Preparation method of platinum modified titanium dioxide nanowire filter membrane

A titanium dioxide and nanowire technology is applied in the field of preparation of platinum-modified titanium dioxide nanowire filter membranes to achieve the effects of improving catalytic activity, saving experimental steps and costs, improving toughness and catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A preparation method of platinum modified titanium dioxide nanowire filter membrane, which comprises the following steps:

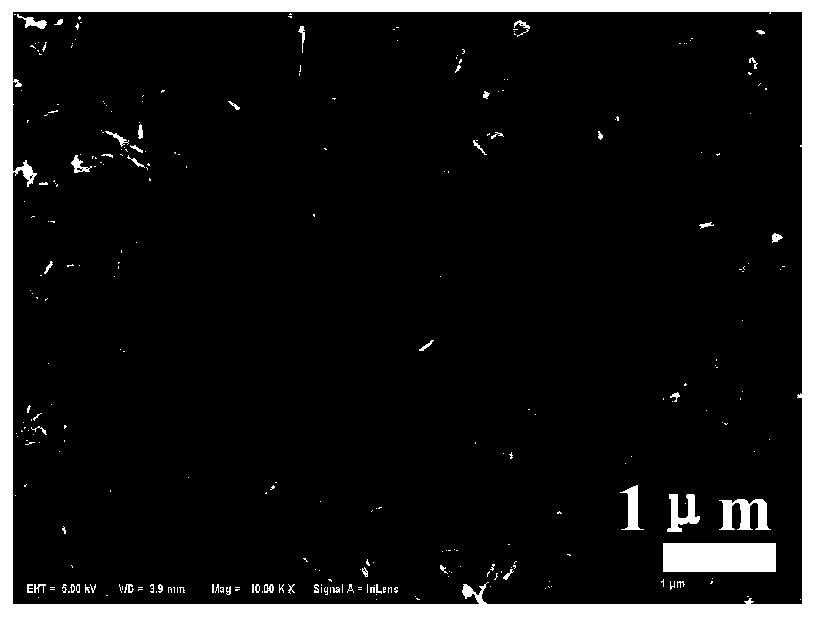

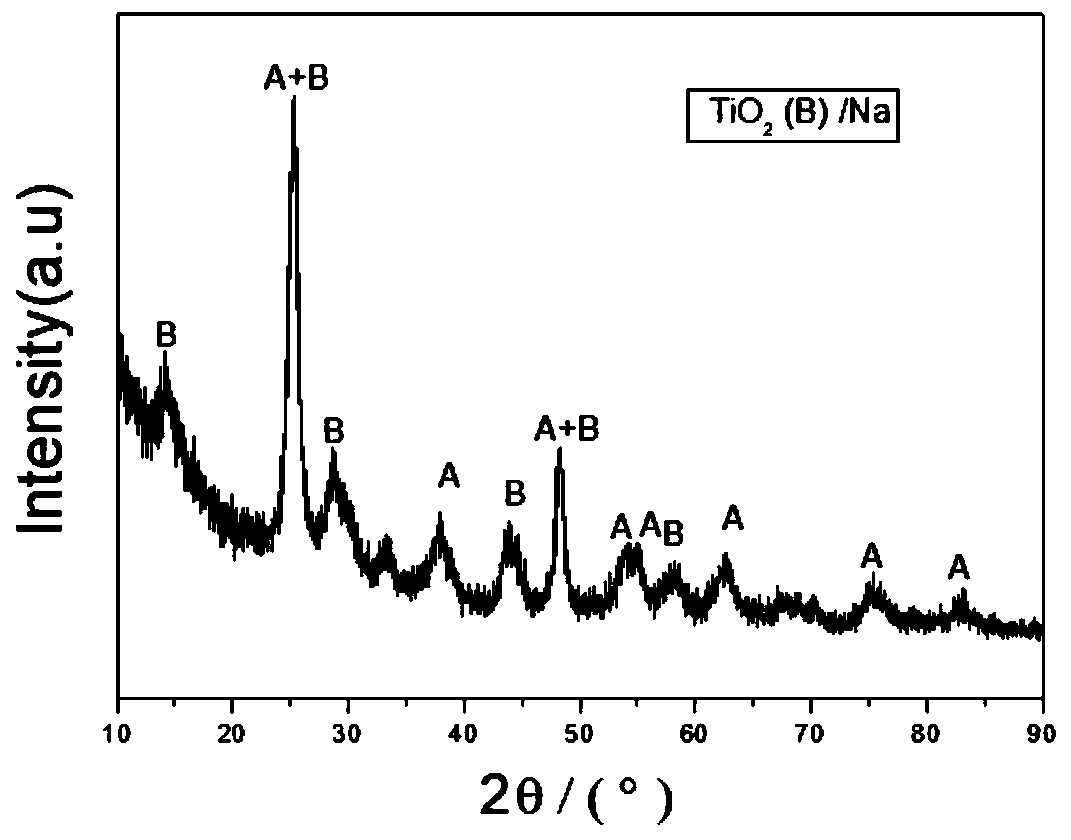

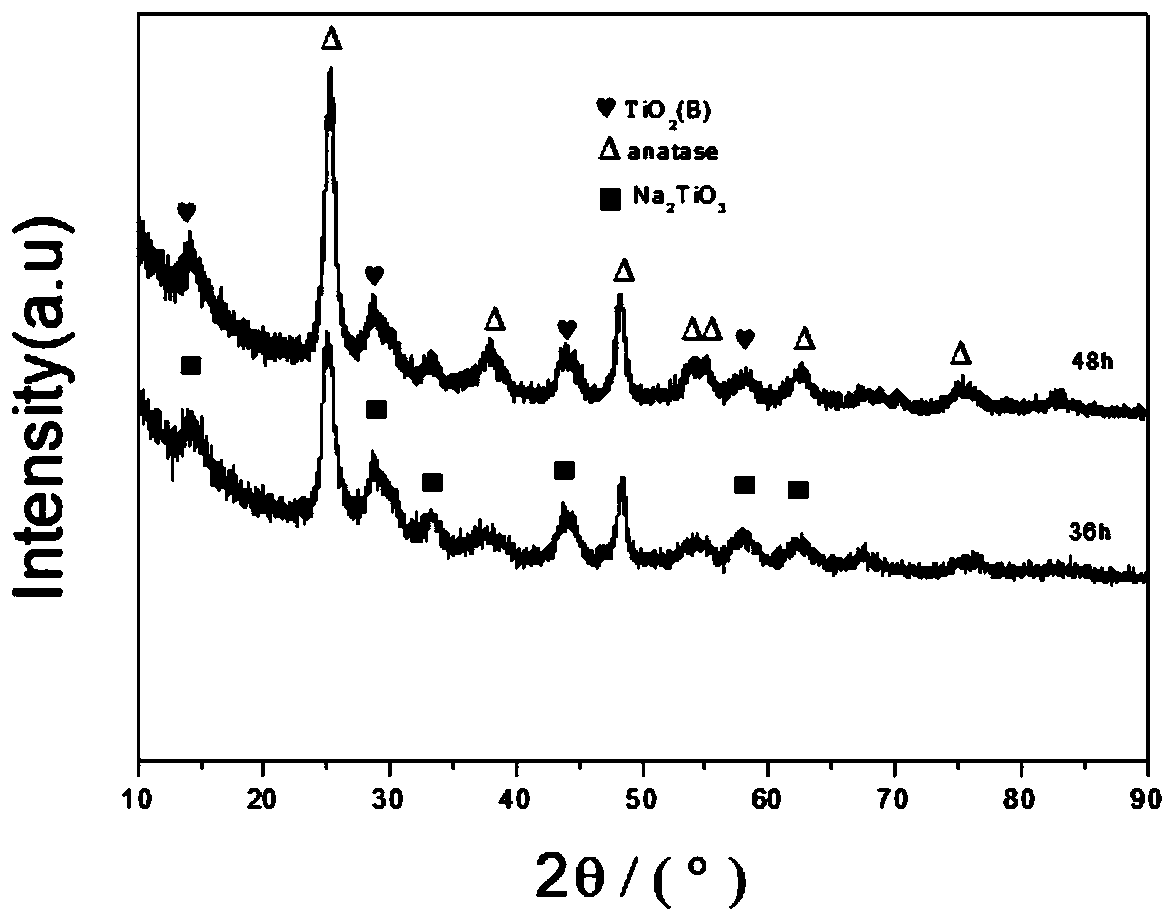

[0038] 1) Mix 2ml of tetrabutyl titanate, 0.3g of polyvinylpyrrolidone, 3.5ml of acetic acid, and 3.5ml of ethanol and stir them evenly, add them to 30ml of water dissolved in 10g of sodium hydroxide, put them into the reactor, and stir for 14h in an oil bath at 180°C. After the reaction is over, after the reactor is cooled to room temperature, the obtained hydrothermal solid product (about 0.835g) is filtered and washed with water until the pH is neutral, and then poured into 300ml, 0.1mol / L hydrochloric acid for ion exchange for 48h, and then Filter and wash to neutrality to obtain titanium-containing nanowire material;

[0039] Dissolve 1g of chloroplatinic acid hexahydrate in 100ml of deionized water, add 1ml of chloroplatinic acid aqueous solution to the above titanium-containing nanowire material (about 0.576g), then add 5ml of methanol, 100ml of ...

Embodiment 2

[0042] A preparation method of platinum modified titanium dioxide nanowire filter membrane, which comprises the following steps:

[0043] 1) Mix 2ml of tetrabutyl titanate, 0.3g of polyvinylpyrrolidone, 3.5ml of acetic acid, and 3.5ml of ethanol and mix them evenly, add them to 30ml of water dissolved in 10g of sodium hydroxide, put them into the reactor, and stir for 14h in an oil bath at 180°C. After the reaction is over, after the reactor is cooled to room temperature, the obtained hydrothermal solid product (about 0.835g) is filtered and washed with water until the pH is neutral, and then poured into 300ml, 0.1mol / L hydrochloric acid for ion exchange for 12h, and then Filter and wash to neutrality to obtain titanium-containing nanowire material;

[0044] 2) Dissolve 1g of chloroplatinic acid hexahydrate in 100ml of deionized water, add 1ml of chloroplatinic acid aqueous solution to the above titanium-containing nanowire material (about 0.576g), then add 5ml of methanol, 100ml o...

Embodiment 3

[0047] A method for preparing platinum modified titanium dioxide nanowire filter membrane, which comprises the following steps:

[0048] 1) Mix 0.65ml of titanium tetrachloride, 0.3g of polyvinylpyrrolidone, 3.5ml of acetic acid, and 3.5ml of ethanol and mix them evenly, add them to 30ml of water dissolved in 10g of sodium hydroxide, put them into the reactor, and stir for 14h in an oil bath at 180°C. After the reaction, after the reaction kettle is cooled to room temperature, the obtained hydrothermal solid product (about 0.835g) is filtered and washed with water until the pH is neutral, and then poured into 300ml, 0.1mol / L hydrochloric acid for ion exchange for 48h, and then Filter and wash to neutrality to obtain titanium-containing nanowire material;

[0049] 2) Dissolve 1g of chloroplatinic acid in 100ml of deionized water, add 1ml of chloroplatinic acid aqueous solution to the above titanium-containing nanowire material (about 0.576g), then add 5ml of methanol, 100ml of deion...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com