Device for recovering residual heat from exhaust gas

a technology of exhaust gas and residual heat, which is applied in the direction of heat recovery, greenhouse gas reduction, lighting and heating apparatus, etc., can solve the problems of increasing the size of the apparatus, complicated structure, stress corrosion cracking (scc) of the water pipe, etc., to prevent stress corrosion cracking, improve heat recovery efficiency, and increase the partial pressure of the vapor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

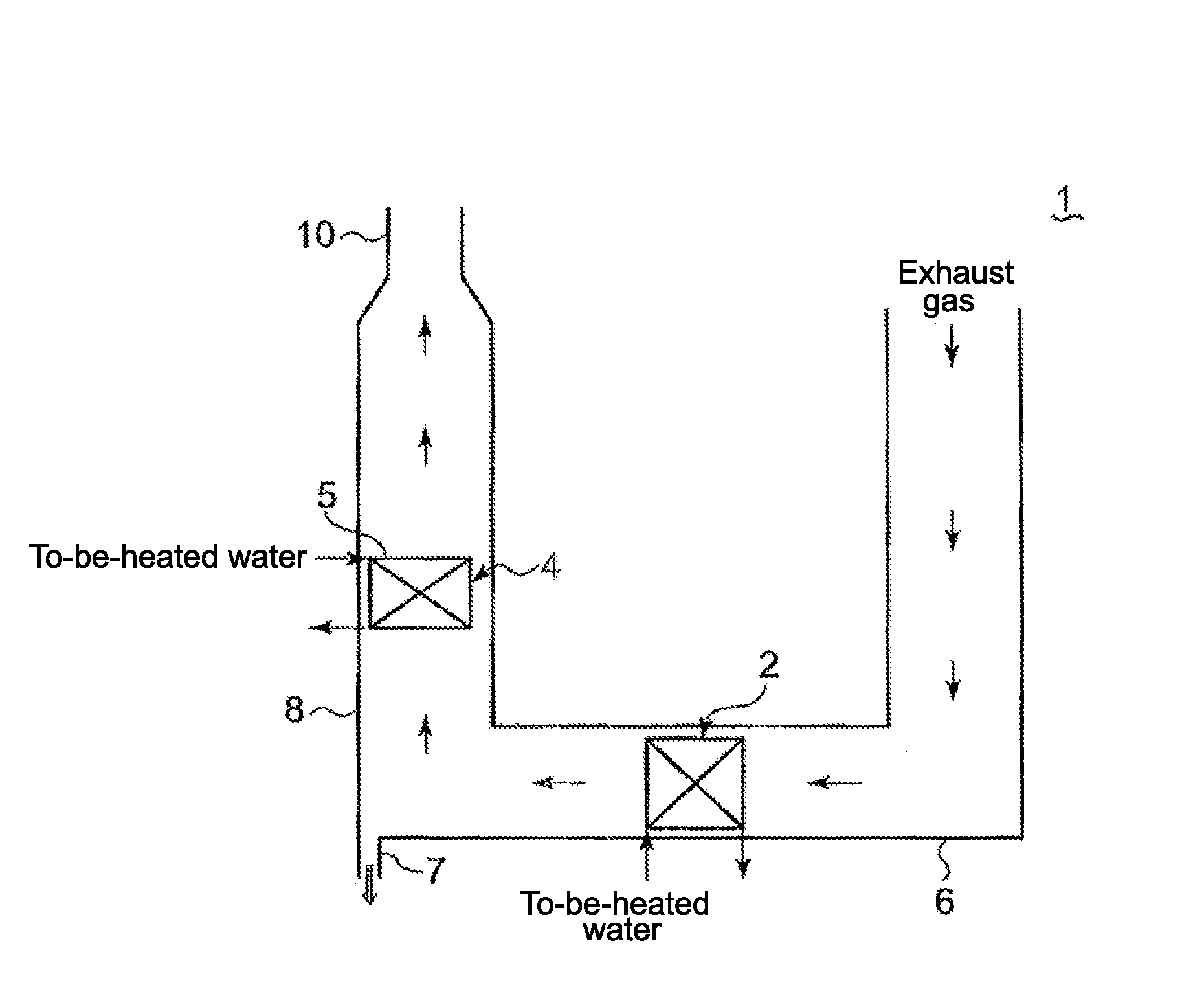

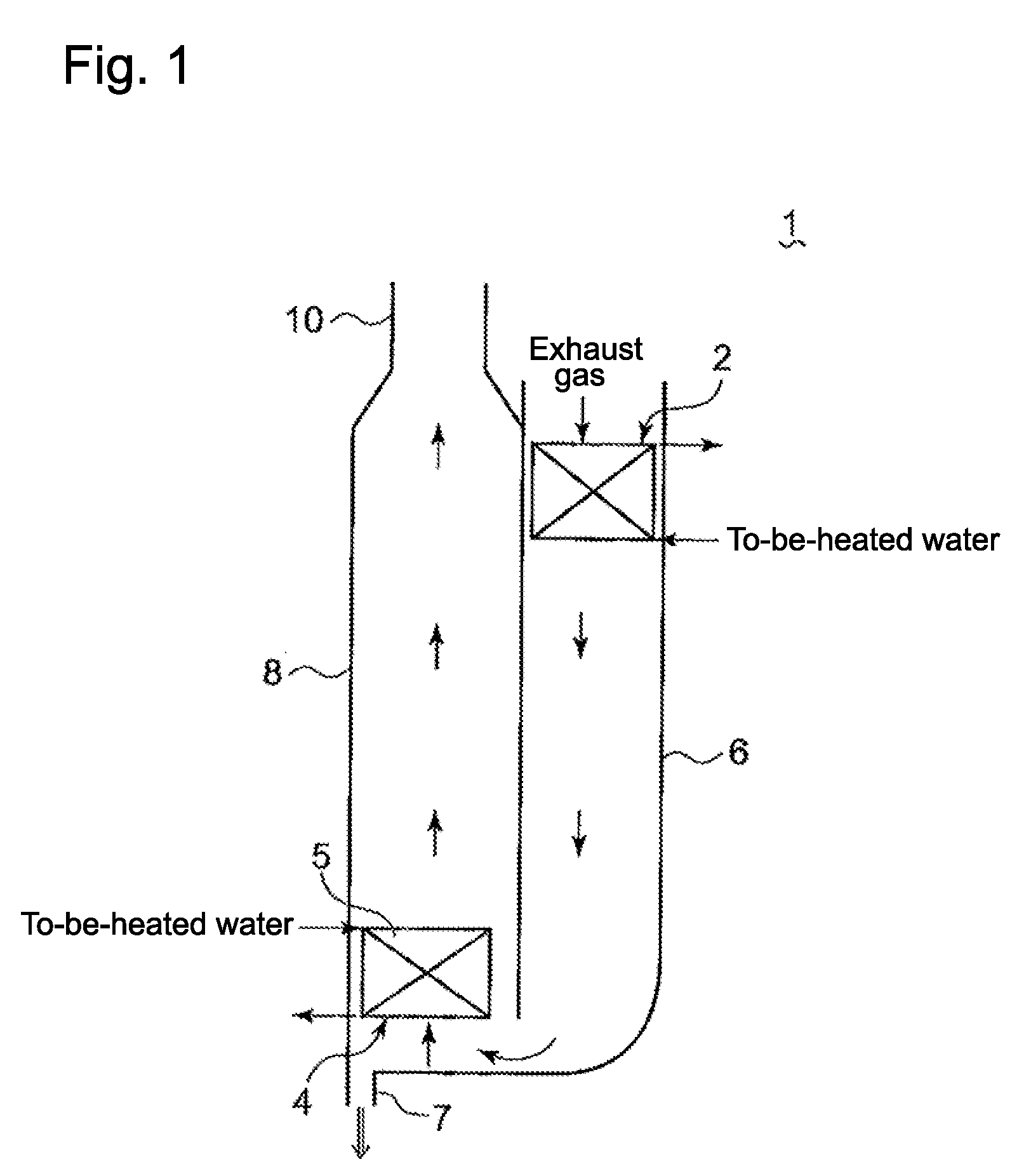

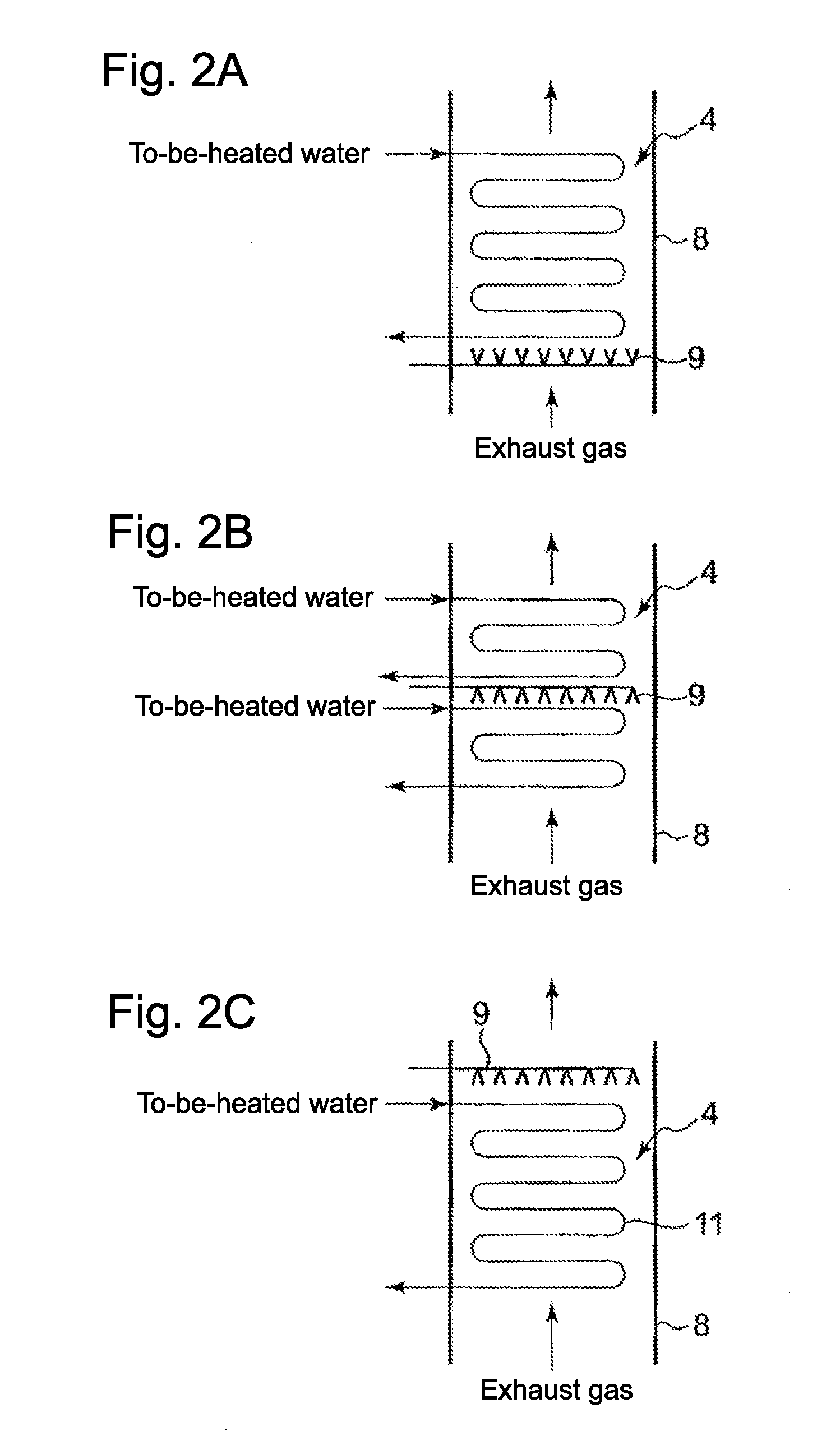

[0040]FIG. 1 is a schematic configuration diagram that illustrates an example of the device for recovering residual heat from exhaust gas according to a first embodiment of the present invention. FIG. 2 is a schematic diagram that illustrates an installation example of a spray nozzle provided at the vicinity of a condensation economizer.

[0041]The device 1 for recovering residual heat from exhaust gas according to the present invention is provided in a duct connected to a funnel 10 that discharges the exhaust gas from a boiler to the atmosphere. As shown in FIG. 1, the device 1 for recovering residual heat from exhaust gas mainly includes a dry economizer 2 and a condensation economizer 4.

[0042]The dry economizer 2 and the condensation economizer 4 include a water pipe through which the to-be-heated water (a boiler water) is circulated. A material of the water pipe preferably uses SUS316L added with molybdenum in austenitic stainless steel from the viewpoint of improving a corrosion ...

second embodiment

[0062]Next, the device for recovering residual heat from exhaust gas according to a second embodiment will be described.

[0063]FIG. 4 is a schematic configuration diagram that illustrates a device for recovering residual heat from exhaust gas according to a second embodiment.

[0064]The device 1 for recovering residual heat according to the second embodiment has the same configuration as that of the device 1 for recovering residual heat described in the first embodiment except that white smoke to be discharged from the funnel to the atmosphere is suppressed. For that reason, the detailed description of the same configuration as that of the first embodiment will be omitted.

[0065]As shown in FIG. 4, the device 1 for recovering residual heat further includes a white-smoke detector 12, a heater 14, and a heating controller 22, besides the configuration described in FIG. 1.

[0066]The white-smoke detector 12 detects the white smoke to be discharged from the funnel 10 to the atmosphere. The wh...

third embodiment

[0075]Next, a device for recovering residual heat according to a third embodiment will be described.

[0076]FIG. 5 is a schematic configuration diagram that illustrates a device for recovering residual heat from exhaust gas according to the third embodiment.

[0077]The device 1 for recovering residual heat from exhaust gas according to the third embodiment has the same configuration as the device 1 for recovering residual heat described in the second embodiment except that a bypass channel and a damper are provided instead of the gas-gas heater 14 as the heater, and thus, the detailed description of the same configuration will be omitted.

[0078]As shown in FIG. 5, the heater includes a bypass channel 28 and a damper 32. The bypass channel 28 connects the upstream duct 6 with the downstream duct 8, and joins a part of the exhaust gas of the upstream duct 6 on the downstream side of the exhaust gas flow of the condensation economizer 4. The damper 32 controls the flow rate of the exhaust g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com