Loading-type copper-manganese catalyst and preparation method and application in CO low-temperature catalytic oxidation thereof

A catalyst, supported technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of system safety to be improved, high catalyst activity dependence, and high energy consumption of catalytic reaction, reaching The effect of improving low-temperature CO catalytic activity, simple preparation method, and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] Correspondingly, the present invention provides a preparation method of a supported copper-manganese catalyst, comprising the following steps: mixing cerium oxide with an impregnation solution containing copper salt and manganese salt to obtain a mixture; drying the mixture to obtain a catalyst A precursor: roasting the catalyst precursor to obtain a supported copper-manganese catalyst.

[0035] The method for preparing the supported copper-manganese catalyst in the invention is a mixed impregnation method, which is simple and easy to operate, and is suitable for industrial popularization and application.

Embodiment 1

[0049] The catalyst of this embodiment uses CeO 2 As the carrier, with CuO and MnO 2 Is the active component, the loading of the active component on the carrier is 14%, where CuO and MnO 2 The molar ratio is 1:1.

[0050] The concrete preparation method that this embodiment relates to catalyst is:

[0051] Step 1, according to the mass ratio of the active component and the carrier, take 122.6g of Ce(Ac) 2 ·nH 2 O was calcined at 550 °C for 6 h in a muffle furnace to prepare CeO 2 carrier;

[0052] Step 2, according to the mass ratio of the active component and the carrier, take 12.5g of Cu(Ac) 2 ·H 2 O and 15.3 g of Mn(Ac) 2 4H 2 O was pre-mixed and dissolved in 500mL deionized water, stirred in a constant temperature water bath at 45°C for 8 hours, and a mixed impregnating solution with a concentration of 0.25mol / L was prepared;

[0053] Step 3, the CeO prepared in step 1 2 The support is immersed in Cu(Ac) 2 ·H 2 O and Mn(Ac) 2 4H 2 In the mixed impregnation s...

Embodiment 2

[0062] The catalyst of this embodiment uses CeO 2 As the carrier, with CuO and MnO 2 Is the active component, the loading of the active component on the carrier is 14%, where CuO and MnO 2 The molar ratio is 1:5.

[0063]The concrete preparation method that this embodiment relates to catalyst is:

[0064] Step 1, according to the mass ratio of the active component and the carrier, get 127.3g of Ce(Ac) 2 ·nH 2 O was calcined at 550 °C for 6 h in a muffle furnace to prepare CeO 2 carrier;

[0065] Step 2, according to the mass ratio of the active component and the carrier, take 4.2g of Cu(Ac) 2 ·H 2 O and 25.5 g of Mn(Ac) 2 4H 2 O was pre-mixed and dissolved in 500mL deionized water, stirred in a constant temperature water bath at 45°C for 8 hours, and a mixed impregnating solution with a concentration of 0.25mol / L was prepared;

[0066] Step 3, the CeO prepared in step 1 2 The support is immersed in Cu(Ac) 2 ·H 2 O and Mn(Ac) 2 4H 2 In the mixed impregnation solu...

PUM

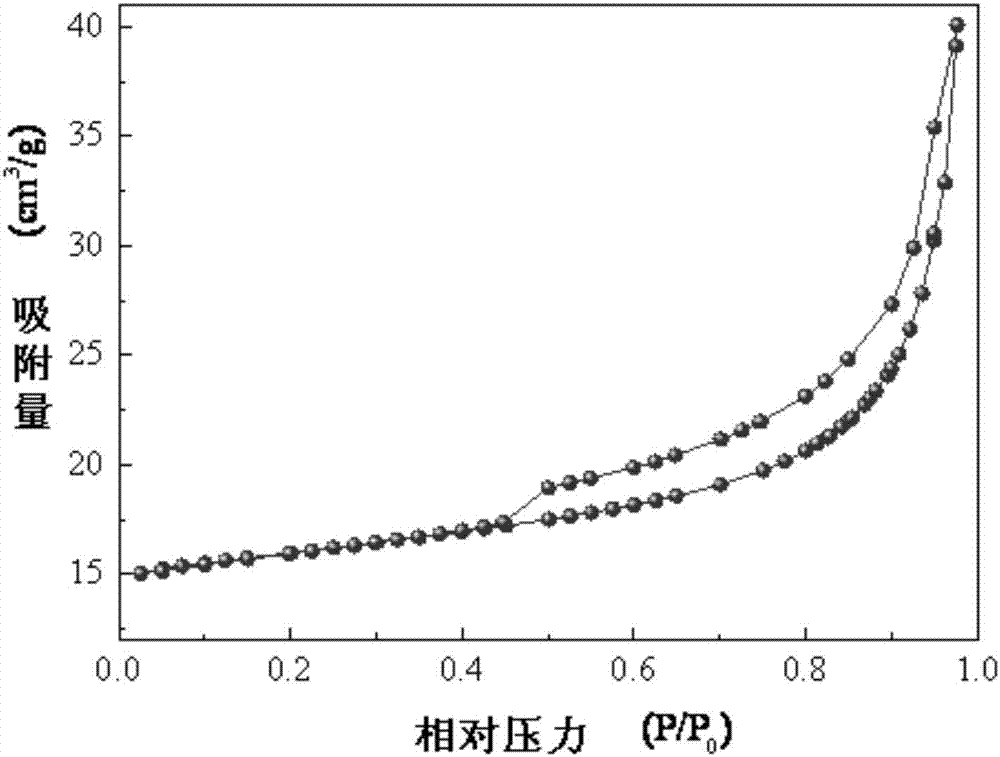

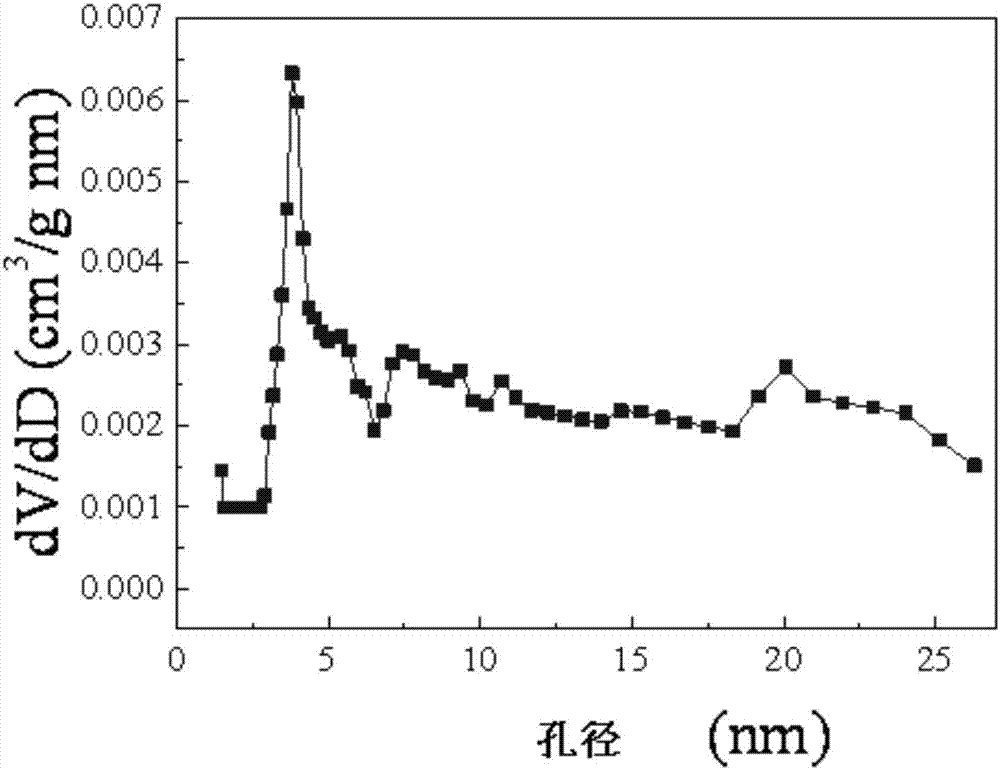

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com