Method of preparing cerium oxide nano-rod

A technology of nanorods and cerium oxide, applied in chemical instruments and methods, inorganic chemistry, rare earth metal compounds, etc., can solve the problems of reducing the performance of nanomaterials, poor particle size uniformity, easy agglomeration, etc., and achieve good catalyst activity and catalytic efficiency Improve the effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

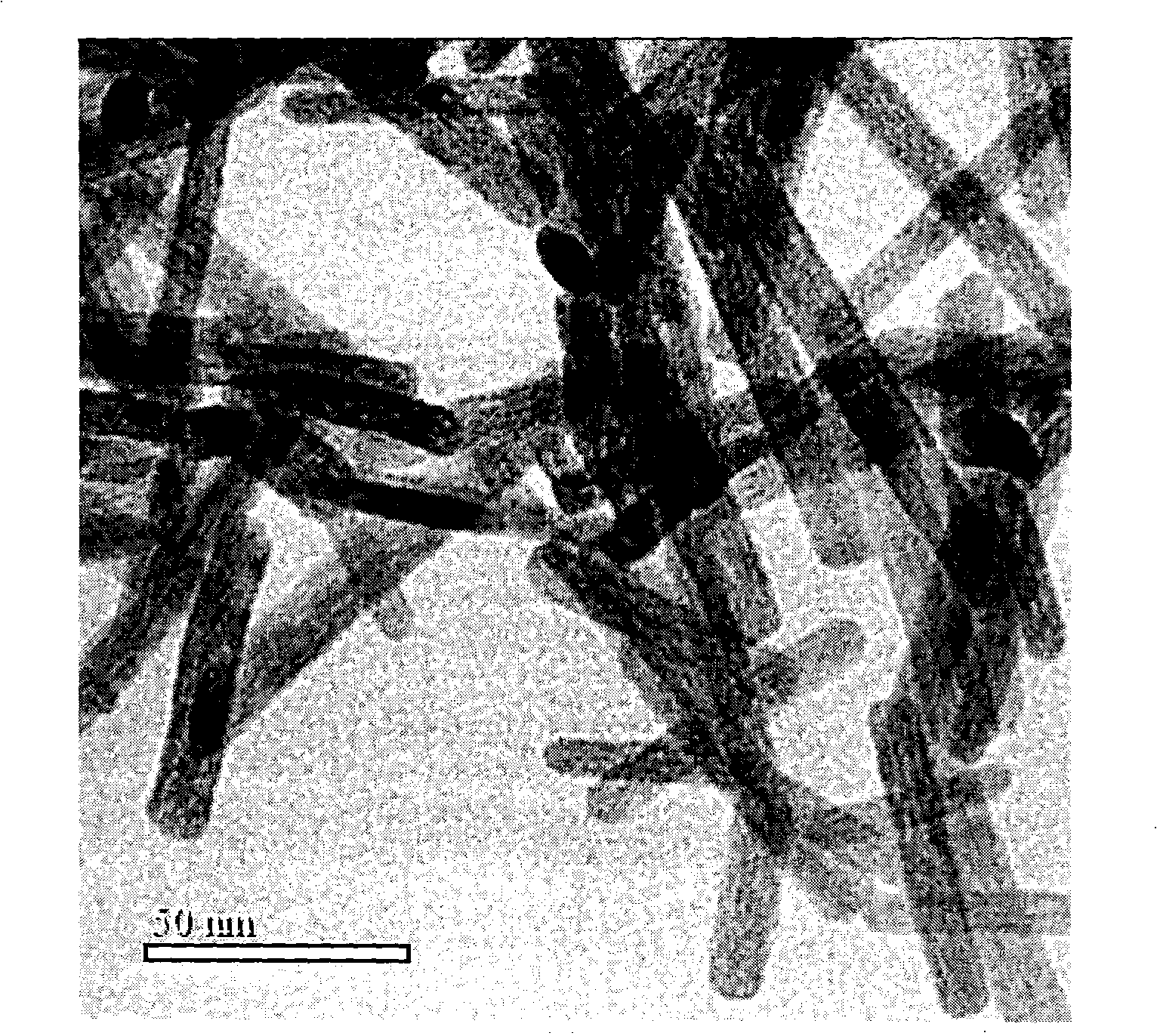

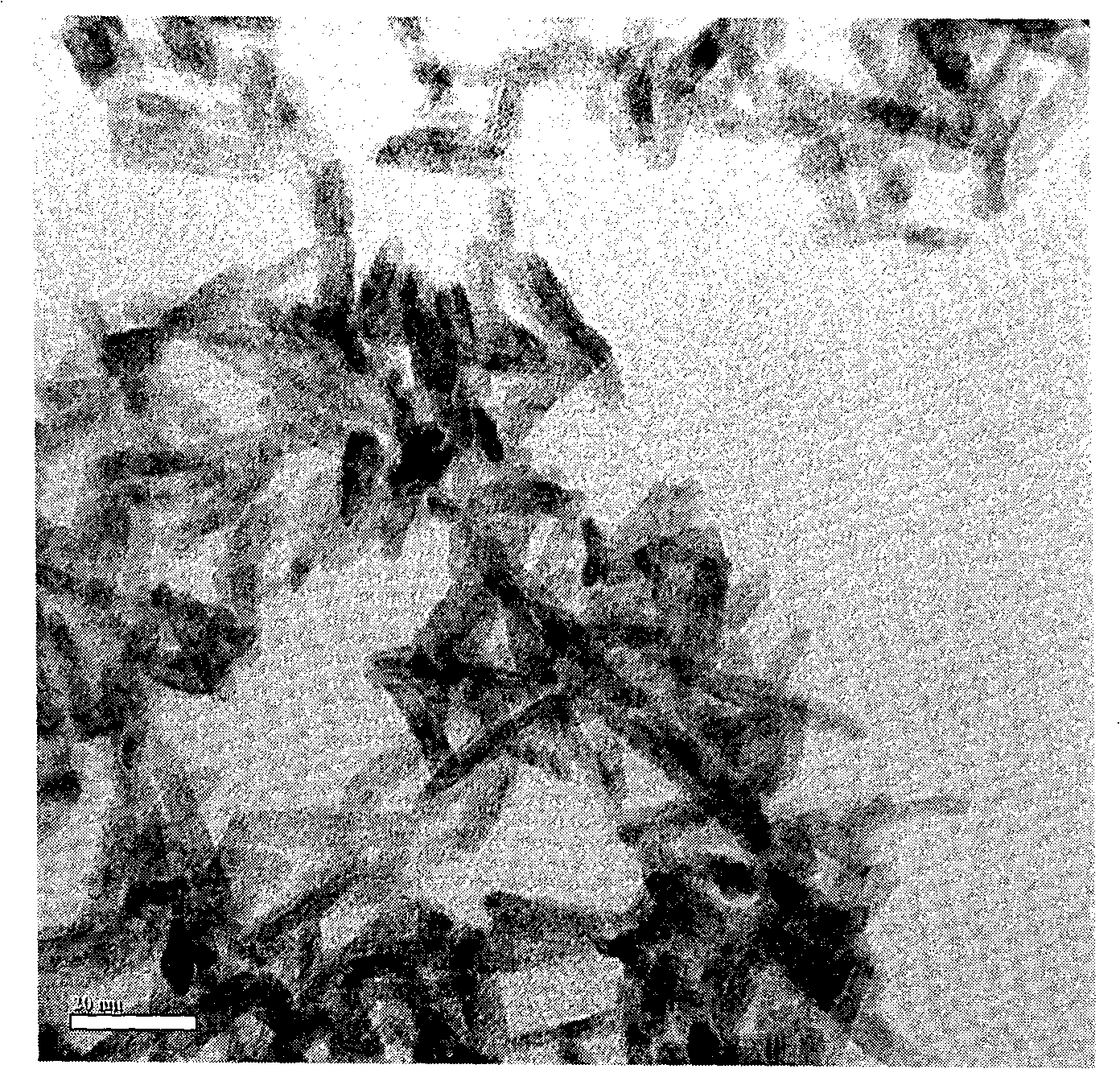

[0017] Embodiment one: with 8mmolCeCl 3 Dissolve in 10mL of water to prepare CeCl with a concentration of 0.8mol / L 3 Solution, at 40°C, pour the above solution into 30ml of 10mol / L KOH solution, the precipitate is white, aged for 9 days, the precipitate turns from white to purple, washed, dried, the precipitate turns yellow, and the yield is about 90% . (The diameter is 10-25nm, and the length is 50-100nm).

Embodiment 2

[0018] Embodiment two: with 0.5mmol Ce (NO 3 ) 3 Dissolved in 5mL of water, prepared to a concentration of 0.1mol / L Ce(NO 3 ) 3 Solution, at 10°C, pour the above solution into 35ml 15mol / L NaOH solution, the precipitate is white, aged for 2h, the precipitate turns from white to purple, washed, dried, the precipitate turns yellow, and the yield is about 90%. (5-10nm in diameter, 20-50nm long).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com