Sea-land camouflage paint and preparation method thereof

A paint and pigment technology, which is applied in the field of sea and land camouflage paint and its preparation, can solve the problems of loss of camouflage performance, reduction of camouflage performance, loss of strength, etc., and achieve excellent salt water resistance, excellent anti-aging performance, and superior anti-corrosion performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The present invention also includes a preparation method of sea and land camouflage paint, comprising the following steps:

[0028] S101. Add the solvent, fluorocarbon resin and cellulose thickener into the container, stir evenly, add anti-corrosion spectrum pigments and functional fillers, stir for 10 minutes, grind at high speed in a grinder, and disperse to a fineness of ≤50 μm ;

[0029] S102. Add the nano-silica modified resin and the siloxane coupling agent into the above container, continue to stir for 30 minutes, and then filter to obtain the marine and land camouflage paint.

[0030] Further, in the step S102, a 120-mesh filter is used for filtering.

Embodiment 1

[0032] Preparation of land and sea camouflage paint T-1

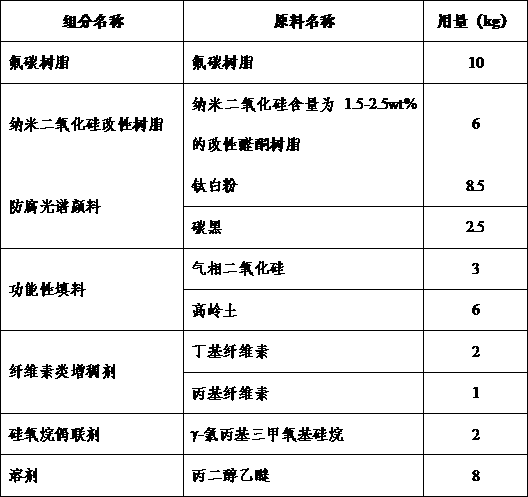

[0033] Table 1 Formulation of land and sea camouflage paint

[0034]

[0035] Add the solvent, fluorocarbon resin and cellulose thickener in the formula amount into the container, stir evenly, add anti-corrosion spectrum pigments and functional fillers, stir for 10 minutes, grind at high speed in a grinder, and disperse to fineness ≤50μm; then add nano-silica modified resin and siloxane coupling agent, continue to stir for 30 minutes, and then filter through a 120-mesh filter to obtain the product.

Embodiment 2

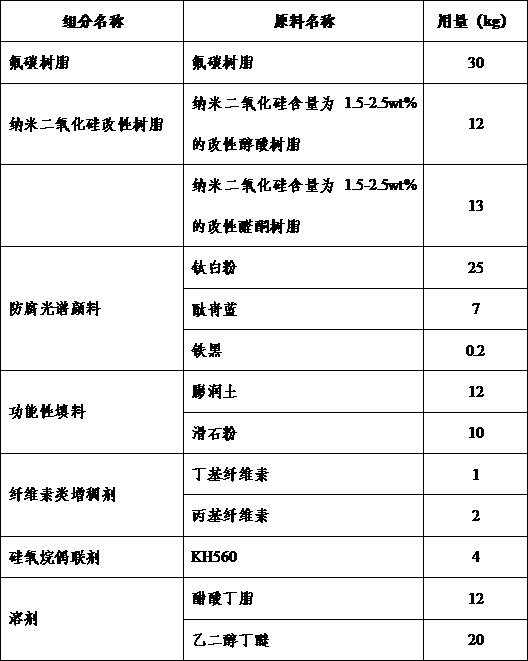

[0037] Preparation of land and sea camouflage paint T-2

[0038] Table 2 Formulation of land and sea camouflage paint

[0039]

[0040] Add the solvent, fluorocarbon resin and cellulose thickener in the formula amount into the container, stir evenly, add anti-corrosion spectrum pigments and functional fillers, stir for 10 minutes, grind at high speed in a grinder, and disperse to fineness ≤50μm; then add nano-silica modified resin and siloxane coupling agent, continue to stir for 30 minutes, and then filter through a 120-mesh filter to obtain the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact resistance | aaaaa | aaaaa |

| Salt spray resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com