the ship ballast tank. The cracking resistant fiber reinforced epoxy paint for the ship ballast tank of the invention has good toughness, corrosion resistance and no toxic antirust pigment like lead or chromium; usage of the crack resistant material can increase stress cracking resistance of the coating and prolong a service life of the coating.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

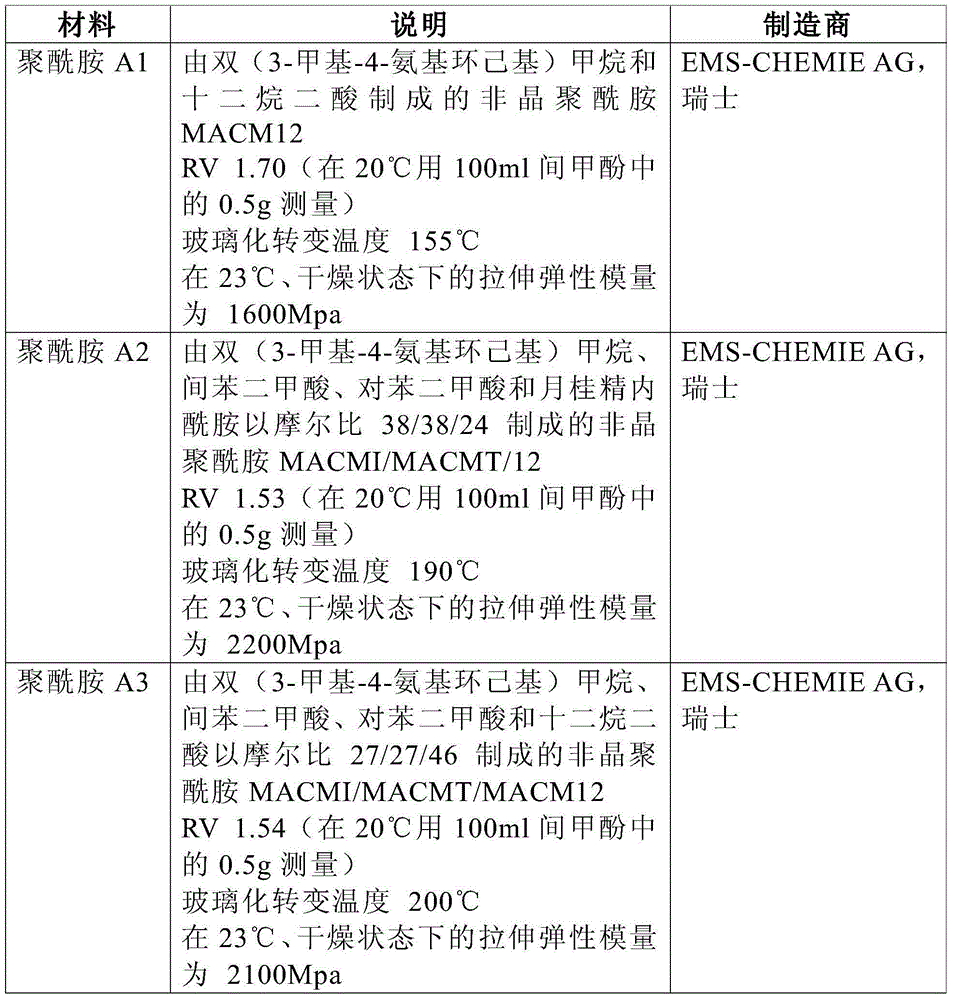

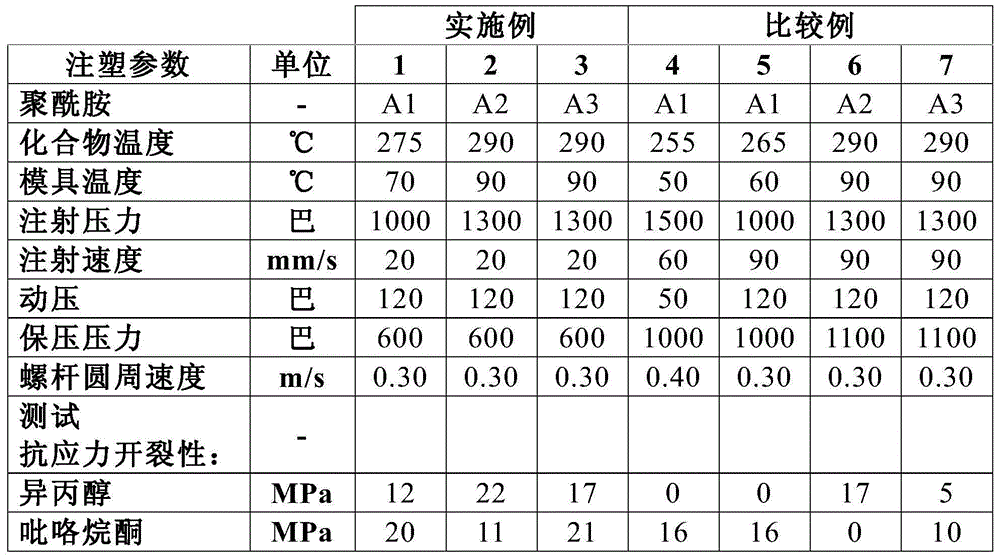

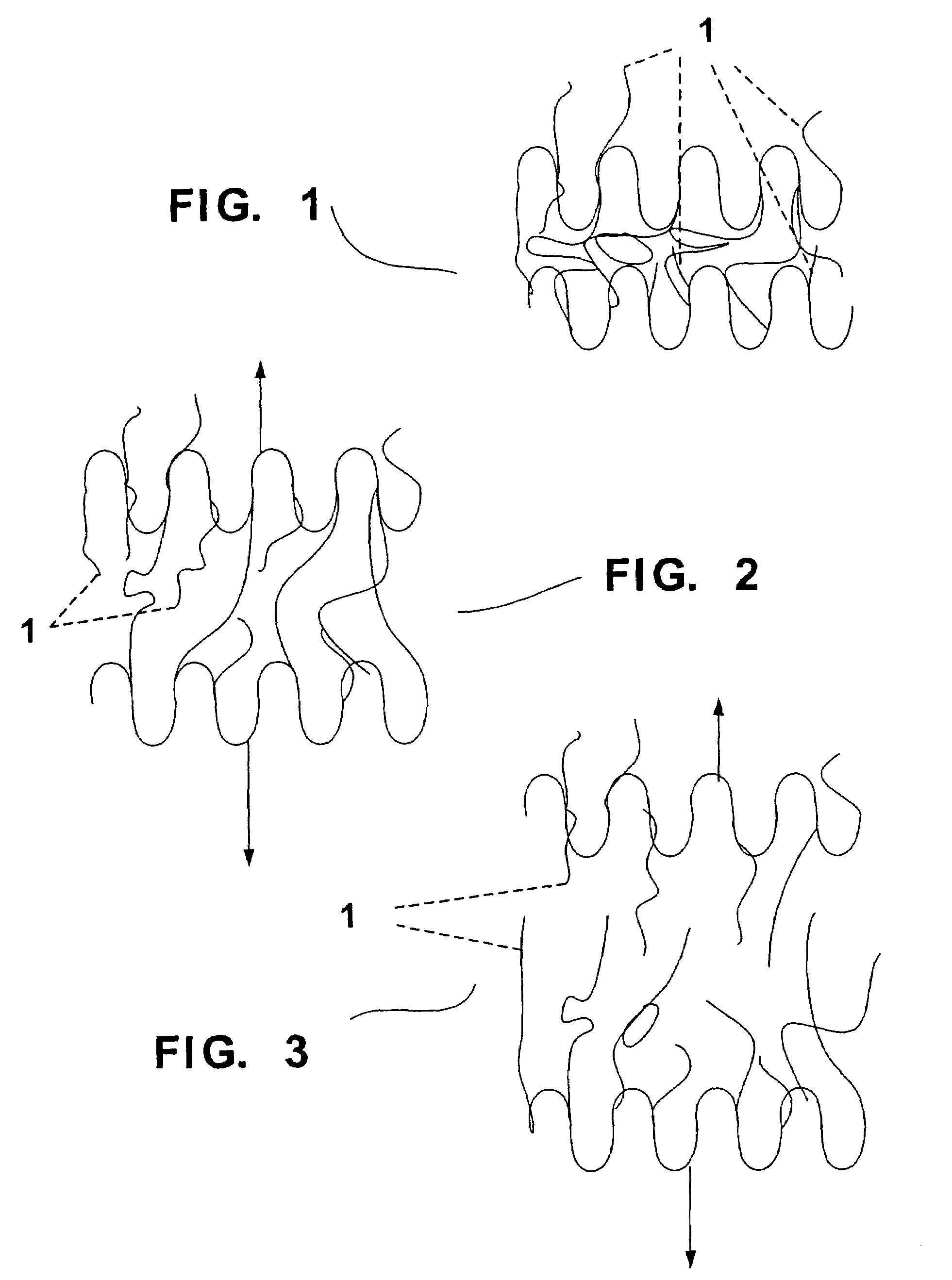

Method for low-stress injection moulding of amorphous or microcrystalline polyamides and also correspondingly produced low-stress polyamide moulded articles

The present invention relates to a method for low-stress injection moulding of amorphous or microcrystalline polyamides, in which a melt of the amorphous or microcrystalline polyamides is processed and injection moulded under specific conditions. Hence, low-stress moulded articles made of the amorphous or microcrystalline polyamides can be produced by injection moulding. The present invention relates in addition to the correspondingly produced moulded articles.

Owner:EMS PATENT AG

Stress blanching and stress crack resistant filling modified polypropylene, preparation method and application

The invention discloses a stress-tolerant whitening and stress cracking filling modifying polypropylene and making method and application, which is characterized by the following: making each index of polypropylene reach or exceed the preset request; solving the defect of stress whitening and stress cracking after reaching rigid and fexible balance; fitting for automobile industry and assembling property; making the bending modulus of material to 1300Mpa at 23 deg. c and collision strength of cantilever beam notch over 25KJ / m2; reaching and exceeding the integrated property of automobile industry.

Owner:SHANGHAI KINGFA SCI & TECH +1

Melt blended high density polyethylene compositions with enhanced properties and method for producing the same

Melt blended HDPE compositions for single and dual wall corrugated HDPE pipe and associated fabricated and molded fittings and accessories with enhanced physical properties and processing and environmental stress crack resistance (ESCR) characteristics and associated blend methods are disclosed in which virgin or recycled homopolymer and / or copolymer HDPE resin components are blended. The invention discloses methods for 1) selecting and determining the relative weight fractions of the HDPE blending components that provide specific physical properties and processability of HDPE blended compositions associated with density and melt index respectively and specific values of environmental stress crack resistance (ESCR) associated with specific molecular parameters and 2) for determining from molecular parameters, the ESCR of linear polyethylene resins and blended compositions within a class having similar densities. The invention reduces the cost of raw materials to corrugated HDPE pipe manufacturers by enabling the use of virgin prime commodity HDPE resins and / or wide and off specification prime HDFE resins in place of single stream specialty HDPE resins and favorably impacts the environment by providing the capability of utilizing recycled HDPE resins in place of prime HDPE resins in the manufacture of corrugated HDPE pipe.

Owner:CORRUGATEDD POLYETHYLENE PIPE

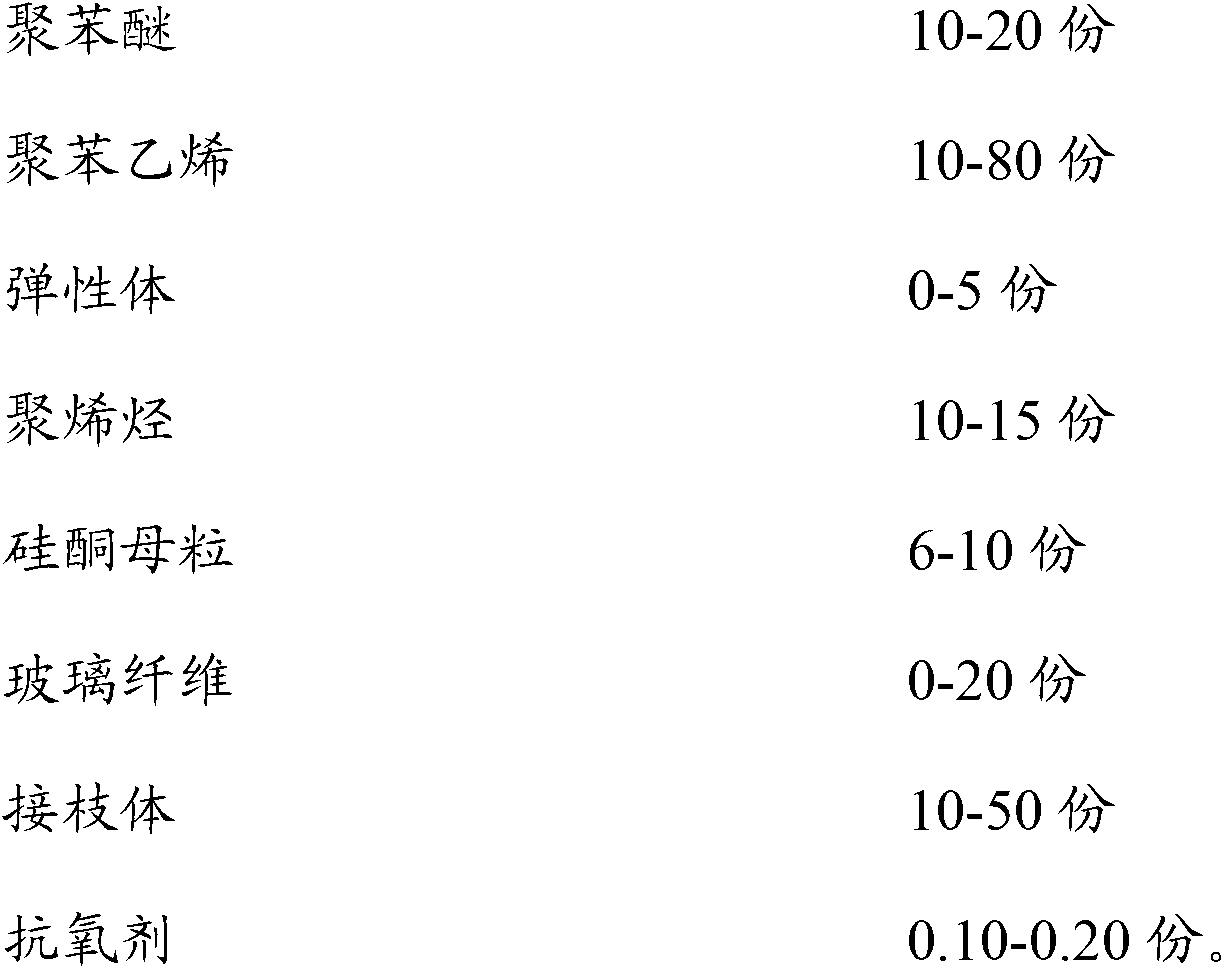

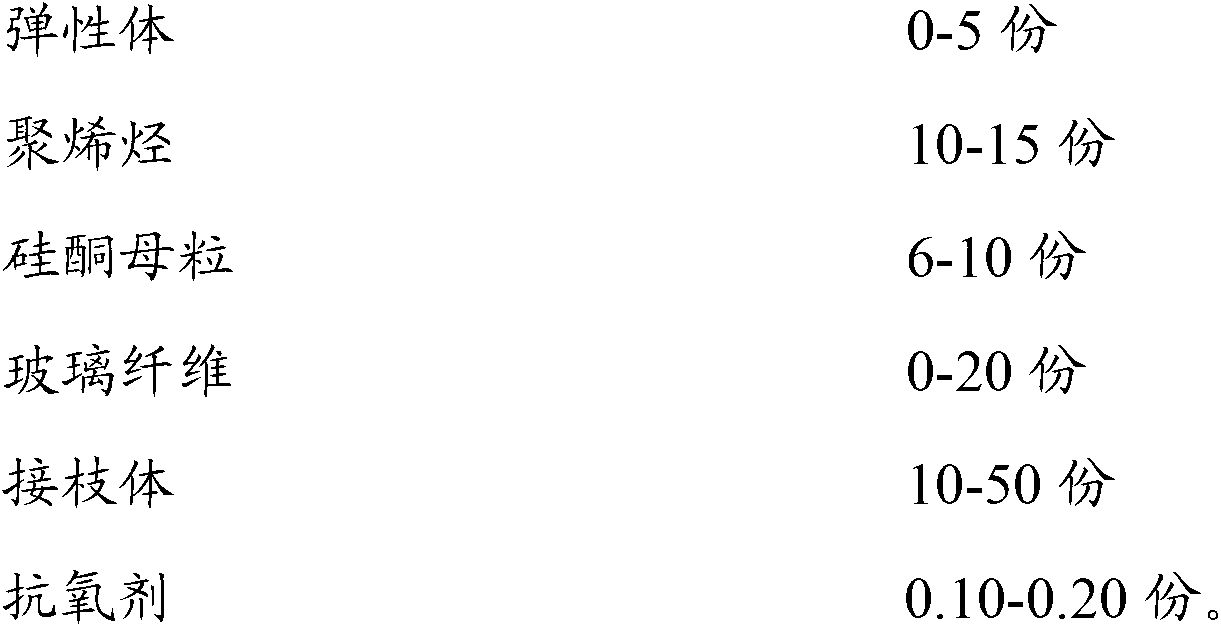

Polyphenylether composite material, and preparation method and application thereof

The invention is applicable to the field of new materials, and provides a polyphenylether composite material, a preparation method and an application field thereof. The polyphenylether composite material provided by the invention is specifically used for a shell and a base of a valve core in the water treatment industry. In the very complicated use process in the water treatment industry, the polyphenylether composite material needs dimension stability during the cold / hot water alternate dutycycle operation and needs to resist stress cracking caused by molecular chain vermiculation of the rigid high polymer material itself. At the present stage, the integrated design of a shell and a base of a valve core is popularized increasingly, and performance requirements for all aspects of the material are severe increasingly; and especially for a polyphenylether / glass fiber composite material, high requirements for surface smoothness, stress release resistance and the like exist. The polyphenylether composite material provided by the invention is used in the water treatment industry, has favorable surface smoothness and stress resistance, and is very applicable to a shell and a base of a valve core in water treatment.

Owner:江苏沃特新材料科技有限公司

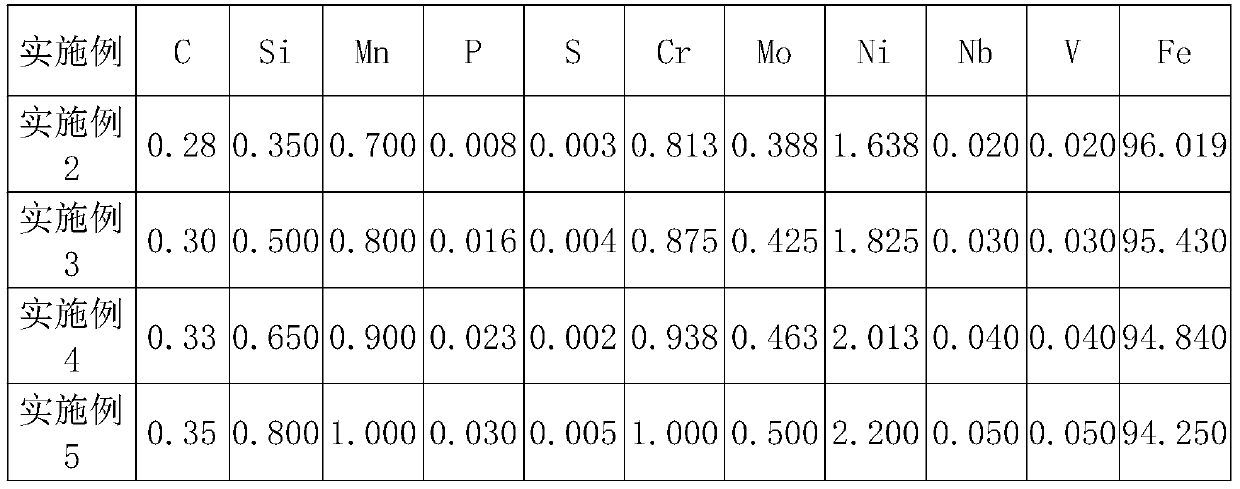

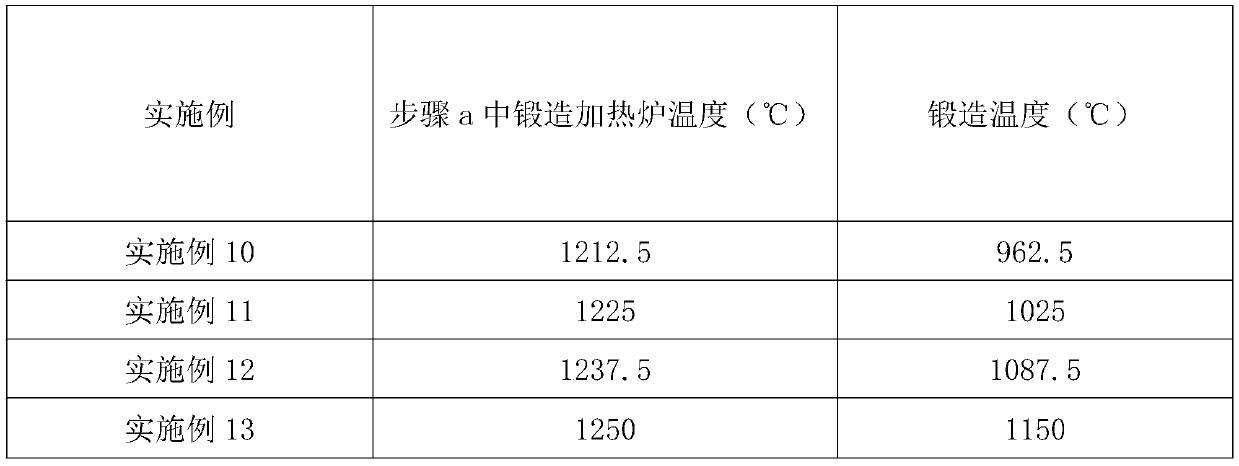

Preparing process of alloy steel forge piece

The invention discloses a preparing process of an alloy steel forge piece. The process comprises the following process steps of S1, steel ingot pouring; S2, shifting and adjusting a steel ingot afterpouring is finished into a 600 DEG C annealing furnace at the temperature of 600 to 900 DEG C, and enabling the temperature to rise to 700 DEG C temperature equilibrium; S3, shifting the steel ingot into a forging heating furnace to be subjected to heating and forging; S4, carrying out normalizing treatment on the steel ingot after forging; S5, carrying out hydrogen diffusion treatment on the steel ingot after normalizing treatment; S6, carrying out heating austenitizing treatment on the steel ingot after hydrogen diffusion treatment; and S7, shifting the steel ingot after austenitizing treatment into a quenching pool to be subjected to graded quenching treatment, and carrying out tempering treatment on the steel ingot after graded quenching treatment. The alloy steel forge piece can be obtained through the above seven steps, and the preparing process has the advantages that the casting cost of the alloy steel forge piece can be reduced, and resources are saved.

Owner:浙江天基重工机械有限公司

Heat resistant fluoroelastomer bushings

InactiveUS20120259054A1Maintain good propertiesImproved compressive stress crack resistanceSpecial tyresDibutyl phthalateFluoroelastomer

A cured fluoroelastomer sensor bushing comprises A) fluoroelastomer having at least 53 wt. % fluorine, and B) 10 to 50 parts by weight, per hundred parts by weight fluoroelastomer, of carbon black a nitrogen adsorption specific surface area of 70-150 m2 / g and a dibutyl phthalate absorption of 90-180 ml / 100 g.

Owner:EI DU PONT DE NEMOURS & CO

Impact modified styrenic polymers with improved stress crack properties

ActiveUS20100240834A1Improved stress crack resistanceOrganic chemistryChemical/physical processesPolyolefinPolymer solution

A method of improving the stress crack resistance of an impact modified styrenic polymer comprising (a) combining about 95 to about 99.5 wt. % of an impact modified styrenic polymer with about 0.5 to about 5 wt. % of a polymer solution comprising about 25 to about 75 wt. % polyisobutylene and about 25 to about 75 wt. % of a polyolefin comprising one or more C2 to C12 alpha olefins.

Owner:INEOS STYROLUTION AMERICA LLC

Melt blended high density polyethylene compositions with enhanced properties and method for producing the same

Melt blended HDPE compositions for single and dual wall corrugated HDPE pipe and associated fabricated and molded fittings and accessories with enhanced physical properties and processing and environmental stress crack resistance (ESCR) characteristics and associated blend methods are disclosed in which virgin or recycled homopolymer and / or copolymer HDPE resin components are blended. The invention discloses methods for 1) selecting and determining the relative weight fractions of the HDPE blending components that provide specific physical properties and processability of HDPE blended compositions associated with density and melt index respectively and specific values of environmental stress crack resistance (ESCR) associated with specific molecular parameters and 2) for determining from molecular parameters, the ESCR of linear polyethylene resins and blended compositions within a class having similar densities. The invention reduces the cost of raw materials to corrugated HDPE pipe manufacturers by enabling the use of virgin prime commodity HDPE resins and / or wide and off specification prime HDPE resins in place of single stream specialty HDPE resins and favorably impacts the environment by providing the capability of utilizing recycled HDPE resins in place of prime HDPE resins in the manufacture of corrugated HDPE pipe.

Owner:CORRUGATED POLYETHYLENE PIPE

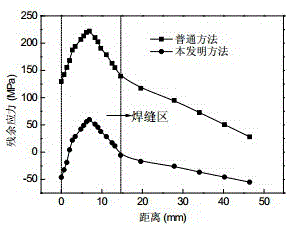

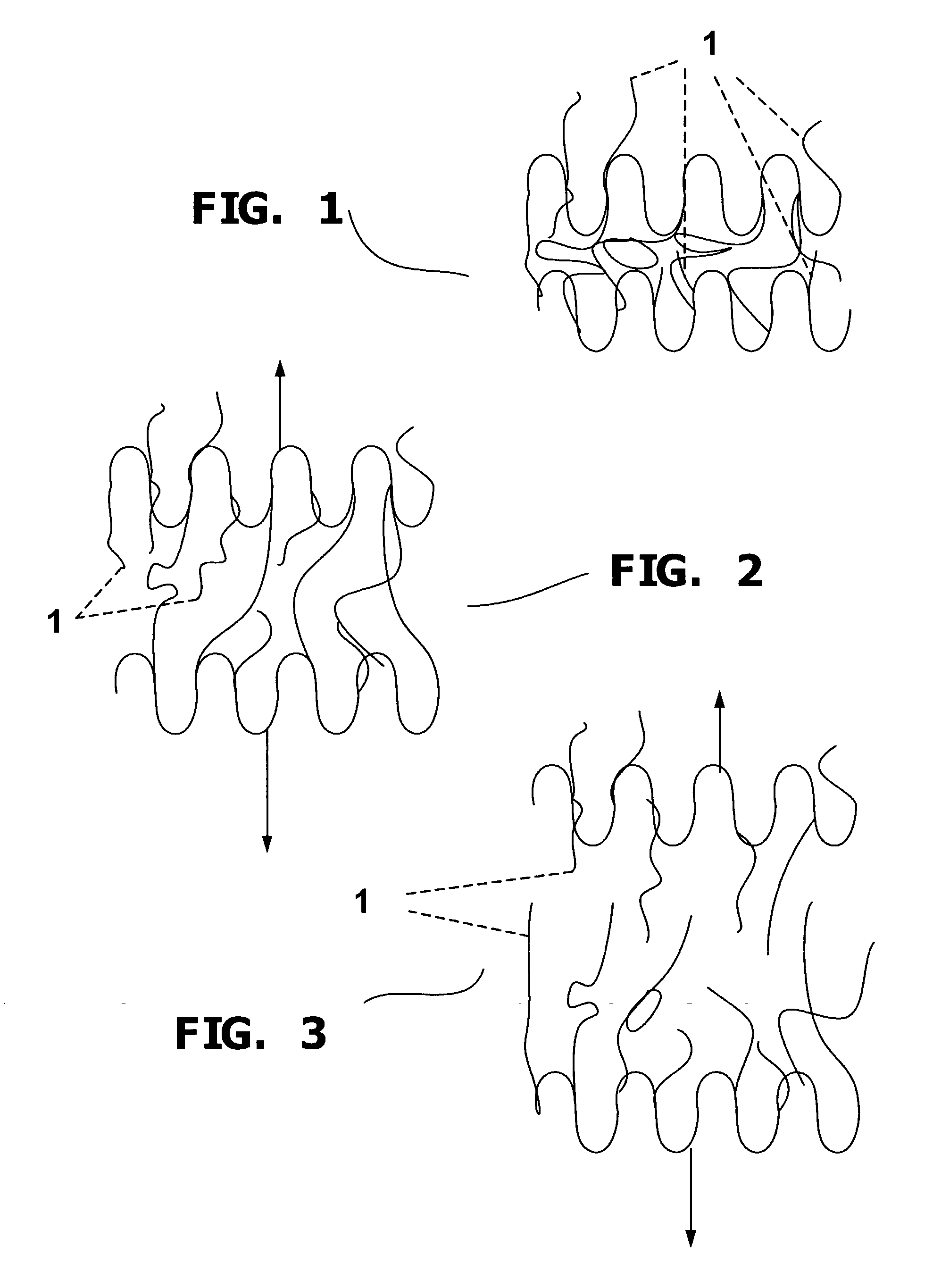

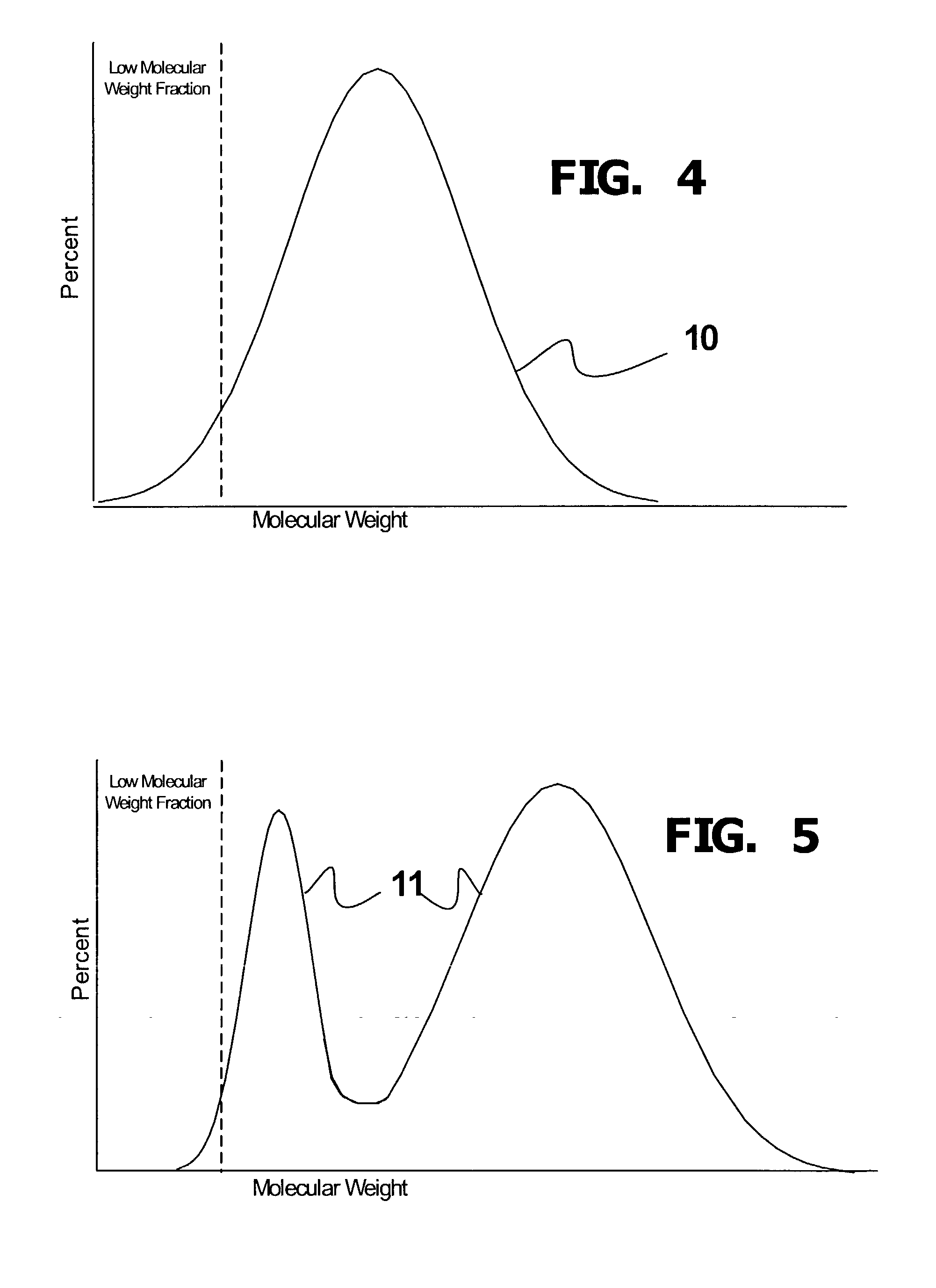

Ethylene-based polymer compositions, methods of making the same, and articles prepared therefrom

The invention provides a composition, comprising at least one high molecular weight ethylene-based interpolymer, and at least one low molecular weight ethylene-based interpolymer, and where the high molecular weight ethylene-based interpolymer has a density less than, or equal to, 0.960 g / cc, and a melt index (I5) less than, or equal to, 1.0 g / 10 min; and where the low molecular weight ethylene-based interpolymer has a density less than, or equal to, 0.915 g / cc, and a melt index (I2) greater than, or equal to, 0.4 g / 10 min.

Owner:DOW GLOBAL TECH LLC

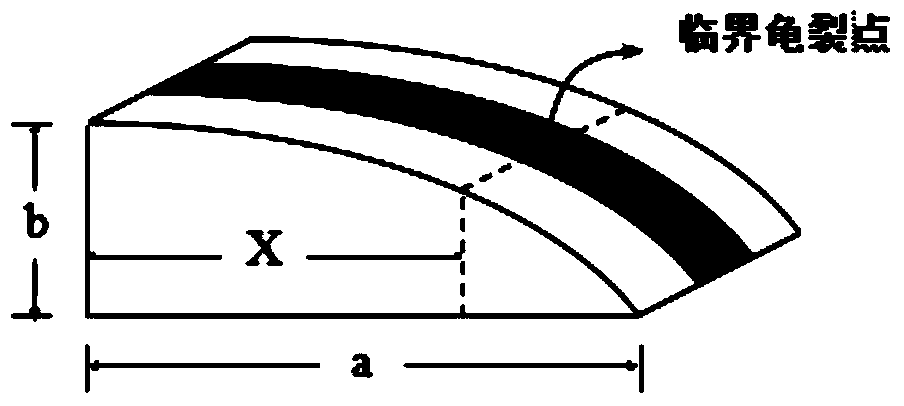

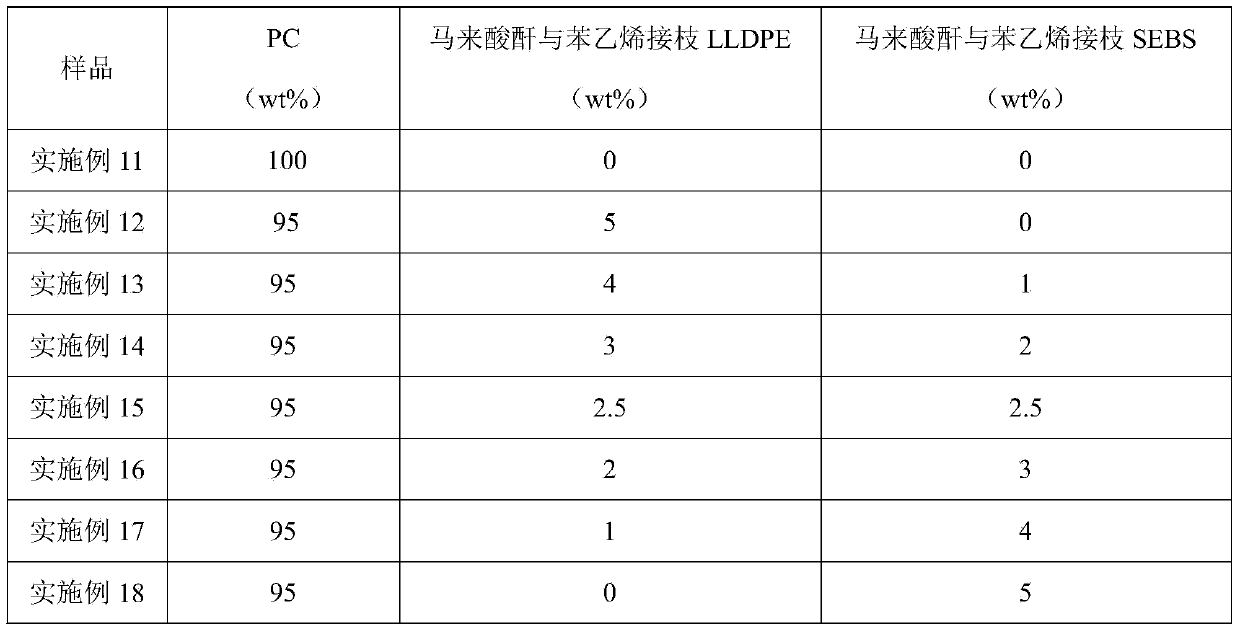

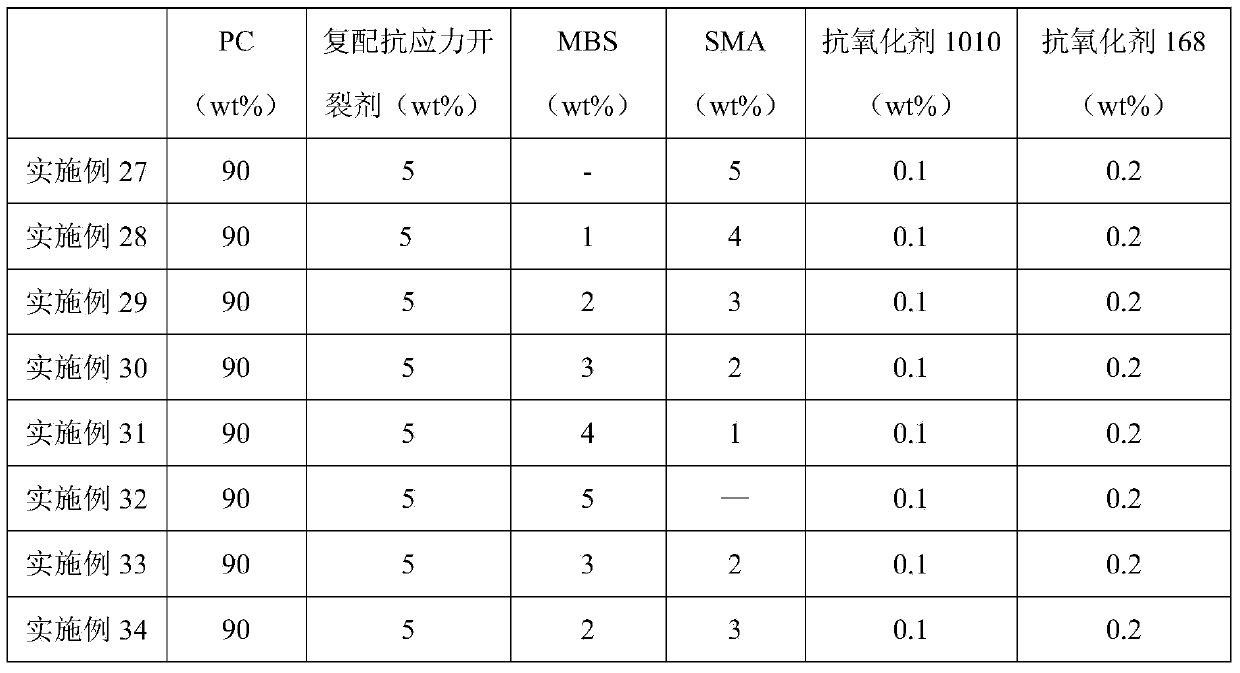

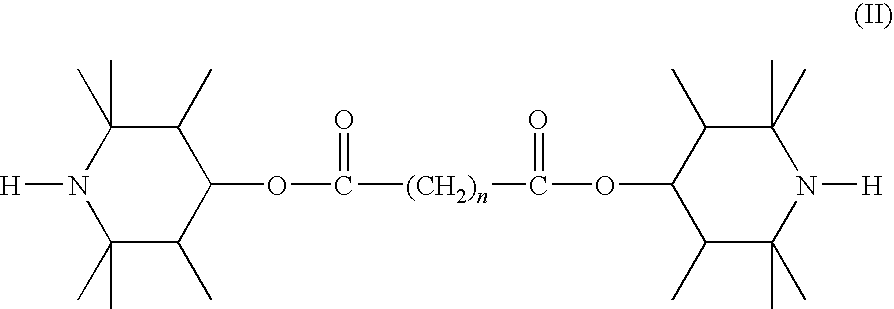

Anti-stress cracking agent, preparation method and application thereof as well as anti-stress PC (Poly Carbonate) polyester

ActiveCN103435753AGood compatibilityImprove interface affinityLinear low-density polyethyleneLow-density polyethylene

The invention relates to an anti-stress cracking agent as well as anti-stress PC (Poly Carbonate). The anti-stress cracking agent is linear low-density polyethylene grafted by maleic anhydride and styrene or hydrogenated SBS (Styrene Butadiene Styrene) grafted by the maleic anhydride and styrene. The mass ratio of the maleic anhydride to the styrene to the linear low-density polyethylene in the linear low-density polyethylene grafted by the maleic anhydride and styrene is (1-5):(1-5):(50-100); the mass ratio of the maleic anhydride to the styrene to the hydrogenated SBS in the hydrogenated SBS grafted by the maleic anhydride and the styrene is (1-5):(1-5):(50-100). The anti-stress cracking agent disclosed by the invention is a composition of the linear low-density polyethylene grafted by the maleic anhydride and the styrene and the hydrogenated SBS) grafted by the maleic anhydride and the styrene in a weight ratio of (1-3):(1-2). Being detected by an anti-stress test, the anti-stress PC disclosed by the invention has good anti-stress cracking performance.

Owner:北京航天凯恩新材料有限公司 +1

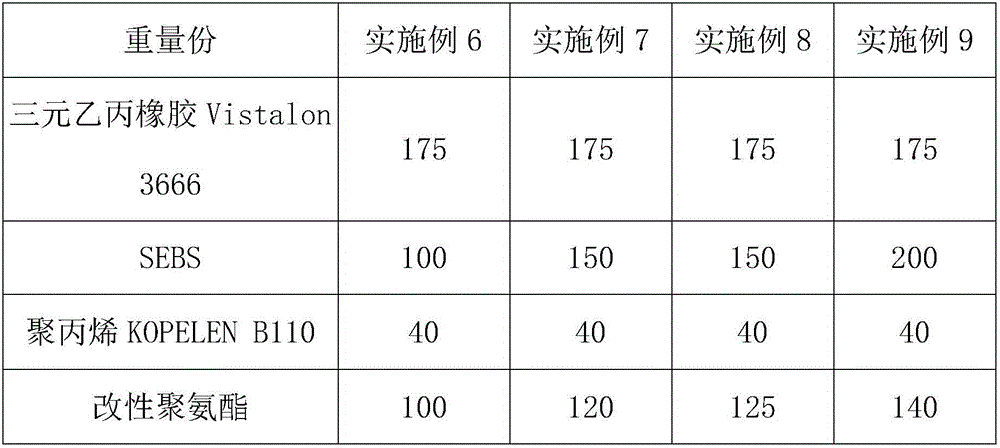

Thermoplastic vulcanized rubber material and preparation method thereof

The invention discloses a thermoplastic vulcanized rubber material. The thermoplastic vulcanized rubber material comprises the following components in parts by weight: 100-300 parts of EPDM rubber, 100-200 parts of SEBS, 25-50 parts of polypropylene, 100-150 parts of modified polyurethane, 100-150 parts of paraffin oil, 5-10 parts of a compatilizer, 5-20 parts of a filling material, 0.5-10 parts of a colouring agent, 0.2-5 parts of a vulcanizing agent, 0.5-5 parts of an antioxidant, and 5-30 parts of a lubricant. The invention also discloses a preparation method of the thermoplastic vulcanized rubber material. The thermoplastic vulcanized rubber material is white or light yellow. The thermoplastic vulcanized rubber material has the advantages of good oil resistant performance and heatproof aging performance, good mechanical property, and good hand feeling, can improve the detect of oil resistant performance of SEBS, and can satisfy the color requirement.

Owner:安徽中翰高分子科技有限公司

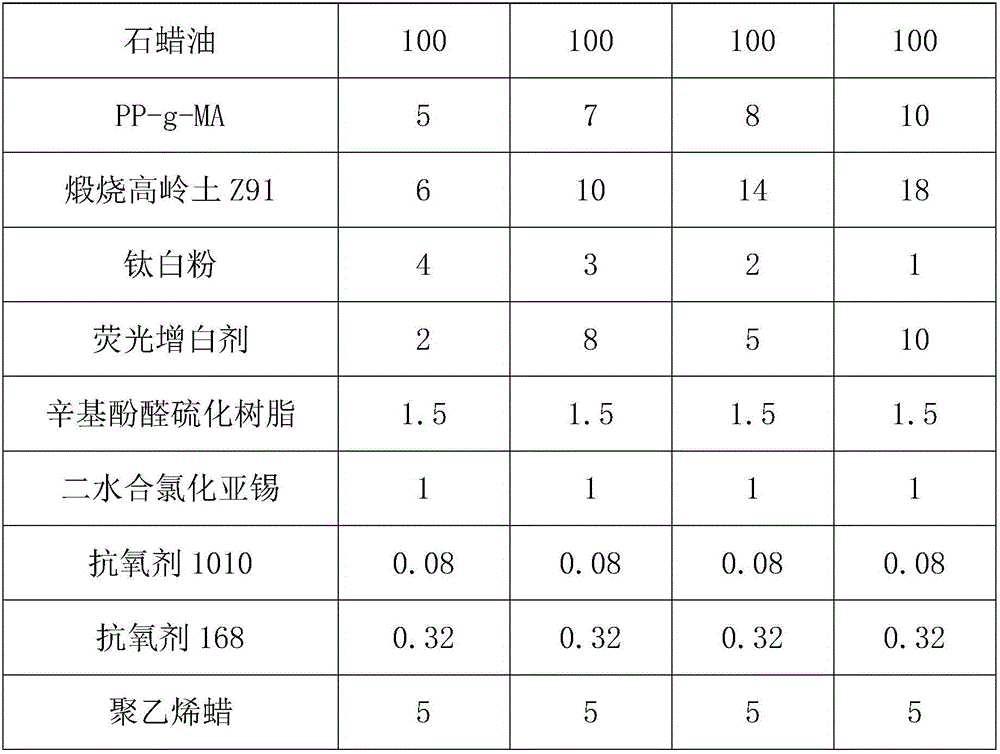

High-toughness halogen-free flame-retardant PC/ABS (polycarbonate/acrylonitrile-butadiene-styrene) alloy reflecting material and preparation method thereof

The invention discloses a high-toughness halogen-free flame-retardant PC / ABS (polycarbonate / acrylonitrile-butadiene-styrene) alloy reflecting material which comprises the following components in percentage by weight: 50-70% of PC resin, 5-10% of ABS resin, 2-3% of self-made compatilizer, 10-30% of titanium white, 0.2-0.5% of halogen-free flame retardant 1, 0.2-1% of halogen-free flame retardant 2, 0.2-0.3% of anti-dripping agent, 0.2-0.5% of antioxidant and 0.4-0.8% of processing assistant. The preparation method comprises the following steps: weighing the components in percentage by weight, mixing in a high-speed mixer for 2-3 minutes, discharging, and carrying out extrusion granulation on a double screw extruder, wherein the processing temperature is 220-260 DEG C, and the rotation speed of the screw is 380-420 rpm. The method improves the processibility, stress cracking resistance and solvent resistance of the PC. The two halogen-free flame retardant are compounded, so that the reflecting material can be more widely applied to manufacturing of reflecting cups and various other illumination reflecting products, and reflecting panels.

Owner:GUANGDONG WAYLAM ENG PLASTICS

Flame retardant PC/ABS composite with high rigidity and high stability

The invention relates to a flame retardant PC / ABS composite with high rigidity and high stability, which is characterized in that the composite comprises the following components in parts by weight according to the formula: 40-98 parts of polycarbonate, 0.5-50 parts of graft polymer, 5-30 parts of talc powder and 2-20 parts of wollastonite. Compared with the prior art, the invention has the advantages of improving the rigidity of materials, having size stability and strength under the heated condition, and the like.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

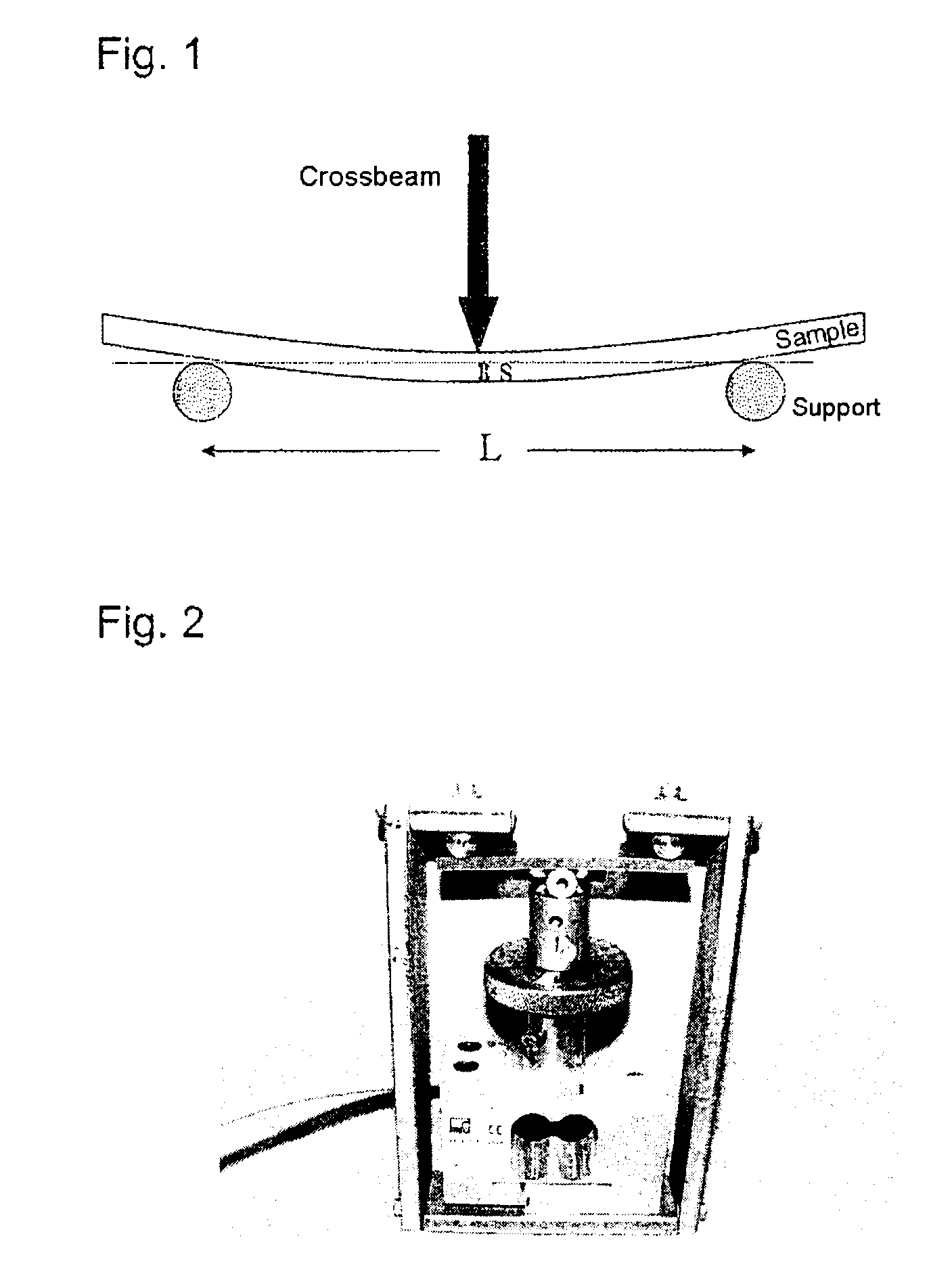

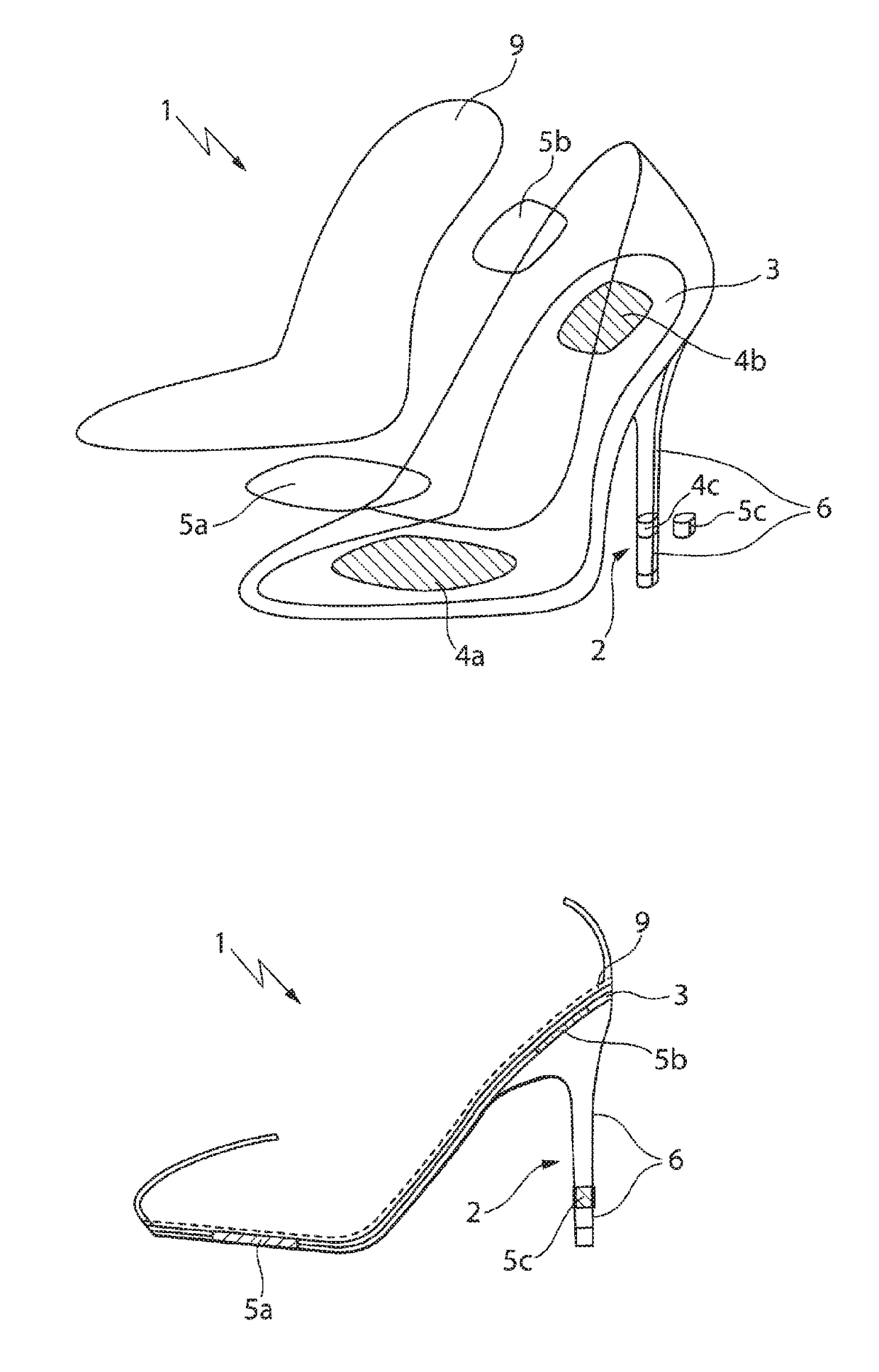

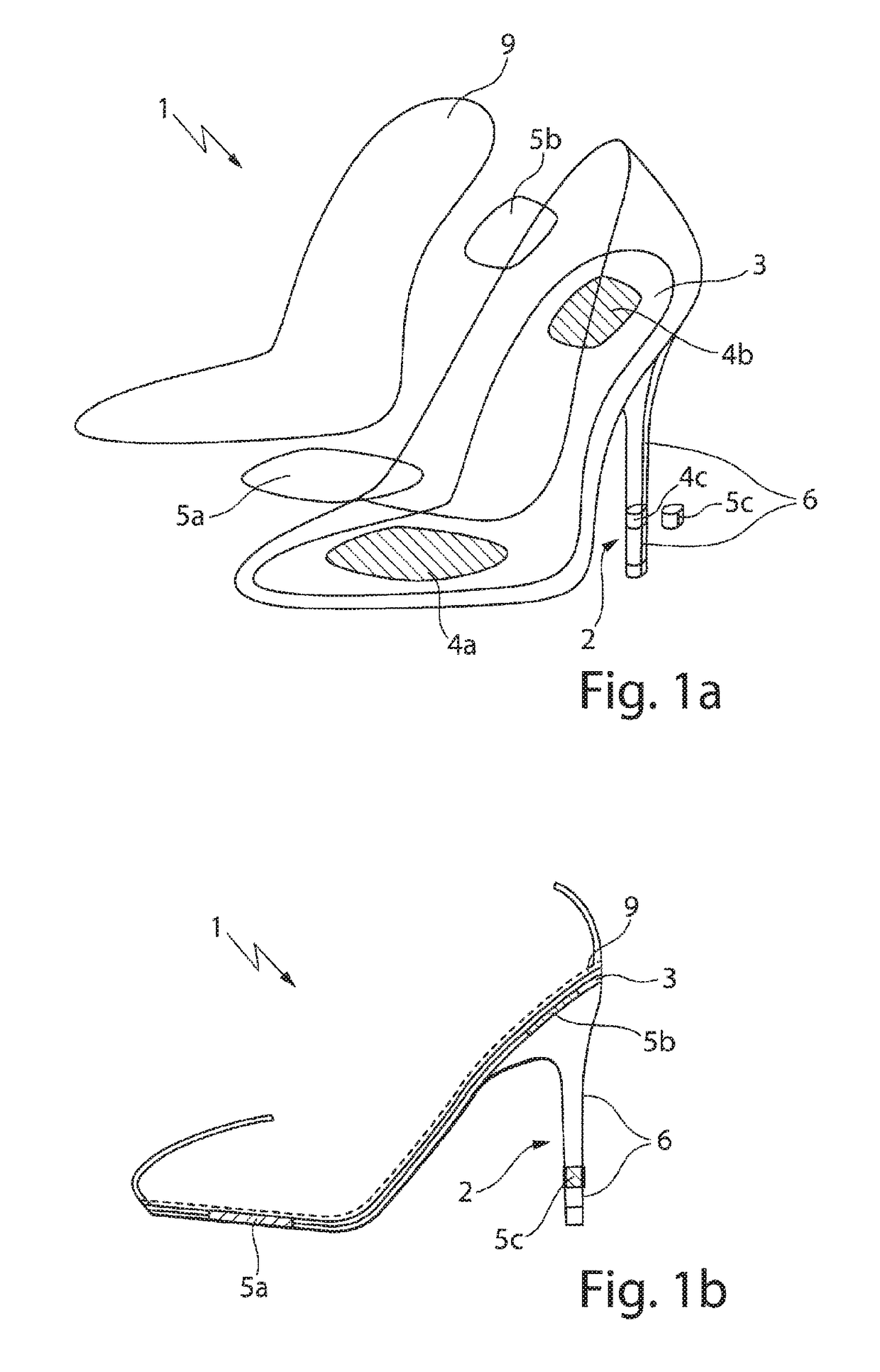

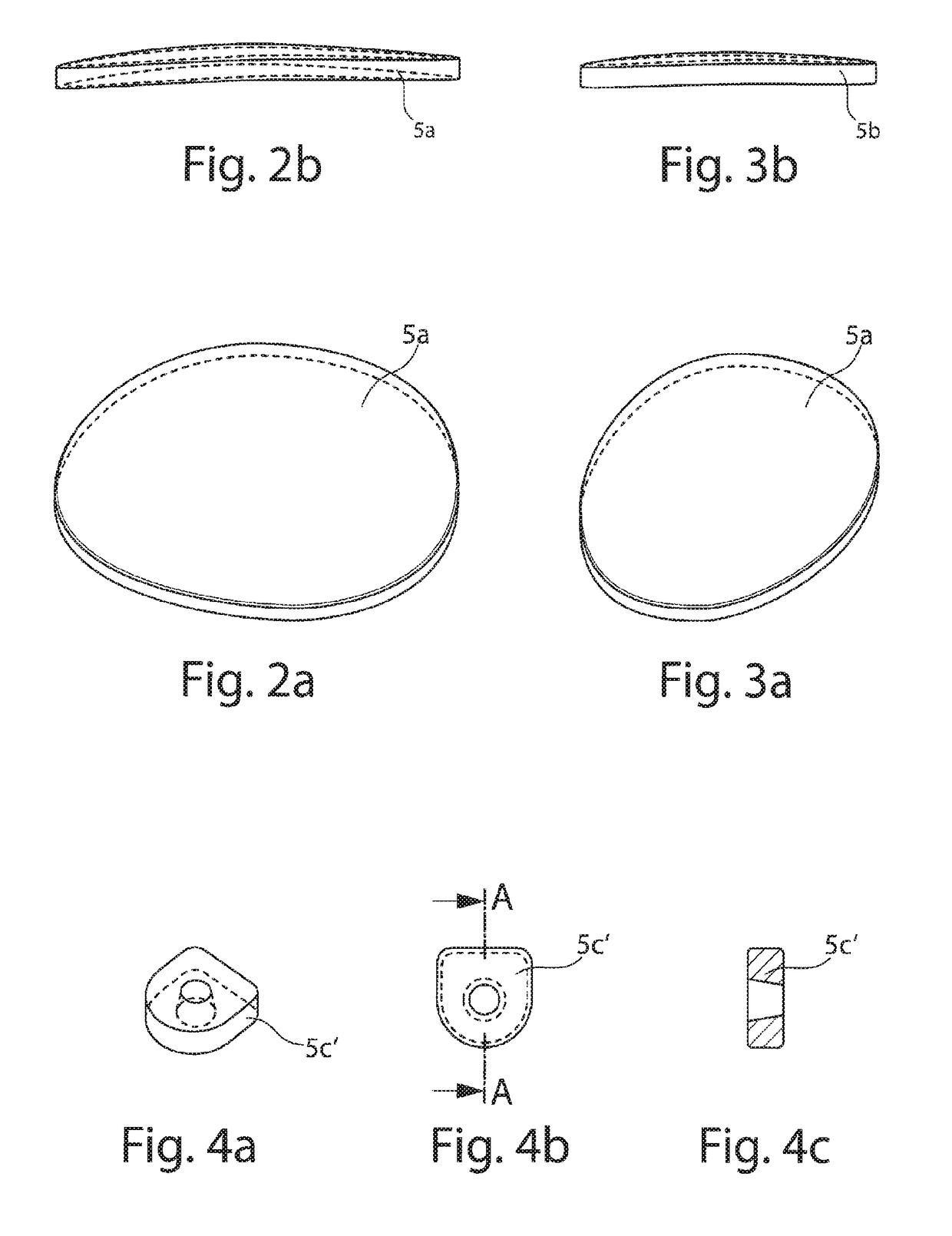

Shoe having a spinal disk material damping element

A shoe such as a pump, high heel shoe, or stiletto, has an insole and a heel. In the heel, the insole and / or the ball region, at least one damping element is integrated. The damping element has a Shore D hardness in the range of 28-33, a modulus of elasticity in the range of 28-38 MPa, and a tensile stress of 9-11 at 600% elongation. In this way, a shoe is realized that is elegantly fashioned and can be provided with a high-quality design without having to compromise on comfort and convenience.

Owner:JACQ

Melt blended high density polyethylene compositions with enhanced properties and method for producing the same

Melt blended HDPE compositions for single and dual wall corrugated HDPE pipe and associated fabricated and molded fittings and accessories having a density in the range of 0.951 to 0.954 grams per cubic centimeter, values of melt flow index according to ASTM D1238 in the range of about 0.15 to 0.35 with enhanced physical properties, process and environmental stress crack resistance (ESCR) characteristics and associated blend methods are disclosed in which virgin or recycled homopolymer and / or copolymer HDPE resin components are blended. The invention discloses a method selecting and determining the relative weight fractions of the HDPE blending components that provides specific physical properties and processability of HDPE blended compositions associated with density and melt index respectively and specific values of environmental stress crack resistance (ESCR) associated with specific molecular parameters. The principal benefits of this invention include cost reduction of raw materials to the corrugated HDPE pipe manufacturers by use of virgin prime commodity HDPE resins and / or wide and off specification prime HDPE resins in place of single stream specialty HDPE resins and favorable impact on the environment by providing the capability of utilizing billions of pounds of recycled HDPE resins in place of prime HDPE resins in the manufacture of corrugated HDPE pipe.

Owner:CORRUGATED POLYETHYLENE PIPE

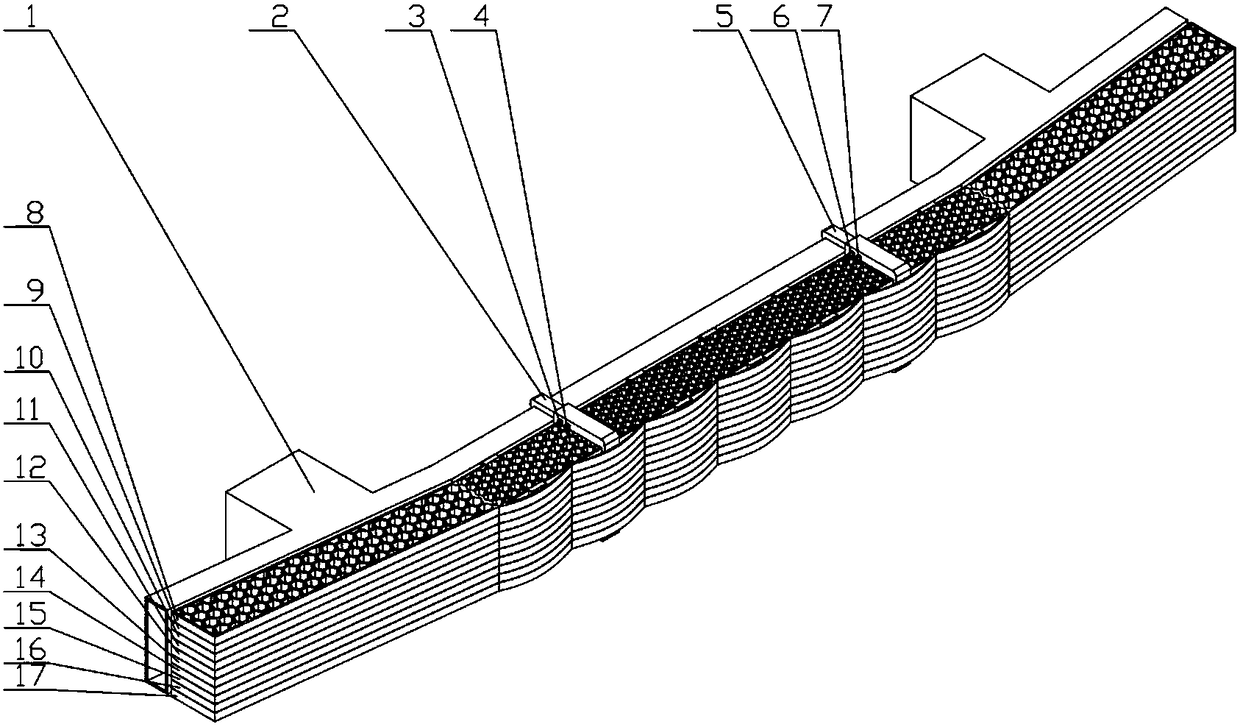

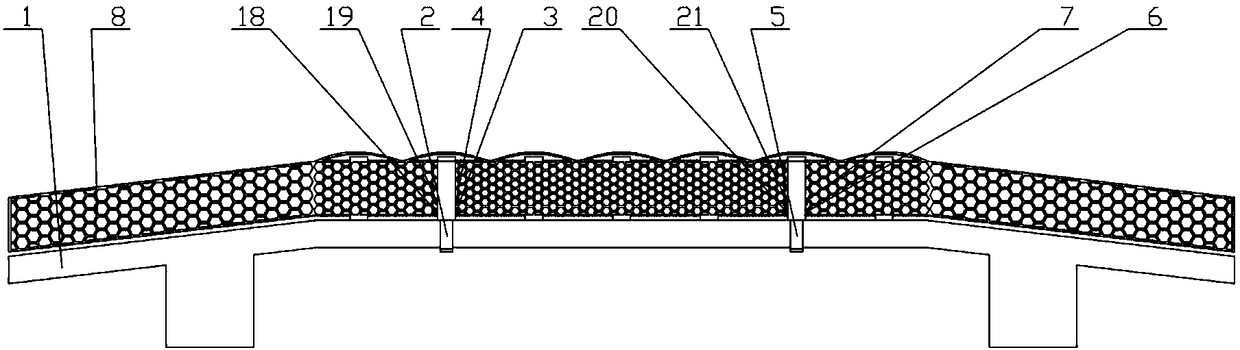

Anti-collision beam buffering structure with stiffness compensation function

PendingCN108501844ASimple structureEasy to installPedestrian/occupant safety arrangementBumpersAutomobile safetyEngineering

The invention belongs to an automobile safety protection device, in particular to an anti-collision beam buffering structure with a stiffness compensation function. The anti-collision beam buffering structure comprises an existing anti-collision beam and buffering devices connected with the existing collision beam through a first fastening buckle, a second fastening buckle, a third fastening buckle and a fourth fastening buckle. The buffering devices each comprise an upper connecting layer, a connecting layer with the buckles for connection, and a lower connecting layer sequentially from top to bottom. The connecting layers with the buckles are constituted by filling layers, and the number of the filling layers is determined by the size of an actual car type anti-collision beam. The connecting layers with the buckles comprise the filling layers with the corresponding number sequentially from top to bottom. The anti-collision beam buffering structure with the stiffness compensation function is simple in structure, convenient to mount, high in applicability and capable of effectively reducing collision impact force, and the problems that as for an existing safety protection structureon the front portion of a car, the anti-impact performance is poor, stiffness is inconsistent, and an anti-collision beam is prone to being damaged are solved.

Owner:JILIN UNIV

Composition with increased stress cracking resistance

InactiveUS8227549B2Improved stress crack resistanceImprove heat deformation resistanceInksOrganic dyesCrack resistanceMeth-

Owner:EVONIK ROEHM GMBH

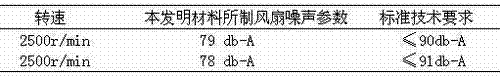

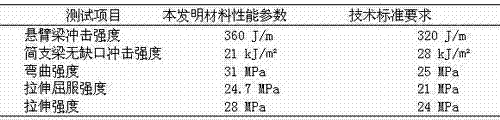

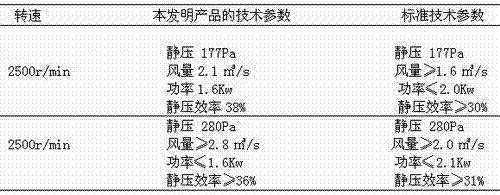

Cooling fan blade of diesel engine and manufacture method thereof

ActiveCN102212230AHigh mechanical strengthImprove toughnessPump componentsPumpsStress concentrationUltraviolet

The invention relates to a cooling fan blade of a diesel engine and a manufacture method thereof and belongs to the technical field of diesel engines. The cooling fan blade of the diesel engine comprises the following components in parts by weight: 70-90 parts of polypropylene, 15-20 parts of high-density polyethylene, 0.15-0.20 part of hydroisomerization dewax base oil 5CST, 0.13-0.18 part of hydroisomerization dewax base oil IOCST, 0.1-0.3 part of antioxidant CA (carbonic anhydrase), 0.5-1.0 part of ultraviolet absorbent and 0.1-0.3 part of dilauryl thiodipropionate; and the cooling fan blade is manufactured by virtue of extruding and injection molding. By using the manufacture process, the stress concentration factor is reduced, the impact resistance and fatigue resistance are improved, the flowing and mold-filling performance of the plastic melt is improved, the flowing resistance and local residual stress are reduced, the cracking and warping are prevented and the appearance of the cooling fan blade is beautiful, thus the cooling fan blade can be widely applied to medium trunks, especially to diesel engine trunks.

Owner:临海市四通制管有限公司

Ethylene-tetrafluoroethylene copolymer and preparation method and application thereof

ActiveCN106084113AEnsure uniformity and thoroughnessShorten the polymerization reaction timeFlexible pipesHigh pressureMonomer

The invention relates to the field of fluorine-containing high molecular materials, in particular to an ethylene-tetrafluoroethylene copolymer and a preparation method thereof. The preparation method includes: (1), vacuumizing a high-pressure kettle, and adding a polymerization medium; (2), adding an initial monomer into the polymerization medium until pressure is 0.9-1.2 Mpa, heating to 58-62 DEG C, adding an initiator; (3), after reaction is started, continuously adding a replenishing monomer for equal-temperature equal-pressure polymerization, and stopping adding the replenishing monomer when adding amount of the replenishing monomer accounts for 10-14% of total mass of the polymerization medium and the replenishing monomer; (4), lowering temperature and pressure, discharging, washing materials, and drying to obtain the copolymer. The preparation method is short in polymerization time, simple to operate and easy for industrial production. The invention further provides application of the ethylene-tetrafluoroethylene copolymer in fuel hose inner layers.

Owner:SHANDONG HUAFU FLUORO CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com