Cracking resistant fiber reinforced epoxy paint for ship ballast tank and preparation method thereof

A fiber-reinforced, epoxy coating technology, applied in the coating field, can solve the problems of easy cracking or peeling of the ballast tank coating, and achieve the effects of excellent corrosion resistance, improved stress crack resistance, and good corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

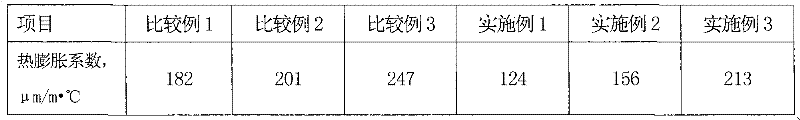

Examples

Embodiment 1

[0051] The preparation method of component 1: Add 23kg of toluene, 30kg of E42 epoxy resin, and 2kg of C5 petroleum resin into the reaction kettle, stir at 300rpm for 15 minutes; then add 0.2kg of Anti-Terra-P dispersant, 0.2kg of Perenol E1 defoamer kg, Tego Flow300 leveling agent 0.3kg, BENTONE 27 anti-settling agent 0.3kg, 400rpm stirring for 10 minutes, finally add 17kg basalt fiber (average length 50 microns, diameter 10 microns), titanium dioxide 2kg (particle size 325 mesh), talc 25kg of powder (with a particle size of 800 mesh), stirred at 1000rpm for 30 minutes, discharged, filtered, and packaged to obtain component 1.

[0052] The preparation method of component two: add 30kg of solvent toluene, 40kg of n-butanol, and 30kg of TY-203 polyamide curing agent into the reaction kettle, stir at 200-500rpm for 10 minutes, discharge, filter, and pack.

[0053] According to the weight ratio, component one: component two = 100:84, when component two is added to component one, ...

Embodiment 2

[0055] The preparation method of component 1: Add 5kg of xylene, 30kg of E51 epoxy resin, and 7kg of C9 petroleum resin into the reaction kettle, stir at 300rpm for 15 minutes; then add 0.5kg of EFKA-44 dispersant, 0.8kg of Perenol S43 defoamer , Tego Glide 100 leveling agent 0.7kg, BENTONE 34 anti-sedimentation agent 1kg, 400rpm stirring for 10 minutes, finally add 10kg basalt fiber (average length 50 microns, diameter 150 microns), titanium dioxide 25kg (particle size is 325 mesh), talcum powder 20kg (with a particle size of 500 mesh), stirred at 1000rpm for 30 minutes, discharged, filtered, and packaged to obtain component 1.

[0056] The preparation method of component 1: the preparation method of component 2: Add 25kg of solvent toluene, 25kg of n-butanol, and 50kg of YD-128 polyamide curing agent into the reaction kettle, stir at 200-500rpm for 15 minutes, discharge, filter, and pack .

[0057] According to the weight ratio, component one: component two = 100:52, when c...

Embodiment 3

[0059] The preparation method of component 1: Add 12kg of xylene, 50kg of E44 epoxy resin, and 12kg of C5 petroleum resin into the reaction kettle, stir at 300rpm for 15 minutes; then add 0.5kg of Disperbyk-163 dispersant, 1kg of PerenolS400 defoamer, Tego Flow ZFS460 leveling agent 1kg, Rilanit HT Extra anti-settling agent 1.5kg, stir at 400rpm for 10 minutes, finally add 5kg of glass fiber (average length 100 microns, diameter 13 microns), titanium dioxide 15kg (particle size 325 mesh), talc powder 2kg (the particle size is 1000 mesh), stirred at 1000 rpm for 30 minutes, discharged, filtered and packaged to obtain component one.

[0060] The preparation method of component two: add 5kg of solvent toluene, 5kg of cyclohexanone, and 90kg of T31 phenolic modified amine curing agent into the reaction kettle, stir at 200-500rpm for 20 minutes, discharge, filter, and pack.

[0061] According to the weight ratio, component one: component two = 100:25, when adding component two into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com