Control rod for nuclear reactor and method of manufacturing control rod

a control rod and nuclear reactor technology, applied in nuclear engineering, nuclear elements, greenhouse gas reduction, etc., can solve the problems of reducing the life of the flux trap-type hafnium control rod, threatening the safety of the nuclear reactor, and revealing no technique for reducing residual stresses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

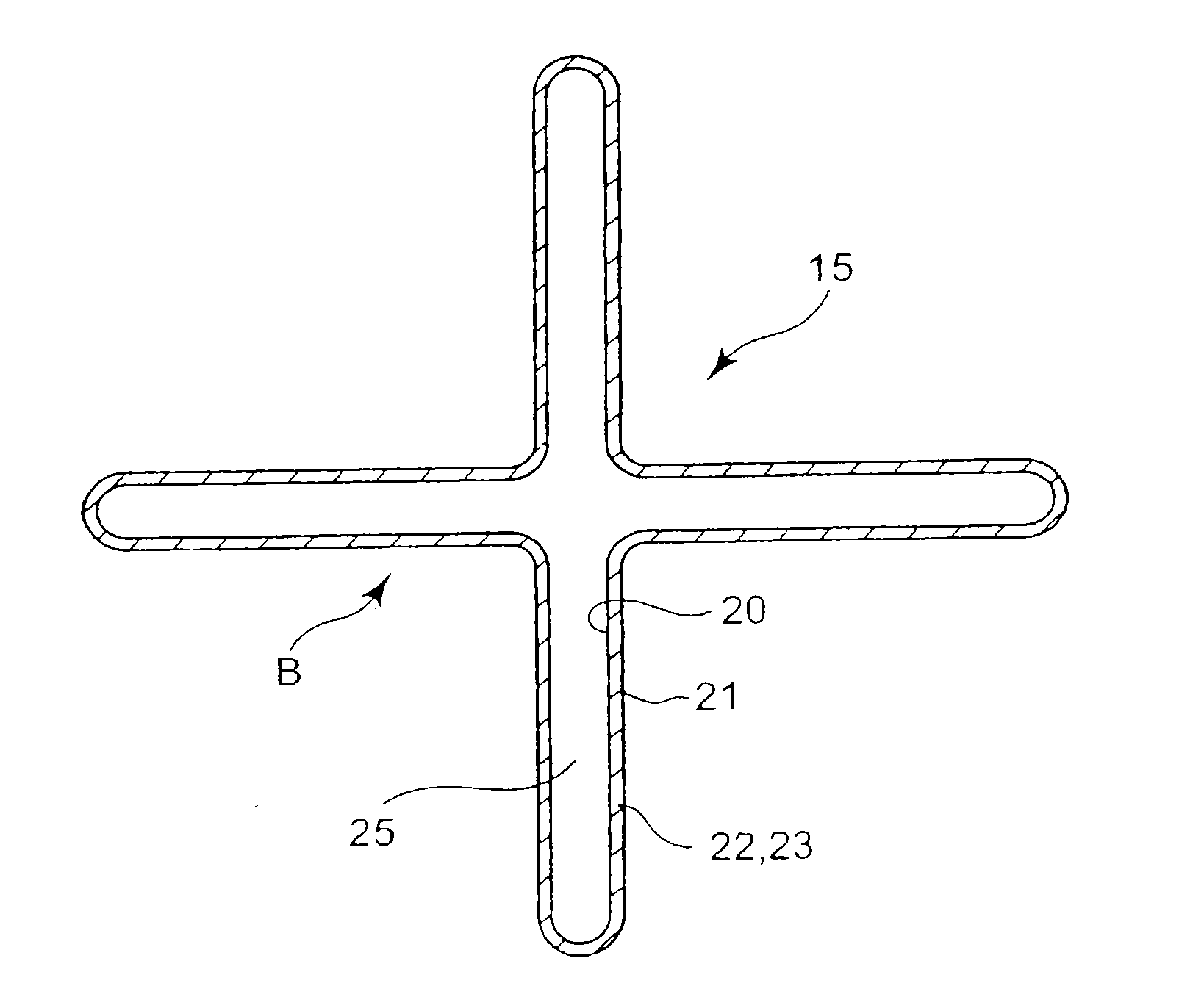

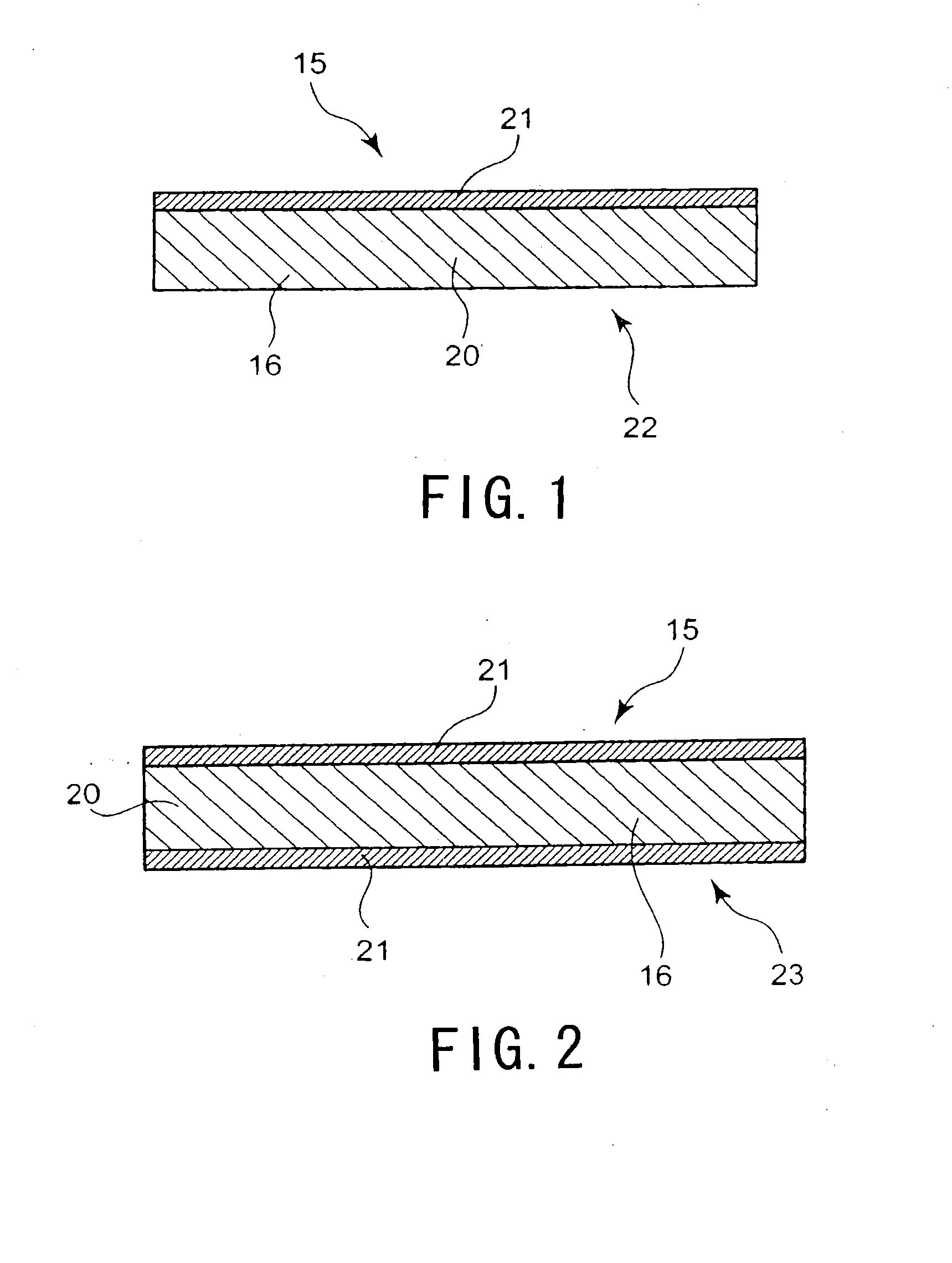

[0093]FIG. 1 is a partial sectional view of a neutron absorber 16 included in a control rod 15 according to a first embodiment of the present invention. The control rod 15 itself has a general structure such as shown in FIG. 30. The neutron absorber 16 includes a hafnium plate 20 bonded to a zirconium plate 21 by means of hot rolling or the like. The hafnium plate 20 and the zirconium plate 21 form a composite member 22.

[0094]A conventional control rod, of the structure mentioned with reference to FIGS. 30 to 32, for example, includes U-shaped sheaths having fitting portions, hafnium plates, and supporting pieces having projecting portions bonded to the fitting portions by TIG welding. If the conventional control rod is exposed to high-temperature water in a nuclear reactor in such a state that the U-shaped sheaths have high residual tensile stress due to welding, stress corrosion cracking occurs in the U-shaped sheaths to deteriorate the performance of the conventional control rod....

second embodiment

[0097]FIG. 2 is a partial sectional view of a neutron absorber 16 included in a control rod 15 according to a second embodiment of the present invention. In this embodiment, the neutron absorber 16 includes a composite member 23 including a hafnium plate 20 and zirconium plates 21 bonded to both surfaces of the hafnium plate 20 by means of hot rolling or the like as shown in FIG. 2.

[0098]The hafnium plate 20 is protected from high-temperature, high-pressure water that is a moderator, and hence, the corrosion of the neutron absorber 16 can be prevented and the creation of oxides in the control rod 15 can be suppressed. This allows the control rod 15 to have a long life.

third embodiment

[0099]A third embodiment of the present invention provides a method of manufacturing the control rod 15 according to the first embodiment. The control rod 15 includes the composite member 22, which includes the hafnium plate 20 and the zirconium plate 21.

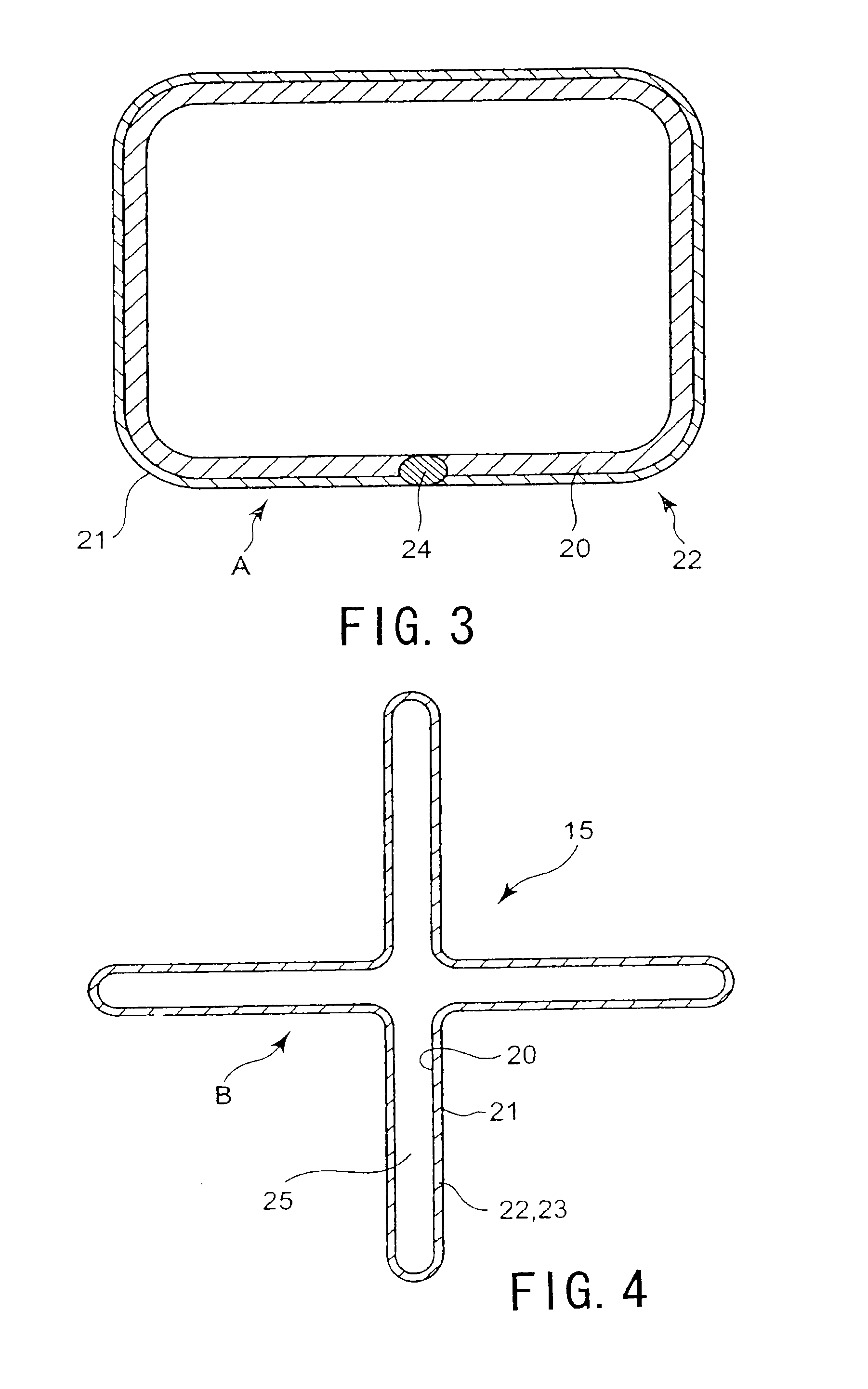

[0100]As shown in FIG. 3, after the composite member 22, which has been prepared by bonding the hafnium plate 20 and the zirconium plate 21 together by means of rolling, for example, is shaped so as to have such a box shape that the zirconium plate 21 is located outside the hafnium plate 20, end portions of the composite member 22 are bonded to each other with a welding member 24 or the like, whereby a rectangular tube A is prepared.

[0101]As shown in FIG. 4, the rectangular tube A is molded into a cross-shaped tube B such that the zirconium plate 21 is located outside the hafnium plate 20. The cross-shaped tube B has an inner space 25 which has a cross shape in cross section and through which water used as a moderator can flow. As s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com