Thermoplastic vulcanized rubber material and preparation method thereof

A technology of thermoplastic vulcanization and rubber materials, applied in the field of rubber, can solve the problems of not meeting the color requirements of SEBS materials, opacity of vulcanized rubber, etc., and achieve the effect of increasing anti-ultraviolet performance, good whiteness and brightness, and good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

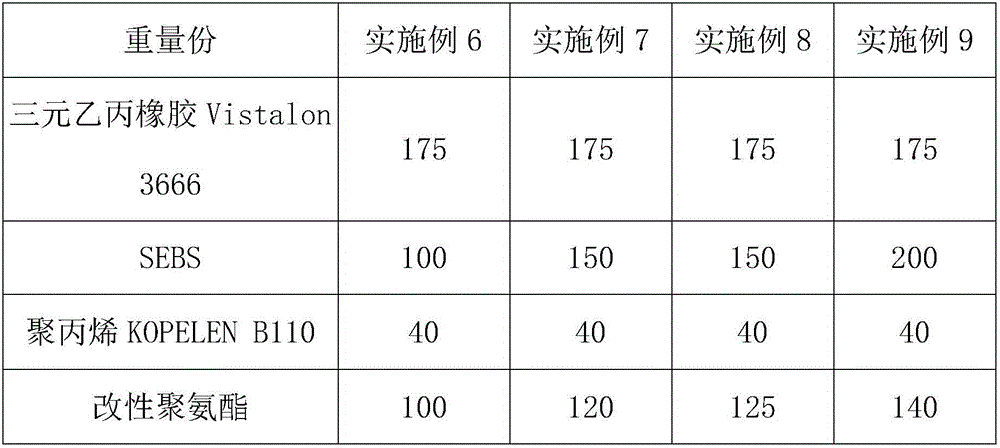

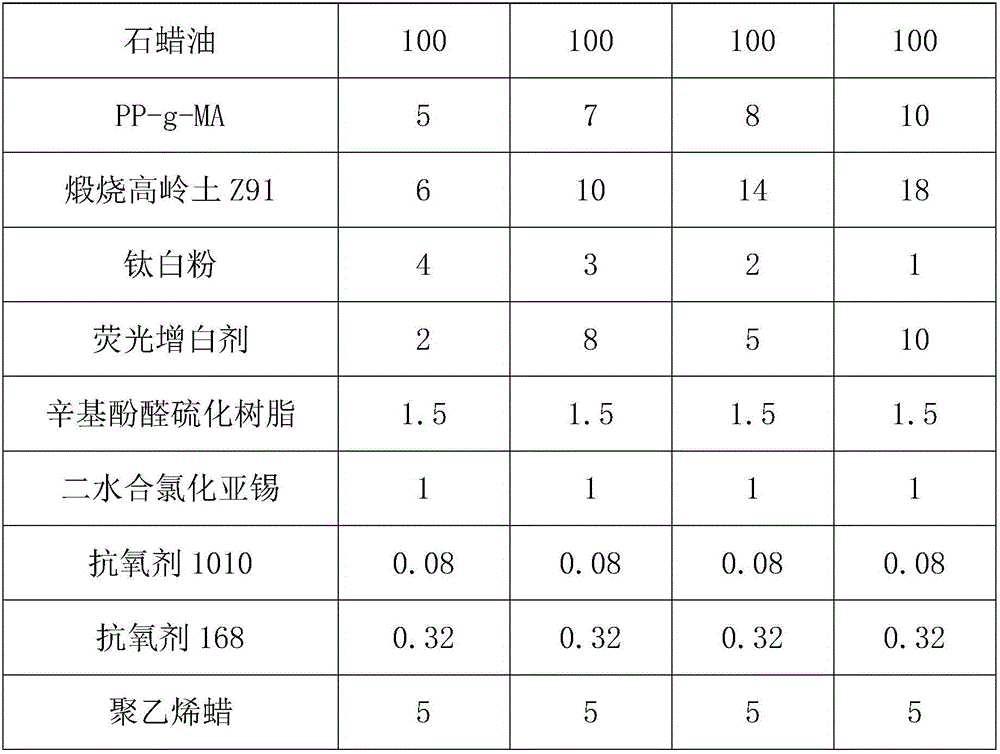

[0037] A thermoplastic vulcanized rubber material, its raw materials include by weight: 200 parts of EPDM rubber, 150 parts of SEBS, 38 parts of polypropylene, 125 parts of modified polyurethane, 125 parts of paraffin oil, 7 parts of compatibilizer, and 12 parts of filler , 5 parts of colorant, 3 parts of vulcanizing agent, 3 parts of anti-aging agent, 18 parts of lubricant.

[0038]The preparation method of the above-mentioned thermoplastic vulcanized rubber material comprises the following steps: mixing and banburying EPDM rubber, SEBS, polypropylene, modified polyurethane, aromatic oil, compatibilizer, anti-aging agent and lubricant, and extruding through a single screw Machine granulation to obtain mixed particles; mix the mixed particles, fillers, colorants, and vulcanizing agents, and dynamically vulcanize them through a twin-screw extruder, then pull them into strands, cool them, and pelletize them to obtain thermoplastic vulcanized rubber materials.

Embodiment 2

[0040] A kind of thermoplastic vulcanized rubber material, its raw material comprises by weight: vinyl content is 30wt% EPDM rubber 300 parts, SEBS 100 parts, polypropylene 50 parts, modified polyurethane 100 parts, paraffin oil 150 parts, PP- 5 parts of g-MA, 20 parts of inorganic filler with a whiteness of 86, 0.5 part of inorganic colorant, 5 parts of vulcanizing agent, 0.5 part of anti-aging agent, 30 parts of lubricant;

[0041] Among them, in the preparation process of modified polyurethane, 4,4'-diphenylmethane diisocyanate, polyoxypropylene glycol 2000, butyltin dilaurate, dimethylol propionic acid, N- Mix methylpyrrolidone to prepare a polyurethane prepolymer solution; adjust the temperature to 50°C, add γ-aminopropyltriethoxysilane modified diatomite and γ-aminopropyl triethoxysilane to the polyurethane prepolymer solution Ethoxysilane modified titanium dioxide, keep stirring for 3 hours, heat up to 70°C, add tridecafluoro-1-octanol, keep stirring for 4 hours, add pe...

Embodiment 3

[0045] A kind of thermoplastic vulcanized rubber material, its raw material comprises by weight: vinyl content is 50wt% EPDM rubber 100 parts, SEBS 200 parts, polypropylene 25 parts, modified polyurethane 150 parts, paraffin oil 100 parts, POE- 10 parts of g-MA, 5 parts of calcined kaolin with a whiteness of 87, 10 parts of organic colorant, 0.2 part of vulcanizing agent, 5 parts of anti-aging agent, and 5 parts of lubricant;

[0046] Among them, in the preparation process of modified polyurethane, 4,4'-diphenylmethane diisocyanate, polyoxypropylene glycol 2000, butyltin dilaurate, dimethylol propionic acid, N- Mix methylpyrrolidone evenly, raise the temperature to 85°C, and keep stirring for 3 hours to obtain a polyurethane prepolymer solution; adjust the temperature to 60°C, and add 400 meshes of γ-aminopropyltriethoxysilane modified silicon Alginate and 500 mesh γ-aminopropyltriethoxysilane modified titanium dioxide, keep stirring for 1h, heat up to 80°C, add tridecafluoro-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com