Residual stress improving method for pipe

a stress improvement and pipe technology, applied in the field of resistive stress improvement methods of pipes, can solve the problems of stress corrosion cracking, the residual stress of pipes may not be sufficiently improved, so as to improve the residual stress condition, prevent stress corrosion cracking, and improve the effect of residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

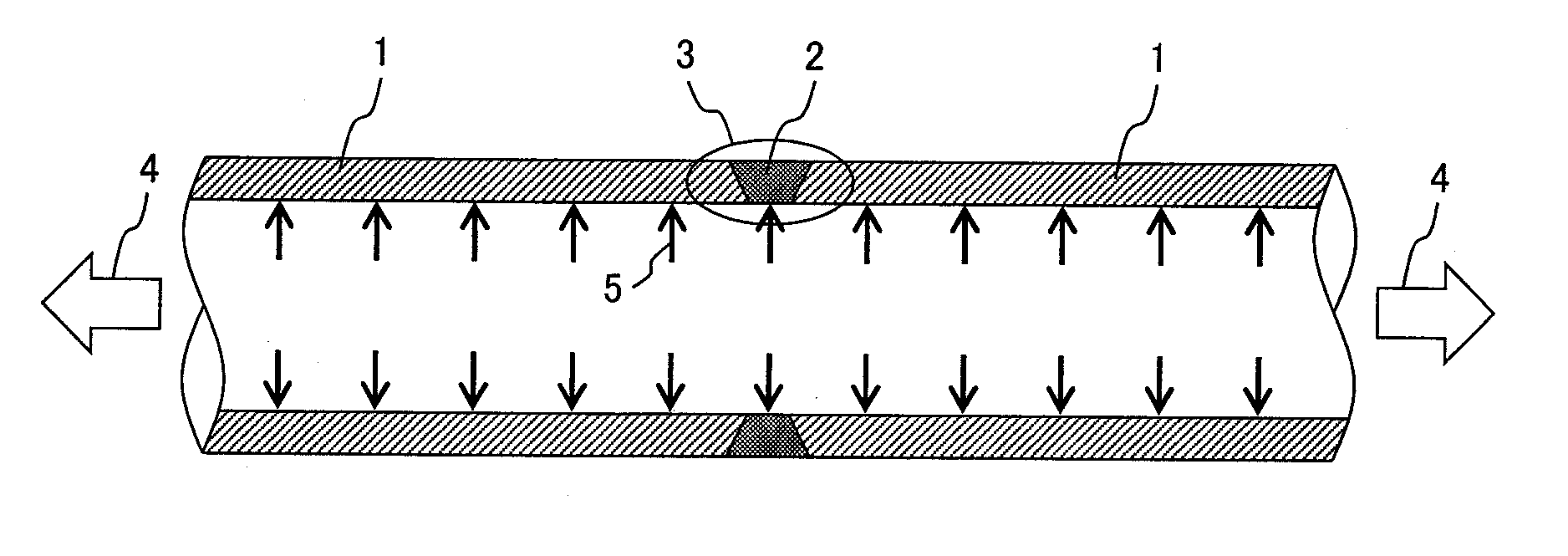

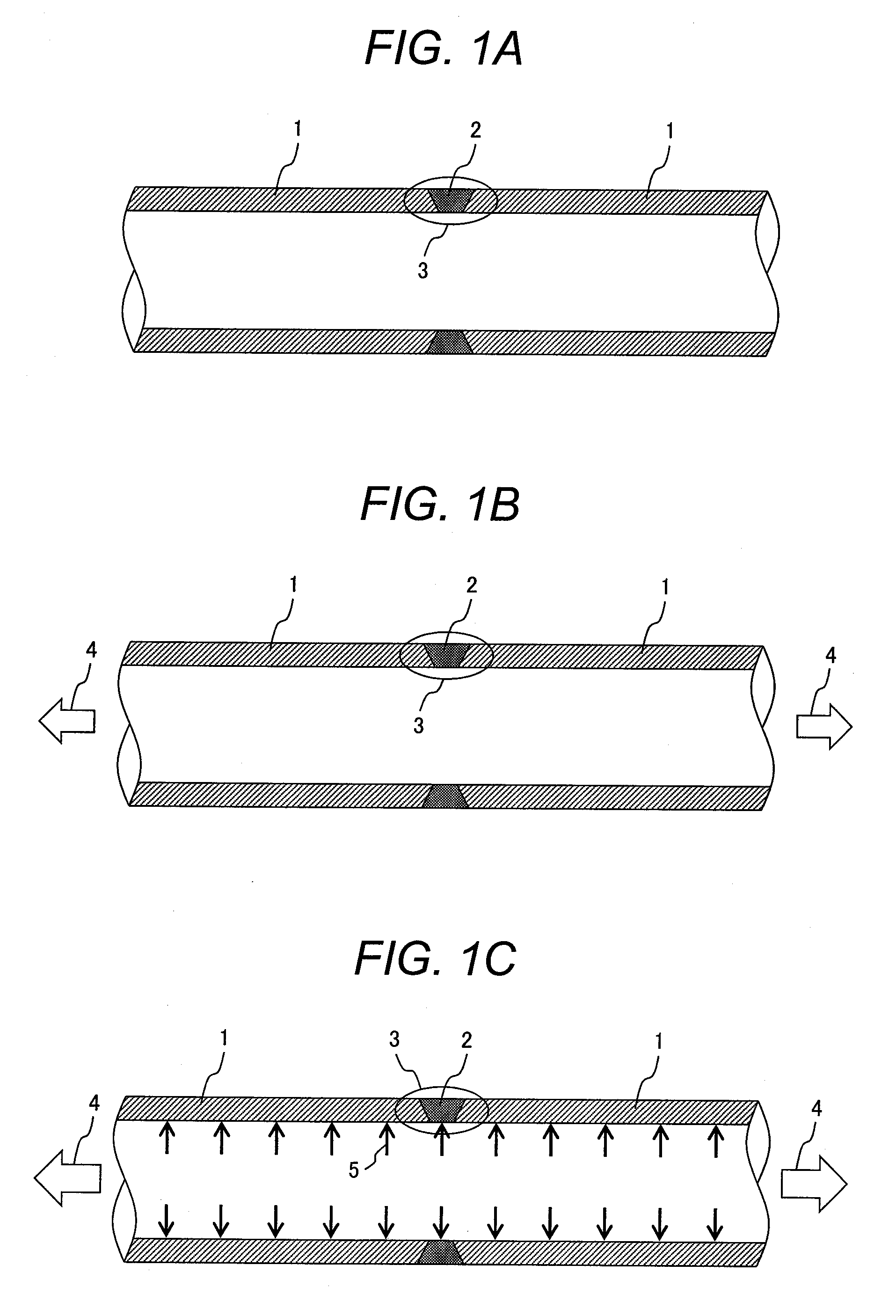

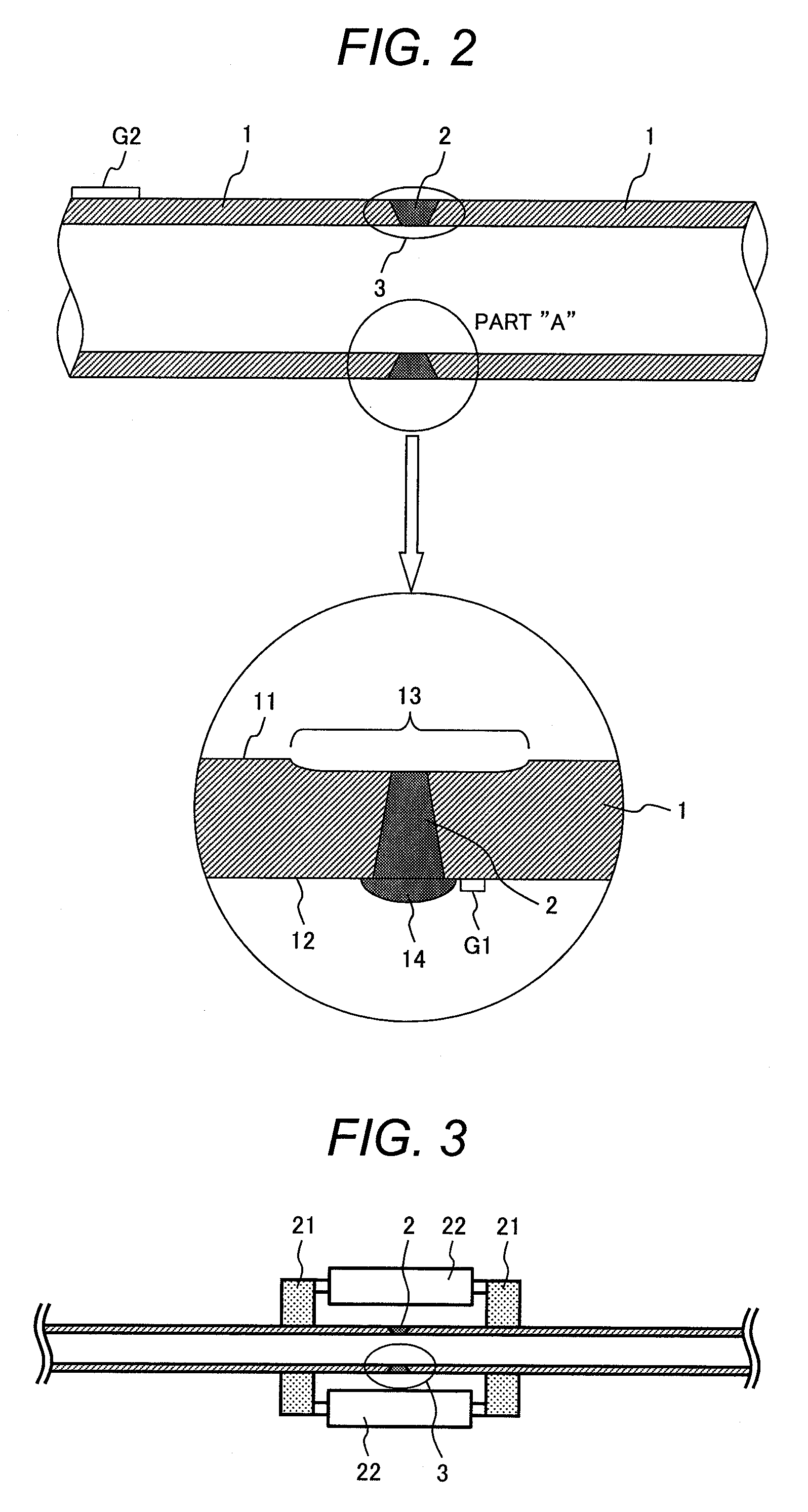

[0038]The present inventors investigated a method capable of imparting larger compressive residual stress on the inner surface of the welding section and the vicinity of the welding section of a pipe. As a result, the present inventors have newly found out that it is preferable to impart large compressive residual stress on the inner surface of a stress improving region of the pipe where the residual stress of the pipe is to be improved by raising the axial load and the internal pressure of the pipe to perform plastic deformation with respect to the stress improving region and applying an axial load with which the axial strain of the outer surface of the pipe is 0% or above and the stress is the yield stress of the pipe or below in plastic deformation.

[0039]Thus, probability of occurrence of stress corrosion crack in a pipe can be further lowered by imparting larger compressive residual stress on the inner surface of the stress improving region of the pipe and reducing the tensile r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield stress | aaaaa | aaaaa |

| Young's modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com