Metal plastic compound screw cap

A technology of metal plastics and nuts, which is applied in the direction of nuts, threaded fasteners, connecting components, etc., can solve the problems of cost reduction, stress corrosion cracking of nuts, etc., and achieve the effect of reducing processing time and avoiding stress corrosion cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

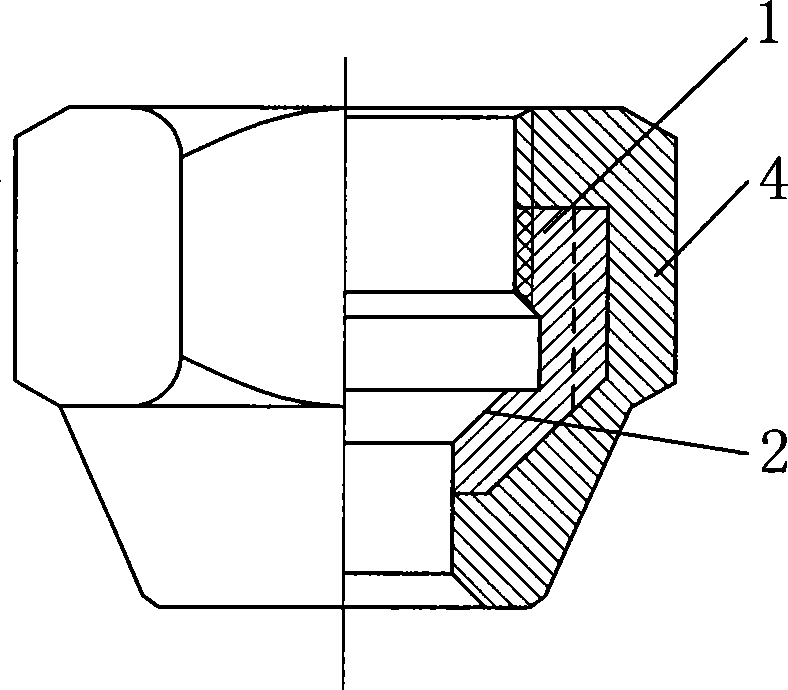

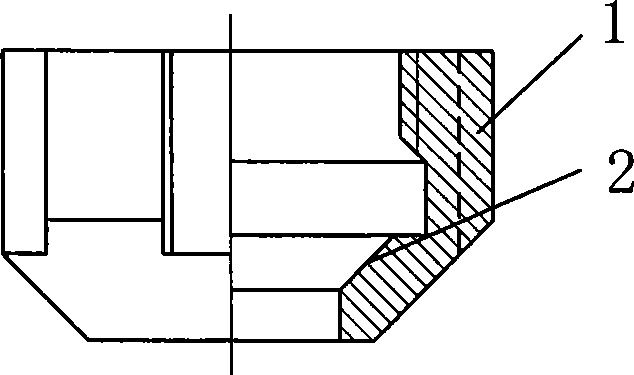

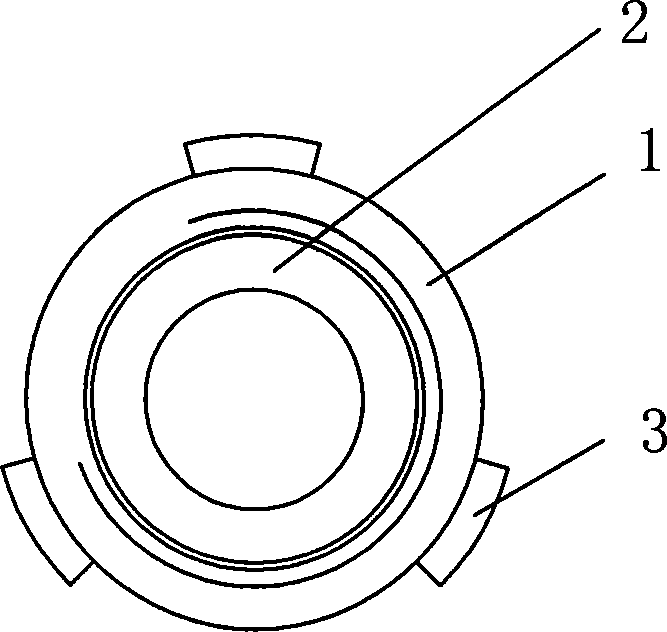

[0016] as attached figure 1 , 2 As shown in and 3, the metal-plastic composite nut includes an insert 1 made of lead brass, the inner surface of the insert 1 is provided with threads, and the inner surface of one end of the insert 1 is provided with a thickness of 1.5-2mm and an angle It is a 45° tapered sealing surface 2, and the outer surface of the insert 1 is uniformly provided with three clip fins 3, each clip fin has a thickness of 1-1.5 mm, and the outside of the insert 1 is wrapped with composite engineering plastics Plastic layer 4, the tensile and flexural modulus of the composite engineering plastic is greater than 10,000Mpa, and can also resist ultraviolet radiation. The main components of the composite engineering plastic are nylon and glass fiber.

[0017] The insert 1 and the plastic layer 4 are integrally injection-molded, and the presence of the snap fin 3 makes the insert 1 and the plastic layer 4 tightly bonded together to prevent falling off.

[0018] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| draft ratio | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com