Small-grain ZSM-5 molecular sieve catalyst used for preparing ethylene from bioethanol and preparation method thereof

A technology of ZSM-5 and bioethanol, which is applied in molecular sieve catalysts, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve problems such as low conversion rate and selectivity, and short service life of ZSM-5 molecular sieves, and achieve Low catalytic temperature, easy control of synthesis conditions, high selectivity and conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

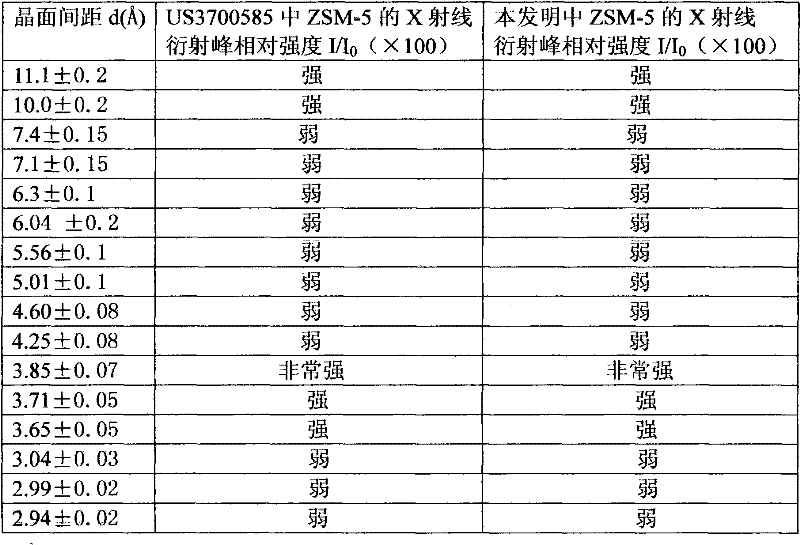

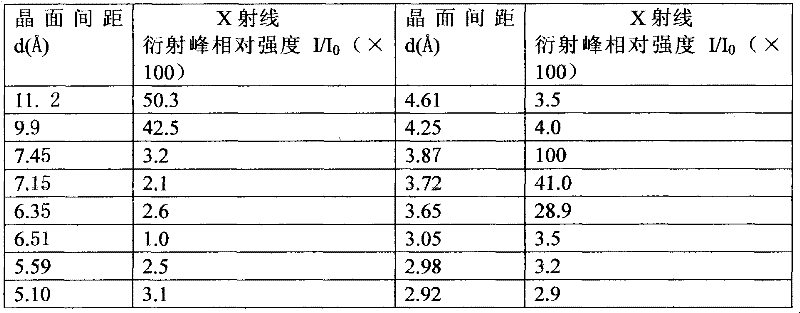

[0027] 1. Synthesis of crude product of ZSM-5 molecular sieve

[0028] First methanol, 23 grams of ethylamine and aniline, 5 grams, and 0.9 grams were mixed evenly, and then 345 grams of water glass (containing 8.16% (w / w) Na 2 O, 28.10% (w / w) SiO 2] and 600 grams of water were made into solution A; 18 grams of aluminum sulfate (98%, containing 18 water, w / w) were dissolved in 29.8 methanesulfonic acid and 400 grams of water to obtain liquid B; Liquid is added to liquid A to prepare a uniform gel-like colloidal liquid. At this point the composition of the reaction mixture is: SiO 2 / Al 2 o 3 =60; organic template / Al 2 o 3 = 15.96; Na 2 O / Al 2 o 3 =5.59;H 2 O / Al 2 o 3 =2600.

[0029] The colloid obtained above was put into a 2-liter synthesis kettle, first crystallized at 35°C for 2 hours, then slowly stirred and crystallized at 80°C for 40 hours, and finally stirred and crystallized at 220°C for 2 hours. At this time, a pure ZSM-5 molecular sieve with very small ...

Embodiment 2

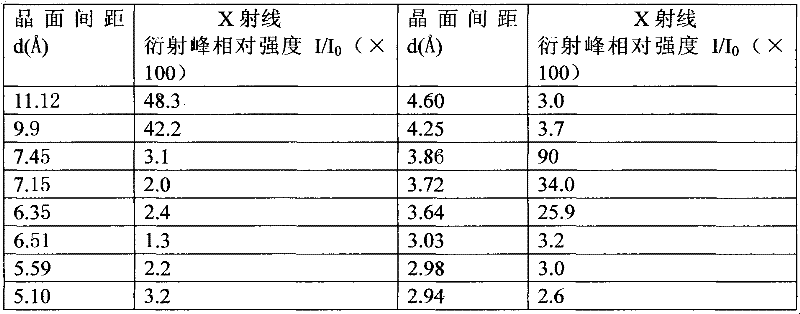

[0038] 1. Synthesis of crude product of ZSM-5 molecular sieve

[0039] First mix 20 grams, 38 grams and 3.5 grams of ethanol, methylamine and p-methylaniline evenly, then add 691 grams of sodium silicate [containing 21.16% (w / w) Na 2 O, 20.90% (w / w) SiO 2 ) and 800 grams of water are made into solution A; 4 grams of sodium aluminate (Al 2 o 3 , 48%, w / w) was dissolved in 65.1 grams of ethanesulfonic acid and 200 grams of water to obtain liquid B; under vigorous stirring, liquid B was added to liquid A to prepare a uniform colloidal colloidal liquid. At this point the composition of the reaction mixture is SiO 2 / Al 2 o 3 =126; organic template / Al 2 o 3 =81; Na 2 O / Al 2 o 3 =18;H 2 O / Al 2 o 3 =3490

[0040] Put the above colloid into a 2-liter synthesis kettle, first crystallize at 25°C for 8 hours, then slowly stir and crystallize at 110°C for 16 hours, and finally stir and crystallize at 160°C for 8 hours. At this time, a pure ZSM-5 molecular sieve with very sm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com