Potassium-doped gamma-manganese dioxide catalyst and preparation method and use thereof

A technology of catalyst and manganese source, which is applied in the field of resources and environment, can solve the problem of no manganese dioxide catalytic activity improvement modification, etc., and achieve the effect of increasing surface defect sites, low preparation cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] a K + doped γ-MnO 2 The preparation method of catalyst specifically comprises the following steps:

[0050] (1) Mn(NO 3 ) 2 Soluble in water, formulated as Mn 2+ The manganese solution with a concentration of 0.2mol / L is added to Mn(NO 3 ) 2 Add NH dropwise to the solution 4 HCO 3 solution, the mixture was filtered, washed and dried, and then calcined at 400°C for 4 hours in the air to obtain γ-MnO 2 ;

[0051] Among them, the NH 4 HCO 3 and Mn in manganese solution 2+ The molar ratio is 8:1;

[0052] (2) To KNO 3 γ-MnO was added to the solution 2 , after standing, washing and drying, calcined in air atmosphere at 400℃ for 4h to obtain K + doped γ-MnO 2 catalyst;

[0053] Among them, the KNO 3 and γ-MnO 2 The molar ratio is 0.5:10.

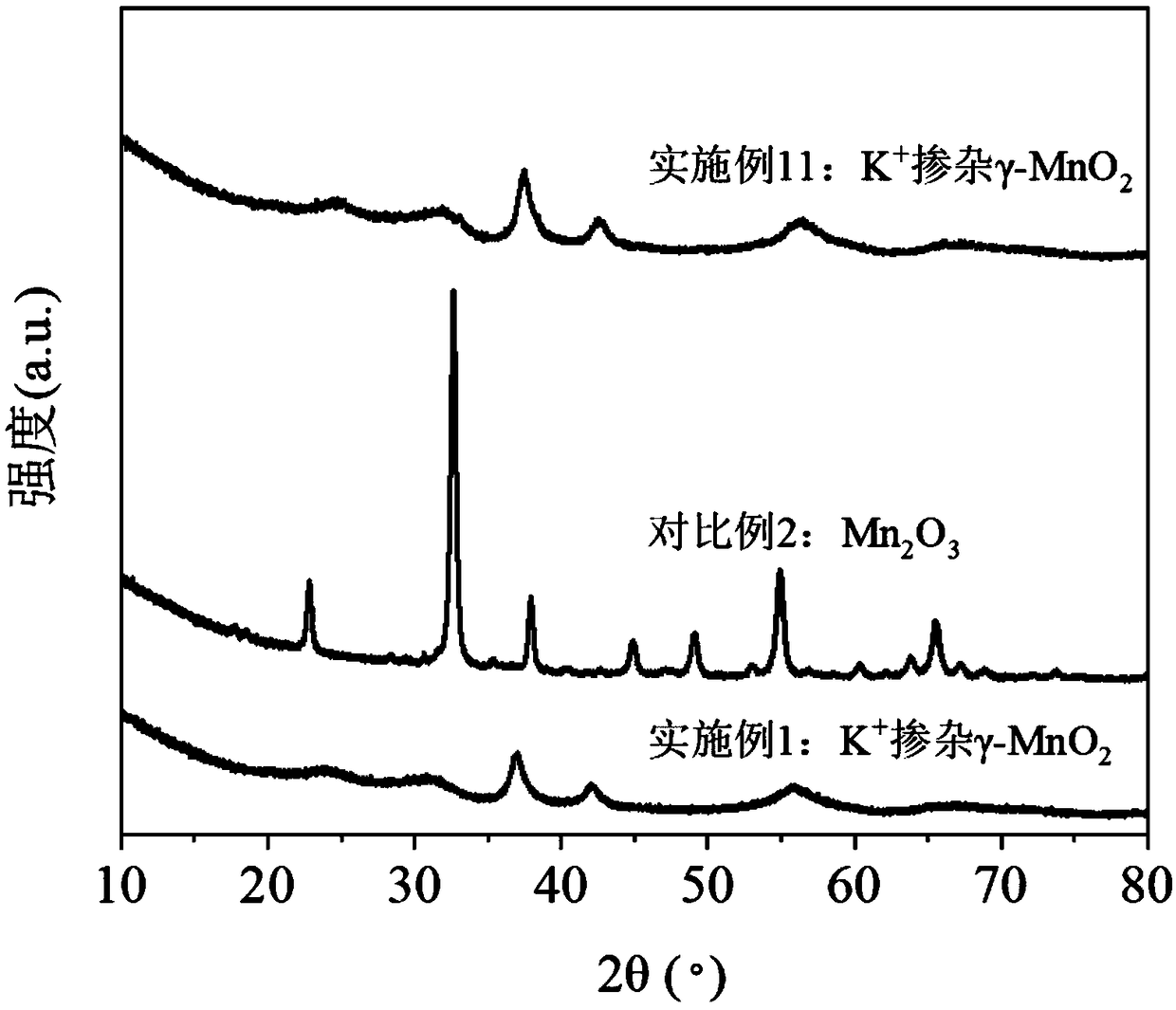

[0054] The K prepared in this example + doped γ-MnO 2 The XRD spectrum of the catalyst is as figure 1 shown.

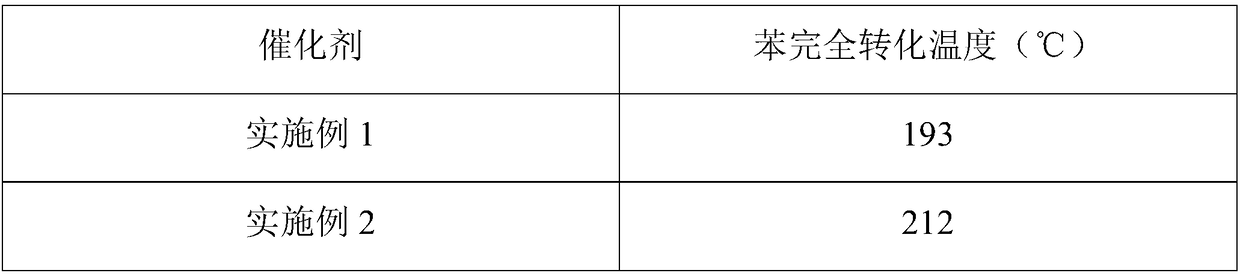

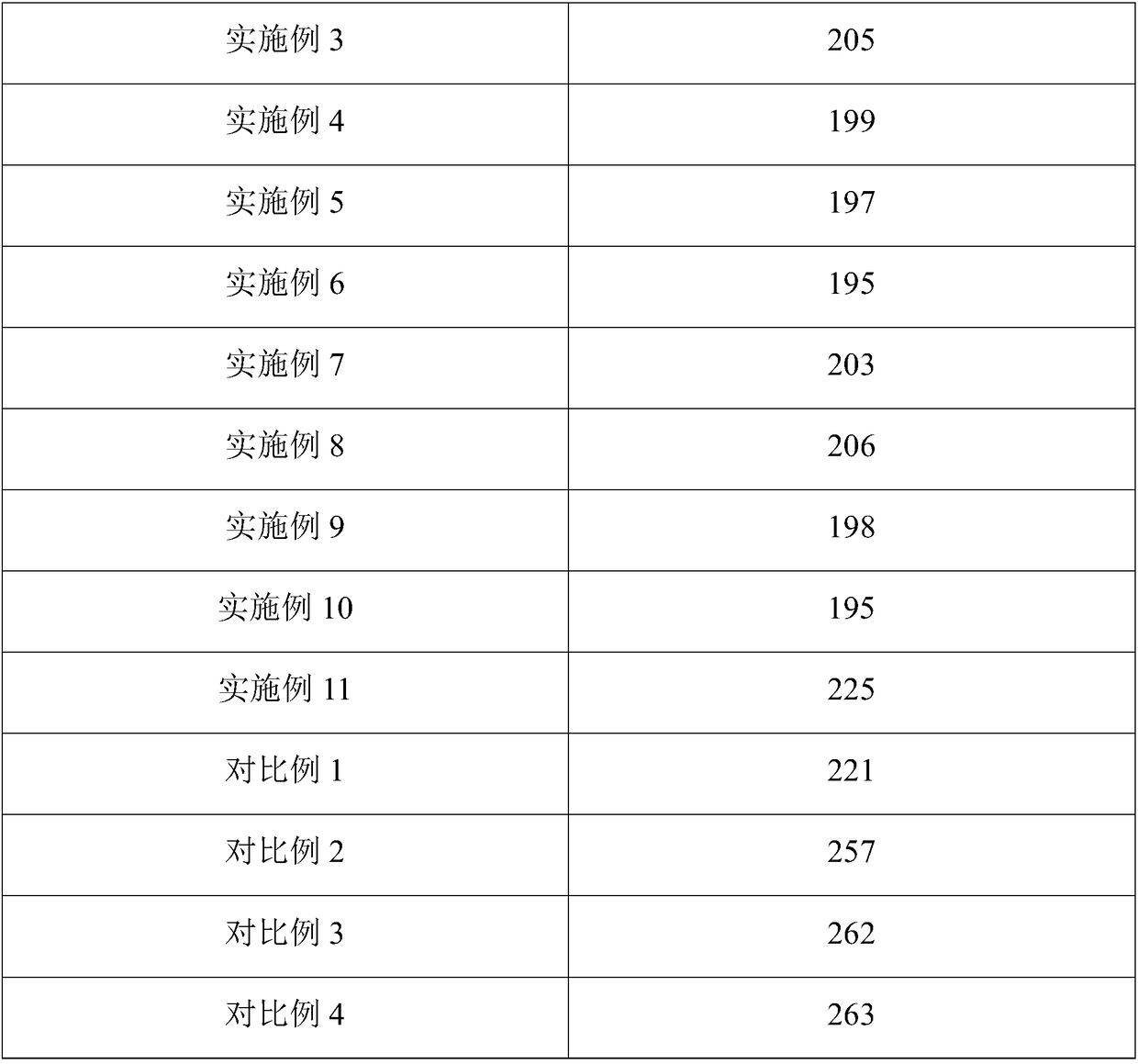

[0055] For the K prepared in this example + doped γ-MnO 2 The performance of the catalyst was evaluated...

Embodiment 2

[0057] a K + doped γ-MnO 2 Catalyst preparation method, except KNO 3 and γ-MnO 2 Except that mol ratio is 0.1:10, all the other are identical with embodiment 1.

[0058] For the K prepared in this example + doped γ-MnO 2 The performance of the catalyst was evaluated, and the results obtained are shown in Table 1.

Embodiment 3

[0060] a K + doped γ-MnO 2 Catalyst preparation method, except KNO 3 and γ-MnO 2 Except that mol ratio is 0.25:10, all the other are identical with embodiment 1.

[0061] For the K prepared in this example + doped γ-MnO 2 The performance of the catalyst was evaluated, and the results obtained are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com