Low-temperature sulfur-resistant vanadium-titanium denitration catalyst and preparing method

A catalyst and catalyst carrier technology, applied in the direction of catalyst carriers, chemical instruments and methods, heterogeneous catalyst chemical elements, etc., can solve the problems of shortening the service life of catalysts, accelerating catalyst deactivation, etc., and achieve short preparation time and reduce Toxic effect, effect of improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

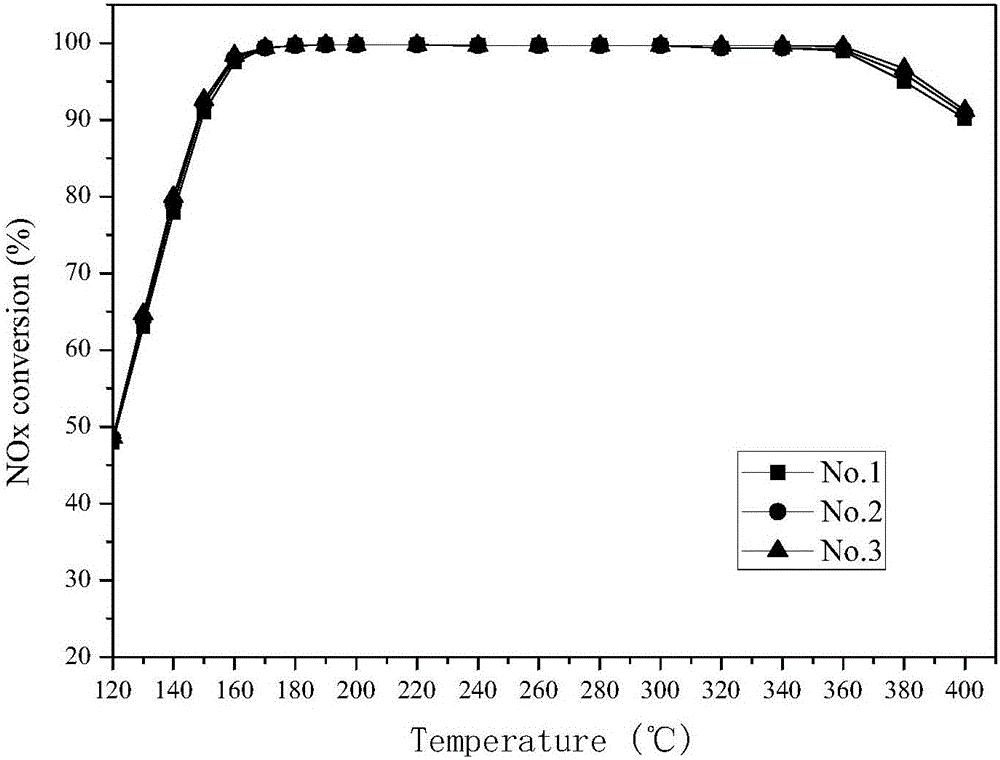

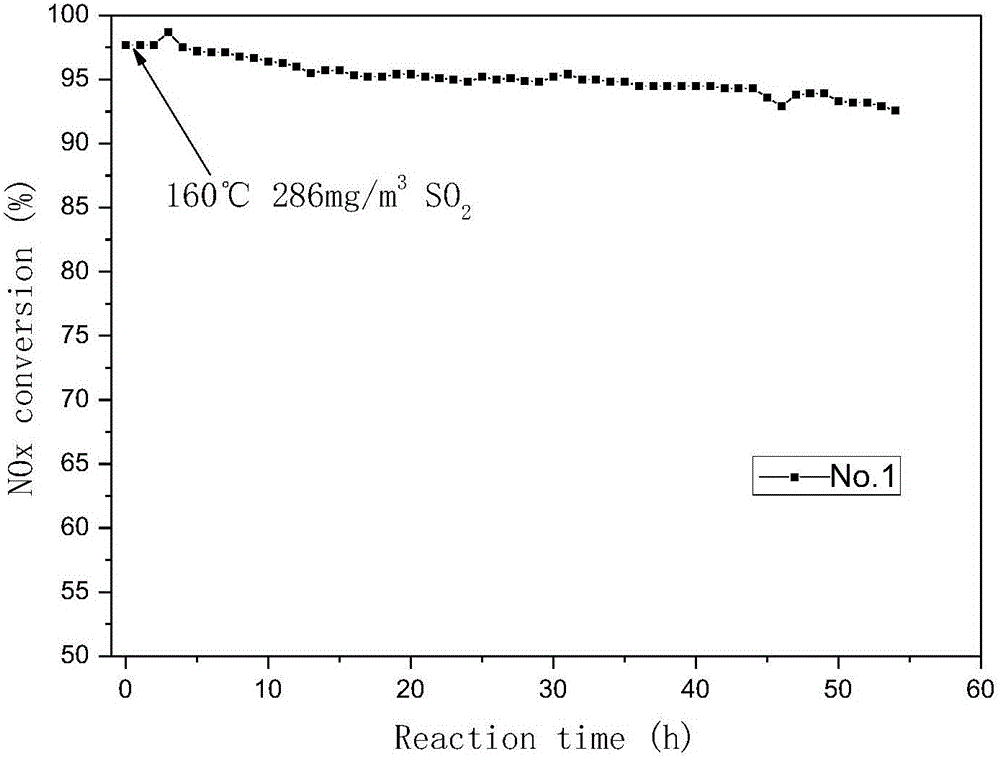

example 1

[0026] Dissolve 3g of oxalic acid and 1g of ammonium metavanadate in 40g of deionized water, and dissolve them all at 40°C; add 1.5g of ammonium tungstate and 0.1g of ruthenium trichloride to the resulting solution in turn, and continue to dissolve at 40°C Conditions to make it all dissolved; finally 20gTiO 2 Slowly add the carrier to the above solution, and make it viscous at 40°C; put the obtained viscous solid in an oven for drying, then put it in a muffle furnace, and make it viscous at 250°C Calcined for 2 hours, then calcined at 450°C for 5 hours, cooled naturally to room temperature, sieved to 20-120 mesh for later use, and obtained 1# catalyst.

example 2

[0028] Dissolve 6g of oxalic acid and 2g of ammonium metavanadate in 80g of deionized water, and dissolve them all at 40°C; add 3g of ammonium tungstate and 0.2g of ruthenium trichloride to the resulting solution in turn, and continue to dissolve at 40°C Make it all dissolve under; Finally, 40gTiO 2 Slowly add the carrier to the above solution, and make it viscous at 40°C; put the obtained viscous solid in an oven for drying, then put it in a muffle furnace, and make it viscous at 250°C Calcined for 2 hours, then calcined at 450°C for 5 hours, cooled naturally to room temperature, sieved to 20-120 mesh for later use, and obtained 2# catalyst.

example 3

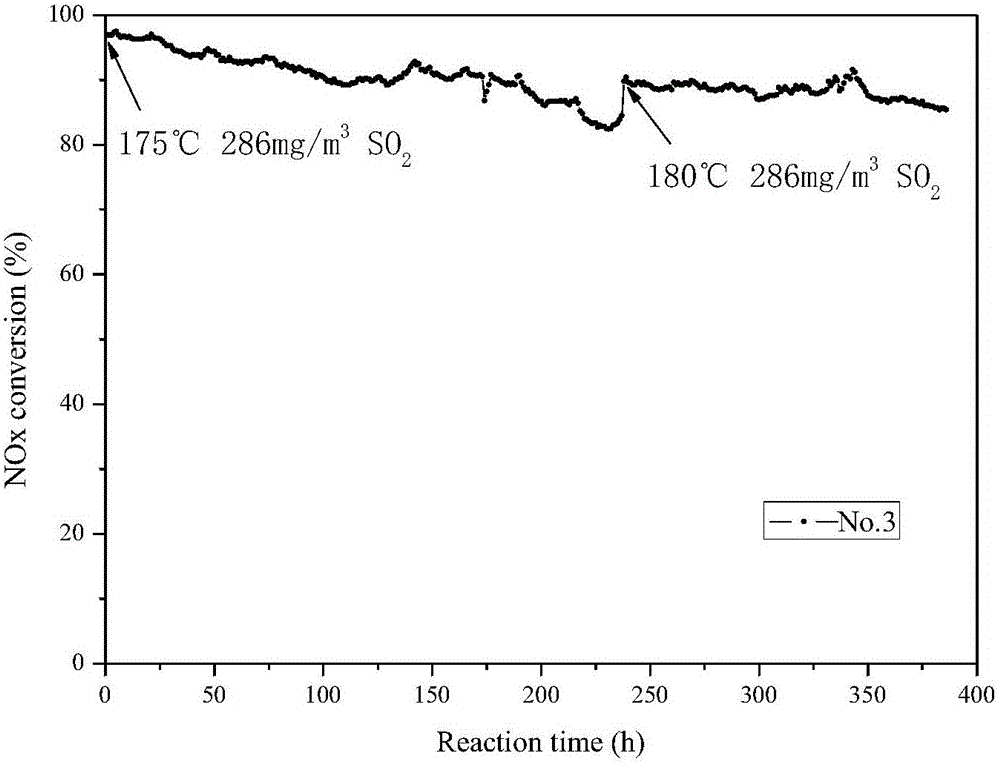

[0030] Dissolve 6g of oxalic acid and 2g of ammonium metavanadate in 80g of deionized water, and dissolve them all at 40°C; add 3g of ammonium tungstate and 0.25g of ruthenium trichloride to the resulting solution in turn, and continue to dissolve at 40°C Make it all dissolve under; Finally, 40gTiO 2 Slowly add the carrier to the above solution, and make it viscous at 40°C; put the obtained viscous solid in an oven for drying, then put it in a muffle furnace, and make it viscous at 250°C Calcined for 2 hours, then calcined at 450°C for 5 hours, cooled naturally to room temperature, sieved to 20-120 mesh for later use, and obtained 3# catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com