Patents

Literature

42results about How to "Lower catalytic temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

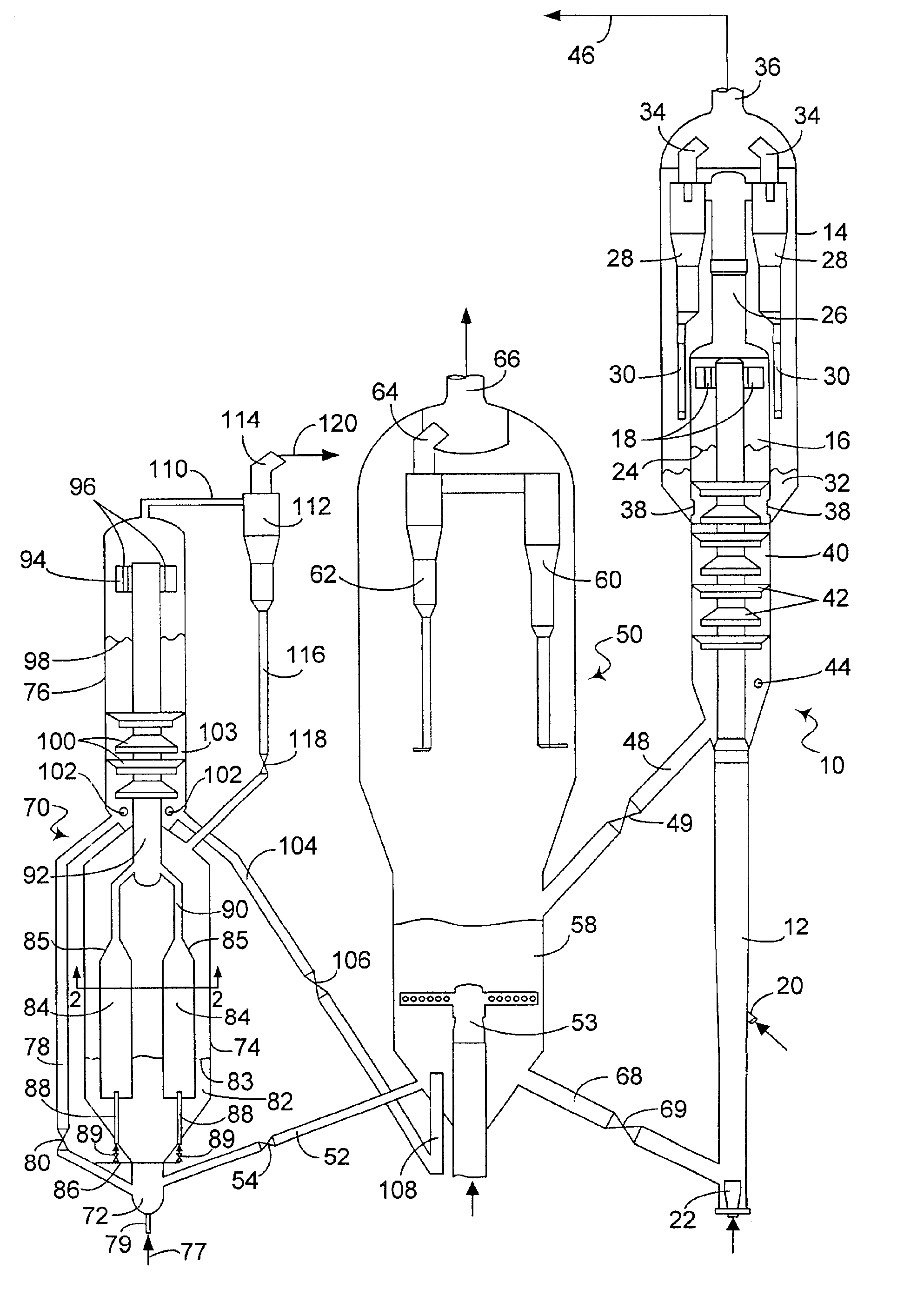

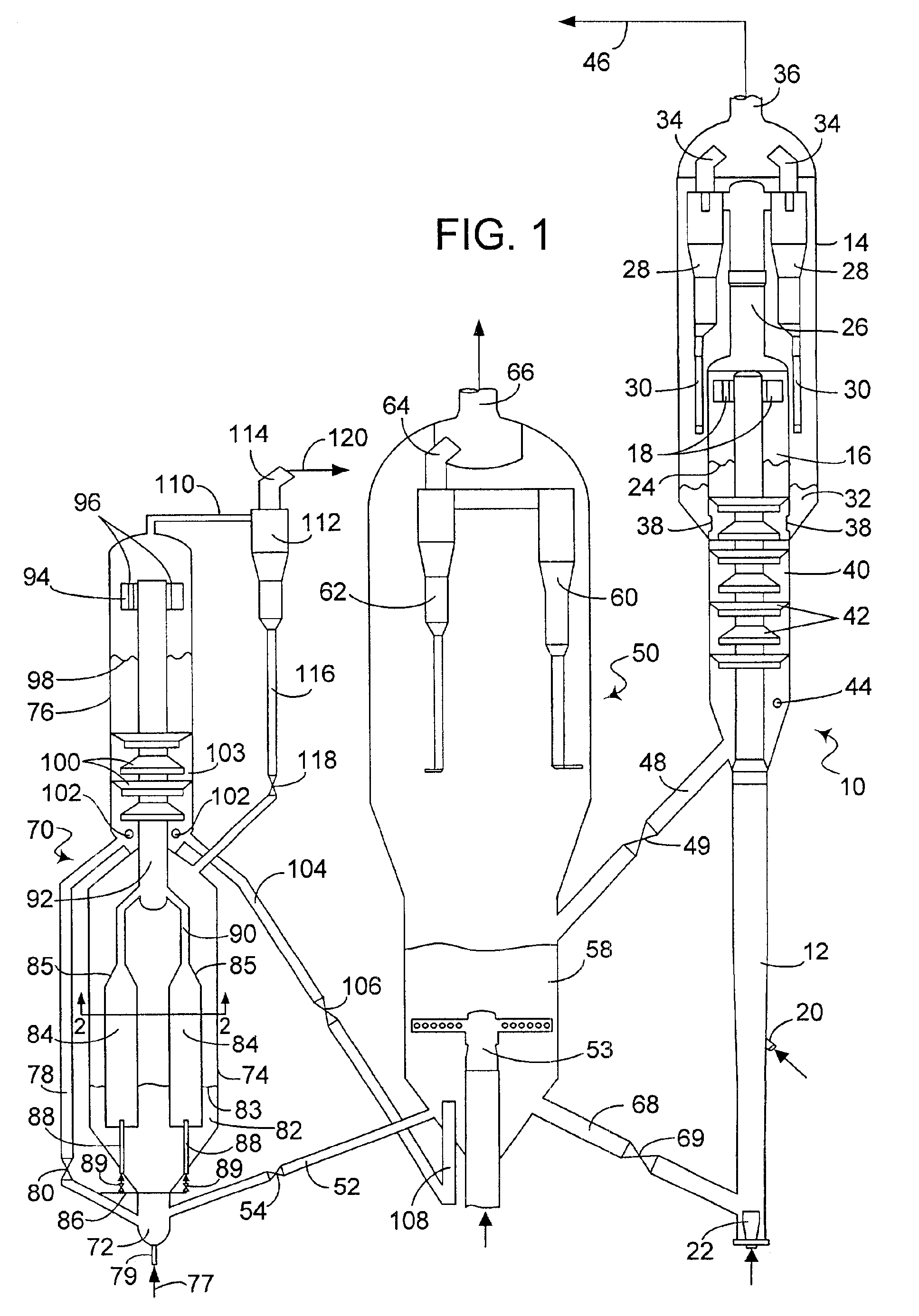

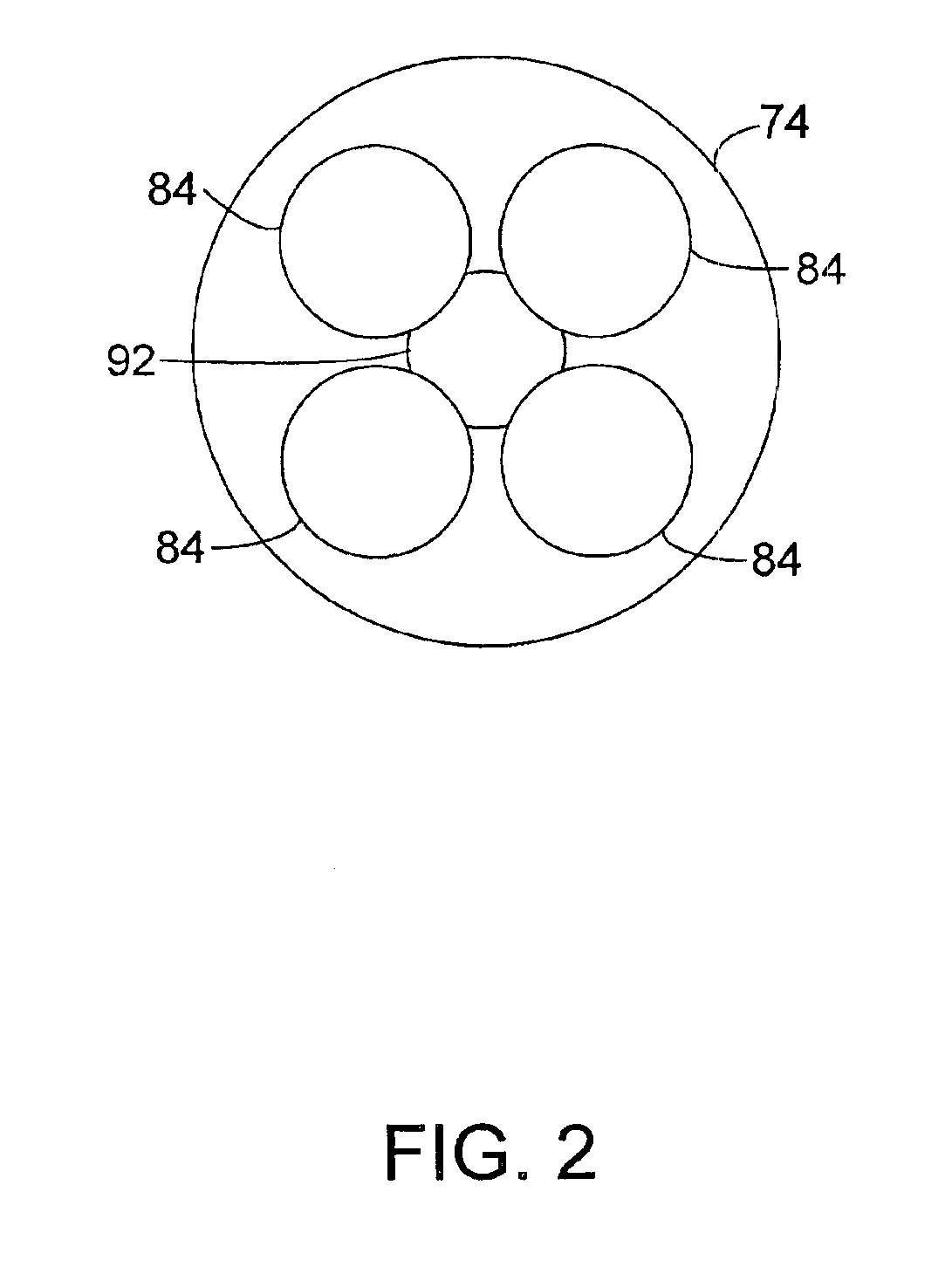

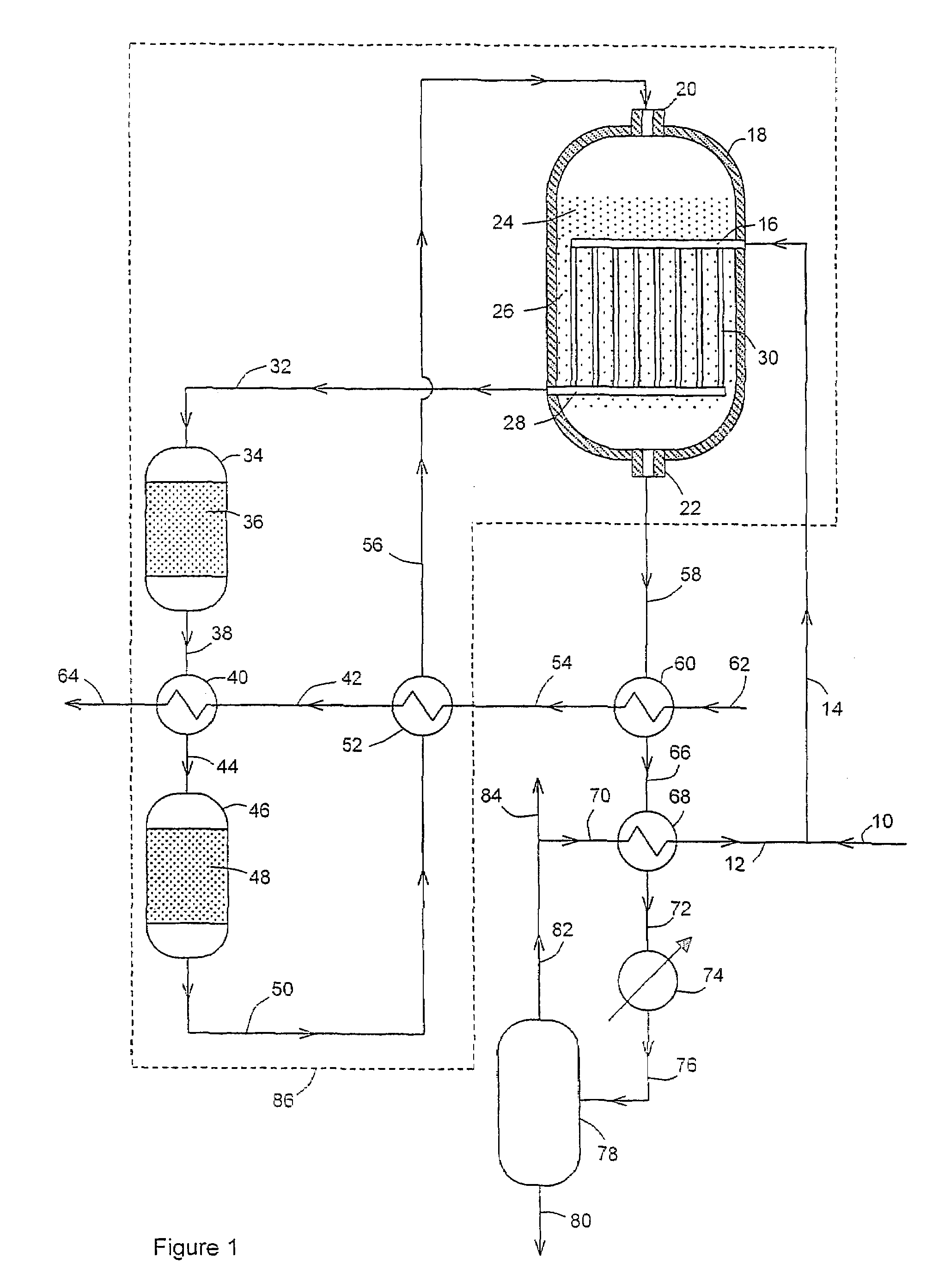

Process and apparatus for upgrading FCC product with additional reactor with catalyst recycle

InactiveUS6866771B2Increase undesirable crackingLower catalytic temperatureTreatment with plural serial cracking stages onlyCatalytic crackingCracking reactionChemistry

Owner:UOP LLC

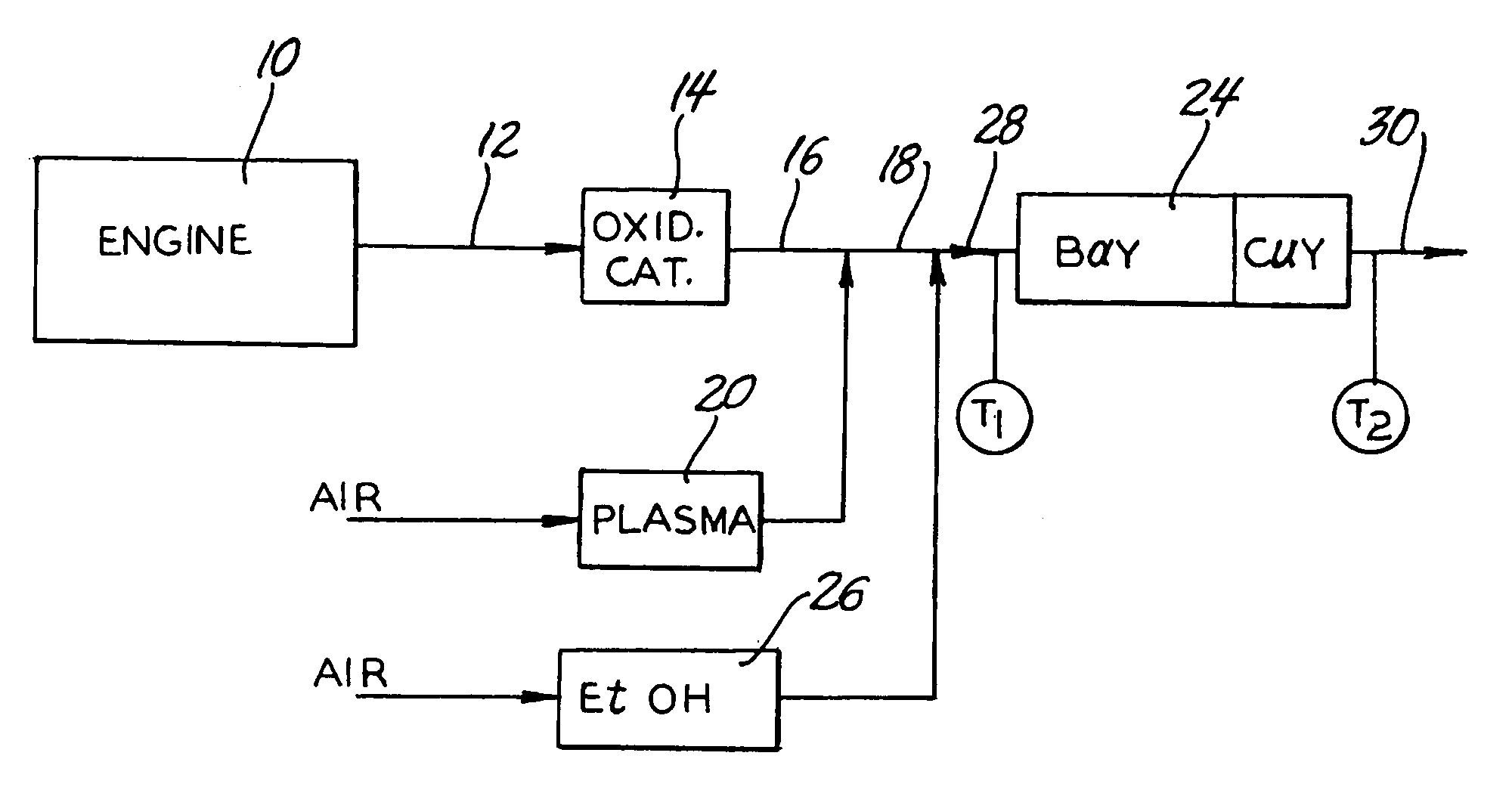

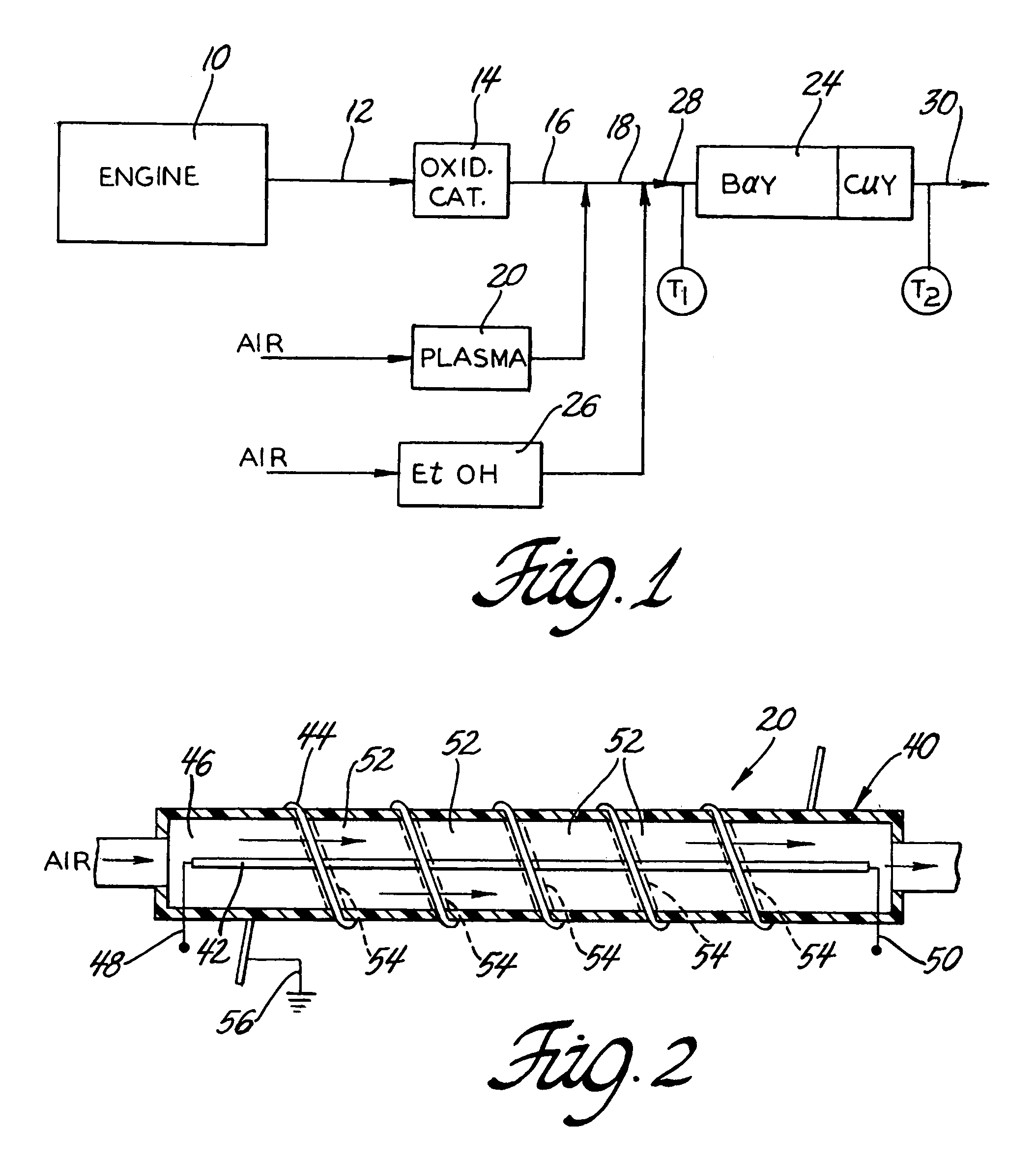

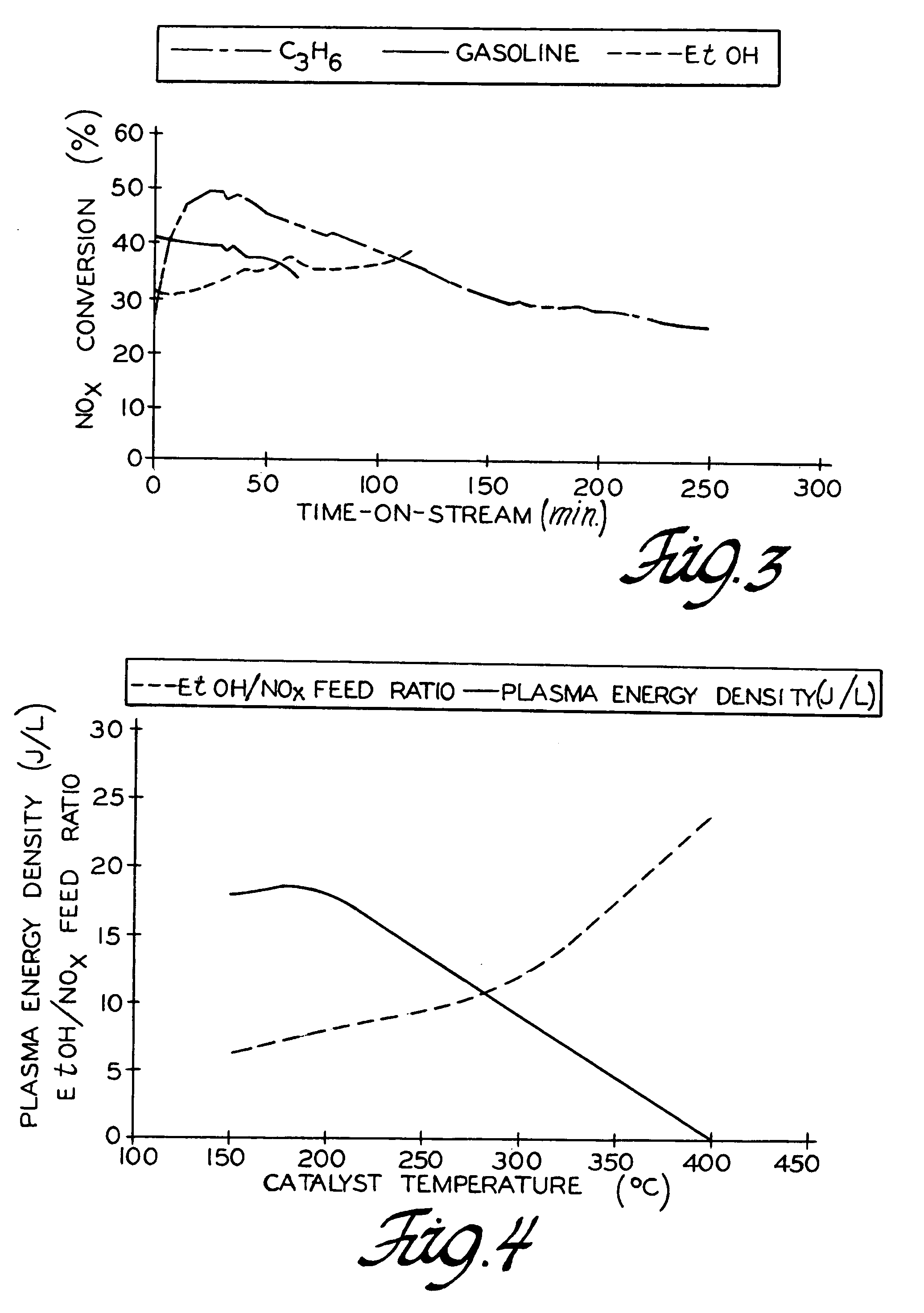

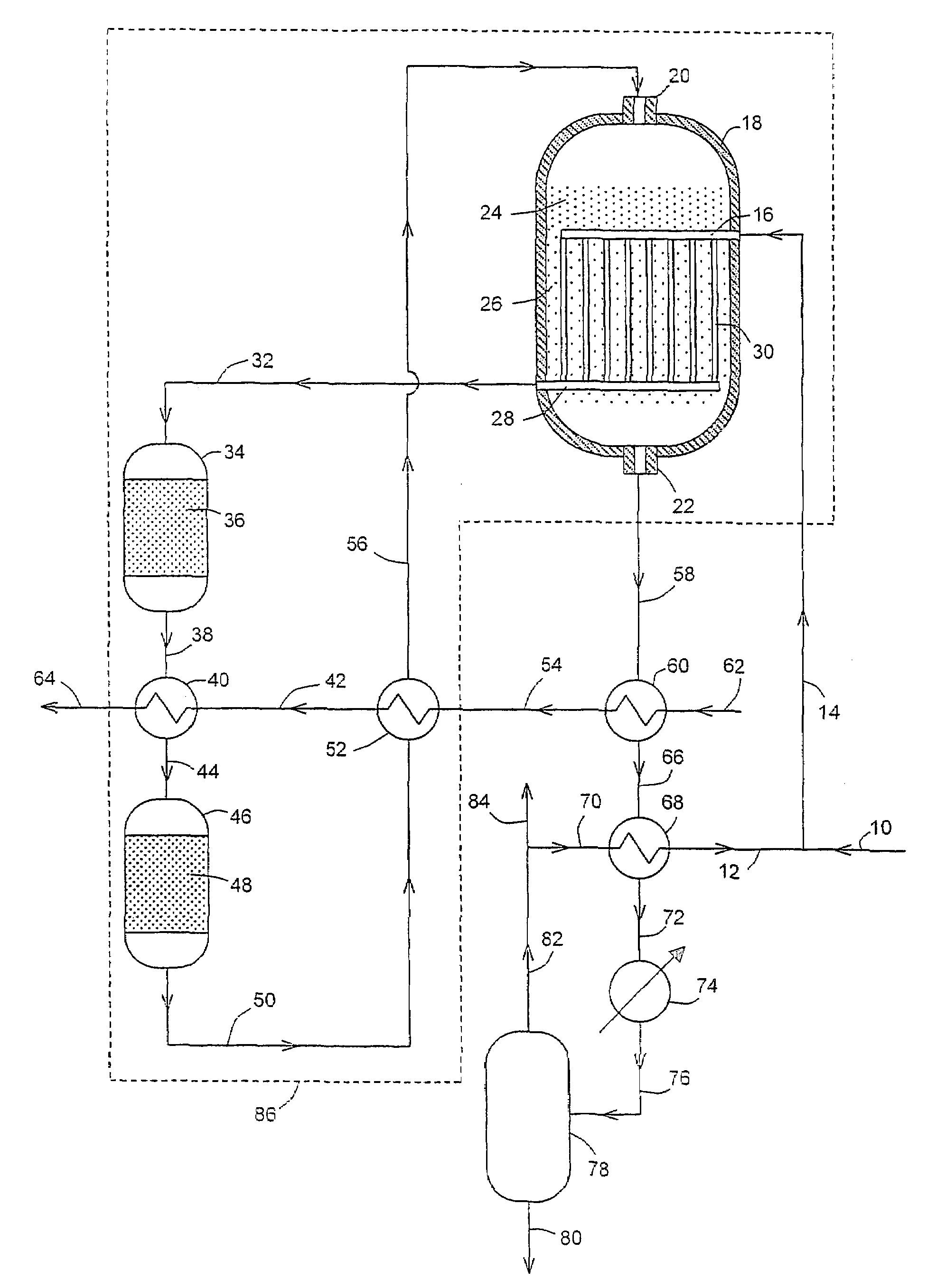

Method of reducing NOx in diesel engine exhaust

InactiveUS7090811B2Improve efficiencyHigh activityNitrogen compoundsInternal combustion piston enginesOxygenPlasma reactor

This invention provides a method of reducing nitrogen oxides in an oxygen containing exhaust stream using ethanol as a reductant for plasma-assisted selective catalytic reduction. The exhaust gas, generated from a diesel engine or other lean-burn power source, comprises nitrogen oxides, especially NO. Ozone generated from a plasma reactor is injected into the exhaust stream to convert NO to NO2 and the plasma injection is followed by the addition of ethanol. The NO2 is then reduced by contacting the exhaust stream with a dual-bed catalytic reactor comprising BaY (or NaY) and CuY zeolite catalysts in the presence of ethanol as the reductant. The plasma power density and the molar ratio of ethanol to NOx fed to the catalytic reactor are controlled as a function of the catalyst temperature for the best performance of the plasma-catalyst system. An average conversion of NOx to N2 of at least 90% is achieved over the temperature range of 200–400° C.

Owner:GM GLOBAL TECH OPERATIONS LLC

Process and apparatus for upgrading FCC product with additional reactor with catalyst recycle

InactiveUS20050074371A1Increase undesirable crackingLower catalytic temperatureTreatment with plural serial cracking stages onlyCatalytic crackingCracking reactionChemistry

A process and apparatus is disclosed for contacting feed with mixed catalyst in a secondary reactor that is incorporated into an FCC reactor. The mixed catalyst used in the secondary reactor is regenerated catalyst from a regenerator that regenerates spent catalyst from an FCC reactor that is mixed with spent catalyst from either the FCC reactor or the secondary reactor. The mixing of spent and regenerated catalyst reduces the catalyst temperature and tempers catalyst activity to inhibit both thermal and catalytic cracking reactions.

Owner:LOMAS DAVID A +1

Methanol synthesis

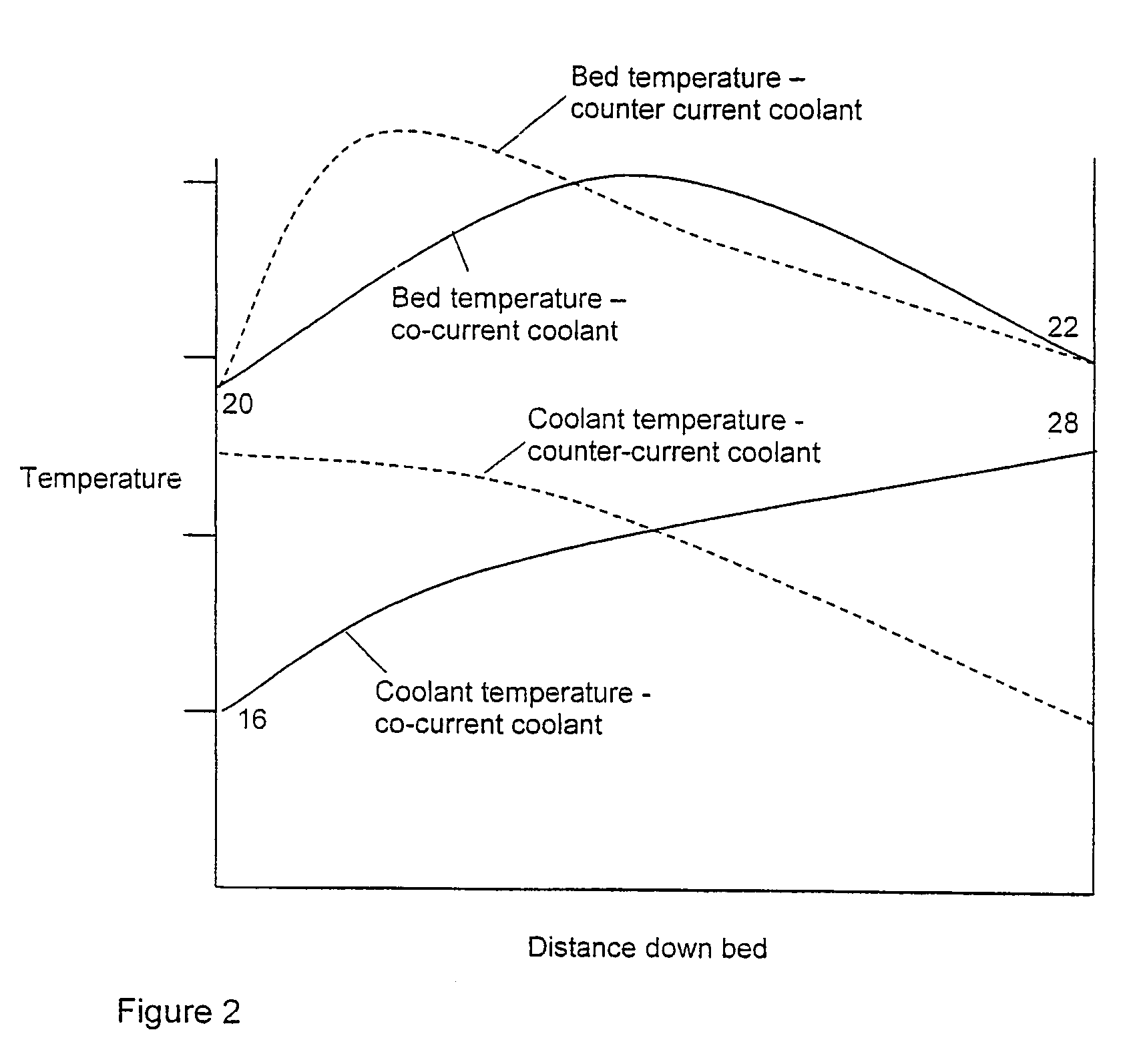

InactiveUS7144923B2Easy temperature controlEfficient heat recoveryOrganic compounds purification/separation/stabilisationOrganic compound preparationSyngasCoolant flow

Methanol is synthesized from pre-heated methanol synthesis gas in one or more adiabatic synthesis stages with cooling of the resultant gas after each stage. Further methanol synthesis is then effected on the resultant partially reacted synthesis gas in a bed of synthesis catalyst cooled by means of a coolant flowing co-currently through tubes disposed in the catalyst bed. After cooling methanol is separated from the unreacted gas. Part of the unreacted gas is combined with make-up gas and used as the coolant fed to the aforesaid tubes, thus producing the pre-heated synthesis gas to be fed to the adiabatic synthesis stages.

Owner:JOHNSON MATTHEY PLC

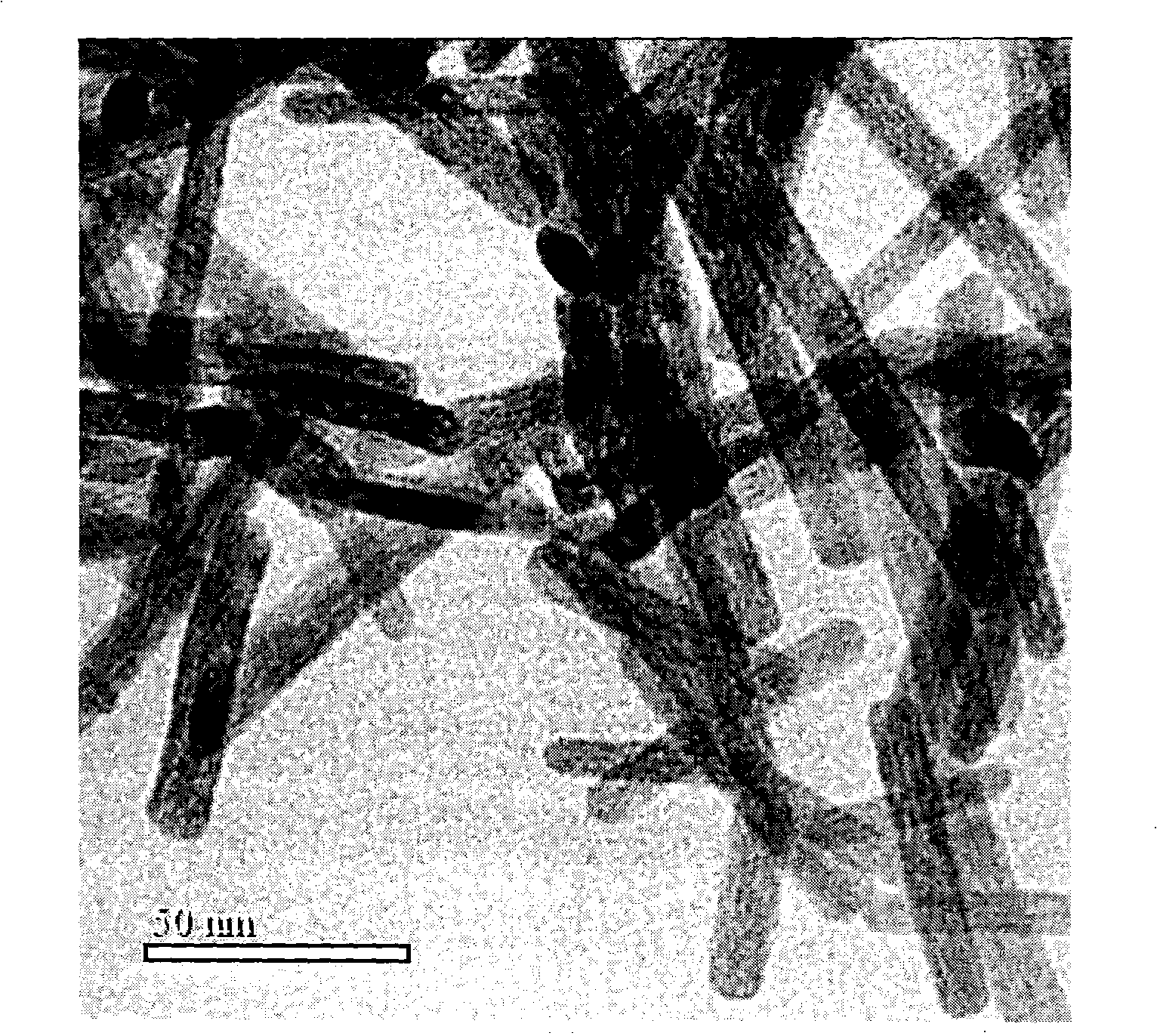

Method of preparing cerium oxide nano-rod

ActiveCN101407330ALarge specific surface areaHigh catalytic activityRare earth metal compoundsCeriumCerium oxide

The invention relates to a method for preparing a cerium oxide nanometer rod at a mild condition, which belongs to the preparation technical field of inorganic nanometer materials, and comprises the main steps as follows: (1) the preparation of a cerium salt liquor: cerium salt is dissolved in an appropriate amount of deionized water and prepared into the 0.1-0.8mol / l cerium salt liquor; (2) the preparation of a concentrated alkali liquor: alkali is dissolved by using the appropriate amount of deionized water and prepared into the 10-15mol / l concentrated alkali liquor; and (3) the mixing of the two liquor for carrying out liquid phase reaction: the cerium salt liquor is quickly poured into the concentrated alkali liquor at the temperature of 10-40 DEG C; the volume ratio of the two used liquor is 1:3 to 1:7; after the reaction is finished, a white precipitate is generated, stayed in the liquor for ageing for 1 hour to 9 days, then washed and dried and finally the cerium oxide nanometer rod is obtained.

Owner:SHANGHAI UNIV

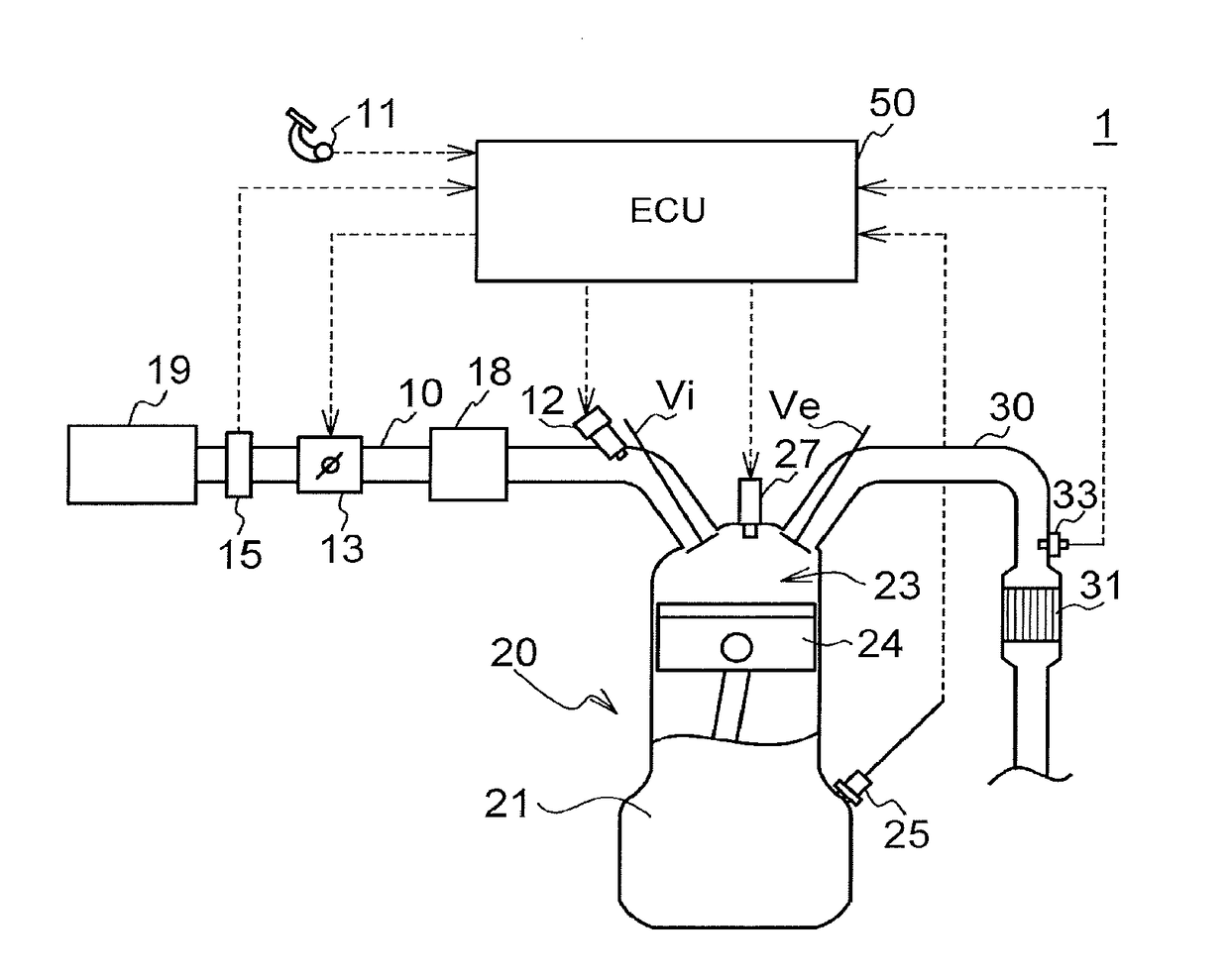

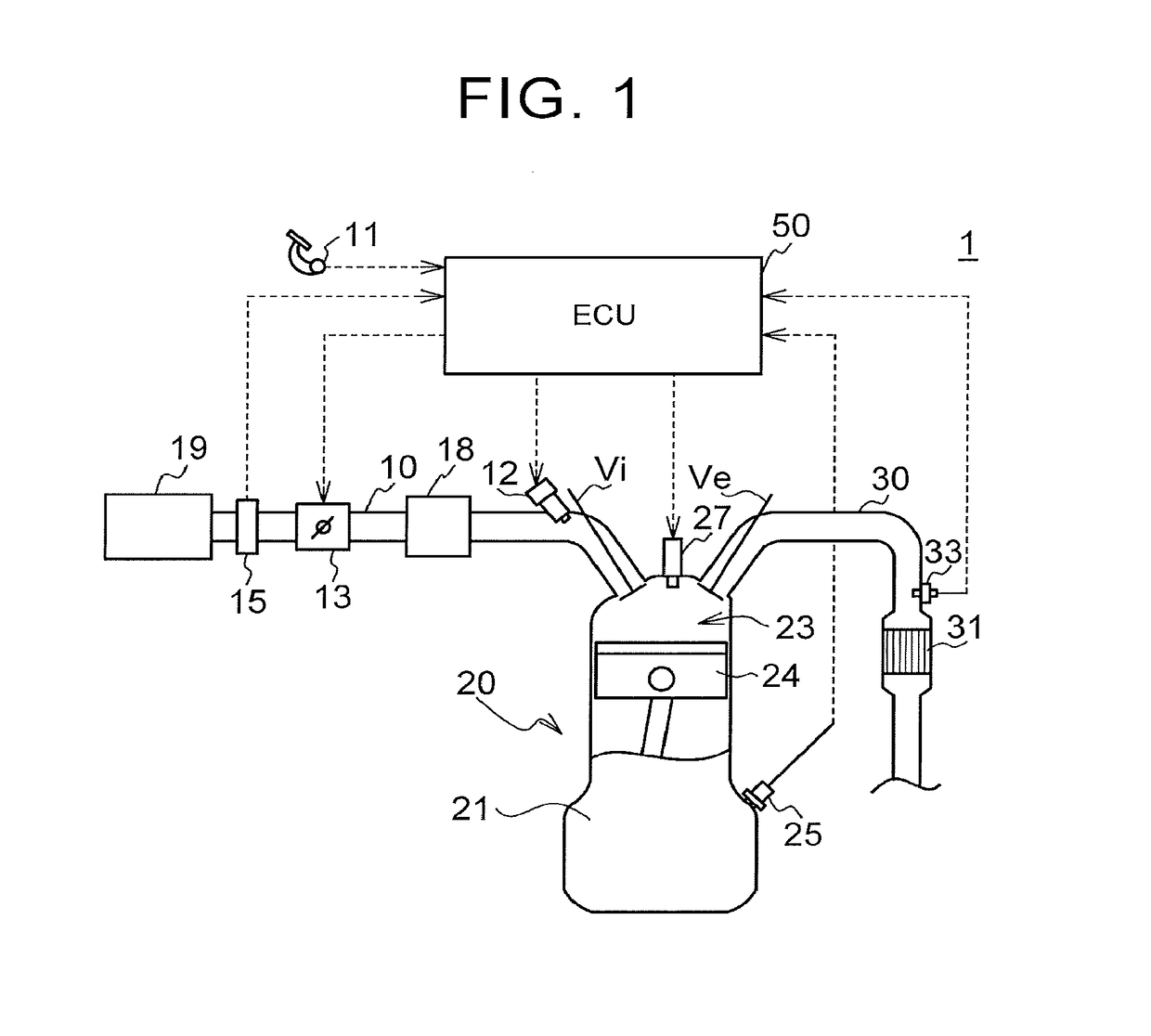

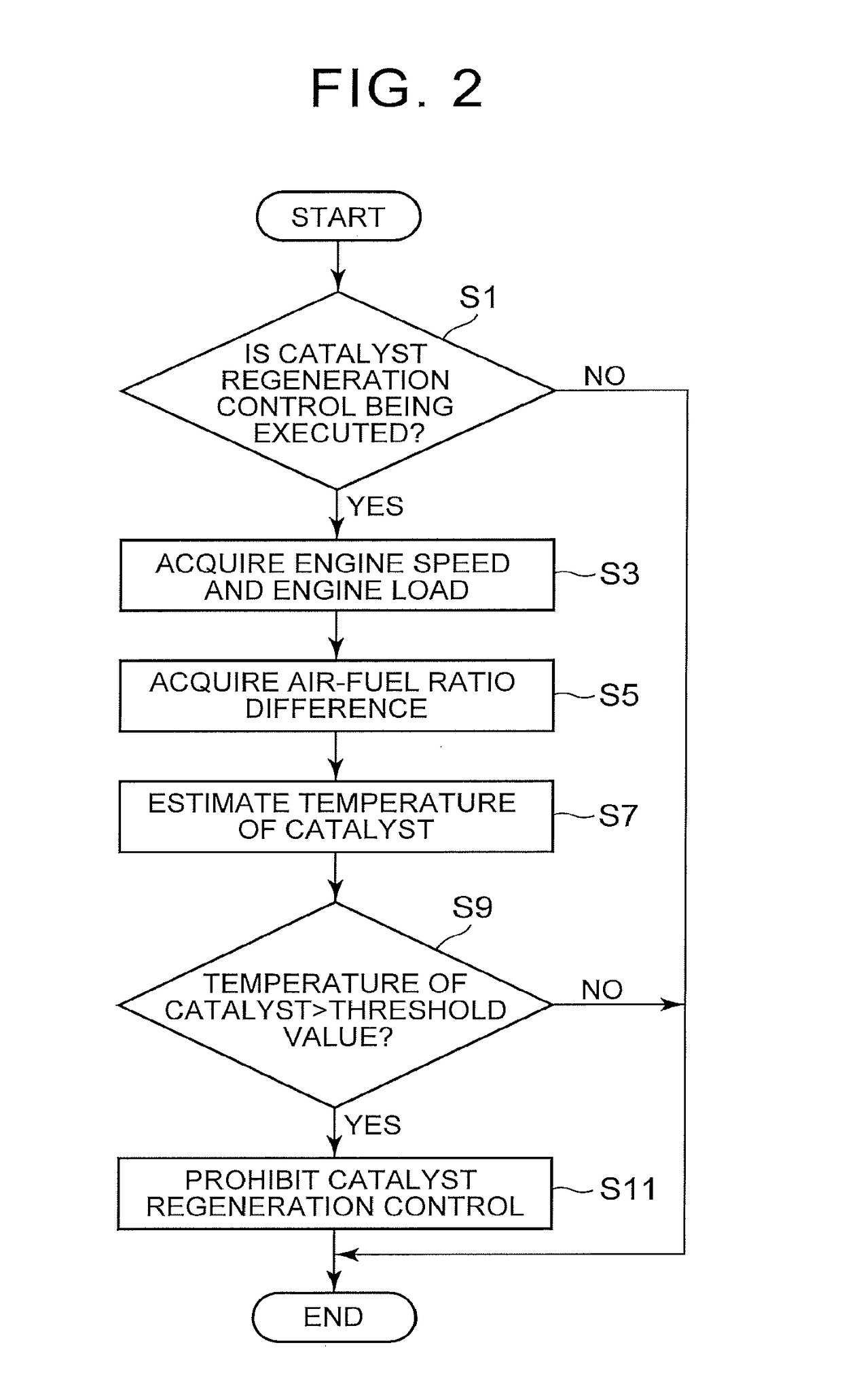

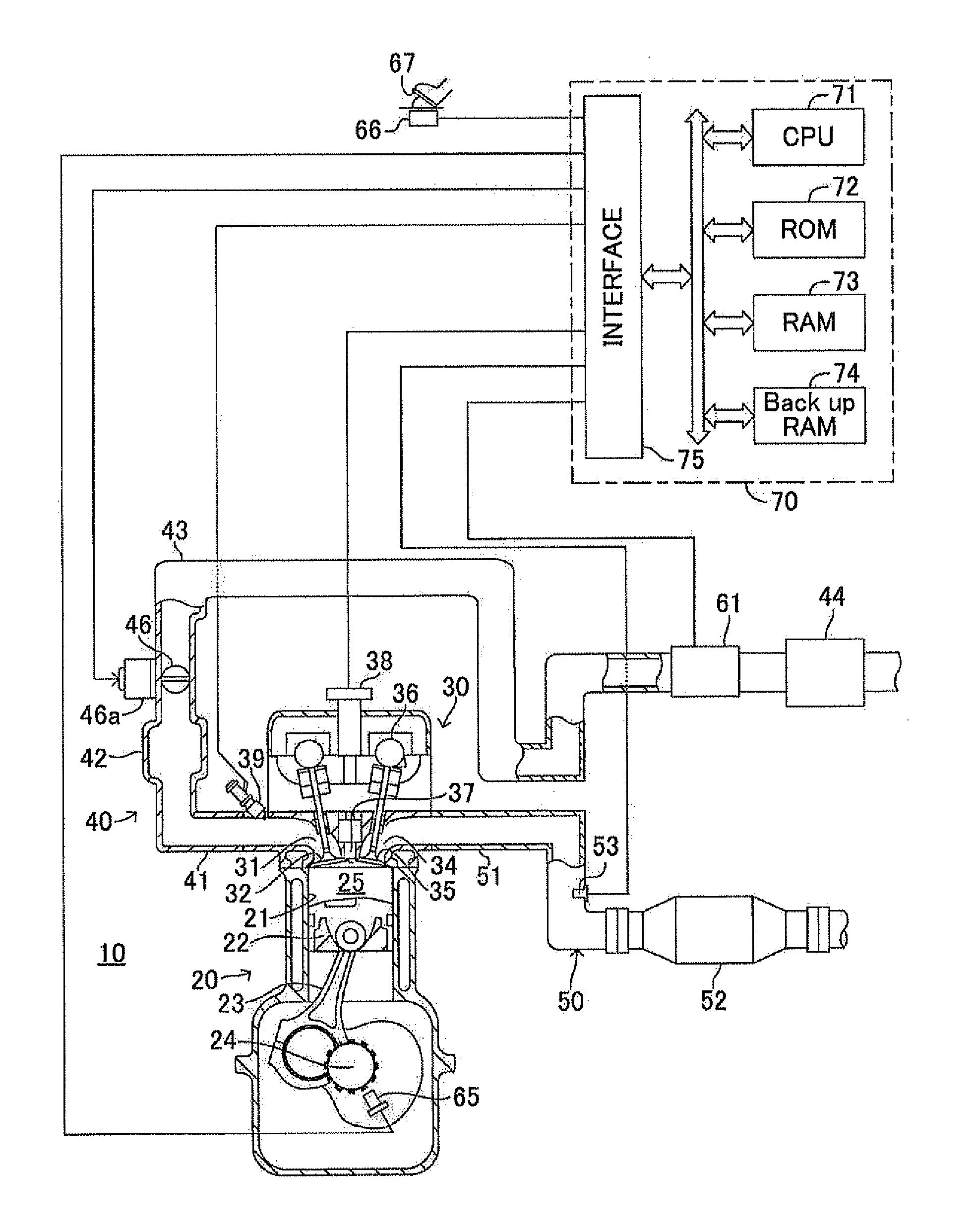

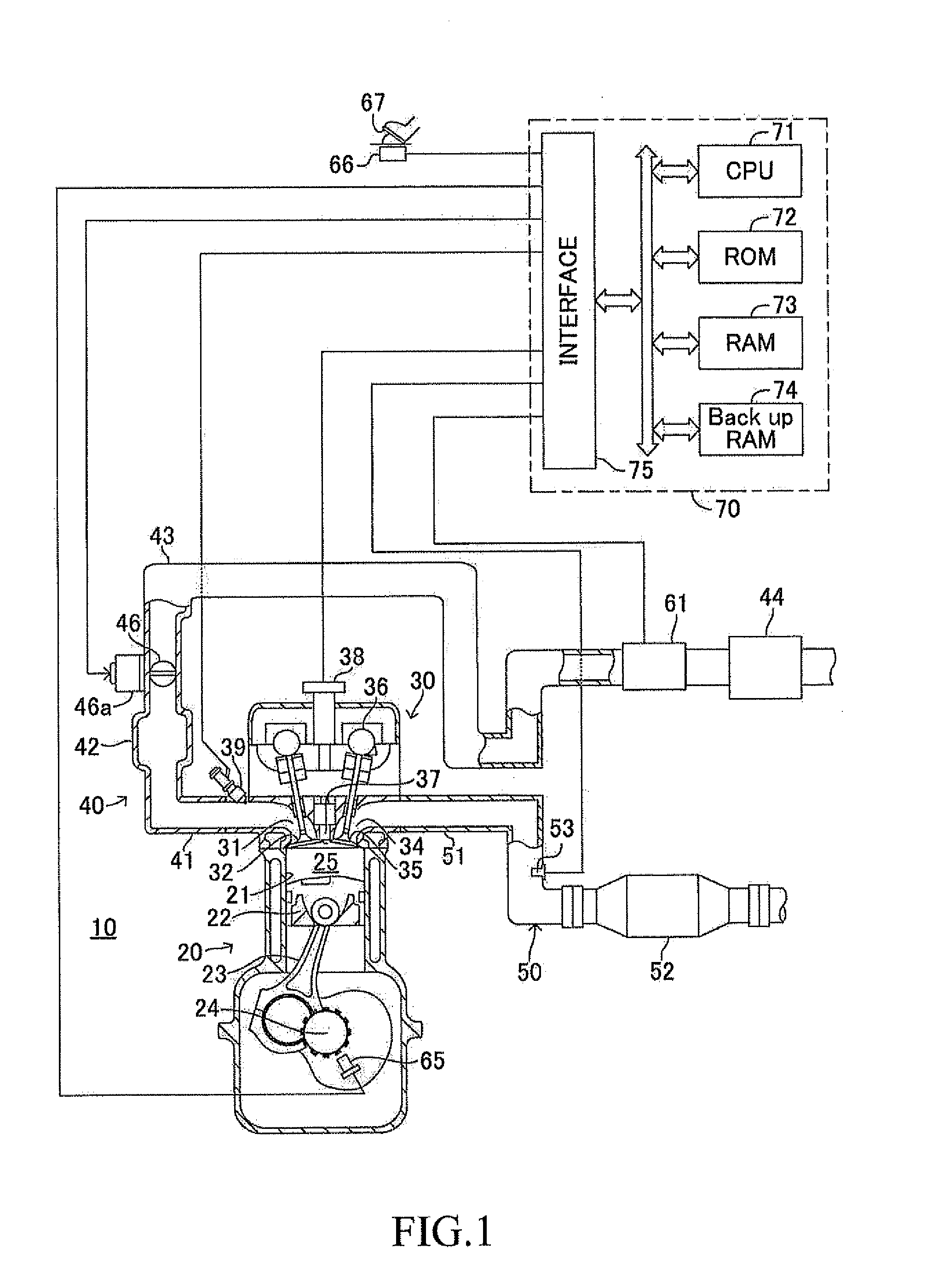

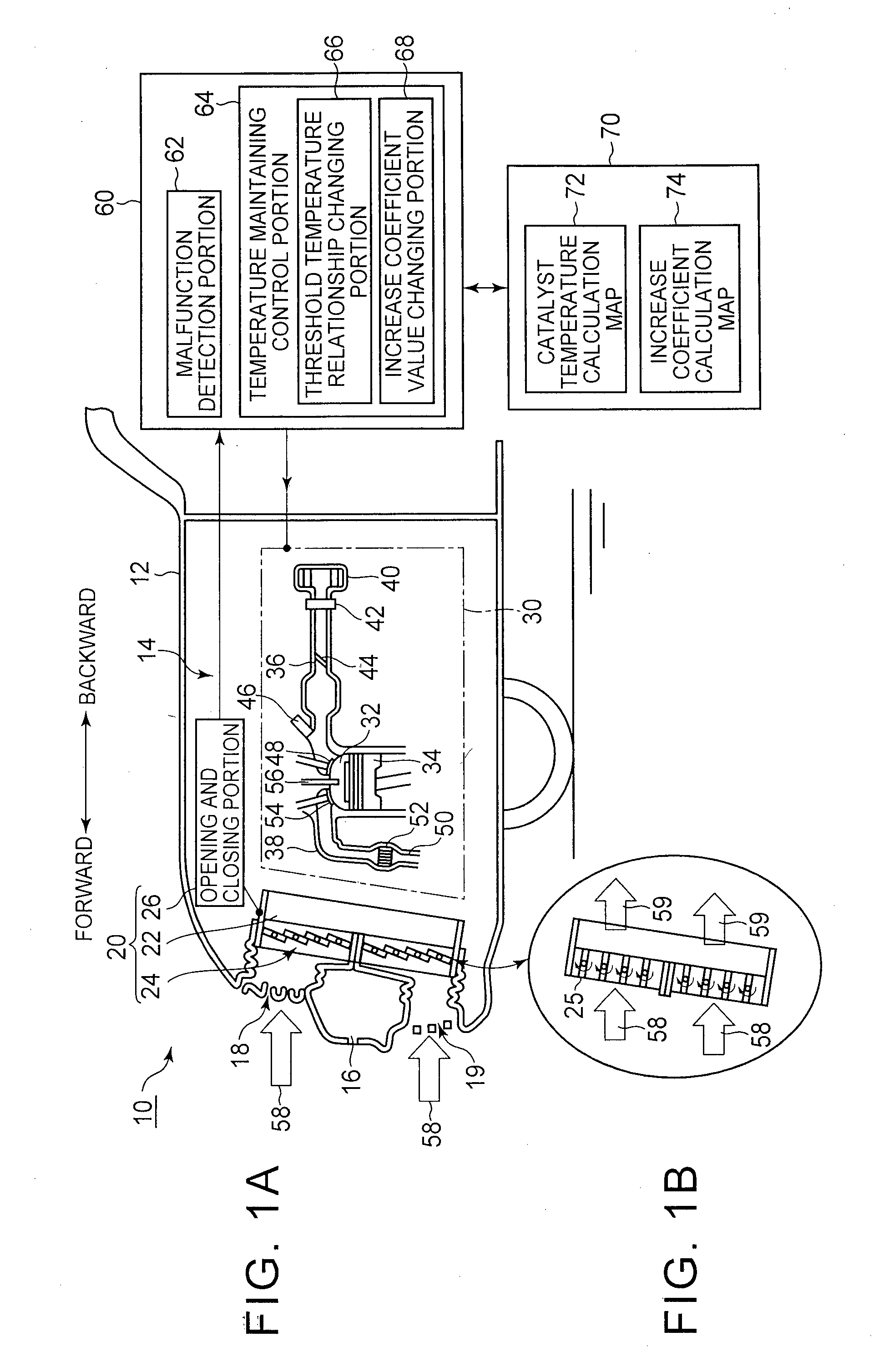

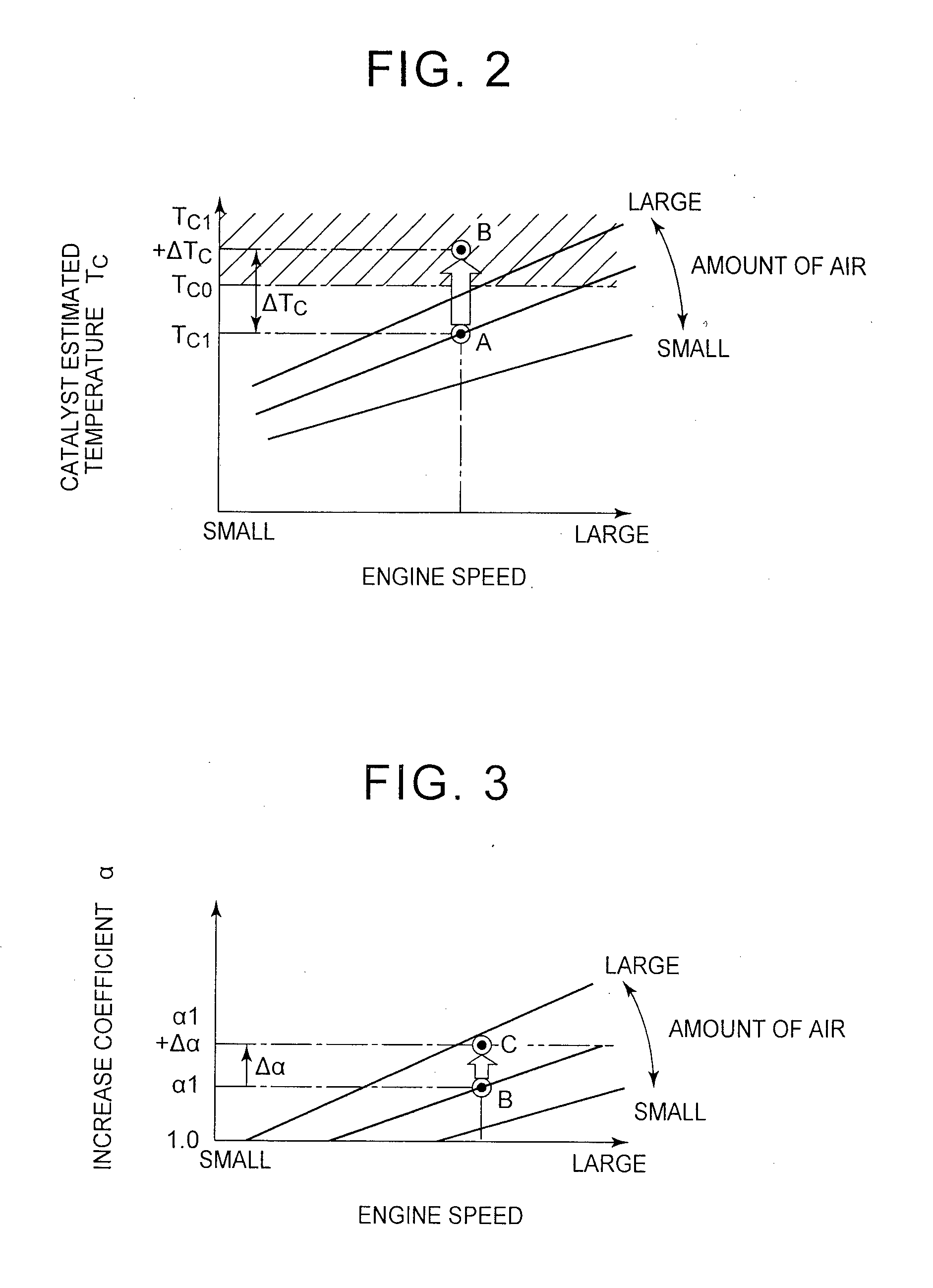

Exhaust gas control device for internal combustion engine and control method thereof

InactiveUS20170284269A1Lower catalytic temperatureIncrease temperatureElectrical controlInternal combustion piston enginesExternal combustion engineProcess engineering

An exhaust gas control device for an internal combustion engine includes an estimation unit configured to estimate a temperature of a catalyst on the basis of an acquired operation state of the internal combustion engine and a difference between a lean air-fuel ratio and a rich air-fuel ratio which are set as target air-fuel ratios during execution of catalyst regeneration control, a determination unit configured to determine whether the estimated temperature of the catalyst is higher than a threshold value during execution of the catalyst regeneration control, and a prohibition unit configured to prohibit the catalyst regeneration control when it is determined that the estimated temperature of the catalyst is higher than the threshold value during execution of the catalyst regeneration control.

Owner:TOYOTA JIDOSHA KK

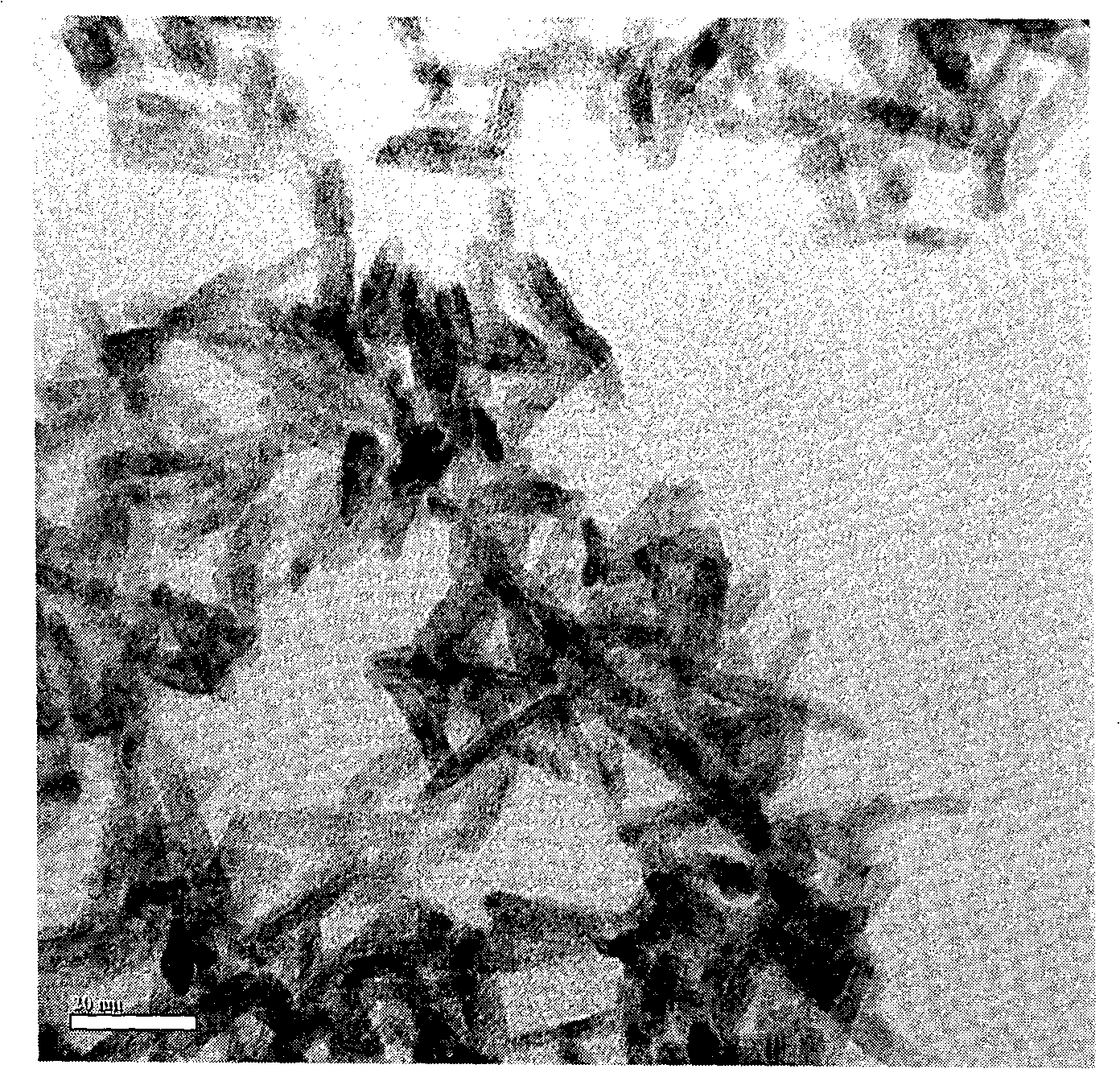

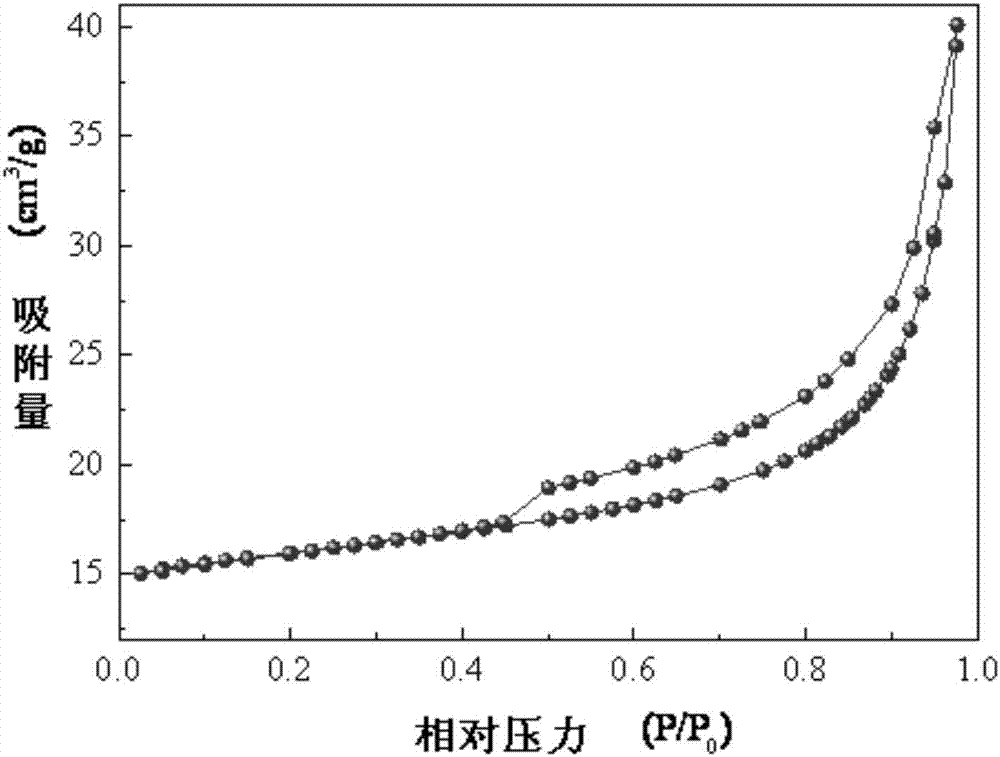

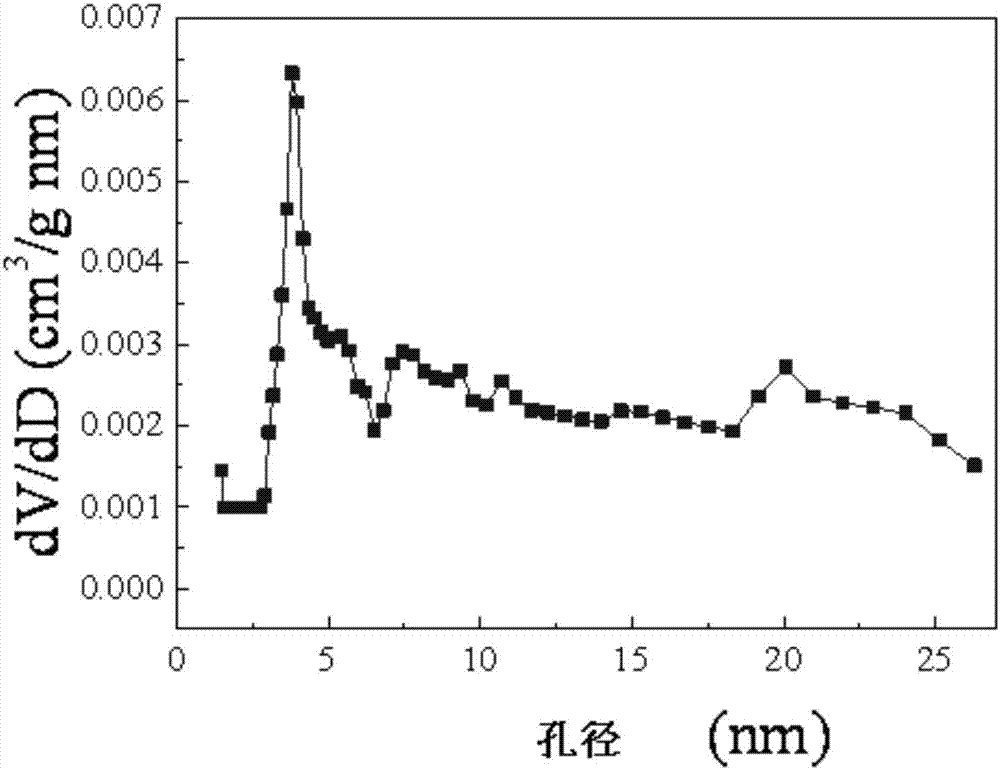

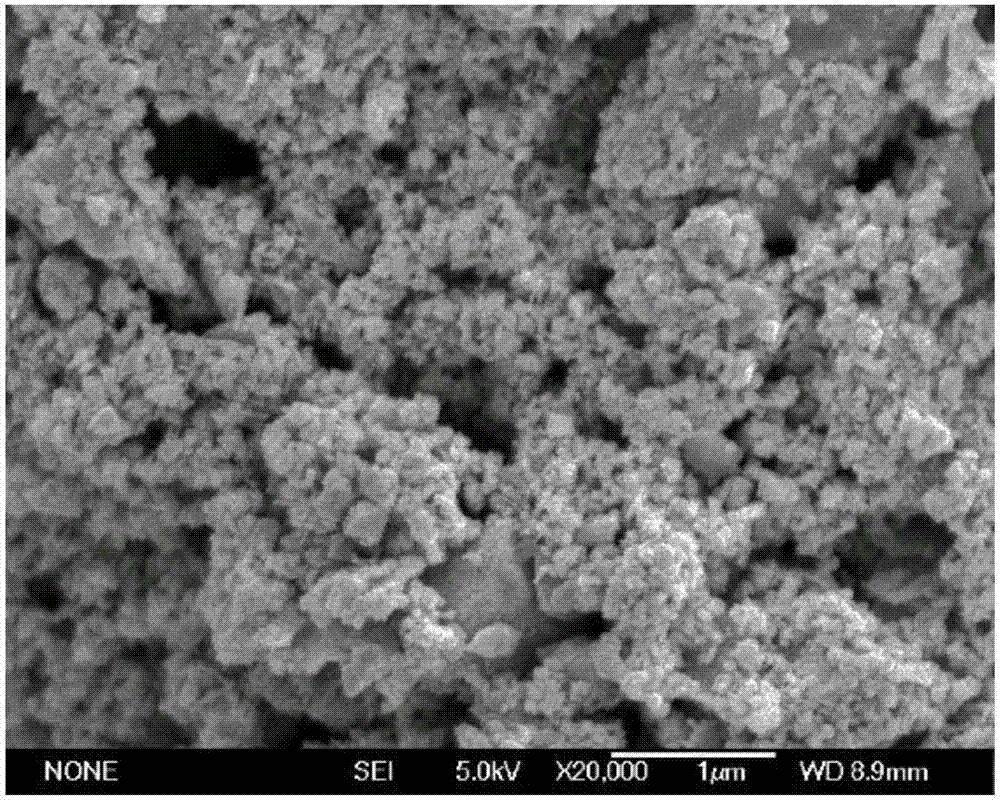

Hollow bead shaped nano-cerium oxide and its preparation method

ActiveCN1948157ALarge specific surface areaLower catalytic temperatureIndividual molecule manipulationRare earth metal compoundsSpherical granuleOrganic solvent

The present invention relates to a hollow pearl nano cerium oxide and its preparation method. The invented nano cerium oxide is a spherical granule whose diameter is 80-200 nm and centre has a through hole whose diameter is 10-60 nm. Said invention utilizes organic solvent to make the cerium salt be dissolved, and further utilizes solvent heat to make the hollow pearl nano cerium oxide be formed on the surface of carbon nano tube, then the template is removed, so that the correspondent hollow pearl nano cerium oxide can be obtained.

Owner:SHANGHAI UNIV

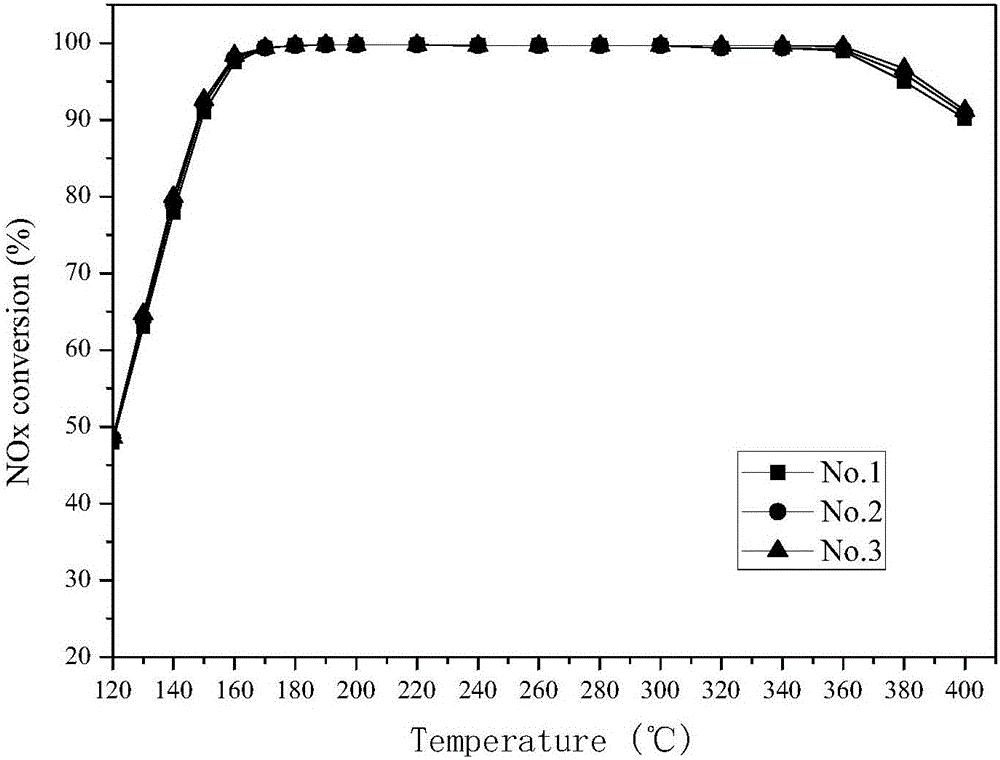

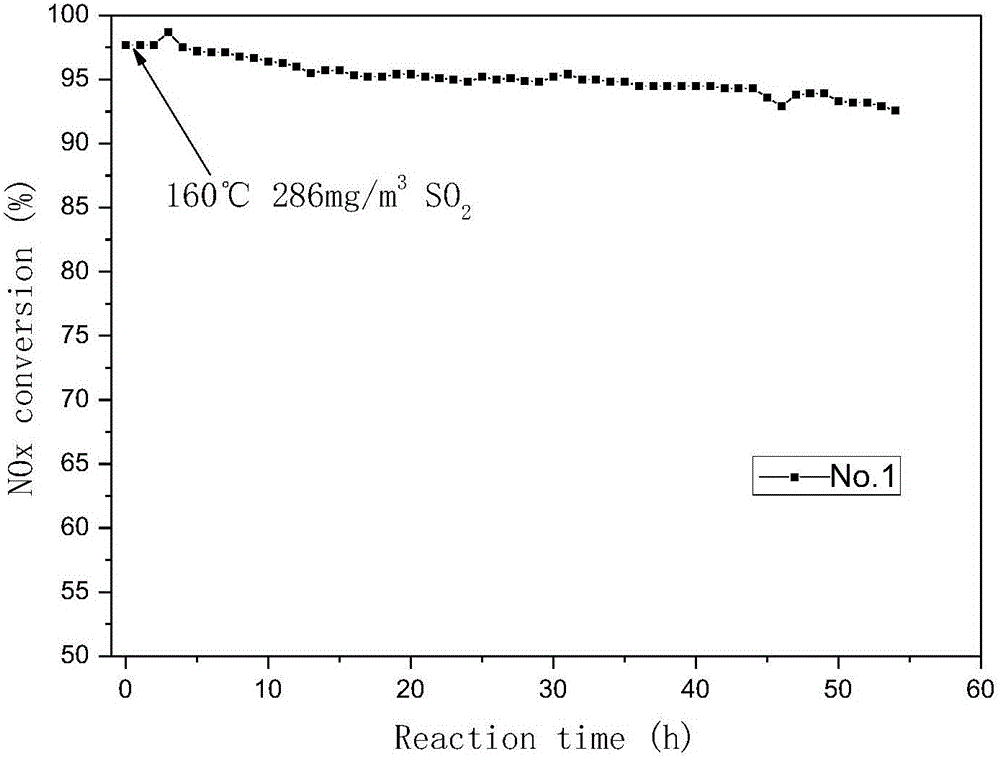

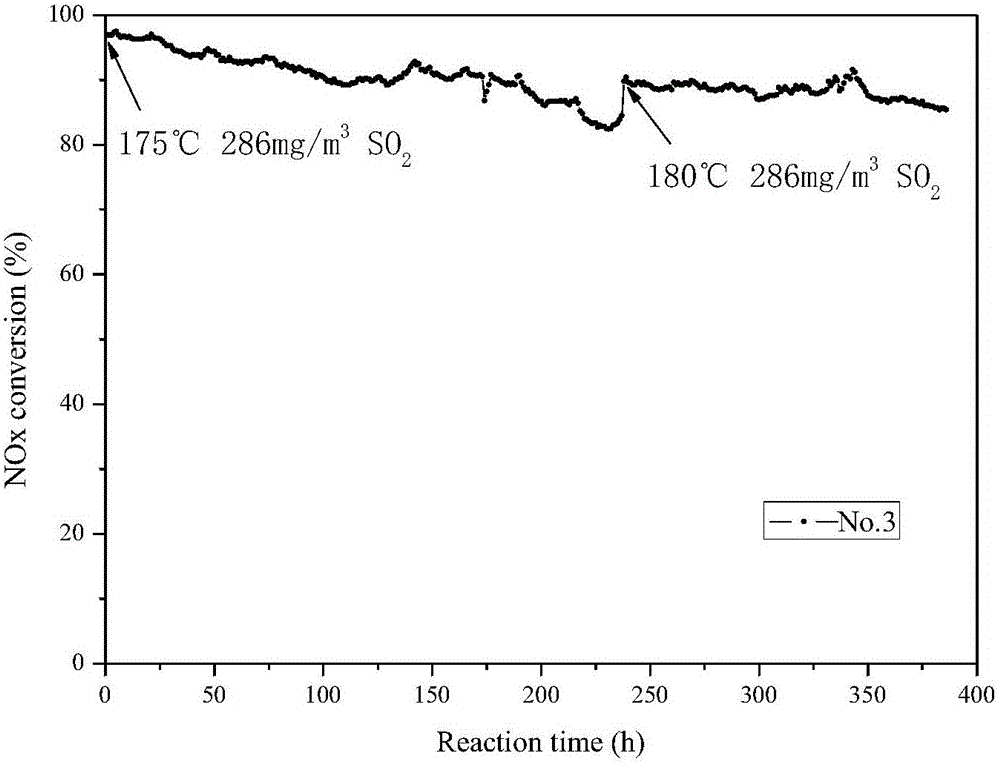

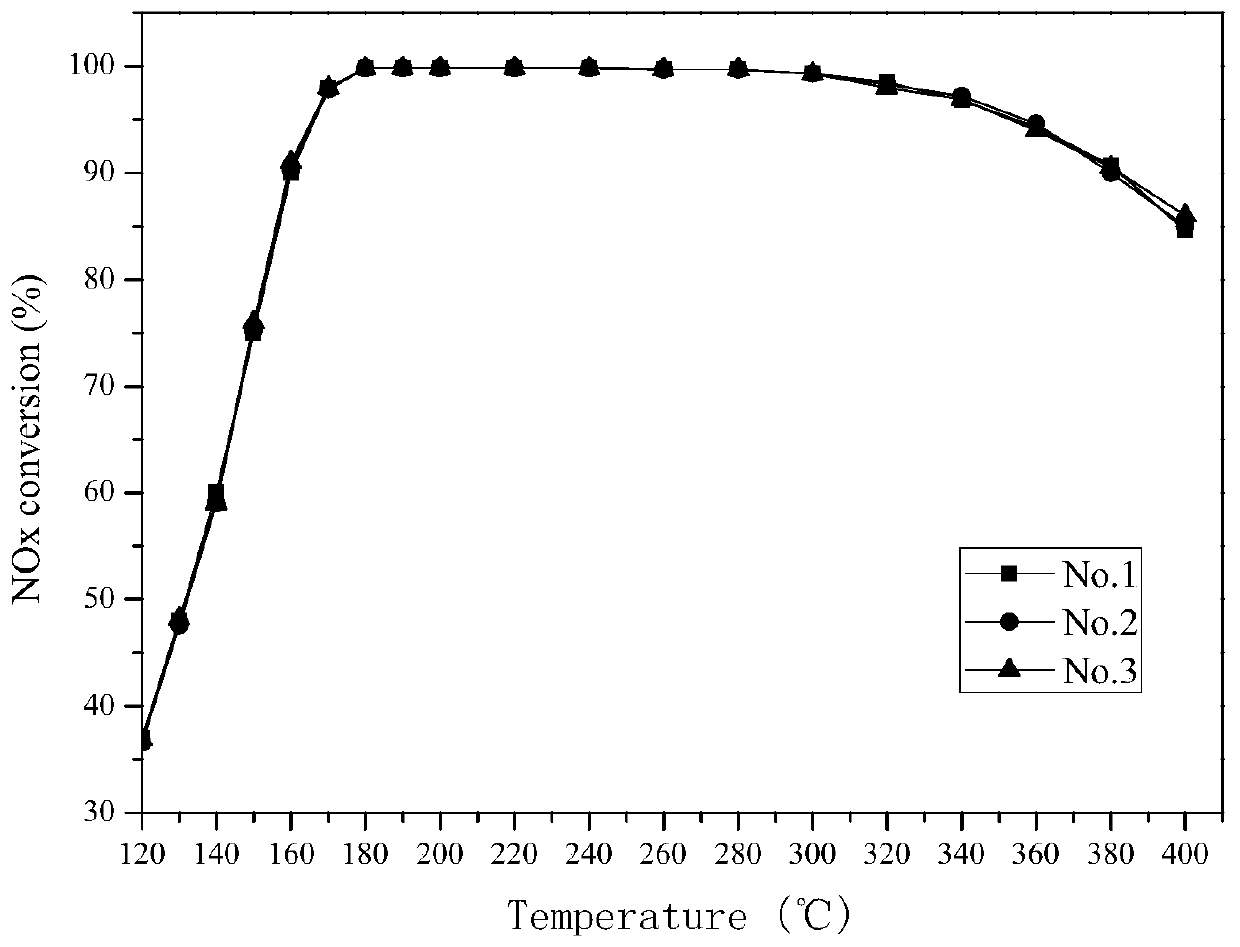

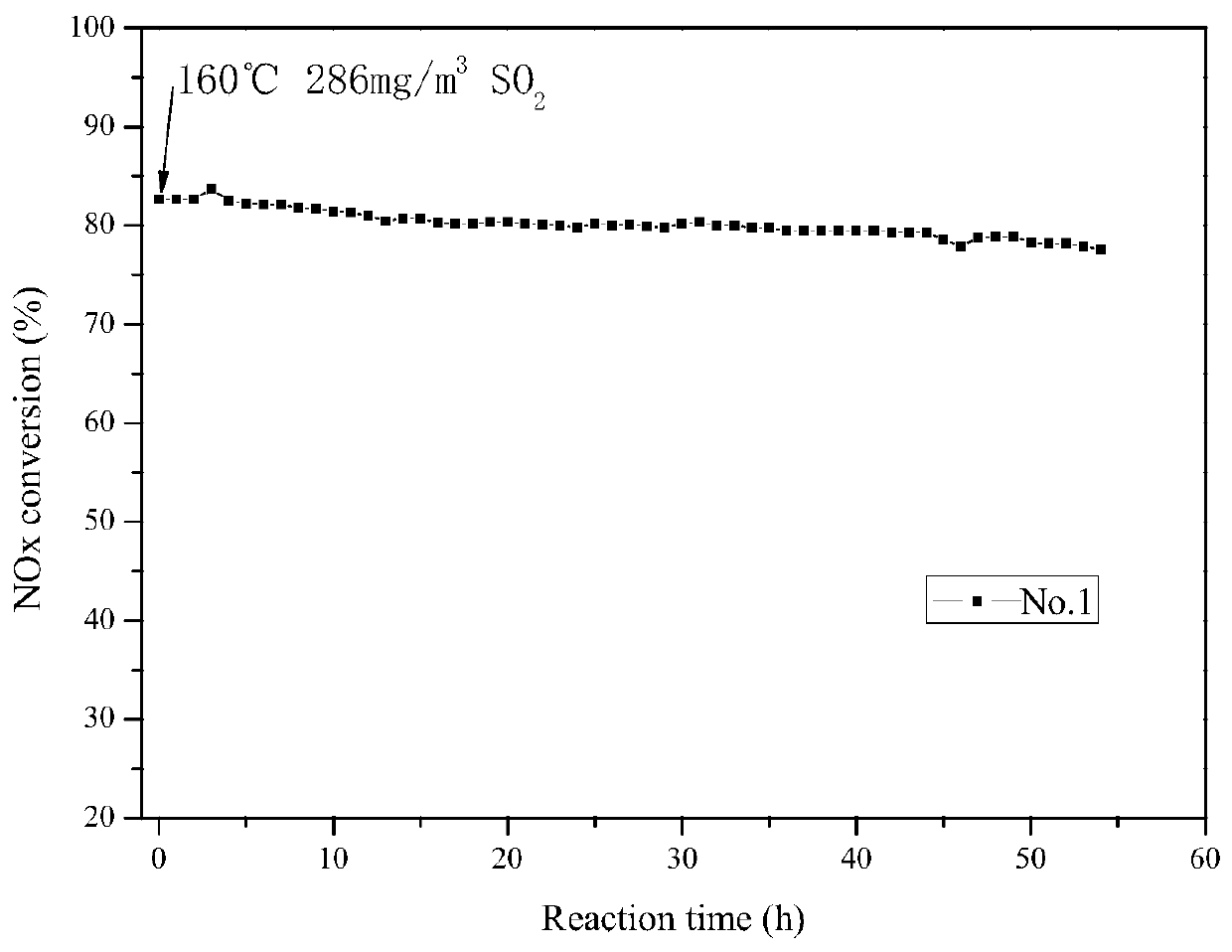

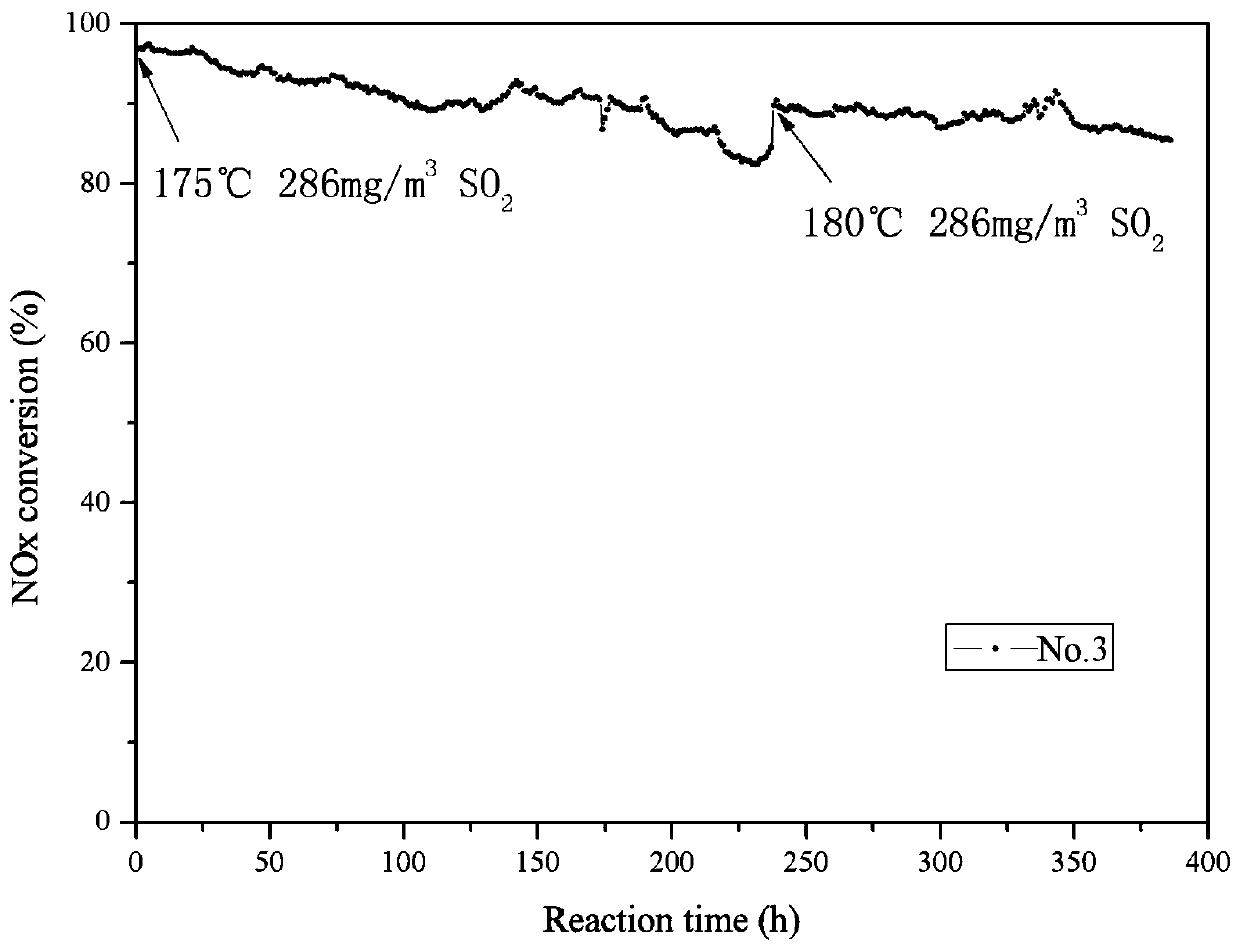

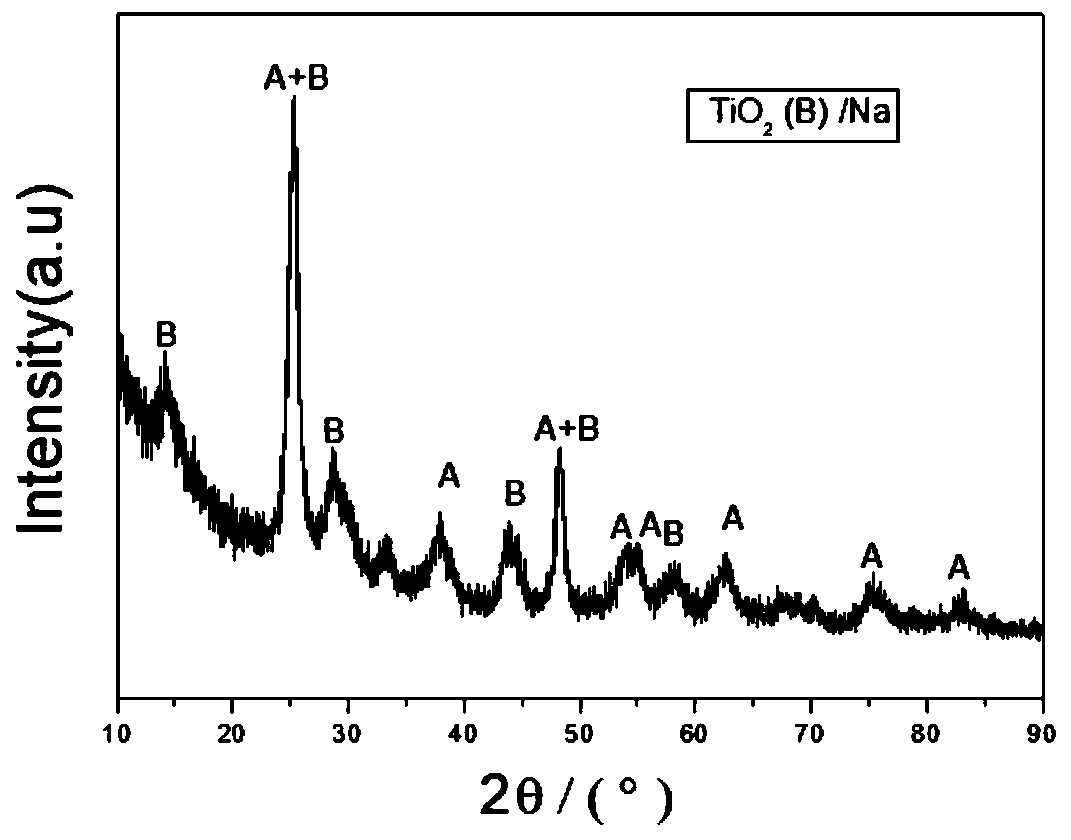

Low-temperature sulfur-resistant vanadium-titanium denitration catalyst and preparing method

InactiveCN106111135ALower catalytic temperatureExcellent low temperature sulfur resistanceCatalyst carriersGas treatmentTungstateAmmonium metavanadate

A low-temperature sulfur-resistant vanadium-titanium denitration catalyst and a preparing method are disclosed and belong to the field of denitration catalysts. The low-temperature sulfur-resistant vanadium-titanium denitration catalyst is prepared with a steeping method, anatase type titanium dioxide serves as a carrier, and vanadium pentoxide, tungsten trioxide and ruthenium are loaded on the surface of the carrier, wherein TiO2 accounts for 70-95 wt%, V2O5 accounts for 0-10 wt%, WO3 accounts for 0-20 wt%, and Ru accounts for 0.1-0.8 wt%. The chemical composition precursors of V2O5, WO3 and Ru are ammonium metavanadate, ammonium tungstate and ruthenium trichloride respectively. By loading trace precious metal elements, the denitration catalyst can maintain the efficiency of 90% or above at 150-400 DEG C, and the toxic action of sulfates formed by Sox in the sulfur-containing smoke atmosphere on the catalyst can be relieved. The service life of the catalyst can be prolonged, the preparing method is easy and convenient to implement, and the production efficiency is high.

Owner:BEIJING UNIV OF TECH

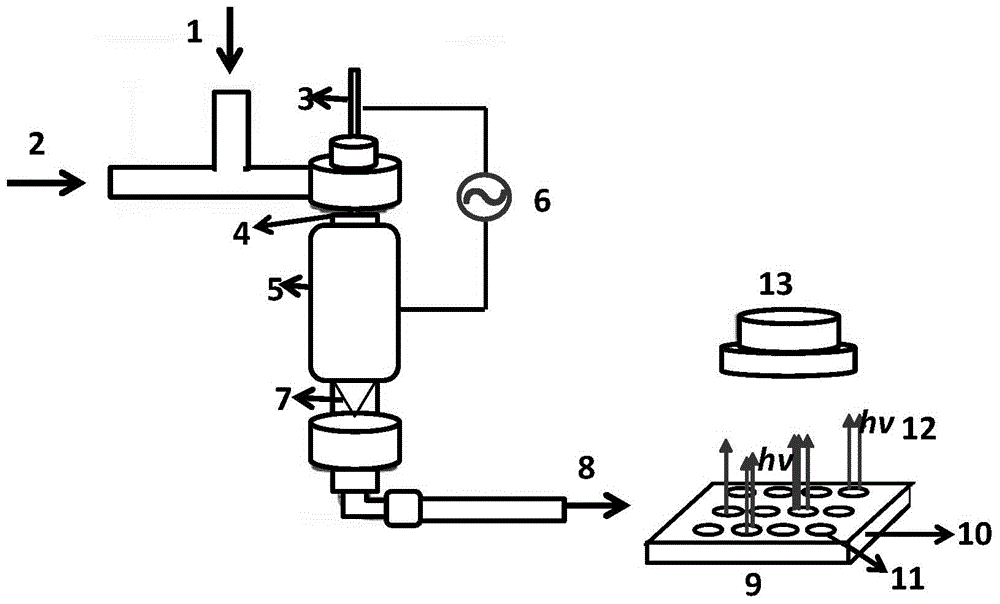

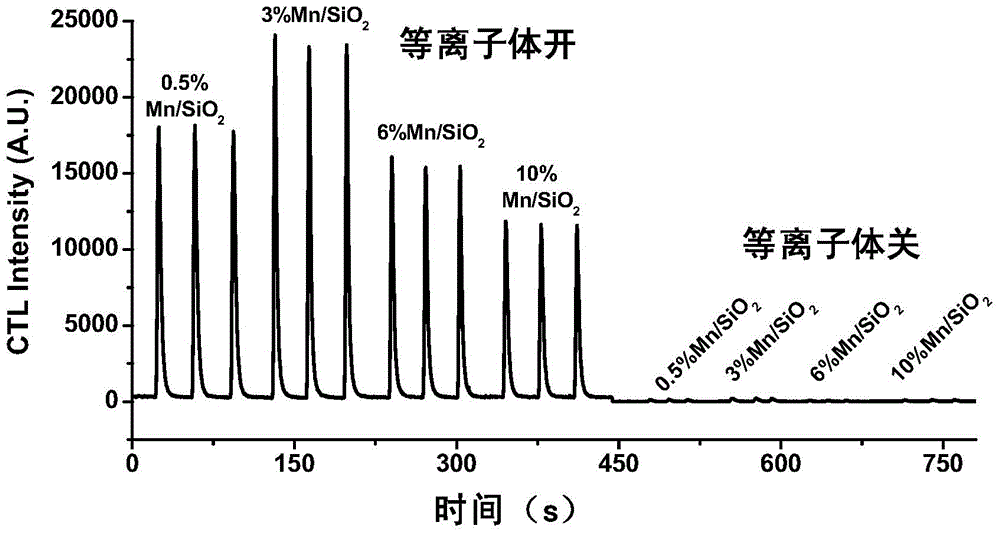

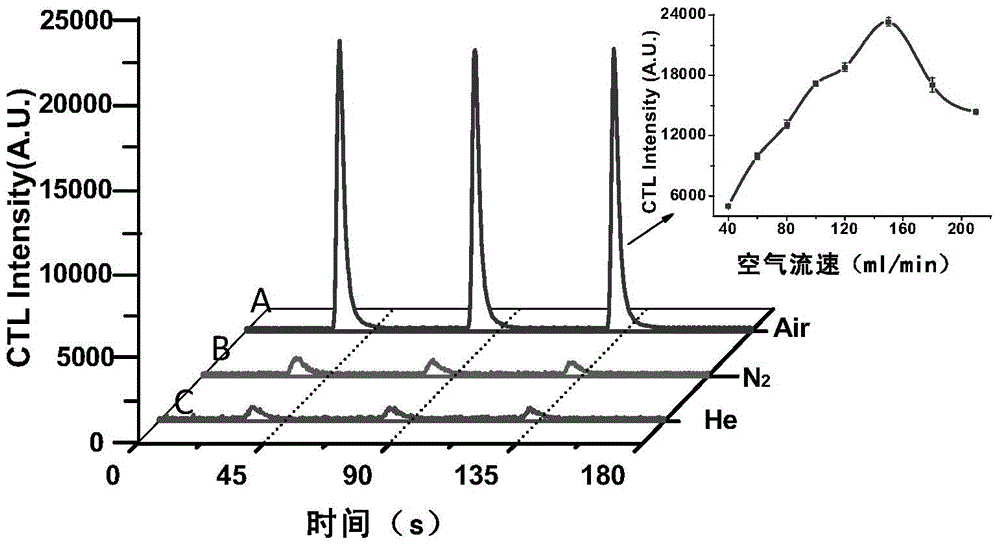

Gas detection method and special sensor array thereof

ActiveCN104634776AHigh reactivityQuick identificationChemiluminescene/bioluminescenceSensor arrayHigh activation

The invention discloses a gas detection method and a special sensor array thereof. The gas sensor array comprises a plasma generator and a sensor array chip, wherein one end of the plasma generator is connected with a three-way pipe; the other two ways of the three-way pipe are used as a sample gas inlet and a carrier gas inlet respectively; the other end of the plasma generator is used for introducing gas to the surface of the sensor array chip through a gas pipeline; the sensor array chip is composed of a temperature controllable inert chip, and an array composed of a plurality of sensing units and arranged on the surface of the inert chip; and different nano catalytic materials are loaded on each sensing unit. The gas sensor array combines high-activation performances of low-temperature plasmas, and the reaction activities of the catalytic materials and reactants are improved; the device is simple, the catalytic temperature is low, the energy consumption is low and the heat background is low; and the gas sensor array can be used for detecting environmental gas-state pollutants and respiratory air leaving away from a human body, and a simple and rapid novel method is provided for rapid diagnosis and early detection of diseases including cancers and the like.

Owner:河北百强医用设备制造有限公司

Heavy oil viscosity reducer and preparation method thereof

InactiveCN107177353ASuccessful viscosity reduction treatmentStrong salt resistanceDrilling compositionSodium bicarbonateAmmonium carbonate

The invention provides a heavy oil viscosity reducer. Based on the total weight of the heavy oil viscosity reducer, the heavy oil viscosity reducer is prepared from 1 to 15 percent by weight of component A, 0.1 to 1.5 percent by weight of component B, 0.1 to 5 percent by weight of component C and water, totaling 100 percent, wherein the component A is at least two of ammonium nitrite, sodium carbonate, sodium bicarbonate, ammonium bicarbonate and ammonium carbonate; the component B is alkylphenoxy polyoxyethylenepolyoxypropylene; the component C is an alkyl imidazole ionic liquid and / or a quaternary ammonium salt ionic liquid. The invention further provides a preparation method of the heavy oil viscosity reducer. The method comprises: mixing and stirring the component A, the component B, the component C and the water. By adopting the heavy oil viscosity reducer, the viscosity of heavy oil can be lowered remarkably; meanwhile, irreversible modification and viscosity reduction can be performed on the thick oil to transform a heavy component of the thick oil to a light component, so that the thick oil recovery efficiency is increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

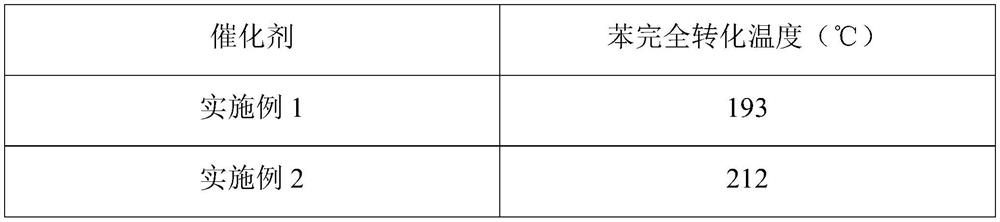

Loading-type copper-manganese catalyst and preparation method and application in CO low-temperature catalytic oxidation thereof

ActiveCN107537515AImprove low-temperature CO catalytic activityLower catalytic temperatureDispersed particle separationCatalyst activation/preparationHigh concentrationDecreased energy

The invention provides a loading-type copper-manganese catalyst and a preparation method and application in CO low-temperature catalytic oxidation thereof. The method includes the steps of blending ceric oxide with steeping liquid containing copper salt and manganese salt to obtain a mixture; drying the mixture to obtain a catalyst precursor; conducting calcine on the catalyst precursor to obtainthe loading-type copper-manganese catalyst. The catalyst includes a ceric oxide carrier and active components loaded on the carrier, wherein the active components are copper oxide and manganese dioxide. According to an experimental result, the loading -type copper-manganese catalyst prepared in the embodiment of the invention can maintain high catalytic activity for high-concentration CO catalyticoxidation (4000 ppm) under a low-temperature condition (0-150 DEG C), effectively reduce catalytic temperature of traditional Hopcalite and decrease energy consumption of a system reaction. Additionally, the preparation method is simple, the prepared catalyst can be applied to low-temperature CO catalytic clearance of sealed spaces including submarines and space stations and the like.

Owner:UNIV OF SCI & TECH OF CHINA

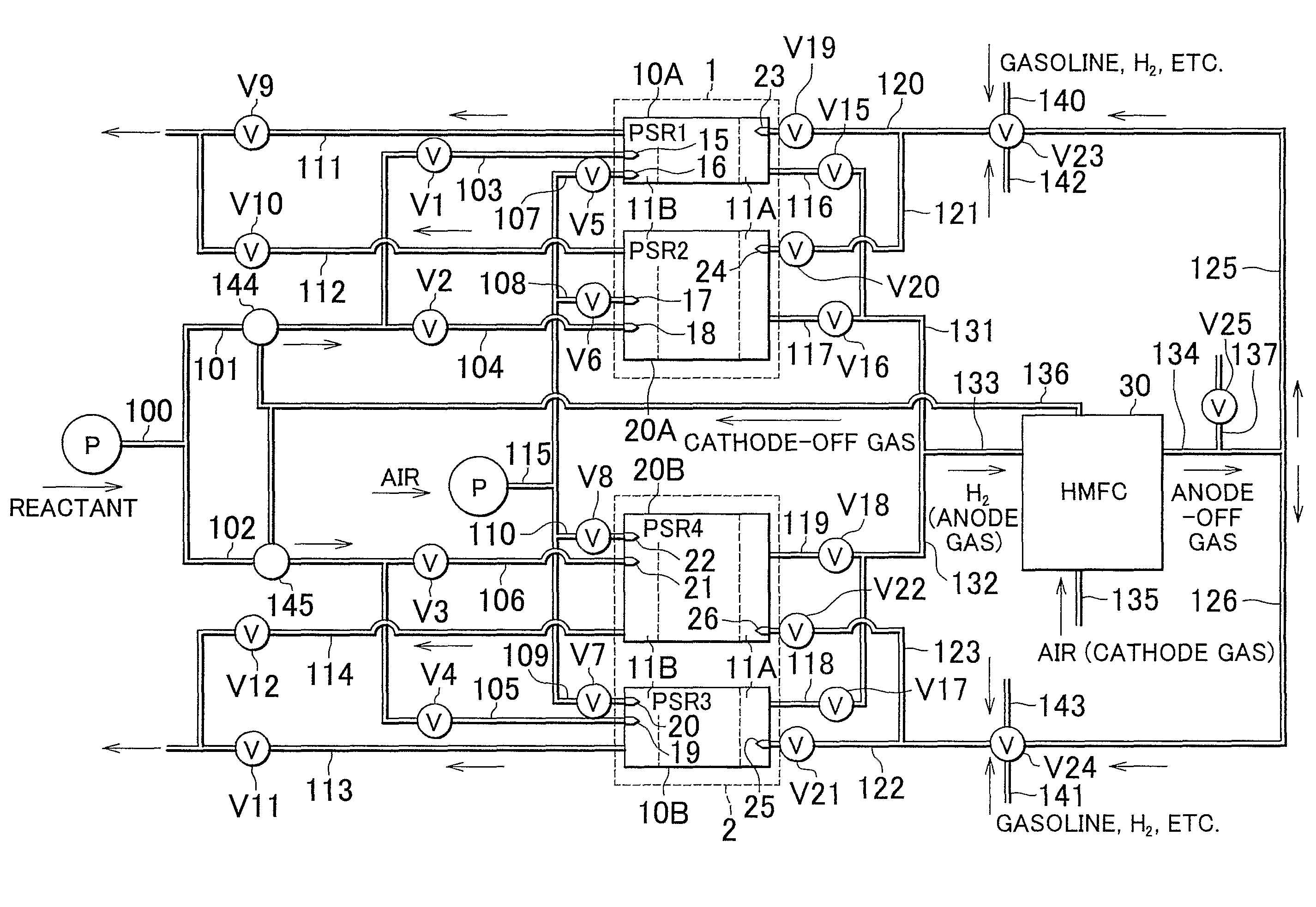

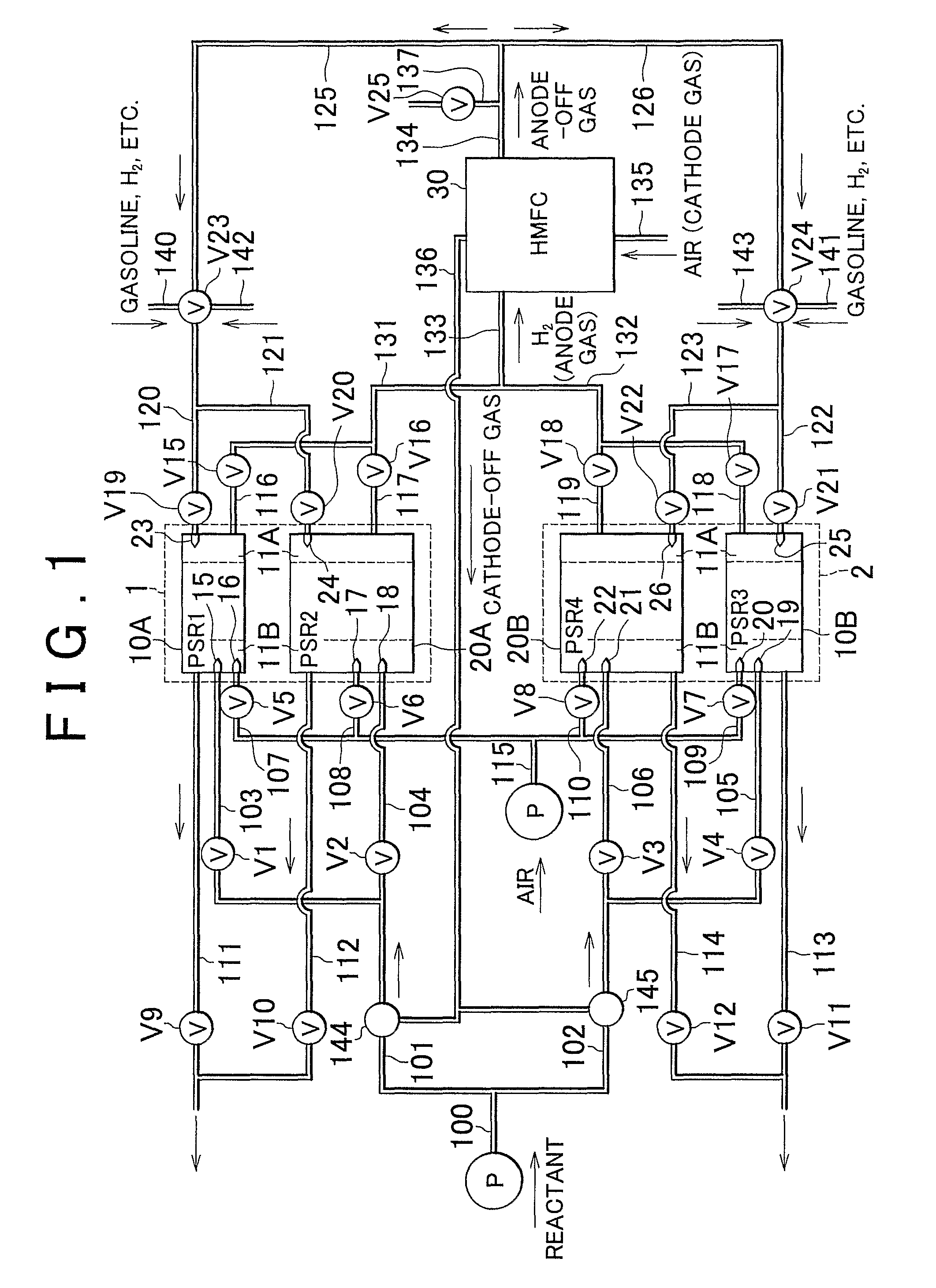

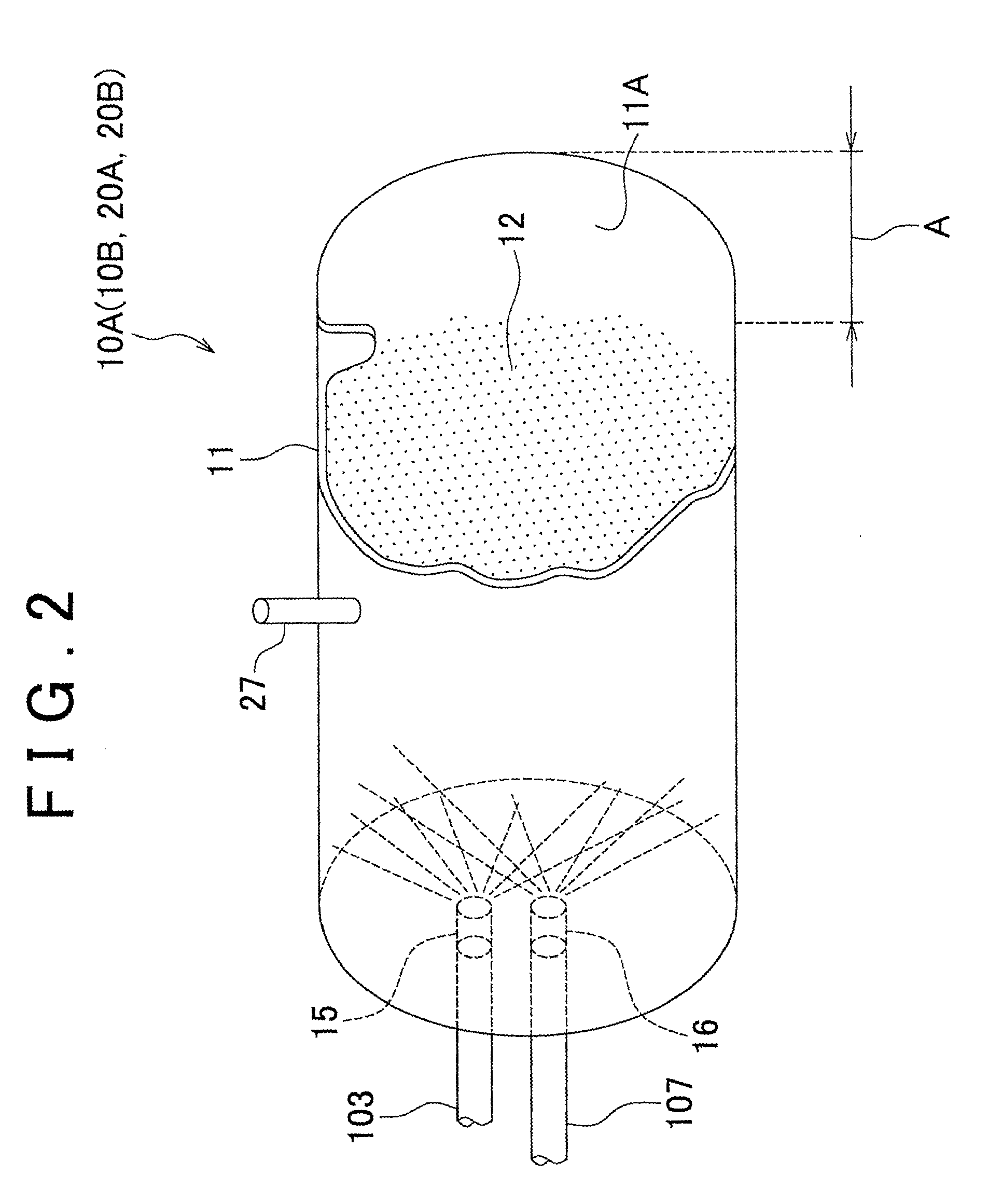

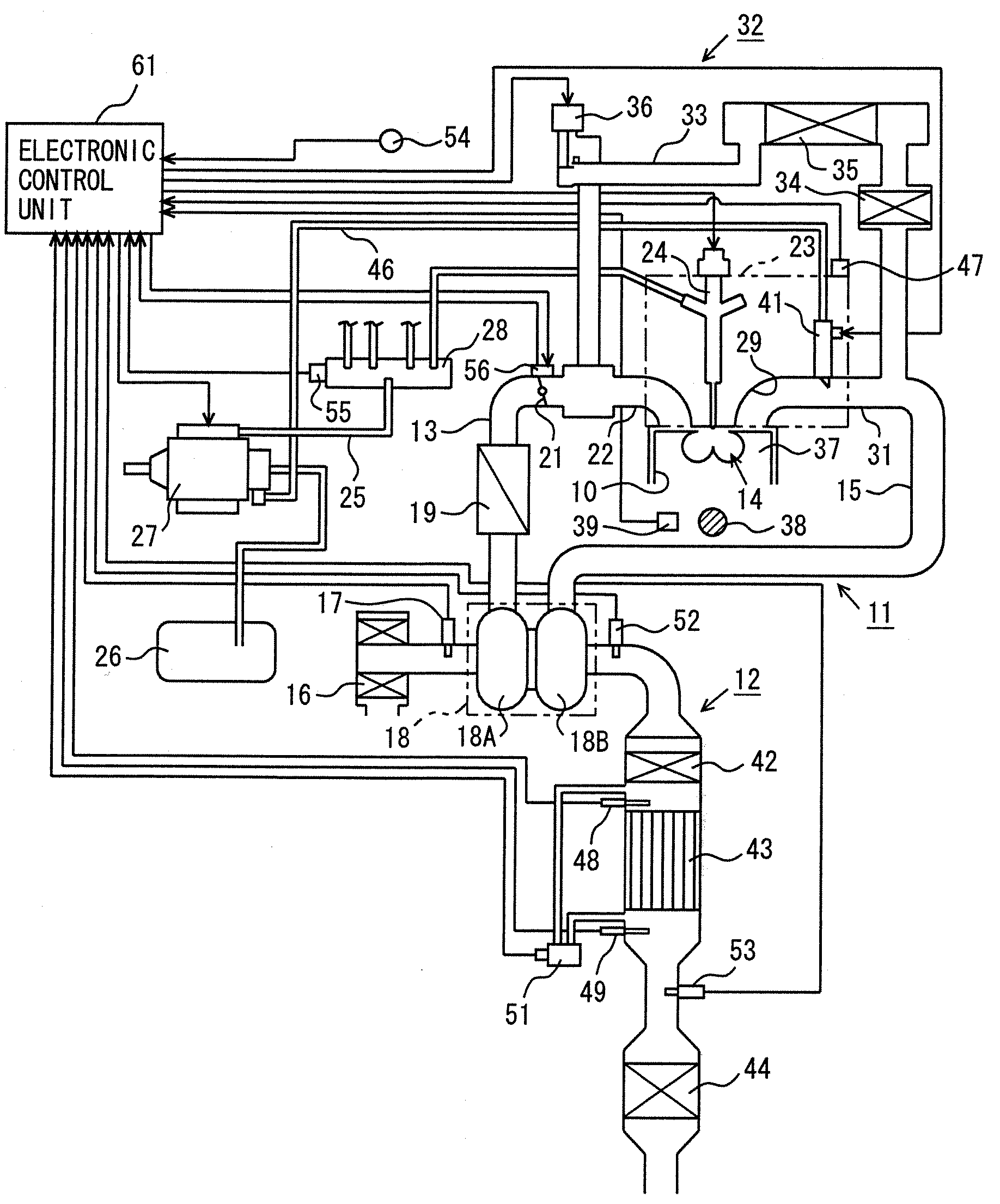

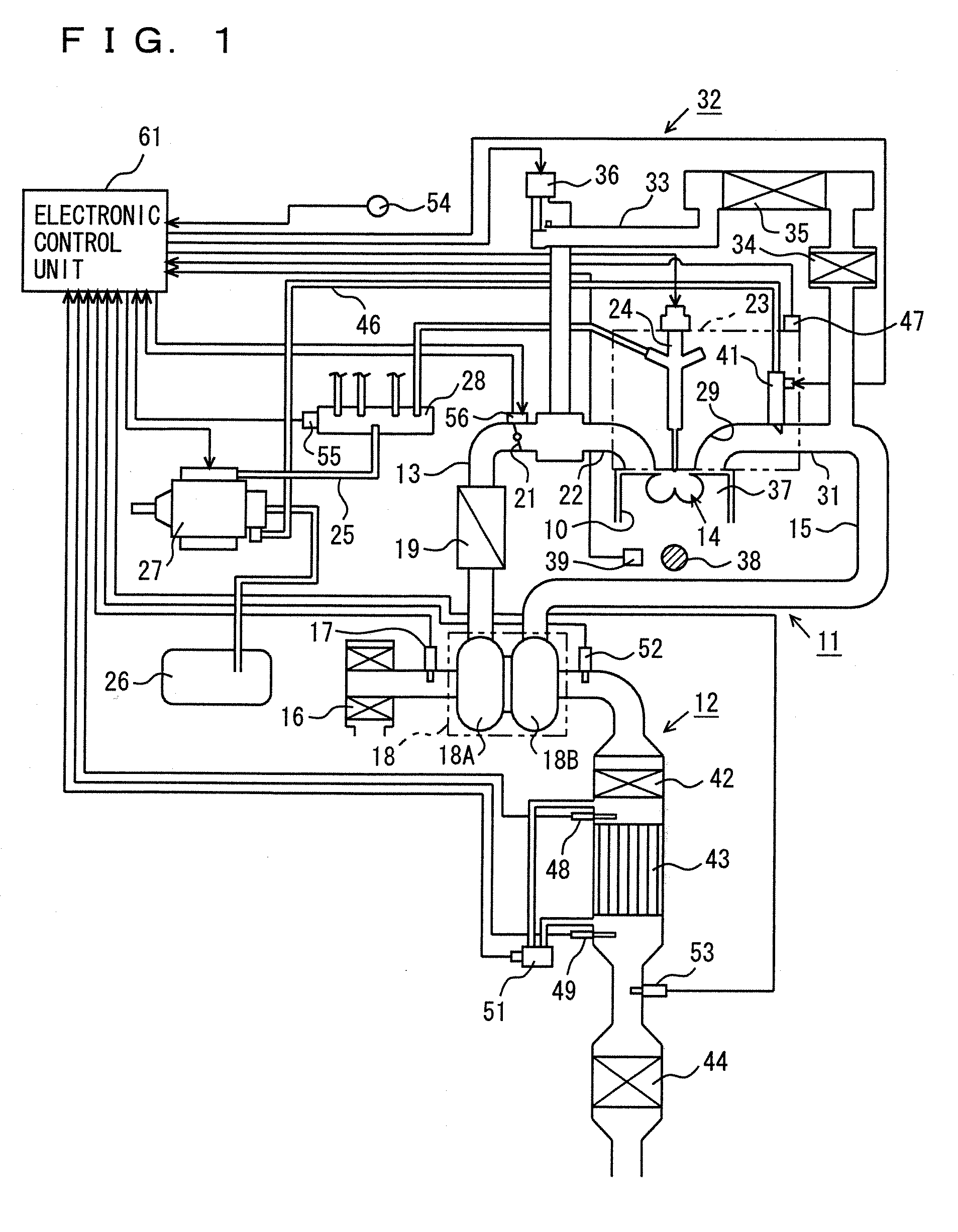

Hydrogen Generation Device and Fuel Cell System Including Same

InactiveUS20080160367A1Quickly and efficiently generatedStart fastFuel cell heat exchangeExhaust apparatusFuel cellsHydrogen

In a hydrogen generation device according to the invention, PSR reformers have a heat capacity smaller than that of the other PSR reformers. Therefore, the temperature of the catalyst reaches to a reforming-start temperature more quickly in the PSR reformers than in the other PSR reformers. When the hydrogen generation device is started and the reforming reaction is carried out, the mixture of gasoline vapor and water vapor is selectively and preferentially supplied to the PSR reformers so that the reforming reaction is carried out in the PSR reformers.

Owner:TOYOTA JIDOSHA KK

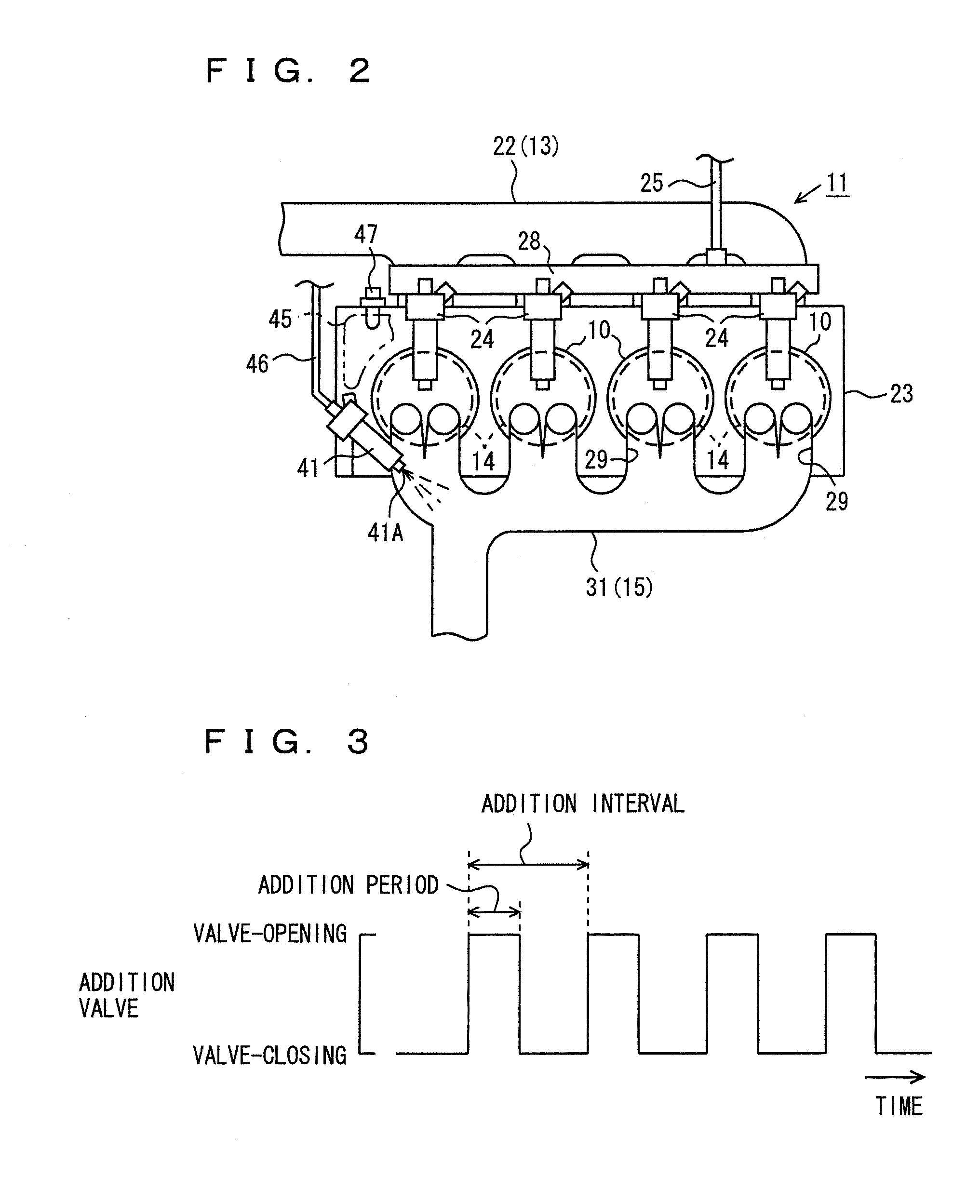

Exhaust Purifier for Internal Combustion Engine

InactiveUS20090007545A1Lower exhaust gas temperatureReduce injection volumeElectrical controlInternal combustion piston enginesCombustion chamberCylinder head

An addition valve is provided upstream of an exhaust gas purifying catalyst (NOx catalyst) in an exhaust pipe and in the vicinity of a water jacket in a cylinder head, in addition to a fuel injection valve injecting fuel for combustion in a combustion chamber. The addition valve injects a reducing agent in an addition amount in accordance with an operation state of an engine. Using an engine coolant temperature correlated to a temperature of the addition valve, a target addition interval of the addition valve is made shorter with increase in the engine coolant temperature, so that the addition amount is increased (step 130). The temperature of the exhaust gas purifying catalyst (catalyst bed temperature) is raised as a result of increase in the addition amount. Here, a target injection amount of fuel, representing one of parameters other than the addition amount that affect the catalyst bed temperature, is restricted by using an injection amount upper limit, such that the catalyst bed temperature does not exceed an upper limit of an allowable range (steps 240, 250).

Owner:TOYOTA JIDOSHA KK +1

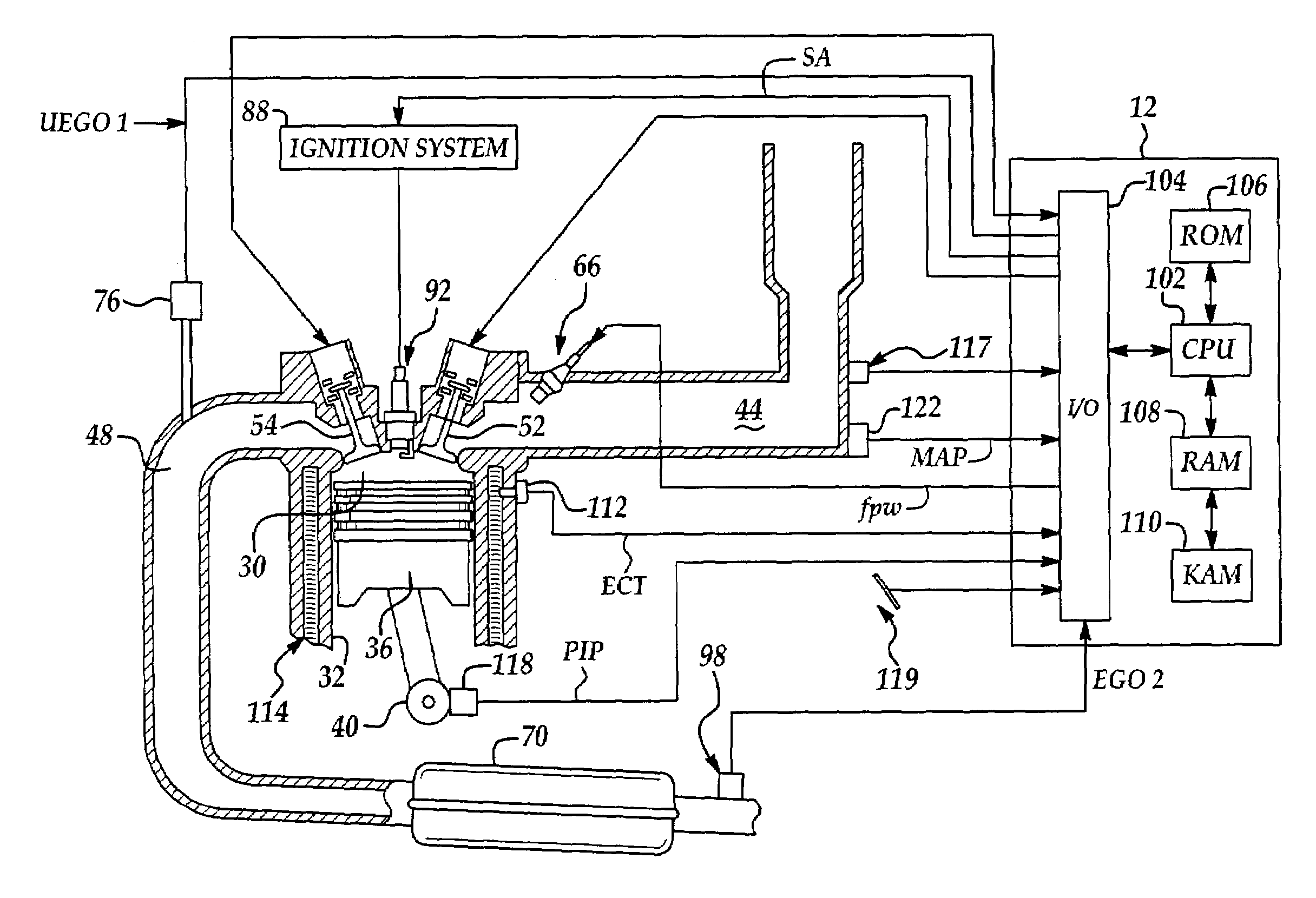

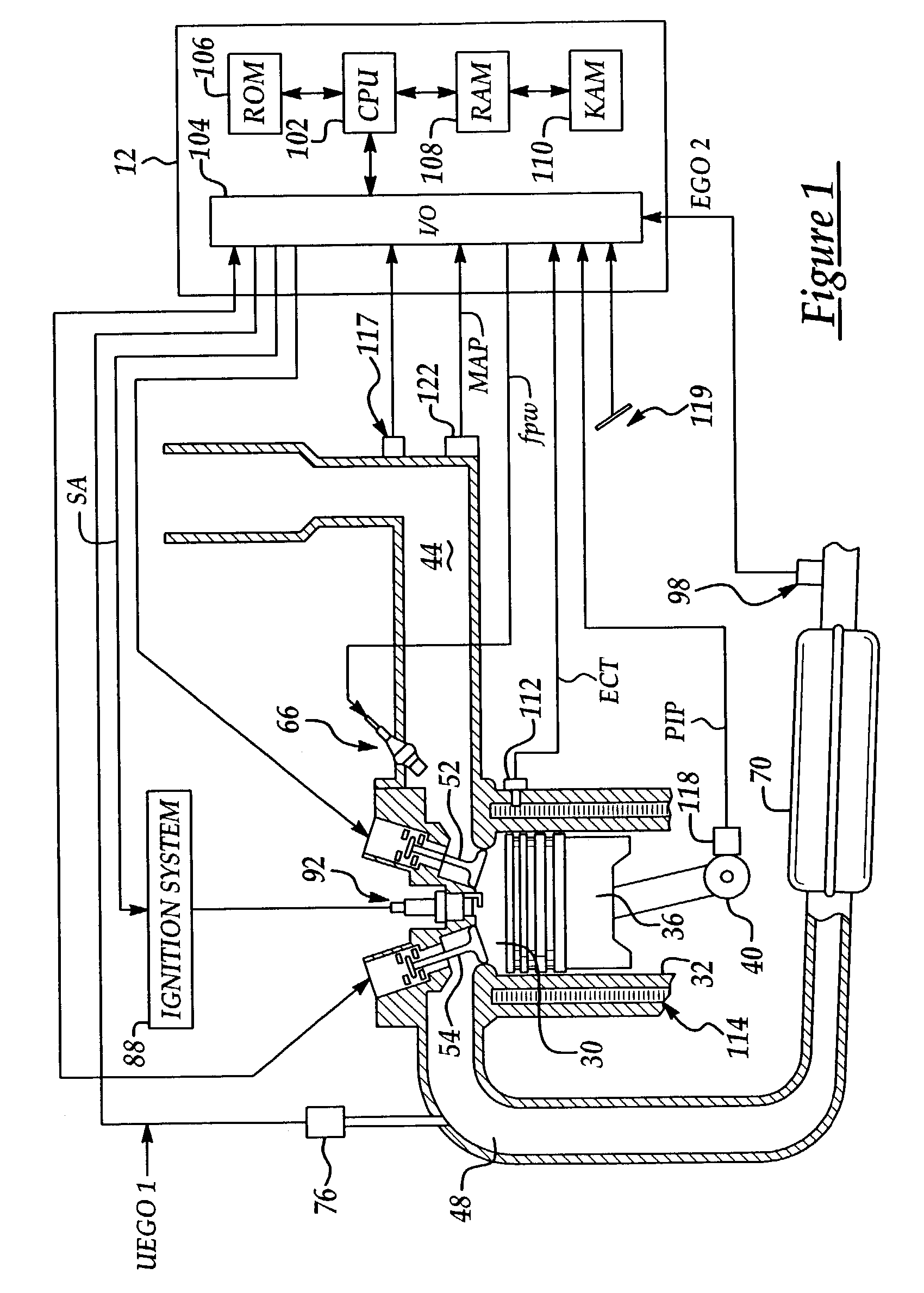

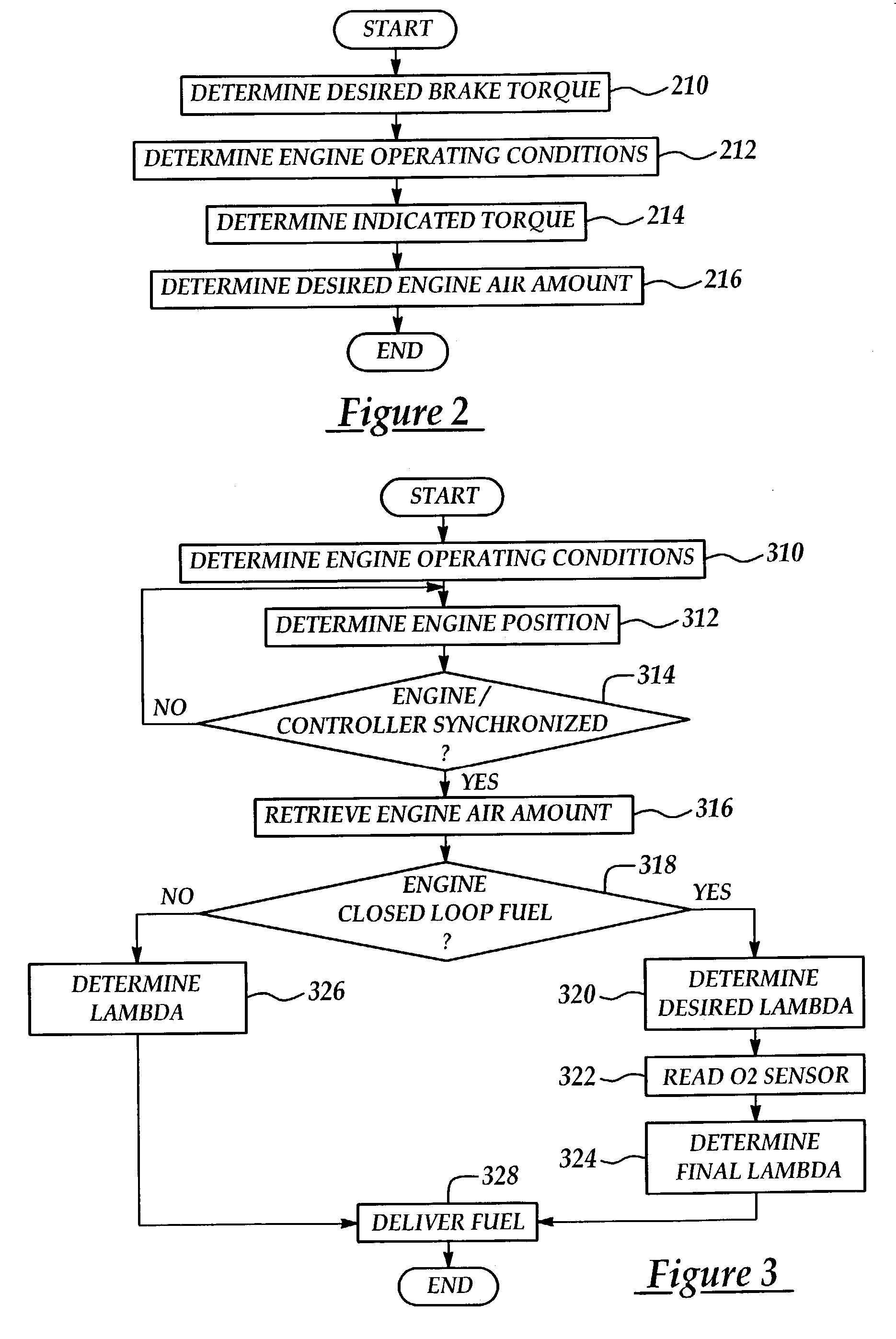

Catalyst temperature control on an electrically throttled engine

ActiveUS7155901B2Reduce restrictionsReduce fuel consumptionValve arrangementsElectrical controlTemperature controlProcess engineering

Owner:FORD GLOBAL TECH LLC

Air-fuel ratio control apparatus for an internal combustion engine

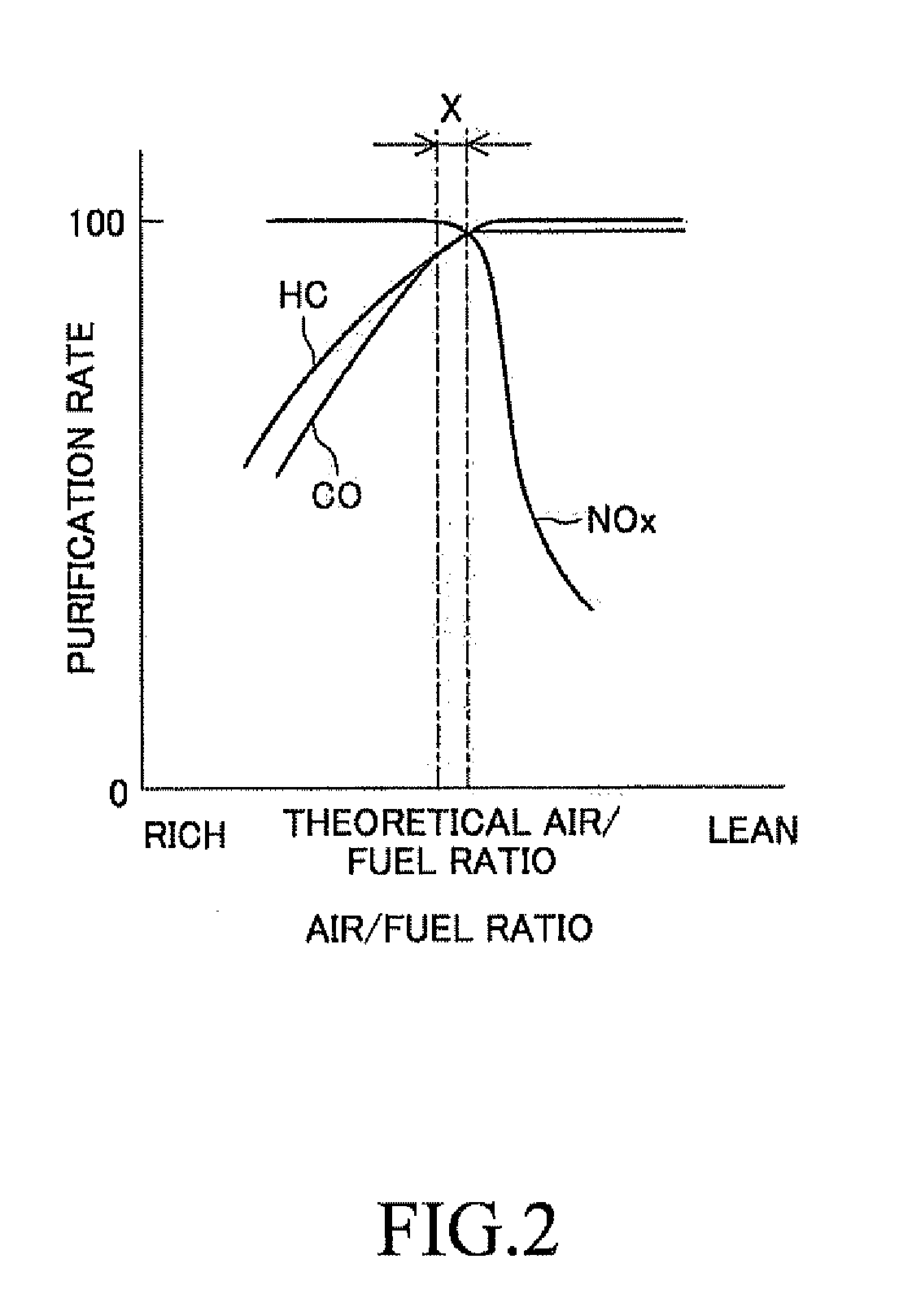

InactiveUS20120245823A1Avoid heatLower catalytic temperatureElectrical controlExhaust apparatusCombustion chamberEngineering

After rich control for controlling the air / fuel ratio of a mixture to be an air / fuel ratio richer than stoichiometric air / fuel ratio, lean control is carried out so that air / fuel ratio of the mixture formed in the combustion chamber is controlled to be an air / fuel ratio leaner by a predetermined degree than the stoichiometric air / fuel ratio, or the air / fuel ratio of the mixture is controlled to temporarily be the air / fuel ratio leaner by the predetermined degree than the stoichiometric air / fuel ratio. If lean control is carried out after rich control is finished, temporary lean control provides that a degree of how much the air / fuel ratio of the mixture is leaner than the stoichiometric air / fuel ratio when the air / fuel ratio of the mixture is controlled to be the air / fuel ratio leaner than the stoichiometric air / fuel ratio in lean control is lower than the predetermined degree according to the temperature of a catalyst.

Owner:TOYOTA JIDOSHA KK

Low-temperature-resistant PVC composite cable material and preparation method thereof

InactiveCN109111673AImprove long-term heat and oil resistanceOzone resistantRubber insulatorsGlycidyl methacrylatePolyvinyl chloride

The invention provides a low-temperature-resistant PVC composite cable material which is prepared from 100 parts of EPDM composite, 18 to 20 parts of ethylene-vinyl acetate copolymer, 16 to 18 parts of nano silicon dioxide, 4 to 6 parts of a composite compatilizer, 15 parts of chlorinated polyethylene, 5 to 8.5 parts of dicumyl peroxide, 0.2 to 0.3 part of sulfur, 0.4 part of a TMTD accelerant, 3.2 to 5.5 parts of a composite vulcanizing agent, 60 to 80 parts of a filling agent, 15 to 20 parts of high polymerization degree polyvinyl chloride, 0.8 part of an anti-aging agent and 20 to 25 partsof a plasticizer, wherein the EPDM composite is prepared from 90 to 94 parts of ethylene-propylene-diene monomer and 6 to 10 parts of modified chlorosulfonated polyethylene; the composite compatilizeris prepared from a mixture of dicumyl peroxide, glycidyl methacrylate and styrene; the composite vulcanizing agent is a mixture of triallyl isocyanurate and trimethylolpropane trimethyl acrylate. According to the composite cable material disclosed by the invention, the ingredients are optimized and designed; thus, the prepared composite cable material has the advantages of better low temperatureresistance and oil resistance and more excellent mechanical property.

Owner:XINYA ELECTRONICS

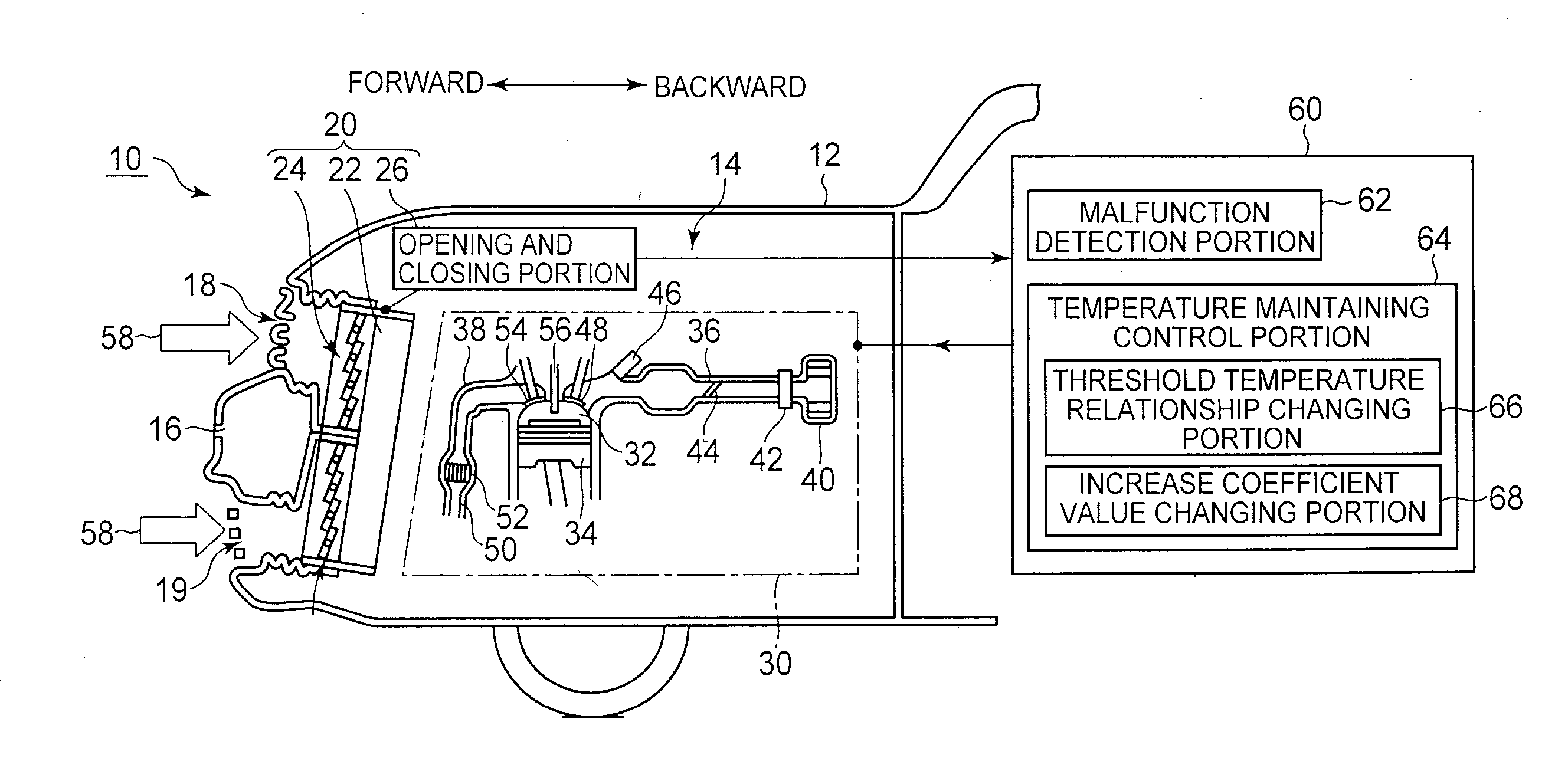

Limp-home method for safeguarding the catalyst of an internal combustion engine in case of a defective controlled grille shutter and vehicle thereof

ActiveUS20160108837A1Avoid overall overheatingLower catalytic temperatureLiquid coolingElectrical controlExternal combustion engineInternal combustion engine

A vehicle is disclosed which includes: an engine; a catalyst purifying exhaust gas of the engine; a grille shutter adjusting an opening area of a radiator grille; and an electronic control unit configured to: (a) control an injection quantity of fuel to be supplied to the engine, (b) detect a malfunction of the grille shutter in a state where the grille shutter is closed, and (c) increase the injection quantity when the malfunction is detected in comparison to when the malfunction is not detected.

Owner:TOYOTA JIDOSHA KK

Low-temperature sulfur-resistant molybdenum-vanadium-titanium denitration catalyst as well as preparation method and application thereof

InactiveCN109847769ALower catalytic temperatureExcellent low temperature sulfur resistancePhysical/chemical process catalystsDispersed particle separationSulfurFlue gas

The invention discloses a low-temperature sulfur-resistant molybdenum-vanadium-titanium denitration catalyst as well as a preparation method and application thereof, and belongs to the field of denitration catalysts. The catalyst comprises the following components: catalyst carrier TiO2, active component V2O5, and auxiliary agent MoO3, P2O5 and RuO2. According to the catalyst provided by the invention, an impregnation method is adopted to prepare the V2O5, MoO3, P2O5 and RuO2 supported denitration catalyst, and the catalyst is mainly applied to removal of nitrogen oxides in flue gas at a low temperature; through loading of microelements of precious metals, high-activity denitration under low-temperature flue gas can be realized, deactivation of the catalyst is slowed down, and the servicelife of the catalyst is improved; and moreover, the preparation method of the denitration catalyst is simple and easy to operate, has high production efficiency, and can lay a foundation for industrialized applications in future.

Owner:BEIJING CHANGXIN TAIHE ENERGY SAVING TECH CO LTD +1

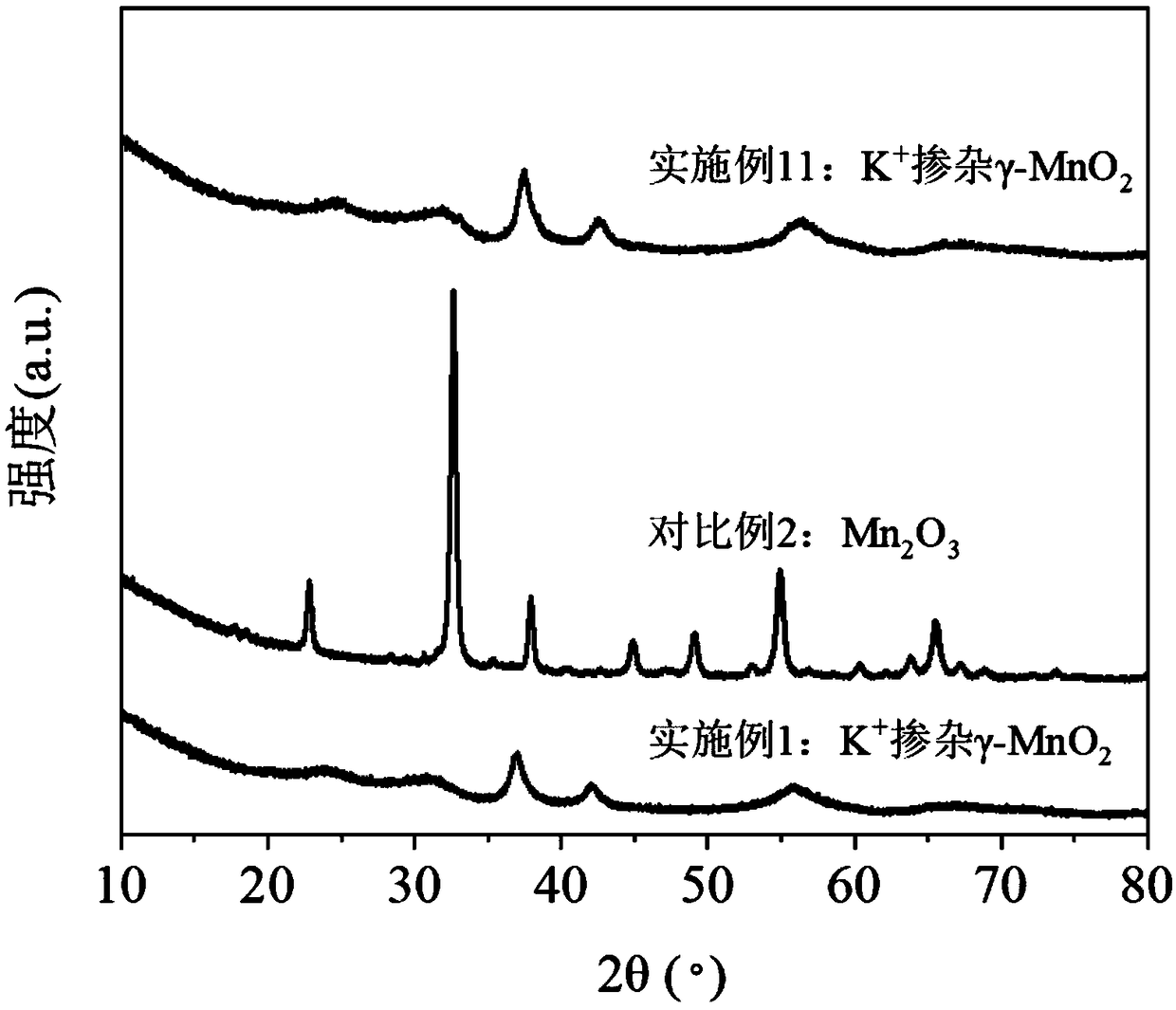

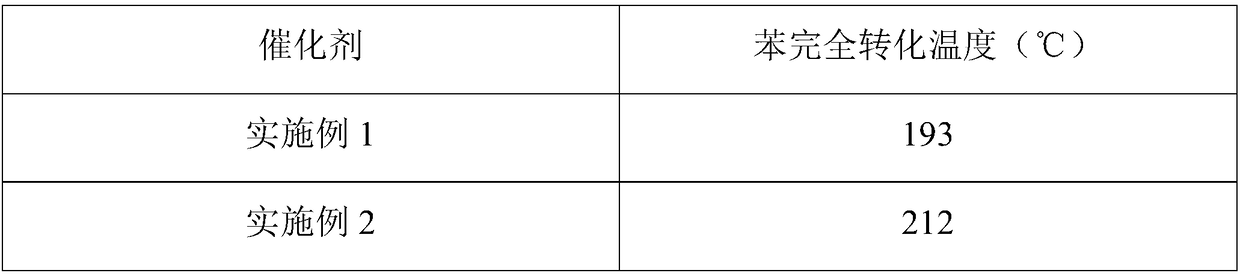

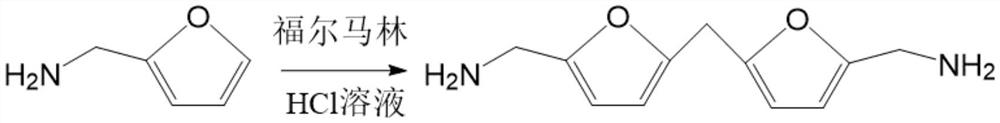

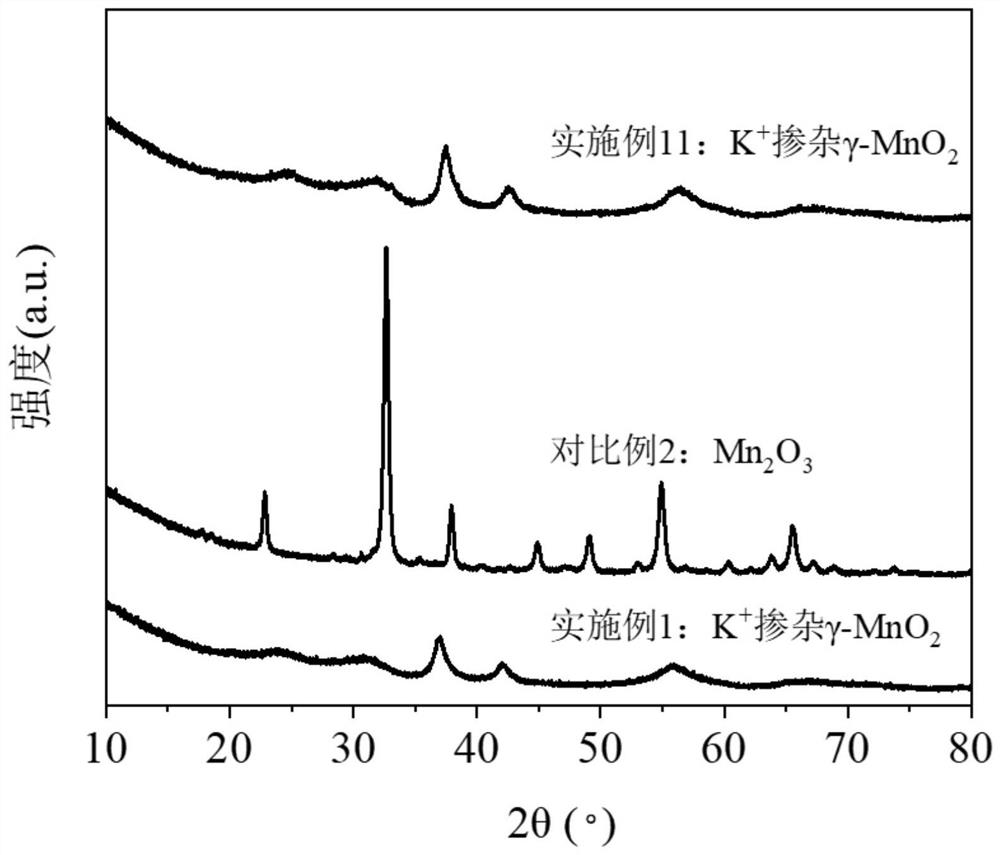

Potassium-doped gamma-manganese dioxide catalyst and preparation method and use thereof

ActiveCN109201044AAdd Surface Defect BitsImprove thermal stabilityGas treatmentDispersed particle separationChemistryActive oxygen

The invention provides a K<+>-doped gamma-MnO2 catalyst and a preparation method and use thereof. A main body structure of the catalyst is gamma-MnO2, and pore passages of the gamma-MnO2 are doped with K<+>. The gamma-MnO2 has a [2*1] pore passage structure, and the thermal stability is higher compared with ion implantation of alpha-MnO2 and lambda-MnO2 in crystal pore passages. Through doping theK<+>, Mn-O bonds of the gamma-MnO2 can be reduced, meanwhile, surface flaw sites are increased, and then, the capacity for adsorbing active oxygen and presenting crystal lattice oxygen is enhanced, so that the K<+>-doped gamma-MnO2 catalyst has relatively high catalytic oxidation activity to VOCs and has a good application prospect.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

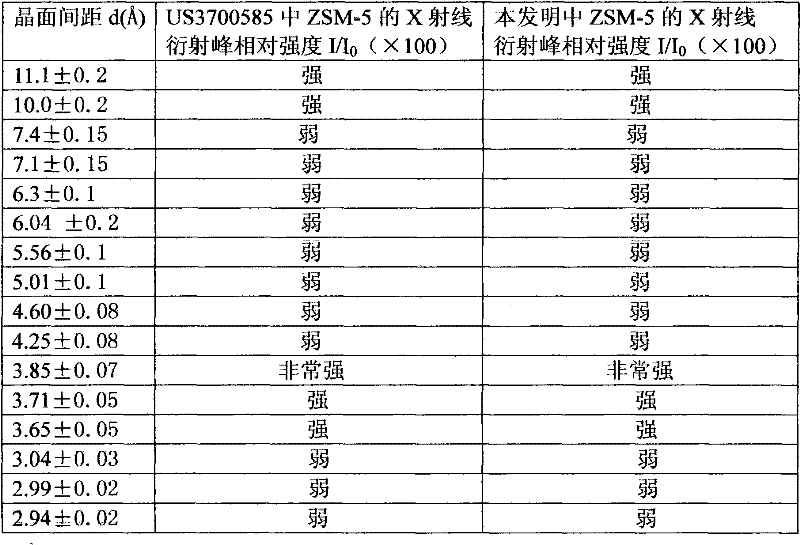

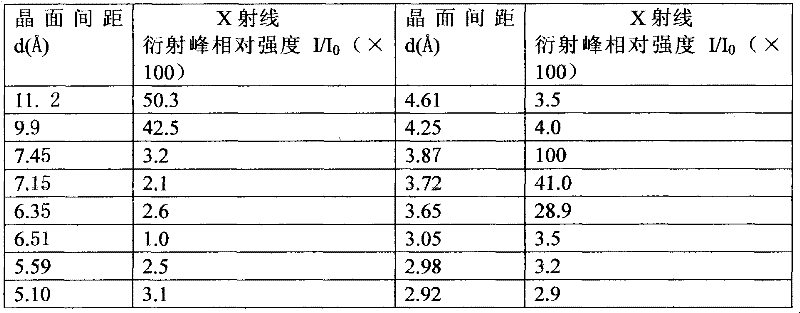

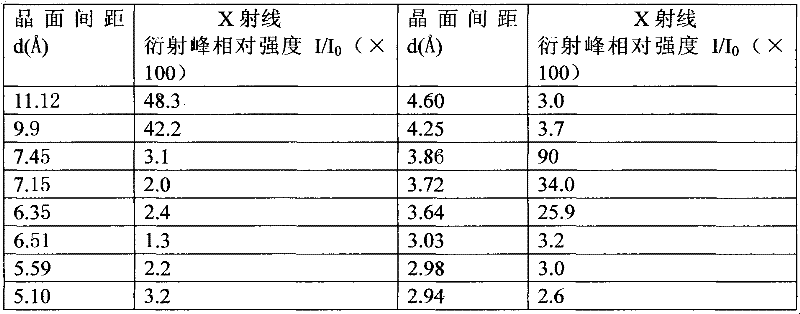

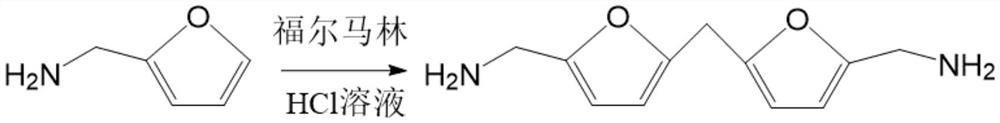

Small-grain ZSM-5 molecular sieve catalyst used for preparing ethylene from bioethanol and preparation method thereof

ActiveCN101837298BRaw materials are easy to getReduce dosageMolecular sieve catalystsCatalyst activation/preparationHigh selectivityZSM-5

The invention discloses a small-grain ZSM-5 molecular sieve catalyst used for preparing ethylene from bioethanol. The weight ratio of silicone of the ZSM-5 molecular sieve to aluminum of the ZSM-5 molecular sieve is 10 to 200 and the grain diameter is 60 to 100nm. A preparation method for the molecular sieve comprises the following steps of: preparing a ternary organic template agent from alkyl alcohol, alkylamine and aromatic amine; dissolving the silicon source in the ternary organic template agent and water to prepare solution A; dissolving the aluminum source in organic acid and water to obtain solution B; adding the solution B into the solution A with serious stirring to prepare a colloidal solution; putting the colloidal solution into a synthesis kettle to react and crystallize; cooling the reaction product to the room temperature; washing the synthetic product with the water and drying the product to obtain the small-grain ZSM-5 molecular sieve; alternately processing the product for several times with ammonium chloride; and drying the product to obtain the small-grain ZSM-5 molecular sieve catalyst. The catalyst has the advantages of easy control of the synthesis condition, simple preparation, low crystallization temperature and short time and has the characteristics of low concentration for ethanol, low crystallization temperature, high selectivity and high conversionof producing ethylene by ethanol dehydration, high feeding air speed and the like when used in catalytic reaction of preparing the ethylene by dehydration of the bioethanol.

Owner:GUANGXI RES INST OF CHEM IND CO LTD

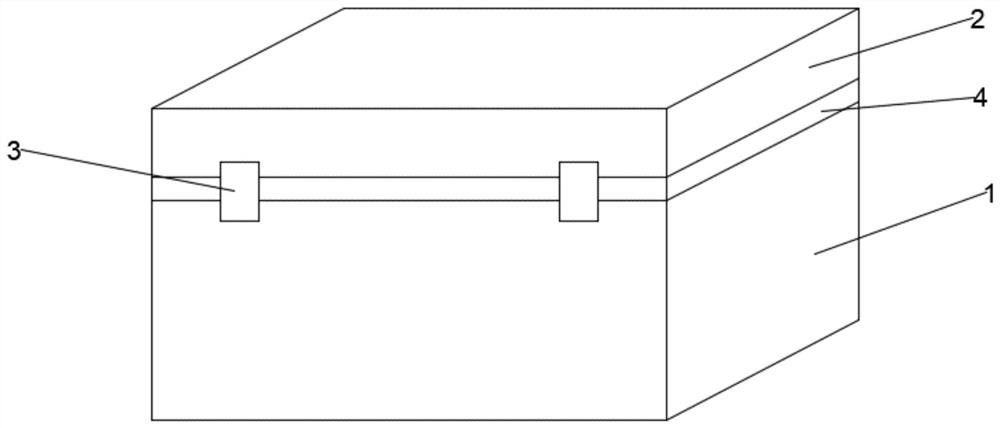

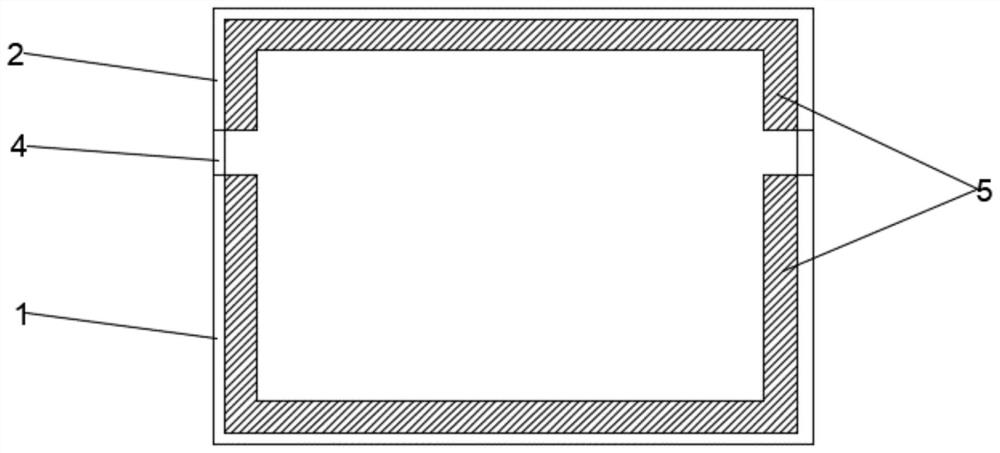

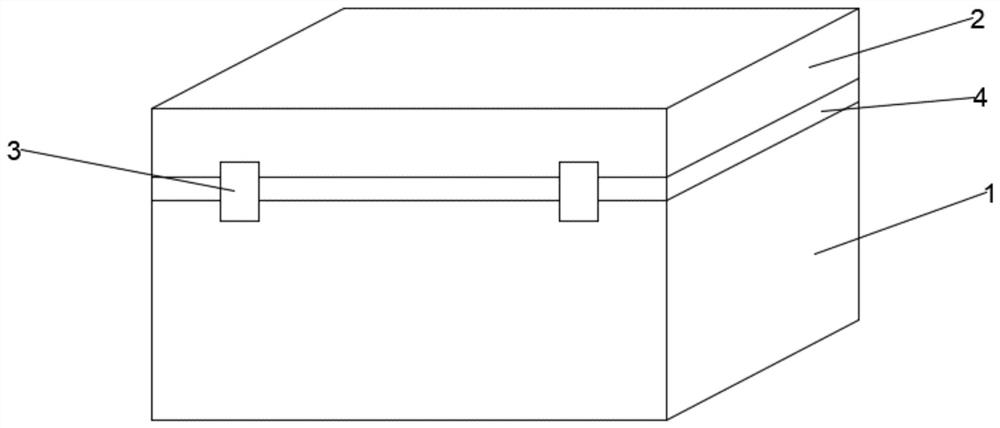

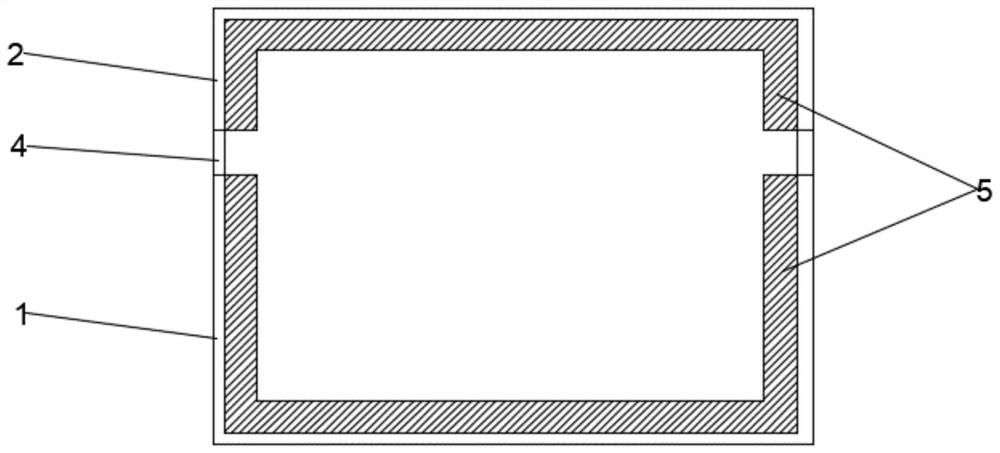

A heat-insulated and flame-retardant new energy battery box

ActiveCN113381112BPrevent explosion hazardsReduce distractionsBattery isolationSecondary cellsGlass fiberFiber

The invention discloses a heat-insulating and flame-retardant new energy battery box, which comprises a battery box body and an upper cover of the box body, the battery box box body and the box body upper cover are connected by buckles, and the battery box box body and the box body upper cover The inner surface of each is equipped with a heat-insulating and flame-retardant layer; the heat-insulating and flame-retardant layer is composed of polycarbonate, modified fiber and flame retardant; the mass ratio of polycarbonate, modified fiber and flame retardant is 50~ 80:10~20:0.2~2; wherein, the modified fiber includes modified glass fiber and chemical fiber. The invention discloses a new type of heat-insulating and flame-retardant new energy battery box, which can make the new energy battery less disturbed by the external temperature when it is working, and can also prevent the battery from Dangers such as explosion during use.

Owner:佛山日克耐热材料有限公司

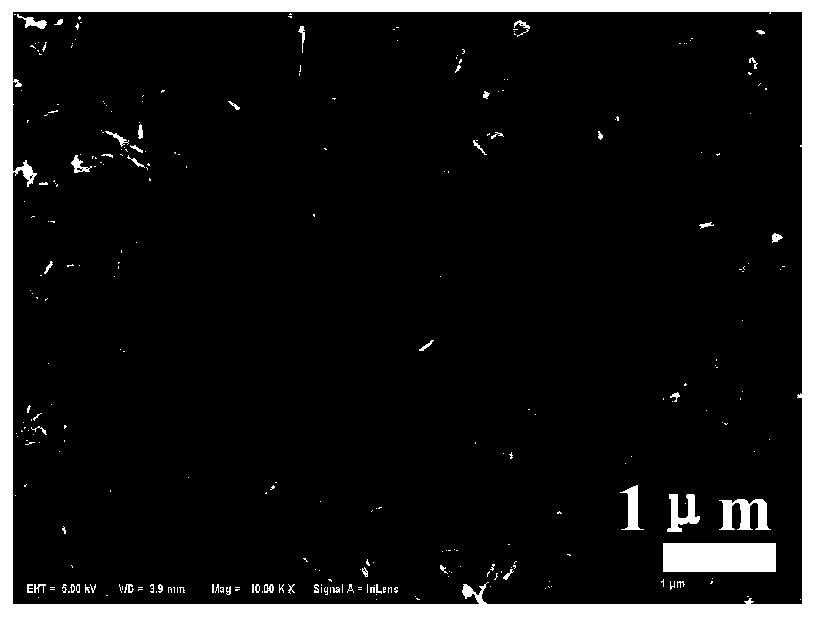

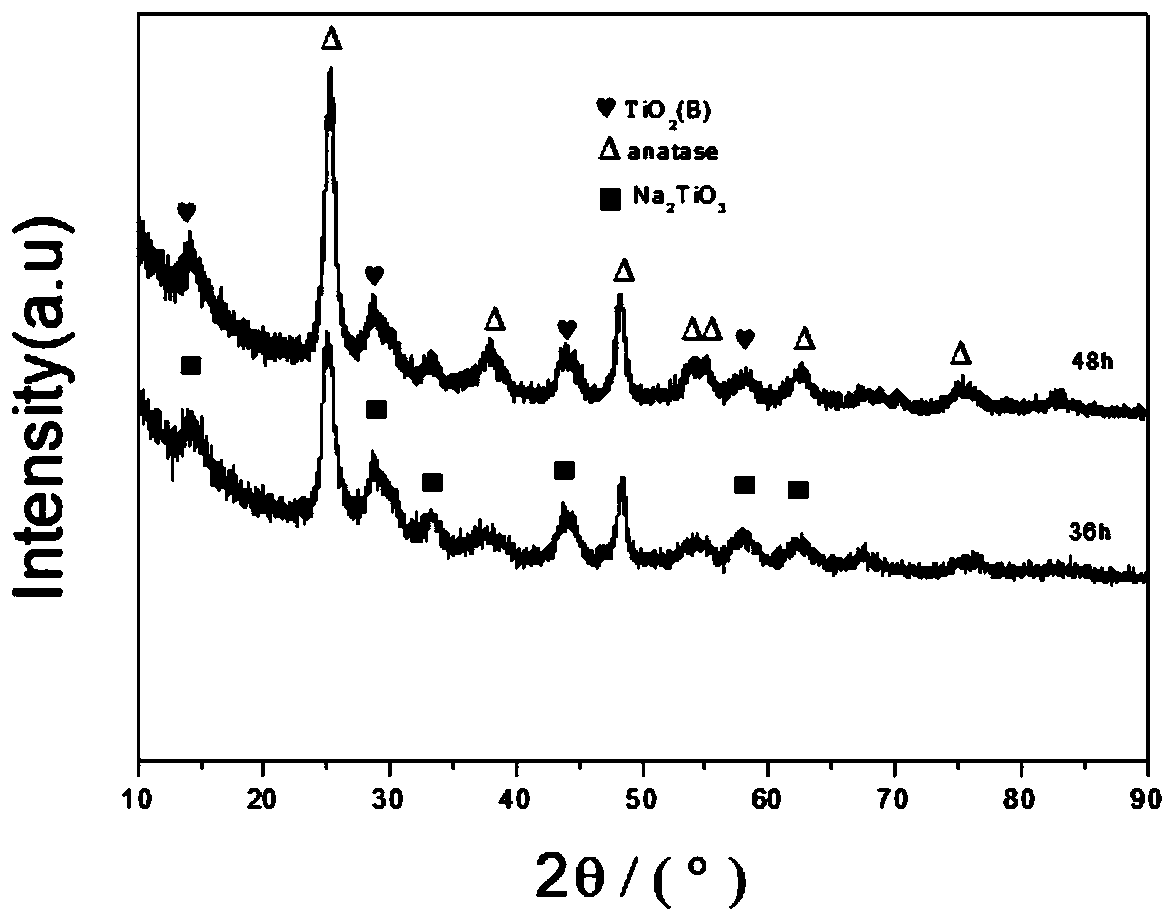

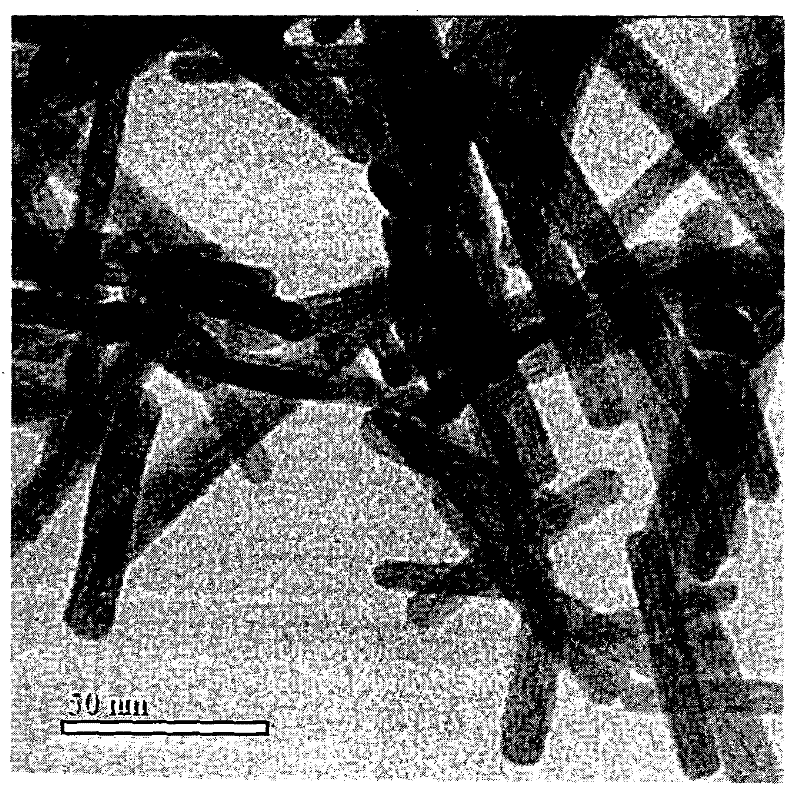

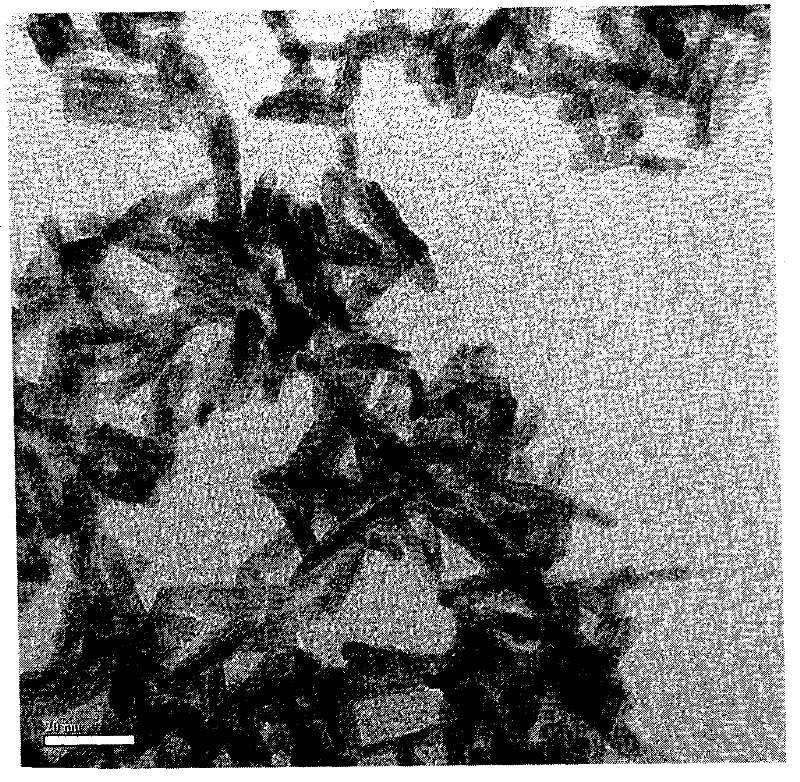

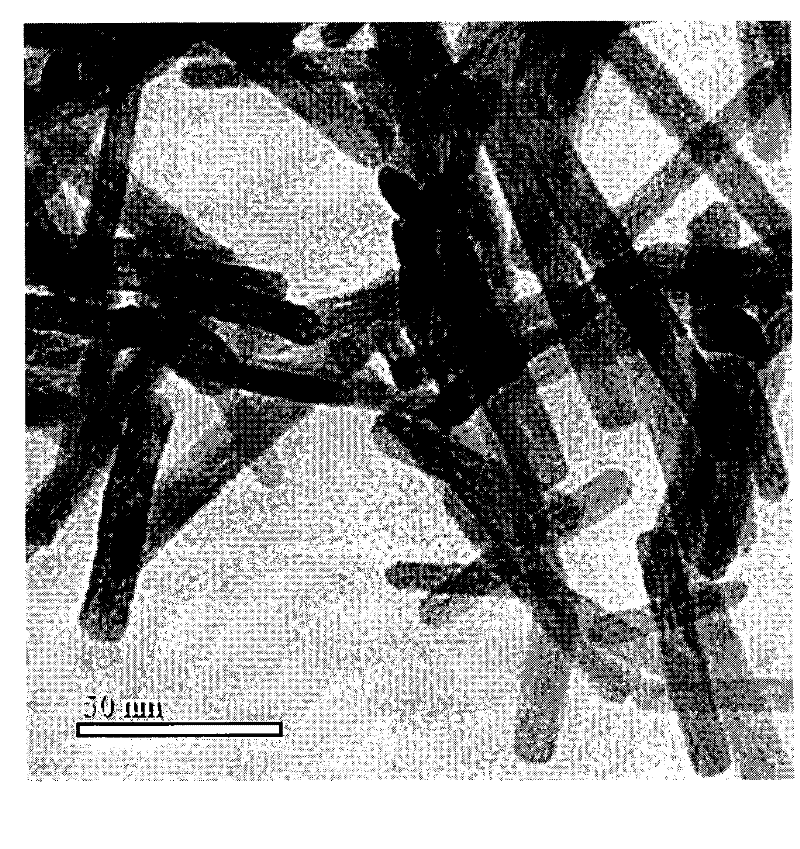

Preparation method of platinum modified titanium dioxide nanowire filter membrane

ActiveCN109908857AIncreased dispersionUniform depositionOther chemical processesDispersed particle separationHigh concentrationNanowire

The invention relates to a preparation method of a platinum modified titanium dioxide nanowire filter membrane. The preparation method comprises the following steps: firstly, uniformly mixing and stirring a titanium precursor, a polymer surfactant, organic acid and an organic solvent; then dissolving a mixture into a high concentration alkaline solution for hydrothermal reaction, enabling a reaction product to carry out ion exchange reaction in an acid solution to prepare a titanium-containing nanowire material; secondly, adding the titanium precursor, a hole trapping agent and water into thetitanium-containing nanowire material obtained in the first step for photodeposition; then filtering and washing to obtain the platinum modified titanium dioxide nanowire filter membrane. According tothe preparation method disclosed by the invention, raw materials are simple and easy to obtain; by taking the titanium precursor as a raw material and modifying the titanium dioxide nanowire throughphotodeposition, the technical process is simple; the obtained platinum modified titanium dioxide nanowire filter membrane has higher photocatalytic capacity and also has significant thermocatalytic effect at room temperature.

Owner:WUHAN UNIV OF TECH

Method of preparing cerium oxide nano-rod

ActiveCN101407330BLarge specific surface areaHigh catalytic activityRare earth metal compoundsCeriumLiquid phase

The invention relates to a method for preparing a cerium oxide nanometer rod at a mild condition, which belongs to the preparation technical field of inorganic nanometer materials, and comprises the main steps as follows: (1) the preparation of a cerium salt liquor: cerium salt is dissolved in an appropriate amount of deionized water and prepared into the 0.1-0.8mol / l cerium salt liquor; (2) the preparation of a concentrated alkali liquor: alkali is dissolved by using the appropriate amount of deionized water and prepared into the 10-15mol / l concentrated alkali liquor; and (3) the mixing of the two liquor for carrying out liquid phase reaction: the cerium salt liquor is quickly poured into the concentrated alkali liquor at the temperature of 10-40 DEG C; the volume ratio of the two used liquor is 1:3 to 1:7; after the reaction is finished, a white precipitate is generated, stayed in the liquor for ageing for 1 hour to 9 days, then washed and dried and finally the cerium oxide nanometer rod is obtained.

Owner:SHANGHAI UNIV

Heat-insulating and flame-retardant new energy battery box

ActiveCN113381112APrevent explosion hazardsReduce distractionsBattery isolationSecondary cellsGlass fiberFiber

The invention discloses a heat-insulating and flame-retardant new energy battery box which comprises a battery box body and a box body upper cover, the battery box body and the box body upper cover are connected through a buckle, and heat-insulating and flame-retardant layers are arranged on the inner surfaces of the battery box body and the box body upper cover; the heat-insulating and flame-retardant layer is formed by compounding polycarbonate, modified fibers and a flame retardant; the mass ratio of the polycarbonate to the modified fiber to the flame retardant is (50-80):(10-20):(0.2-2), wherein the modified fibers comprise modified glass fibers and chemical fibers. The invention discloses a novel heat-insulating and flame-retardant new energy battery box which can enable a new energy battery to be less interfered by external temperature during working and can also prevent the battery from explosion and other dangers in the using process to a great extent.

Owner:佛山日克耐热材料有限公司

A kind of potassium-doped gamma manganese dioxide catalyst and its preparation method and application

ActiveCN109201044BImprove thermal stabilityImprove performanceGas treatmentDispersed particle separationPtru catalystLattice oxygen

The invention provides a K<+>-doped gamma-MnO2 catalyst and a preparation method and use thereof. A main body structure of the catalyst is gamma-MnO2, and pore passages of the gamma-MnO2 are doped with K<+>. The gamma-MnO2 has a [2*1] pore passage structure, and the thermal stability is higher compared with ion implantation of alpha-MnO2 and lambda-MnO2 in crystal pore passages. Through doping theK<+>, Mn-O bonds of the gamma-MnO2 can be reduced, meanwhile, surface flaw sites are increased, and then, the capacity for adsorbing active oxygen and presenting crystal lattice oxygen is enhanced, so that the K<+>-doped gamma-MnO2 catalyst has relatively high catalytic oxidation activity to VOCs and has a good application prospect.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

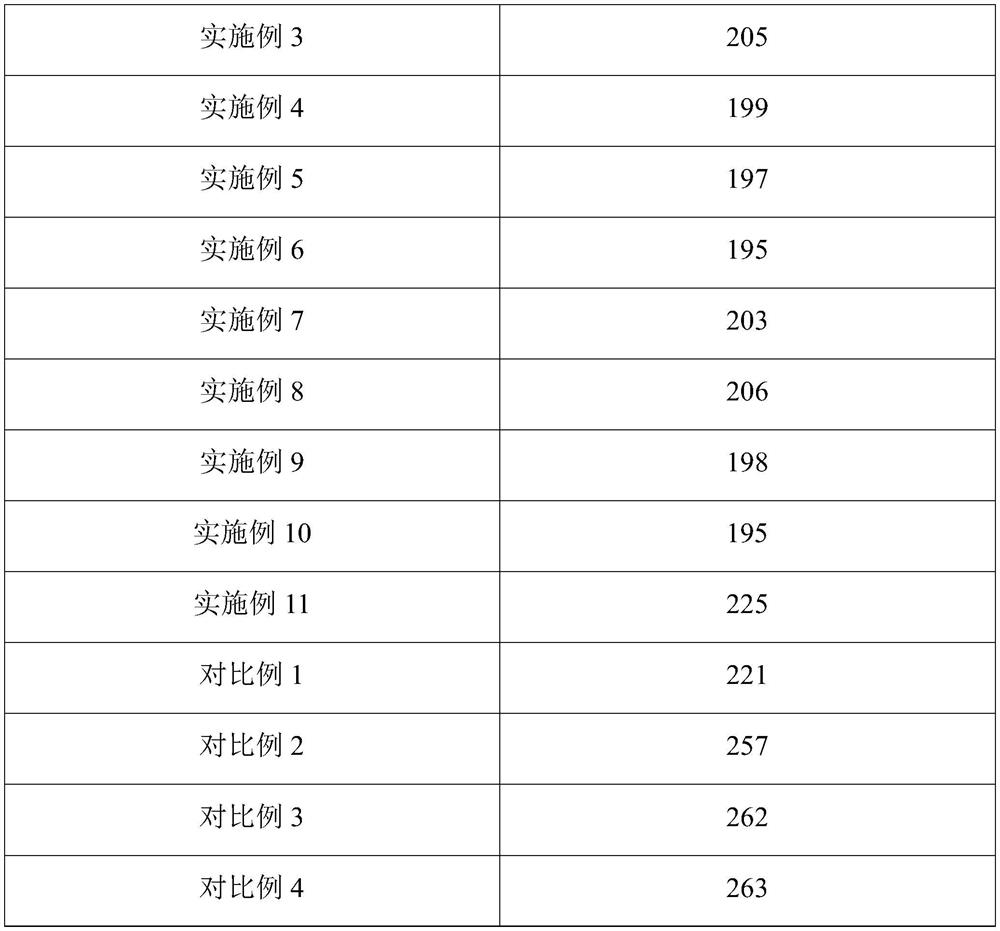

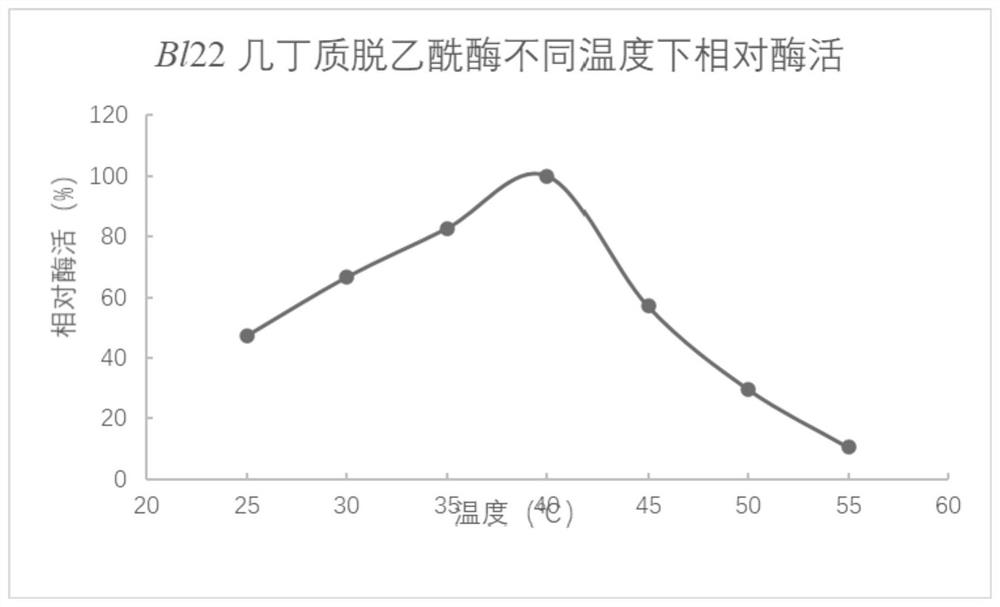

Bacillus licheniformis Bl22 for high-yield production of chitin deacetylase, and related products and application thereof

ActiveCN112458022AThe cultivation method is simpleLower catalytic temperatureBacteriaHydrolasesBiotechnologyBacillus licheniformis

The invention relates to the field of microorganisms, and more specifically, relates to bacillus licheniformis Bl22 for high-yield production of chitin deacetylase, and related products and application thereof. The preservation number of the bacillus licheniformis is CGMCC No. 20490. The bacillus licheniformis Bl22 has the advantages that the provided bacillus licheniformis Bl22 culture method issimple, and a common carbon source and a nitrogen source can be used for rapid culture and fermentation to produce the chitin deacetylase with high yield. The optimum catalytic temperature of the produced chitin deacetylase is relatively low, is about 40 DEG C, and shows high catalytic activity in a wide pH range (pH value of 6-10); the cost of energy, auxiliary materials and the like can be savedin industrial application, and the application prospect is wide.

Owner:JILIN COFCO BIOCHEM +3

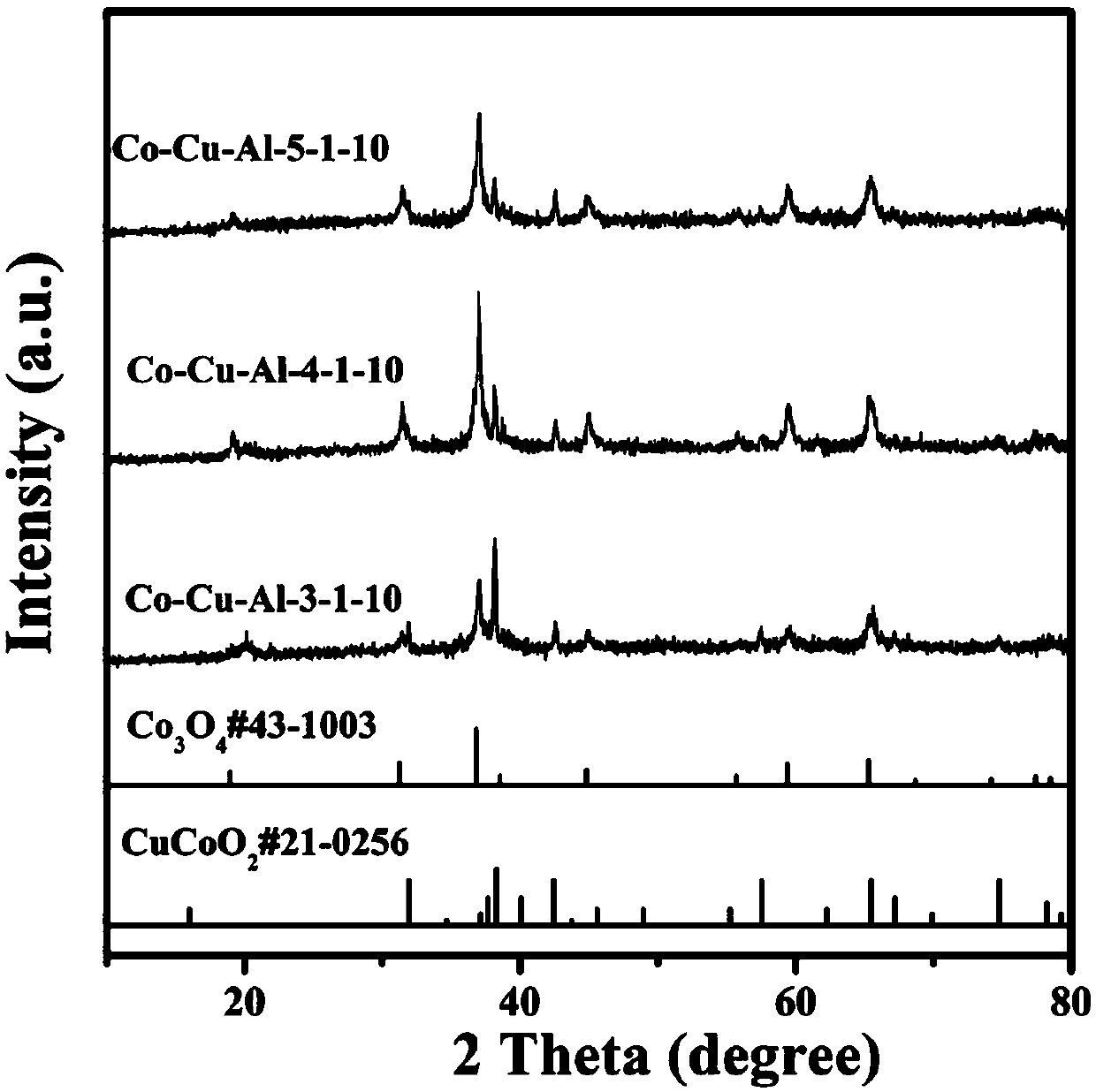

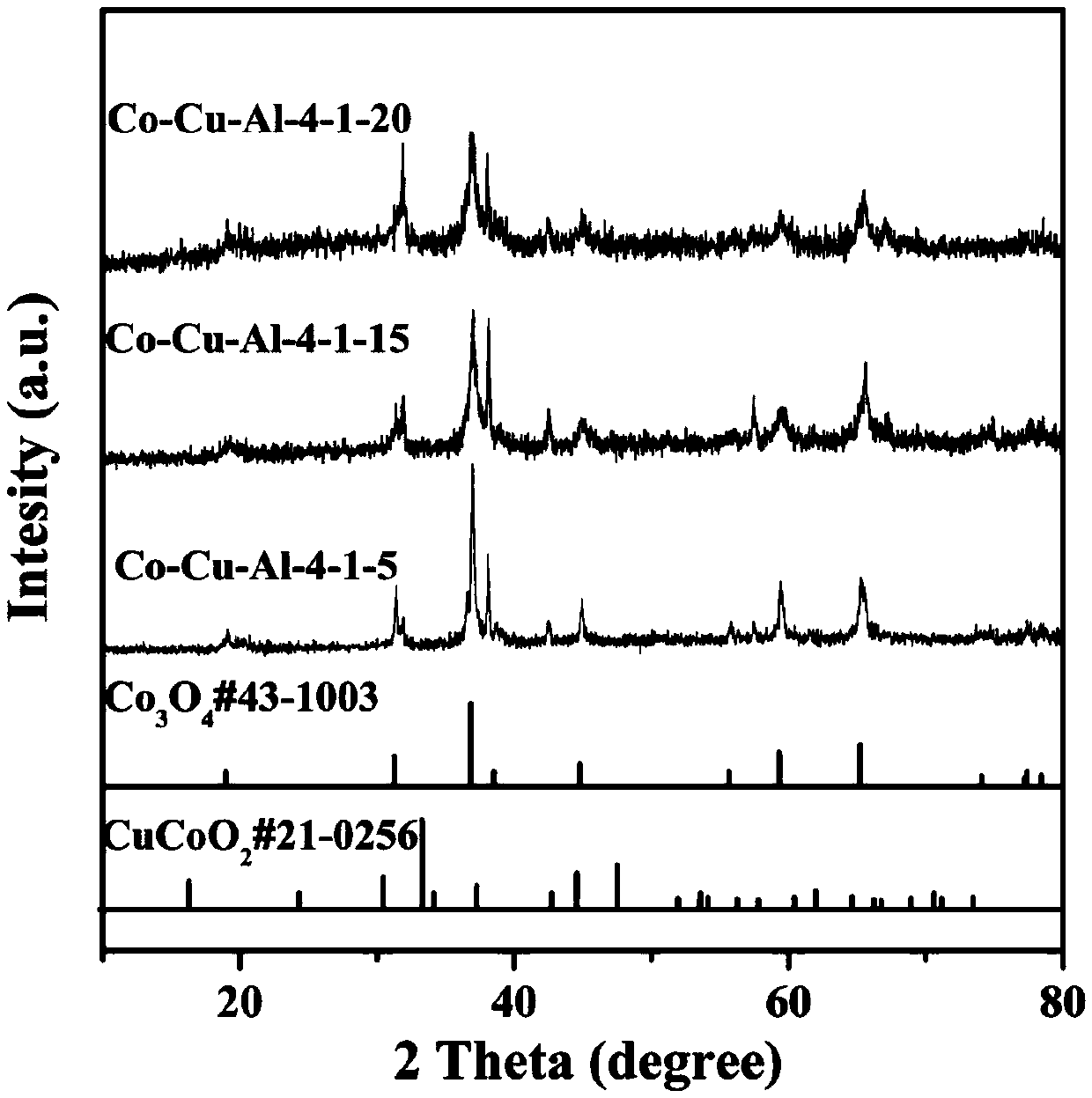

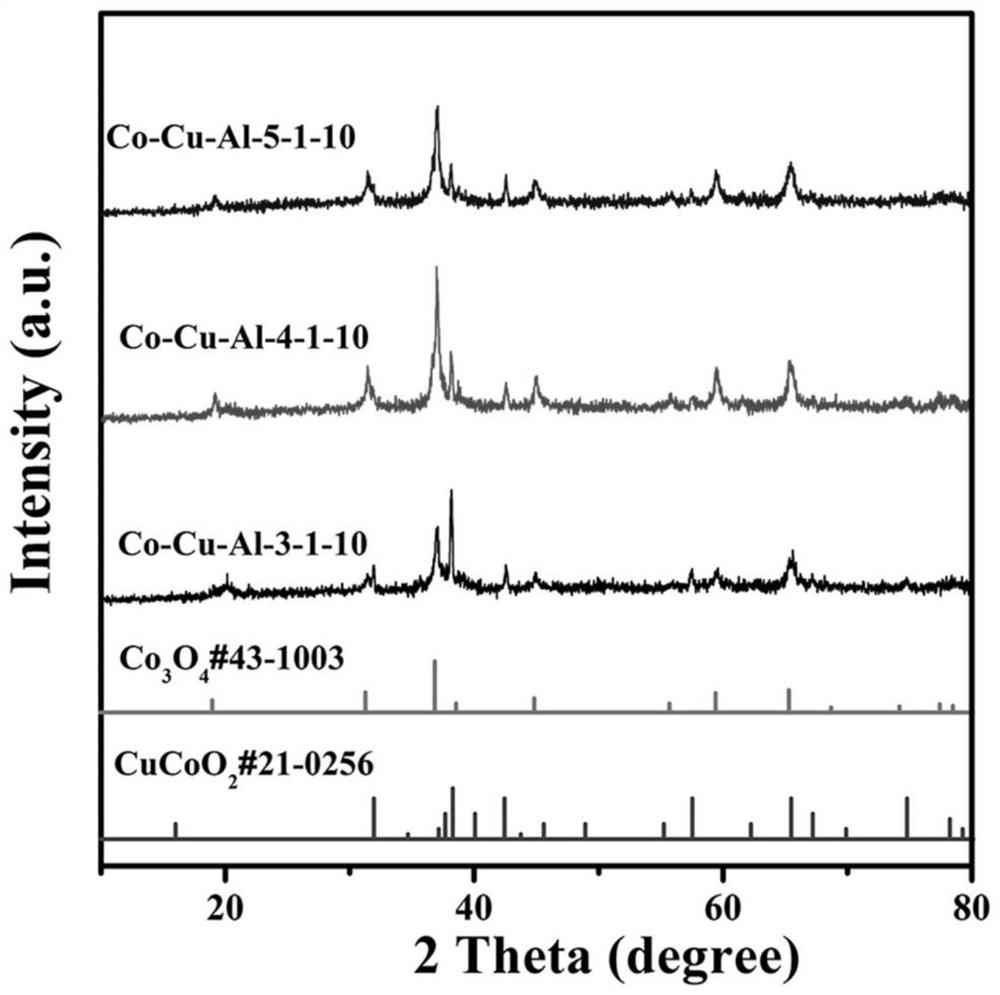

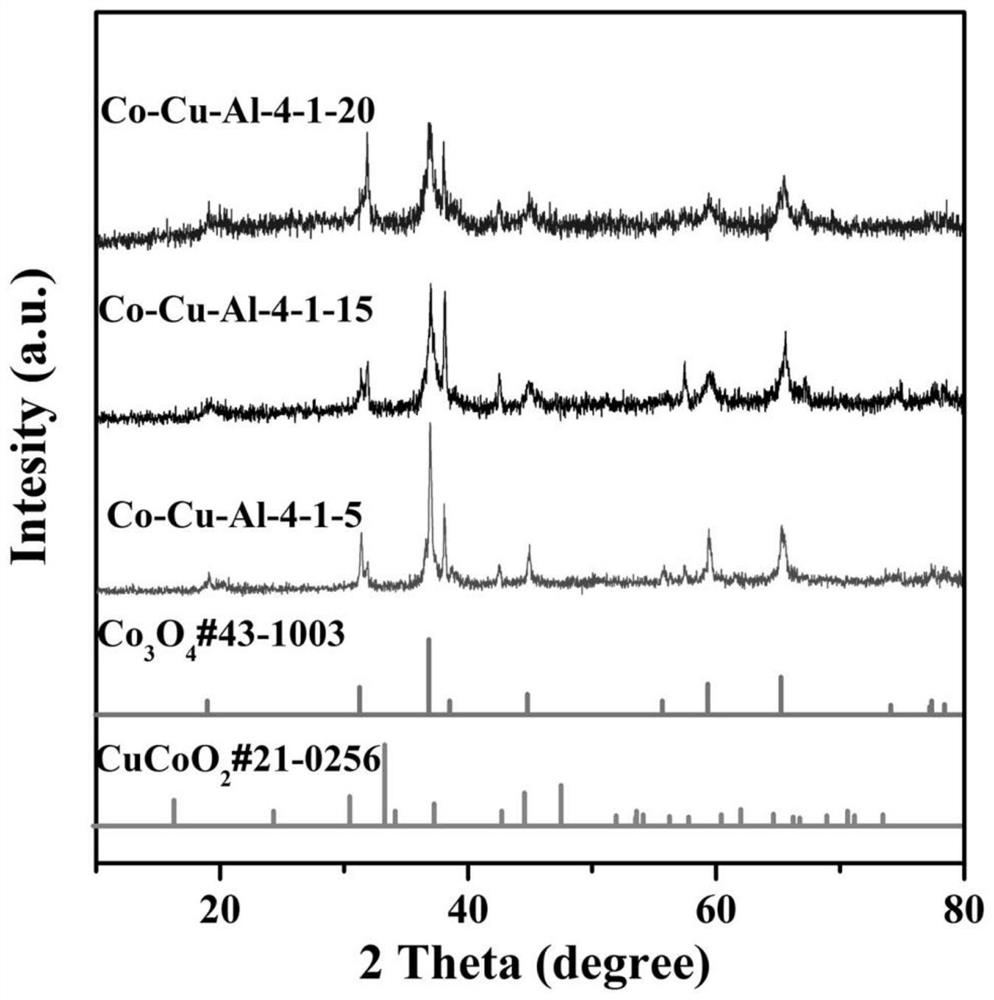

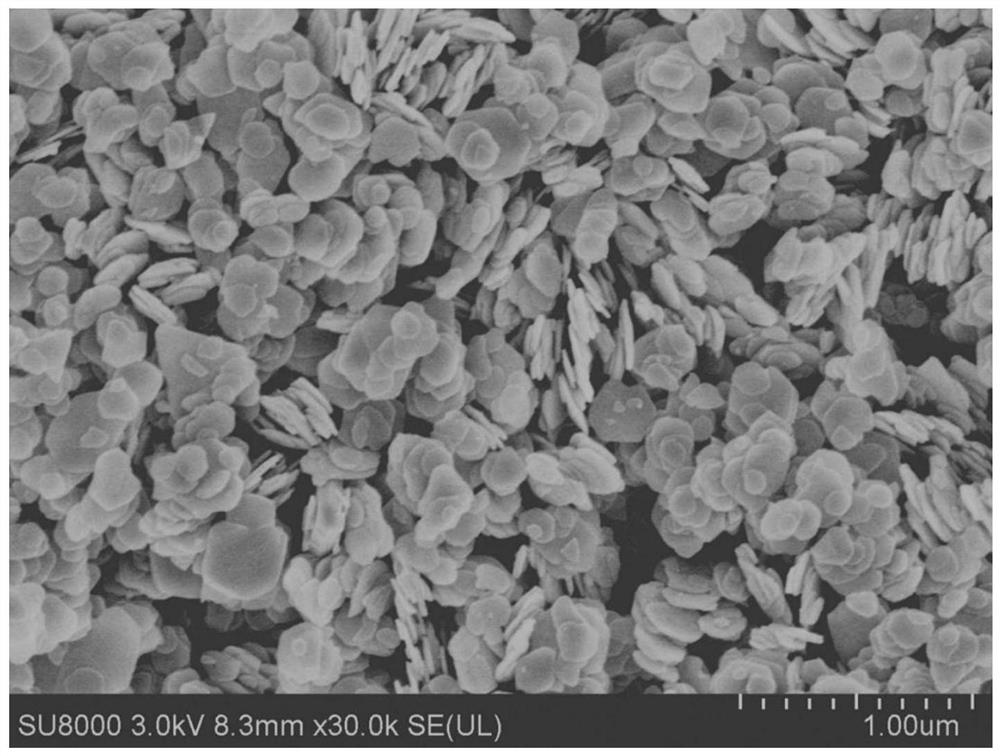

Preparation method of Co3O4-CuCoO2 nano-net material by using aluminum powder as sacrificial agent

ActiveCN110479274AEvenly distributedLower catalytic temperatureMaterial nanotechnologyCatalyst activation/preparationCopper nitratePotassium hydroxide

The invention discloses a preparation method of a Co3O4-CuCoO2 nano-net material by using aluminum powder as a sacrificial agent. The method comprises the following steps: subjecting copper nitrate, cobalt nitrate, potassium hydroxide and aluminum powder which are adopted as raw materials to a hydrothermal reaction at 200 DEG C for 20 hours, cooling the reaction solution to room temperature, thenperforming centrifugation and washing with water, and drying a product at 60 DGE C in vacuum to obtain the nano-net. The method has good universality and has guiding significance for synthesis of thetransition metal nano-net compound. The material has excellent carbon monoxide preferential oxidation performance, and has potential application value in the aspects of hydrogen purification, proton membrane fuel cells and the like. In addition, the material has excellent catalytic performance in electrocatalytic oxygen evolution reaction, and is expected to promote the progress of electrocatalytic hydrogen production.

Owner:JILIN UNIV

Catalytic type infrared heating ironing plate

The invention discloses an infrared heating ironing plate which comprises a plurality of sections of ironing plates; each section of ironing plate comprises a bottom plate and a plate rack frame body; a heating bin is arranged between the bottom plate and the plate rack frame body; the heating bin comprises a bin body defined by a bin body cover and a bin body bottom frame; the upper part of the bin body is provided with an air inlet pipe; the bin body cover is internally provided with a gas dispersion plate and an insulating plate which are arranged under the air inlet pipe; the insulating plate is connected with a preheating tube; an infrared catalytic plate is connected under the preheating tube and is used for enabling gas and air to have a full oxidation reaction; and a protective net which is arranged on the bin body bottom frame is arranged under the infrared catalytic plate. After the structure is adopted, an ironing bottom plate can be evenly heated within a short time; the catalytic infrared heating is a non-flame type reaction, the catalyzing temperature of the catalytic infrared heating is lower than the ignition point and is free from the hidden danger of explosion, and harmful gases such as CO, NO and the like are not produced, so that the infrared heating ironing plate is safe and free from pollution; the infrared heating ironing plate is safe and reliable in heating; and the heating requirement of the ironing plate of a paver can be met.

Owner:江苏华通动力重工有限公司(中外合资)

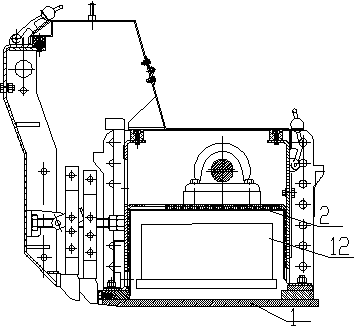

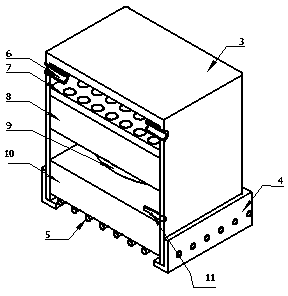

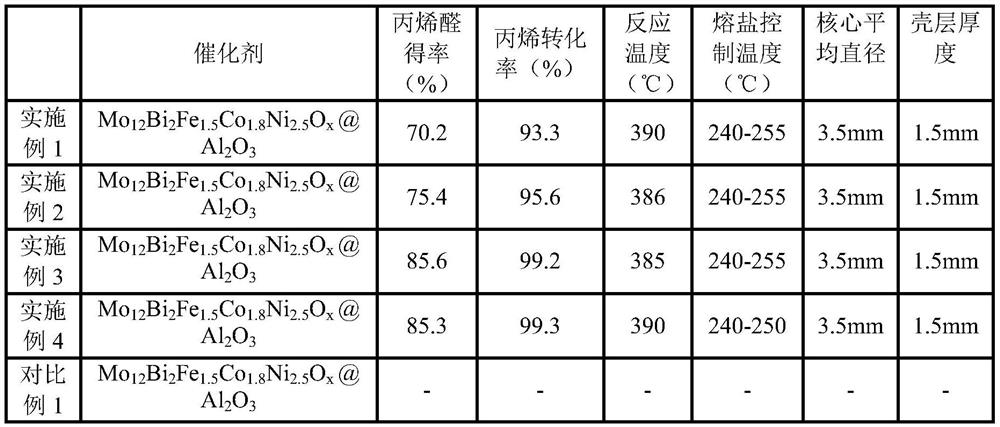

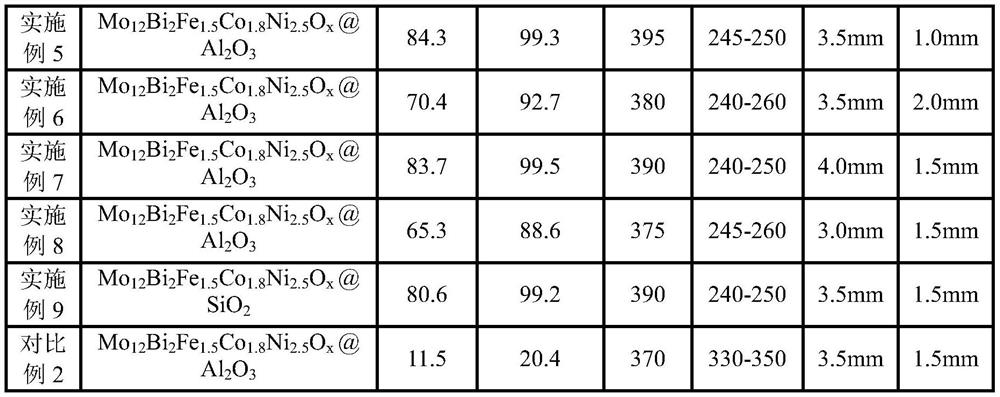

Composite catalyst for acraldehyde synthesis as well as preparation method and application thereof

ActiveCN112691680ALower catalytic temperatureHigh yieldOrganic compound preparationHeterogenous catalyst chemical elementsPtru catalystAcrolein

The invention discloses a composite catalyst for acraldehyde synthesis as well as a preparation method and application of the composite catalyst. The composite catalyst comprises an inner core composed of active components and a shell which covers the surface of the inner core and is made of an inert porous material. When the catalyst is applied to the process of synthesizing acraldehyde through propylene oxidation, the temperature runaway phenomenon can be effectively inhibited, side reactions are reduced, and the product yield is increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

A co that uses aluminum powder as a sacrificial agent 3 o 4 -cucoo 2 Preparation method of nano-net material

ActiveCN110479274BEvenly distributedLower catalytic temperatureMaterial nanotechnologyCatalyst activation/preparationCopper nitratePotassium hydroxide

The invention discloses a Co 3 o 4 -CuCoO 2 The preparation method of the nanometer mesh material firstly uses copper nitrate, cobalt nitrate, potassium hydroxide and aluminum powder as raw materials, then undergoes hydrothermal reaction at 200°C for 20 hours, and after cooling down to room temperature, centrifuges and washes with water. Vacuum drying at 60°C; Co 3 o 4 -CuCoO 2 nanomesh. The method has good universality and has guiding significance for the synthesis of transition metal nanonetwork compounds. The material has excellent carbon monoxide preferential oxidation performance, and has potential application value in hydrogen purification, proton membrane fuel cell and so on. In addition, the material has excellent catalytic performance in the electrocatalytic oxygen evolution reaction, which is expected to promote the process of electrocatalytic hydrogen production.

Owner:JILIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com