Austenitic stainless steel excellent in intergranular corrosion resistance and stress corrosion cracking resistance, and method for producing austenitic stainless steel material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

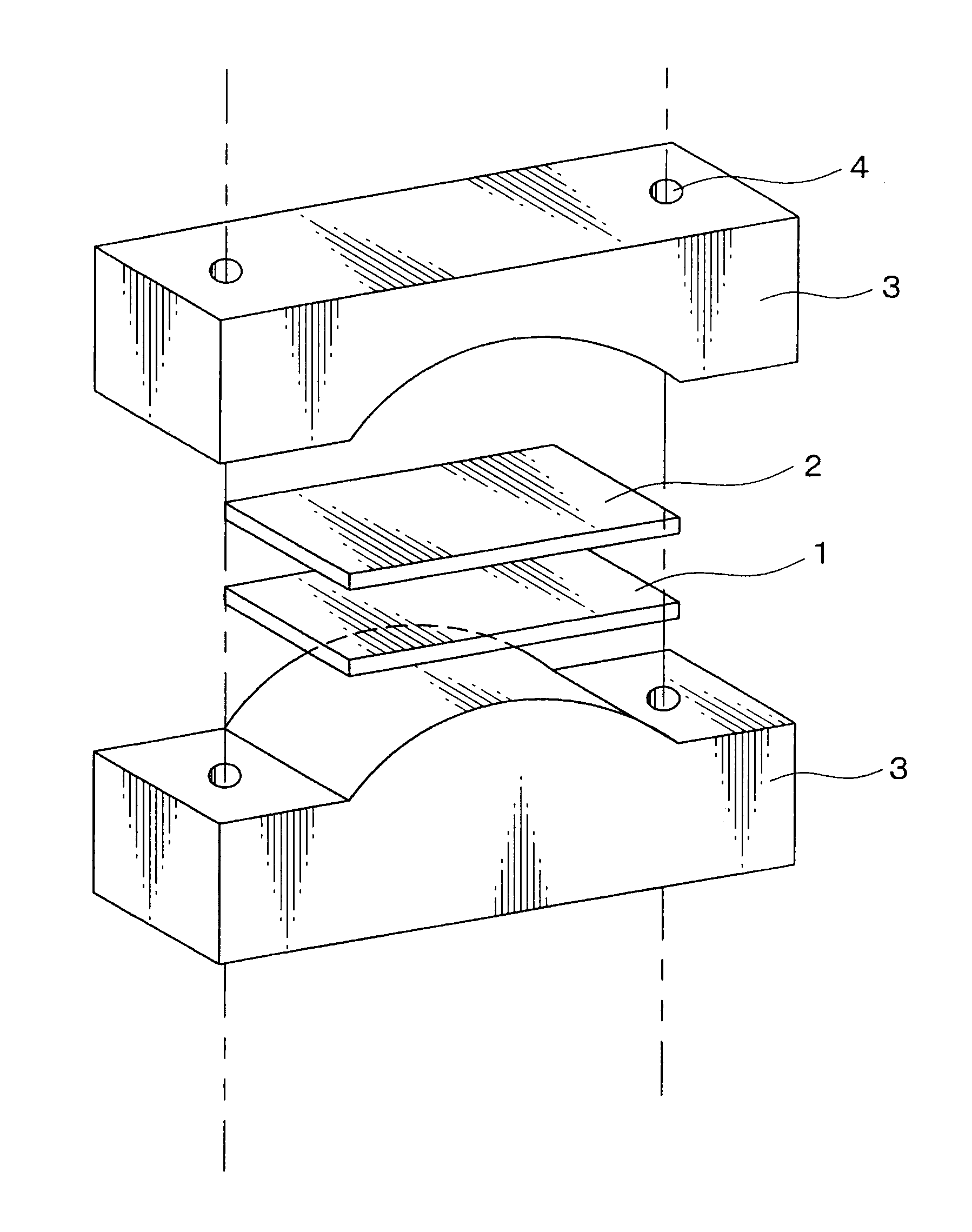

Image

Examples

examples

[0081]Hereinafter, the present invention will be described more specifically with reference to examples. It should be understood that the present invention is not restricted by the Examples at all.

experiment 1

(Experiment 1)

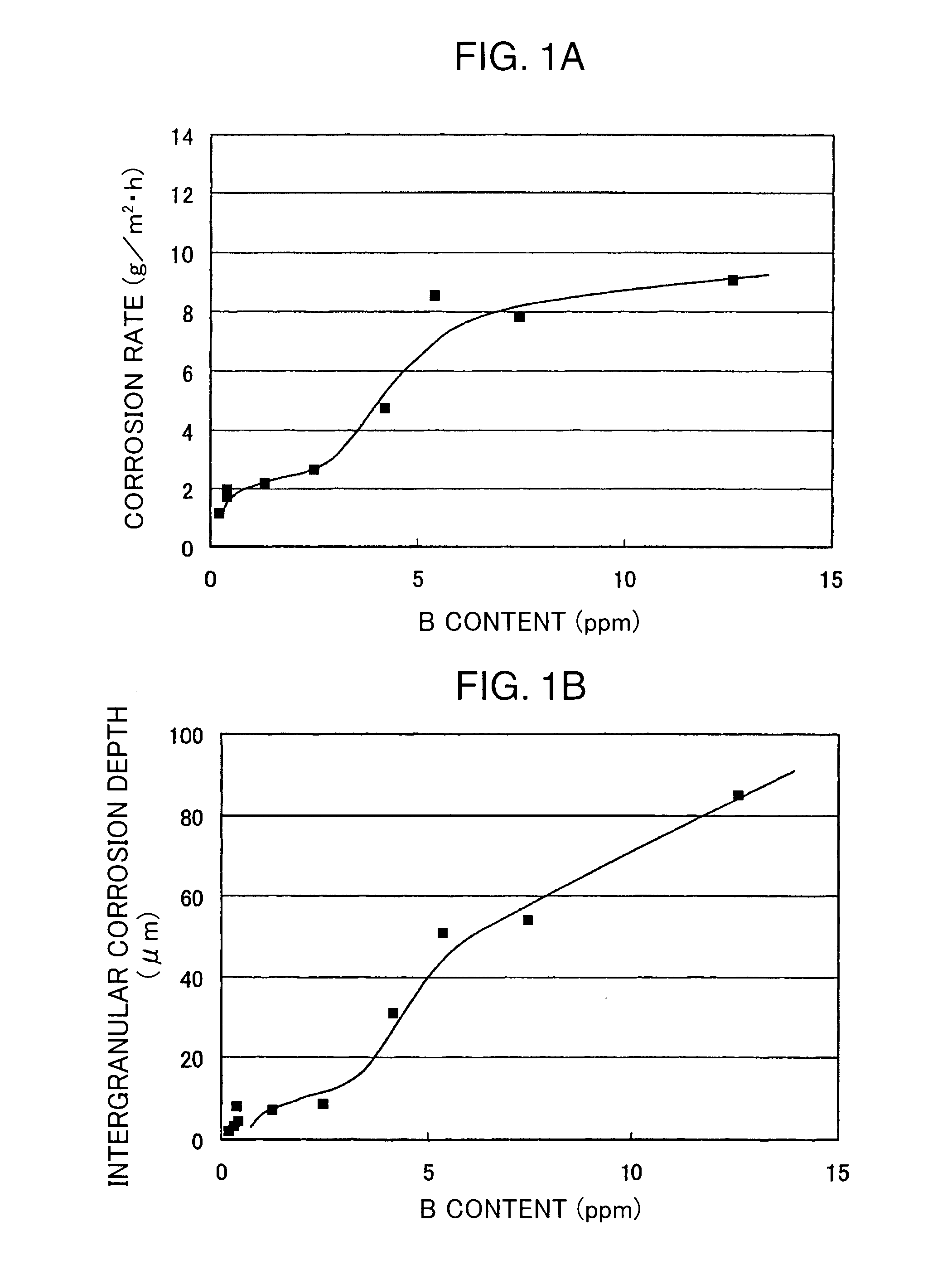

[0082]150 kg of an austenitic stainless steel in the chemical compositions shown in Table 1 was melted by vacuum induction melting (VIM) and cast into a mold, to give an ingot. The units for elements in the chemical compositions shown in Table 1 are respectively weight percentage (wt %), except the unit for B of wt ppm. Then, an electrode was prepared by grinding the vacuum-melted ingot and subjecting the ingot to electron-beam (EB) re-melting, to give a cylindrical ingot. It is then processed by forging and hot rolling into a plate material having a thickness of 6 mm, which is then solution-treated under a condition of 1050° C. for ½ hour, to give a plate material having a thickness of 6 mm. These materials were used as samples in Coriou corrosion test, a test simulating intergranular corrosion in nitric acid solution containing higher-concentration metal ions, and also in slow strain rate test (SSRT) and CBB test, tests simulating stress corrosion cracking in high-te...

experiment 2

(Experiment 2)

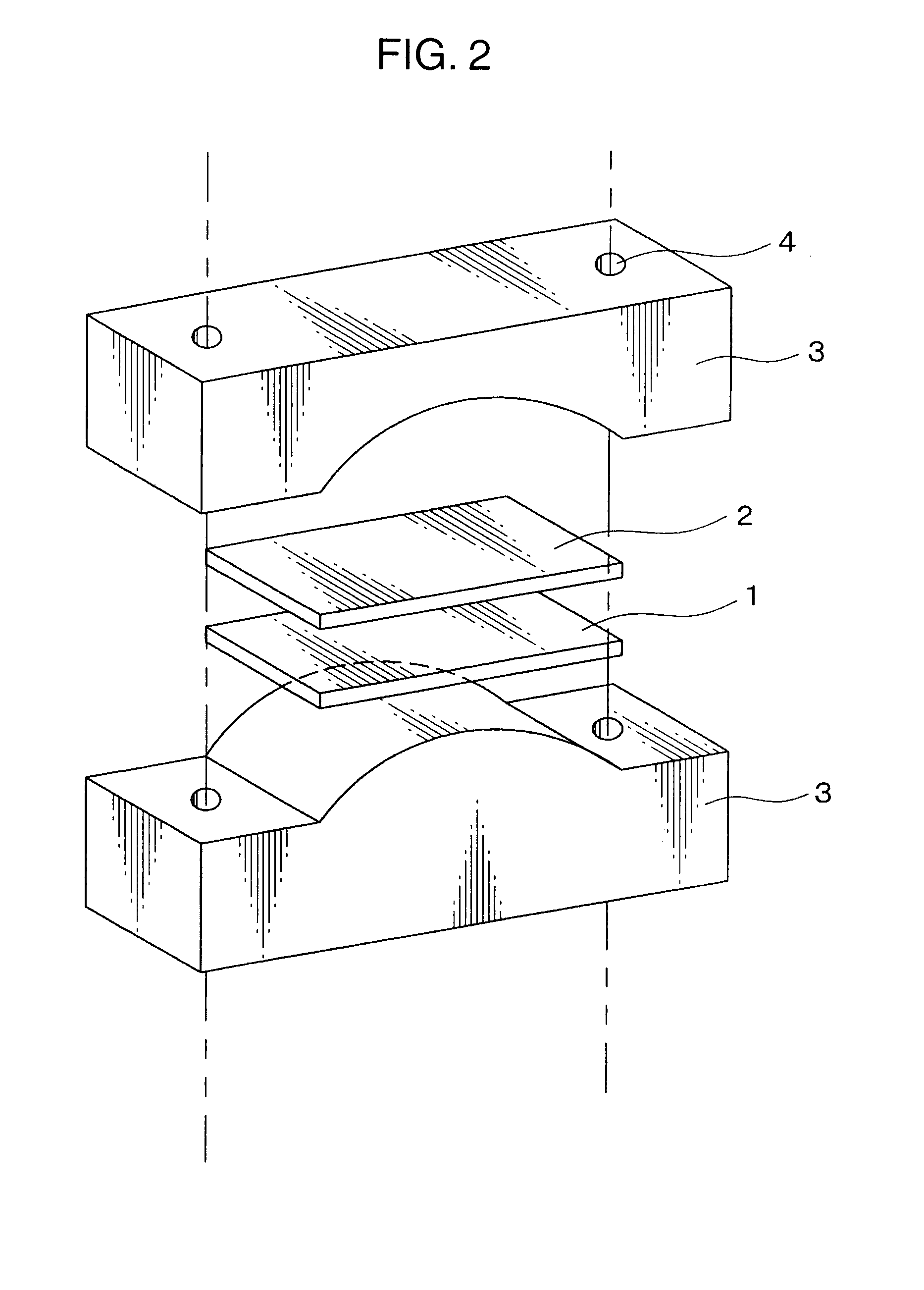

[0095]Plate materials having a thickness of 6 mm were prepared by using the samples of steel numbers B, K and L shown in Table 1 under the various conditions shown in Table 3. The sample of production lot number 1 was an ingot obtained by vacuum induction melting (VIM) and casting into a mold under vacuum, while the samples of other production lot numbers (2 to 8) were subjected additionally to electron-beam re-melting (EB). Each plate material finished by forging and hot rolling was subjected to solution treatment and additionally to thermomechanical treatment (cold work-recrystallization or cold work-carbide precipitation-recrystallization) (the thickness of the plate having a different cold-working ratio was adjusted during solution treatment). The samples were analyzed in the Coriou corrosion test simulating intergranular corrosion in higher-concentration boiling nitric acid solution containing highly oxidizing metal ion, and the slow strain rate test (SSRT) and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com