High-toughness halogen-free flame-retardant PC/ABS (polycarbonate/acrylonitrile-butadiene-styrene) alloy reflecting material and preparation method thereof

A reflective material and high toughness technology, applied in the field of polymer materials, can solve the problems that the flame retardant performance is difficult to meet the flame retardant requirements of thin-walled parts, secondary hazards, a large amount of hydrogen halide gas, etc. Loss of properties, effect of high toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

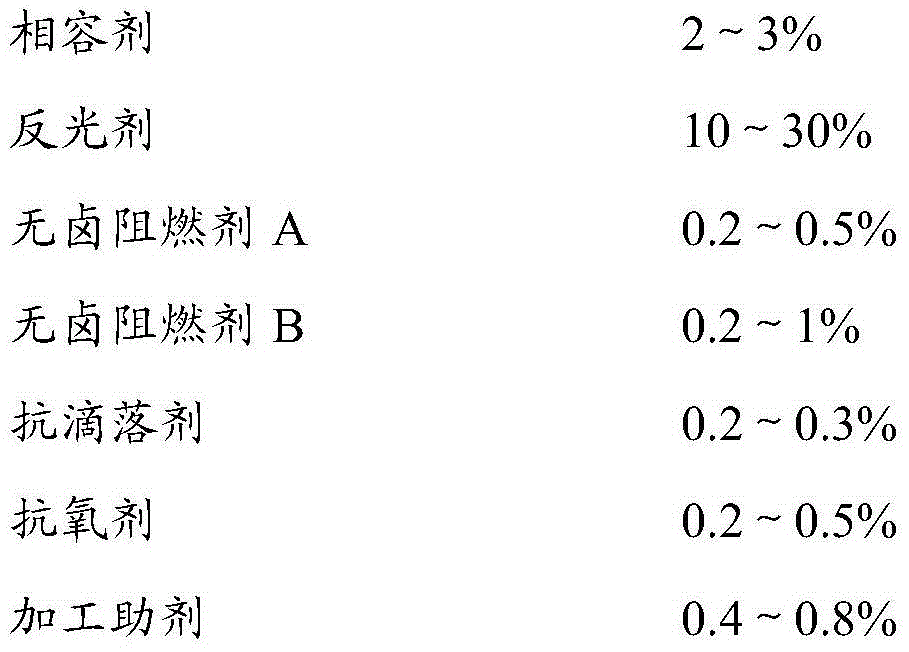

[0029] Weigh each raw material by weight percentage, PC resin 70.5%, ABS resin 5%, compatibilizer 3%, reflective agent 20%, halogen-free flame retardant A 0.2%, halogen-free flame retardant B 0.2%, anti-dripping 0.3% of falling agent, 0.3% of antioxidant, 0.5% of processing aid are mixed by high-speed mixer for 2 minutes, then enter the twin-screw extruder from the metering feeder to be plasticized and melted, and then extruded, cooled, and magnetically passed , Packaging to get the product.

Embodiment 2

[0031] Weigh each raw material by weight percentage, PC resin 65.2%, ABS resin 5%, compatibilizer 3%, reflective agent 25%, halogen-free flame retardant A 0.2%, halogen-free flame retardant B 0.5%, anti-dripping 0.3% of falling agent, 0.3% of antioxidant, 0.5% of processing aid are mixed by a high-speed mixer for 2 minutes, then enter the twin-screw extruder from the metering feeder to be plasticized and melted, and then extruded, cooled, and magnetically passed , Packaging to get the product.

Embodiment 3

[0033] Weigh each raw material by weight percentage, PC resin 56.7%, ABS resin 8%, compatibilizer 3%, reflective agent 30%, halogen-free flame retardant A 0.2%, halogen-free flame retardant B 1%, anti-dripping 0.3% of falling agent, 0.3% of antioxidant, 0.5% of processing aid are mixed by a high-speed mixer for 2 minutes, then enter the twin-screw extruder from the metering feeder to be plasticized and melted, and then extruded, cooled, and magnetically passed , Packaging to get the product.

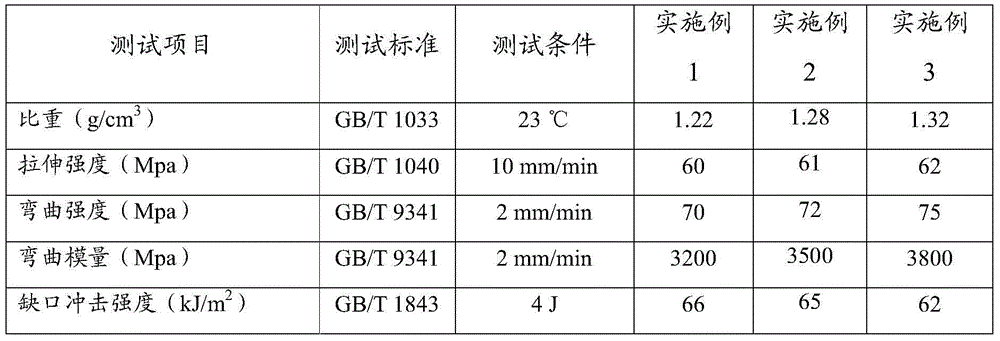

[0034] The performance of a kind of high-toughness halogen-free flame-retardant PC / ABS alloy reflective material obtained in embodiment 1, embodiment 2 and embodiment 3 is as follows

[0035]

[0036]

[0037] The reflective rate of the high-toughness halogen-free flame-retardant PC / ABS alloy reflective material obtained in Examples 1-3 is as follows

[0038]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com