Exhaust Purifier for Internal Combustion Engine

a technology of exhaust gas purifier and internal combustion engine, which is applied in the direction of exhaust treatment electric control, electrical control, separation process, etc., can solve the problems of increasing the temperature of the exhaust gas purifying catalyst, increasing the burning of reducing agents, etc., and lowering the temperature of the exhaust gas and the catalyst. , the effect of lowering the injection amoun

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

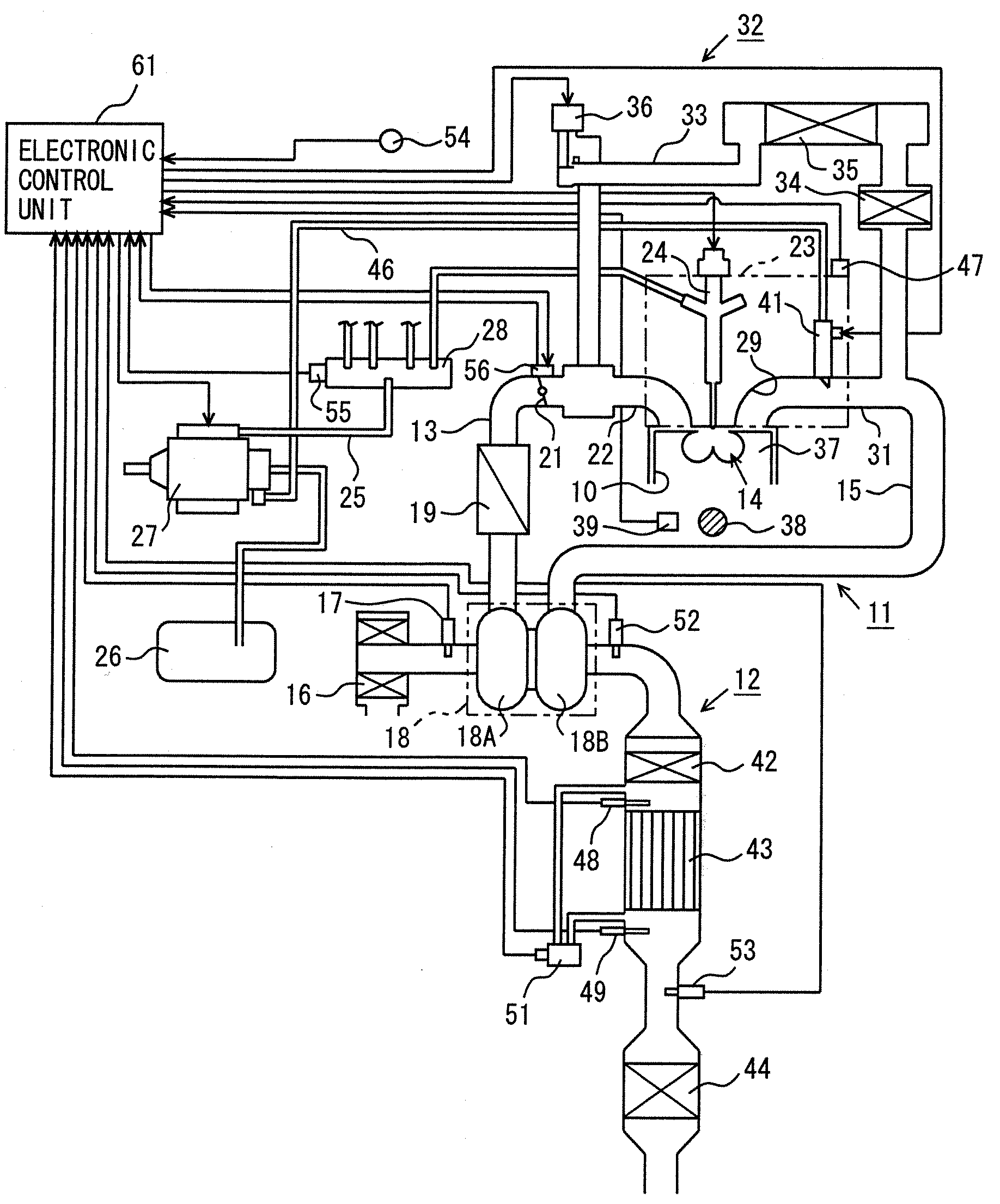

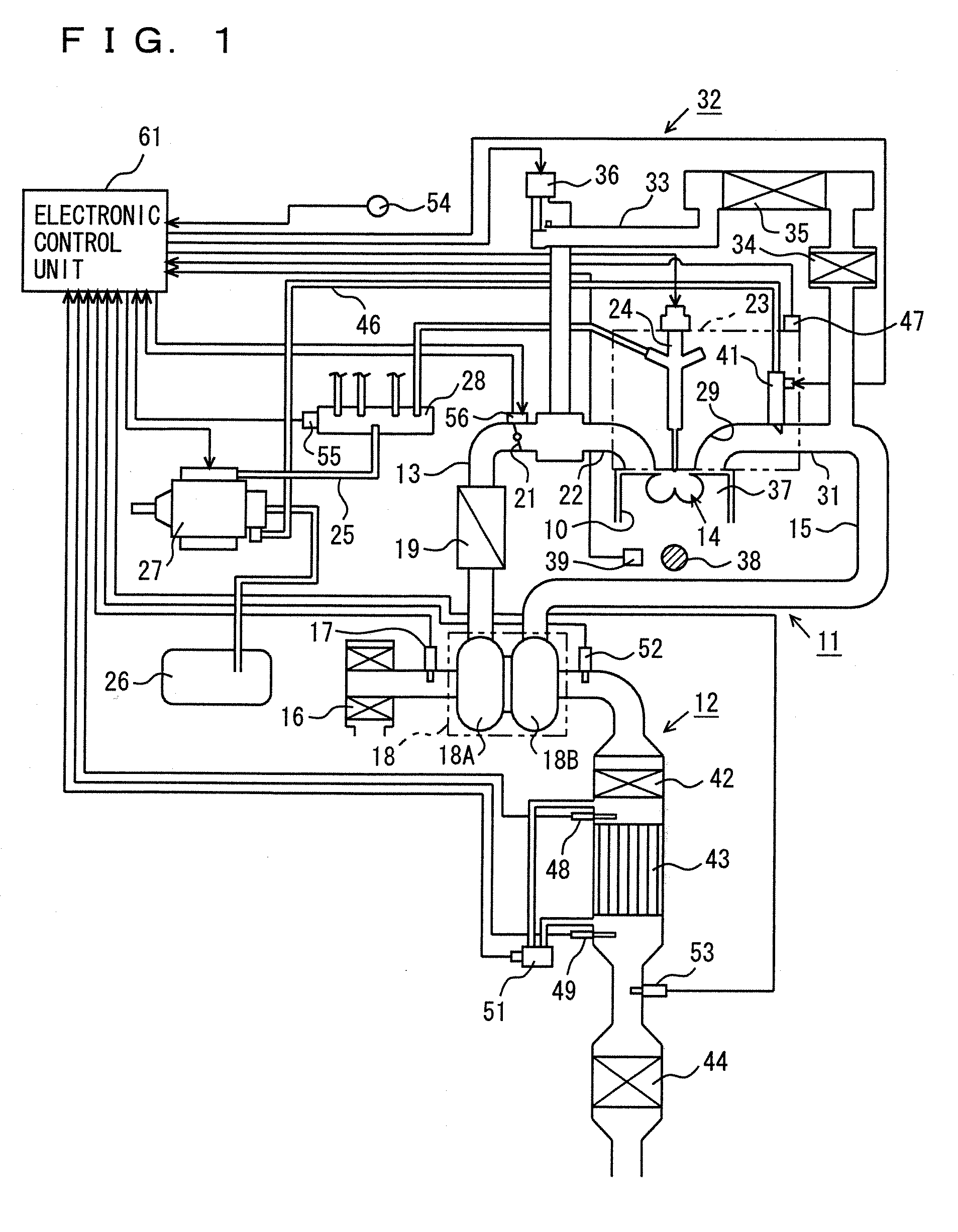

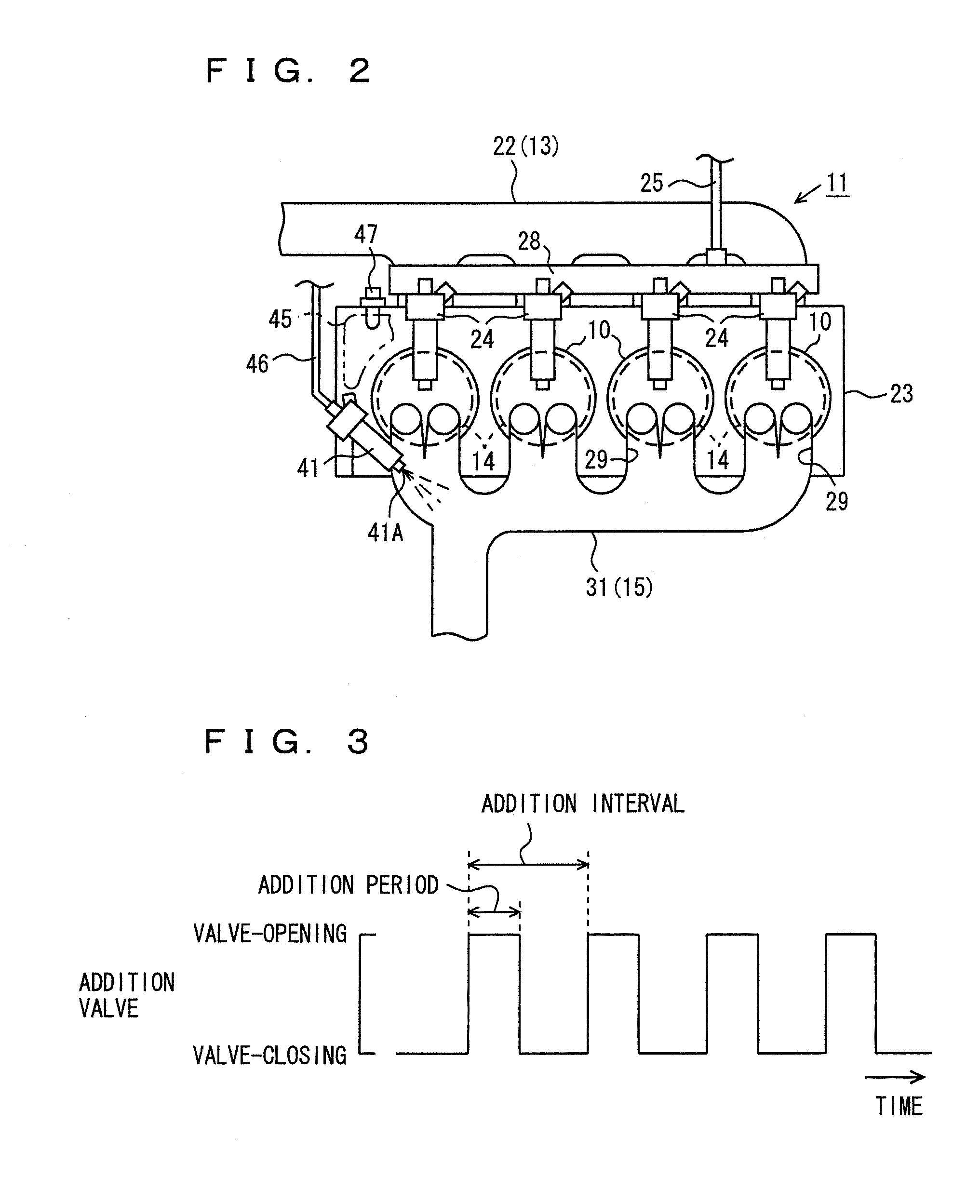

[0033]A first embodiment implementing the present invention will be described hereinafter with reference to FIGS. 1 to 5. FIG. 1 shows a configuration of a multi-cylinder diesel engine (hereinafter, simply referred to as an engine) 11 serving as an internal combustion engine to which the present embodiment is applied and an exhaust gas purifying apparatus 12. FIG. 2 shows a schematic plan view of engine 11.

[0034]Engine 11 generally includes an intake pipe 13, a combustion chamber 14 for each cylinder 10, and an exhaust pipe 15. An air cleaner 16 purifying air taken in intake pipe 13 is provided in a most upstream portion of intake pipe 13. In engine 11, an airflow meter 17 for detecting a flow rate of air in intake pipe 13, a compressor 18A of a turbo charger 18, an intercooler 19, and an intake air throttle valve 21 are sequentially arranged toward the intake air downstream side of air cleaner 16. Intake pipe 13 is branched at an intake manifold 22 provided on the intake air downst...

second embodiment

[0083]A second embodiment implementing the present invention will now be described with reference to FIGS. 6 to 8. The second embodiment is different from the first embodiment in that the target injection amount is decreased, instead of restricting the same, for control such that the catalyst bed temperature does not exceed the upper limit of the allowable range with the increase in the addition amount of the reducing agent. As the configuration of engine 11 and exhaust gas purifying apparatus 12 is the same as in the first embodiment, description thereof will not be repeated.

[0084]FIG. 6 is a flowchart showing a specific procedure for injection amount decrease processing. Electronic control unit 61 executes a series of processing shown in the flowchart as processing to be performed every prescribed time.

[0085]In the injection amount decrease processing, initially in step 310, electronic control unit 61 reads engine coolant temperature THW detected by coolant temperature sensor 47 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| bed temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com