Patents

Literature

30results about How to "Improve nitrogen resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrocracking catalyst containing compound molecular sieve and preparing method thereof

InactiveCN1488726AImprove nitrogen resistanceHigh hydrocracking activityHydrocarbon oil crackingMolecular sieveNitrogen

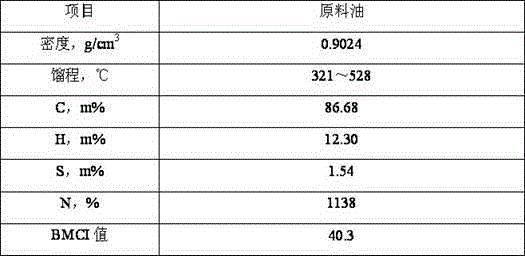

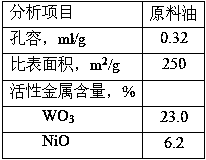

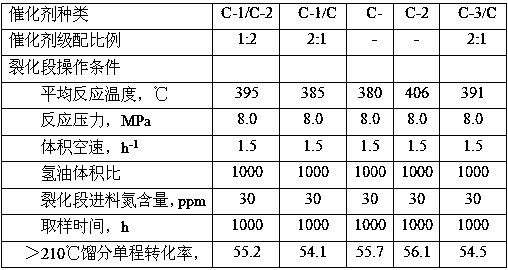

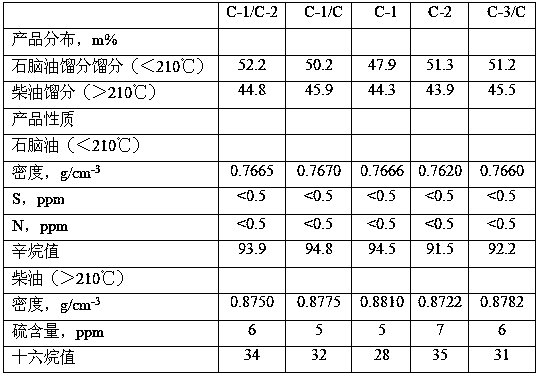

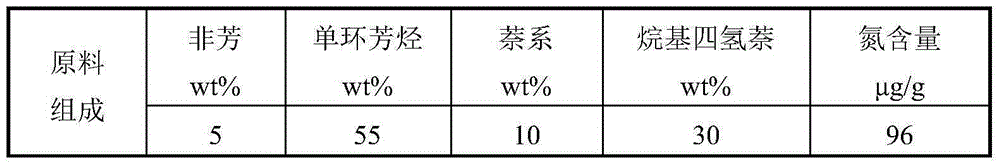

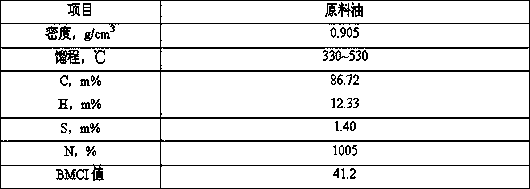

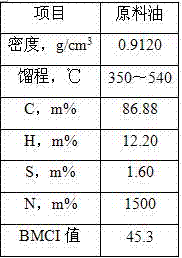

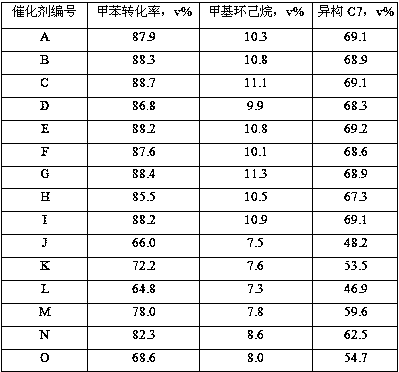

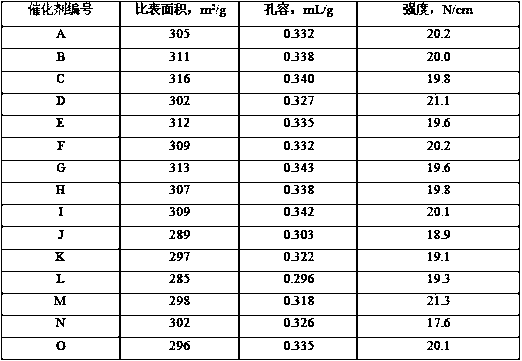

The present invention relates to a hydrocracking catalyst containing compound molecular sieve and its preparation method. Said catalyst composition uses amorphous aluminosilicate and a compound molecular sieve as carrier, in which the amorphous aluminosilicate content is 30-60% of catalyst weight, compound molecular sieve content is 1-20% of catalyst weight, and is the mixture of modified Y molecular sieve and SAPO molecular sieve, VIB group metal oxide content is 10-40%, VIII group metal oxide content is 1-20% of IVB group metal oxide content is 1-10%. Said invented catalyst is prepared by adopting co-precipitation method, and its strength and performance can be raised and improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of nitrogen-resisting hydrocracking catalyst

ActiveCN105618121AIncrease the number of secondary holesImprove nitrogen resistanceMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveOxide

The invention discloses a preparation method of a nitrogen-resisting hydrocracking catalyst. The preparation method comprises the following steps: 1, uniformly mixing a modified Y type molecular sieve, amorphous silicon-aluminum and / or aluminum oxide, adding dilute nitric acid, carrying out slurrying, then performing extrusion molding, and performing drying and calcination to obtain a silicon-aluminum carrier containing the modified Y type molecular sieve; and 2, performing impregnation on the carrier of the step 1 by adopting impregnation liquid containing an active metal, drying the impregnated carrier and calcining the dried carrier to obtain the hydrocracking catalyst, wherein the modified Y type molecular sieve has the following characteristics: the crystal cell constant of the modified Y type molecular sieve is 2.425-2.455nm; the bulk phase silicon-aluminum ratio is 8-30, wherein the surface layer silicon-aluminum ratio is 20-80, and the surface layer silicon-aluminum ratio is higher than the bulk phase silicon-aluminum ratio; and the specific surface area of the modified Y type molecular sieve is 600-800m<2> / g, and the pore volume is 0.40-0.70ml / g. The hydrocracking catalyst prepared by the preparation method disclosed by the invention has good reactivity and nitrogen resistance, and can be applied to different hydrocracking reaction processes such as a process for increasing the production of diesel oil, a process for increasing the production of chemical raw materials, and a process for catalyzing diesel oil hydro-conversion and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

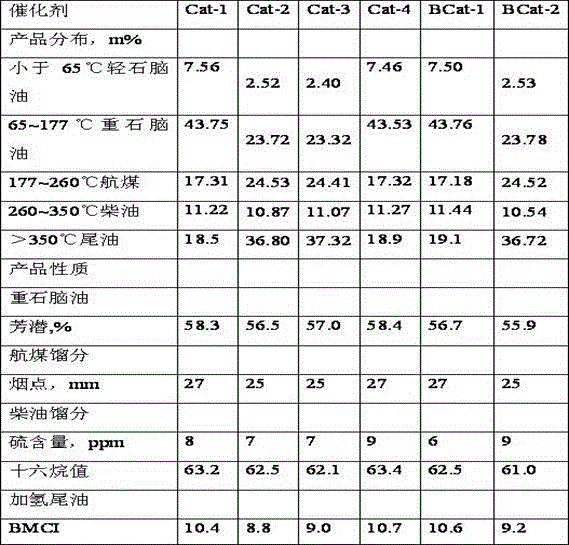

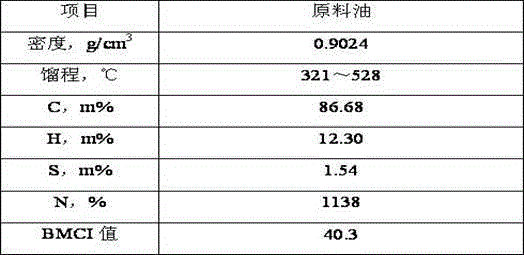

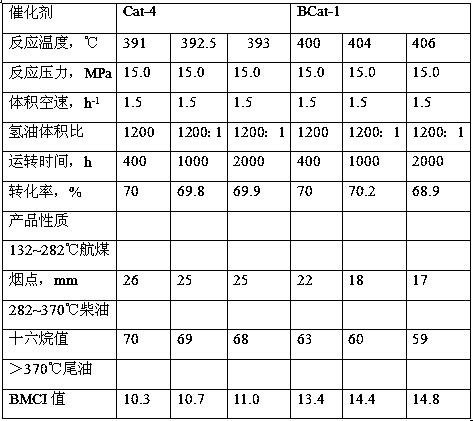

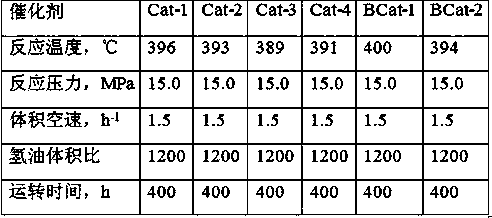

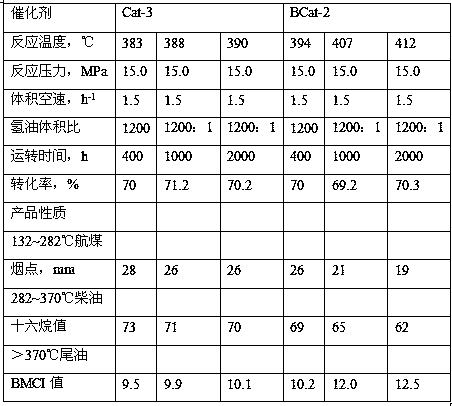

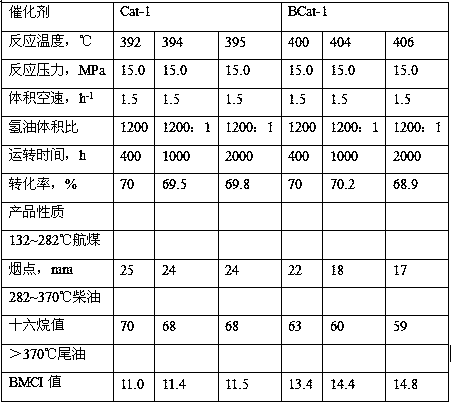

Method for selective hydrocracking of light oil

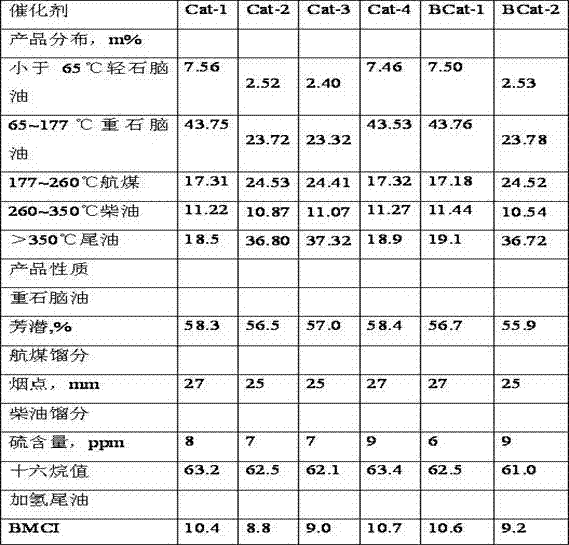

ActiveCN102533316AIncrease the potential content of aromaticsEnhance aromatizationMolecular sieve catalystsHydrocarbon oil crackingTreatment systemOxide

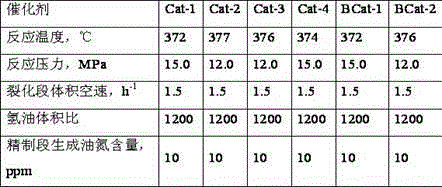

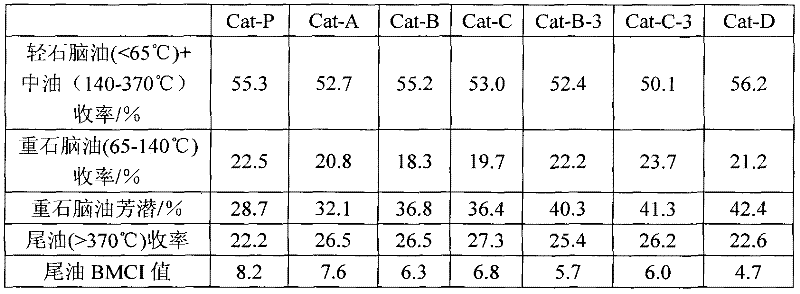

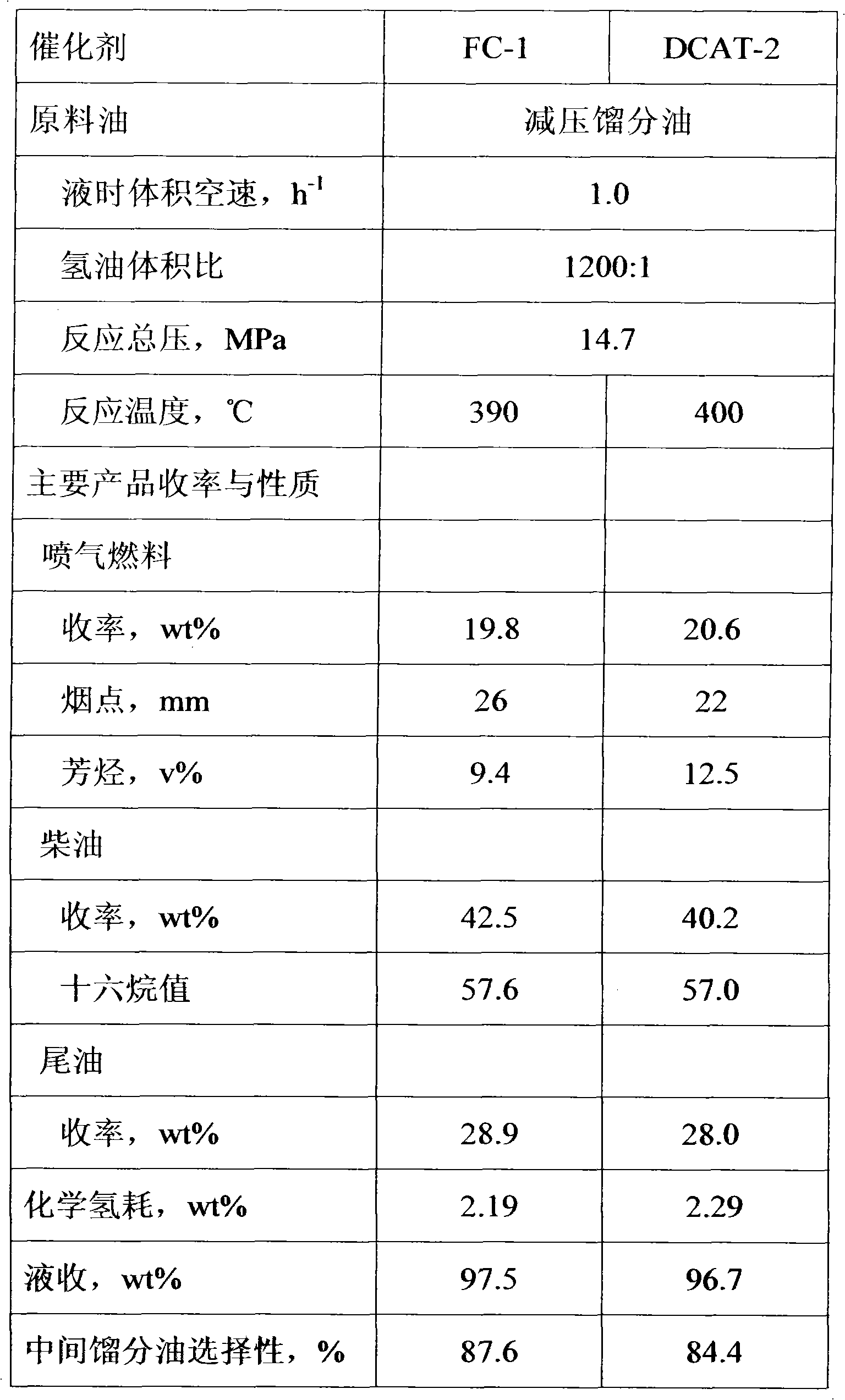

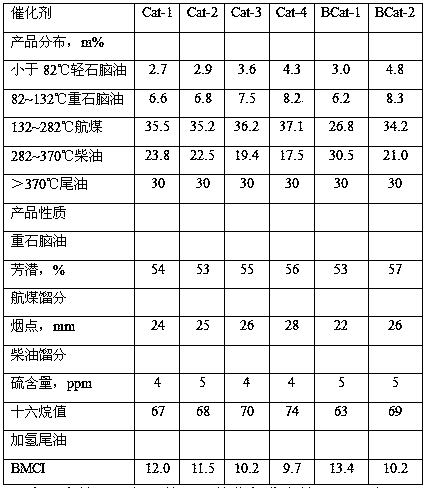

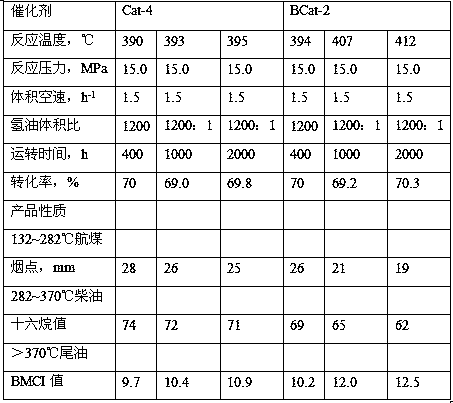

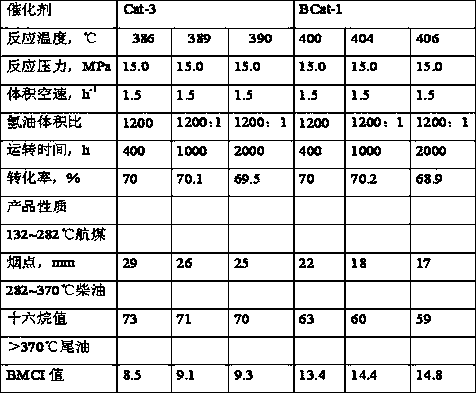

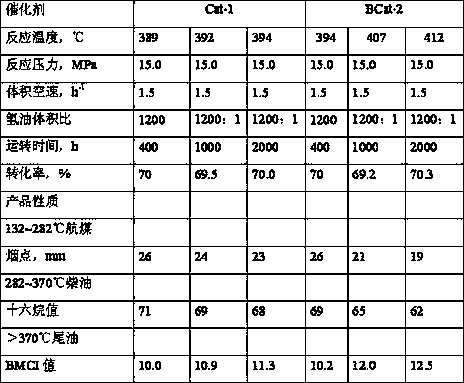

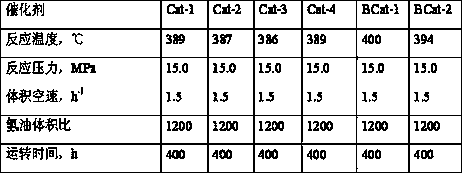

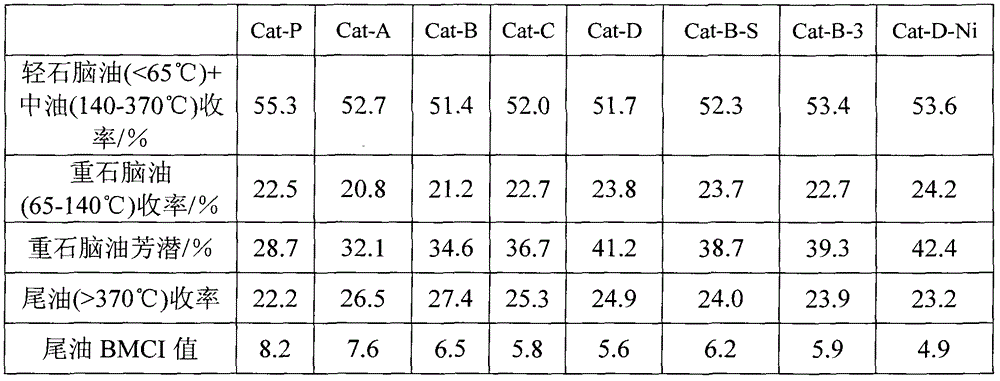

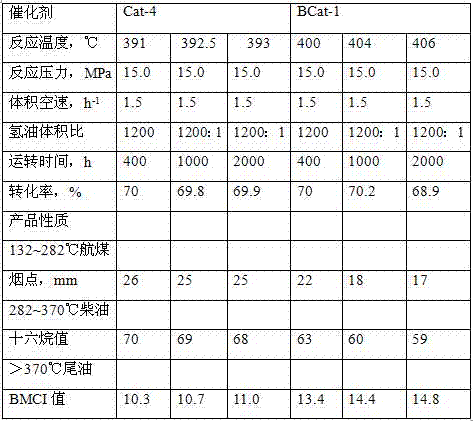

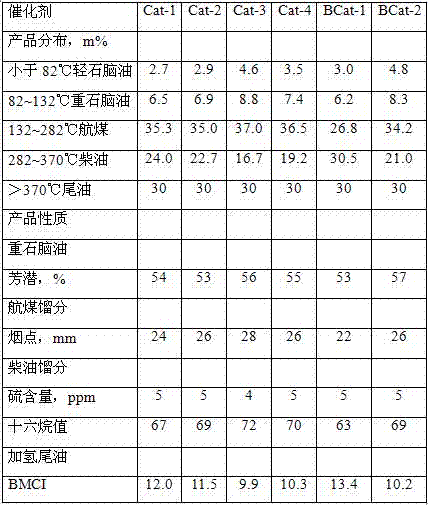

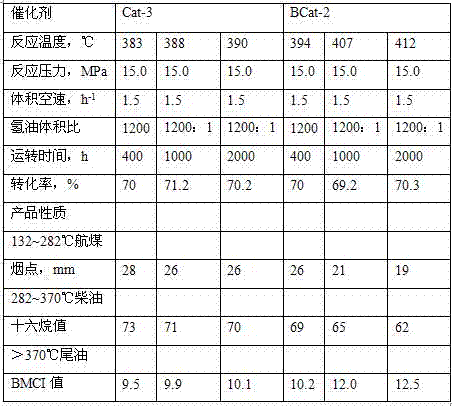

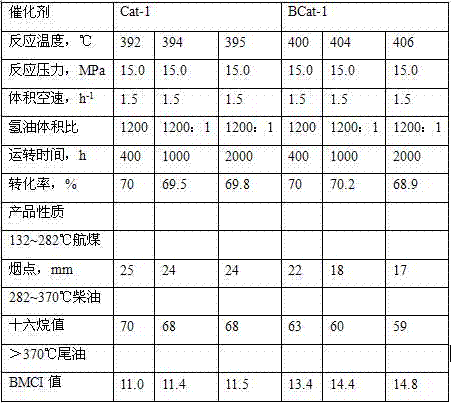

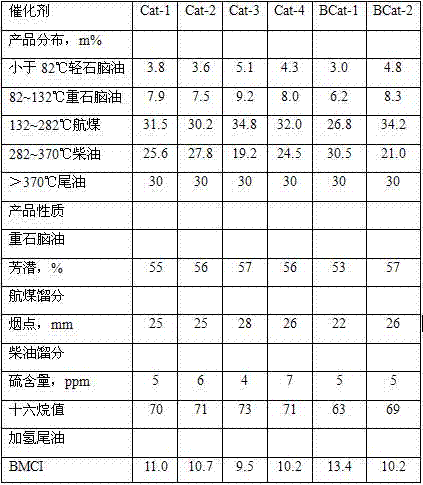

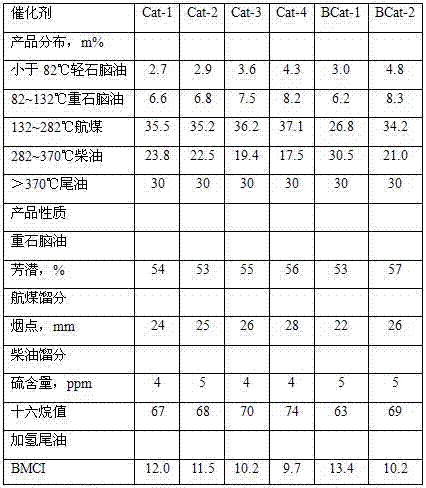

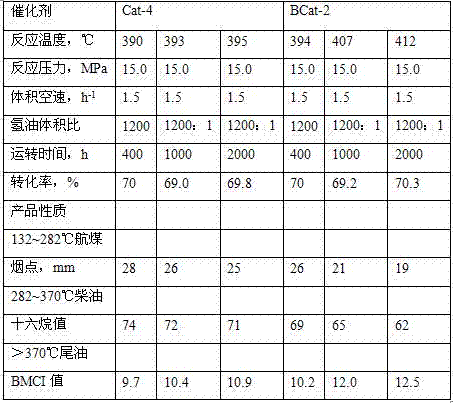

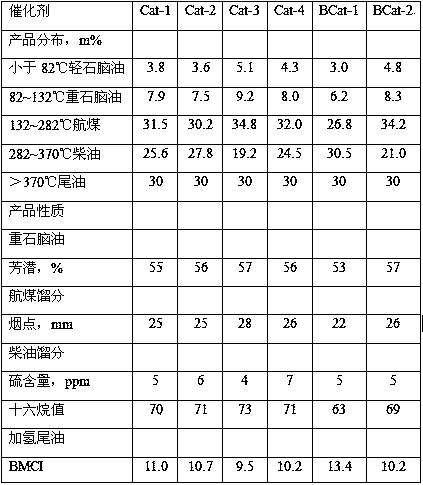

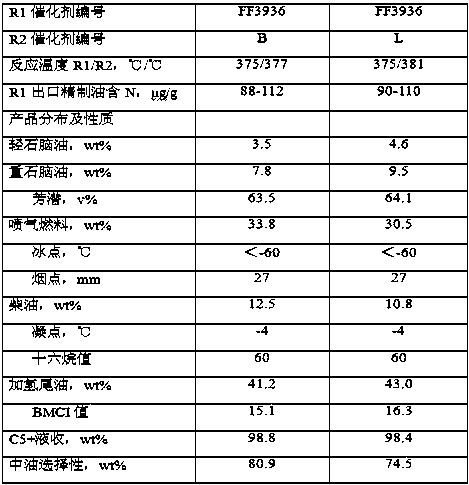

The invention relates to a method for selective hydrocracking of light oil. A catalyst used in the method comprises an acidic carrier and metal oxides NiO and WO3, wherein the acidic carrier comprises two porous beta / Y composite molecular sieves and a mesoporous amorphous silicon / aluminum, and the metal oxides are loaded on the acidic carrier; the two porous beta / Y composite molecular sieves are used for ammonium exchange and organic acid pretreatment, and the two treatment methods are carried out in one process; ammonium salt used in the ammonium exchange is NH4NO3 or NH4HCO3, and the mass ratio of the beta / Y composite molecular sieves and the ammonium salt solution is (1-10):1; the solution of one or mixture of any of citric acid, tartaric acid, acetic acid, malic acid and oxalic acid is used for treatment of the beta / Y composite molecular sieves, and the concentration of the organic acid in the treatment system is 0.5-2.0 mol.L-1; the potential content of aromatic hydrocarbon in heavy naphtha in products obtained in cracking is high, and the exhaust oil has a lower BMCI (Bureau of Mines Correlation Index) value.

Owner:PETROCHINA CO LTD +1

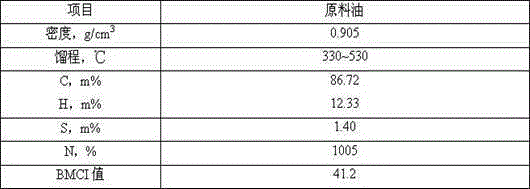

Hydrogenation catalyst carrier and preparation method thereof

ActiveCN102463142AGood nitrogen resistanceUniform strengthCatalyst carriersMolecular sieve catalystsMolecular sieveNitrogen

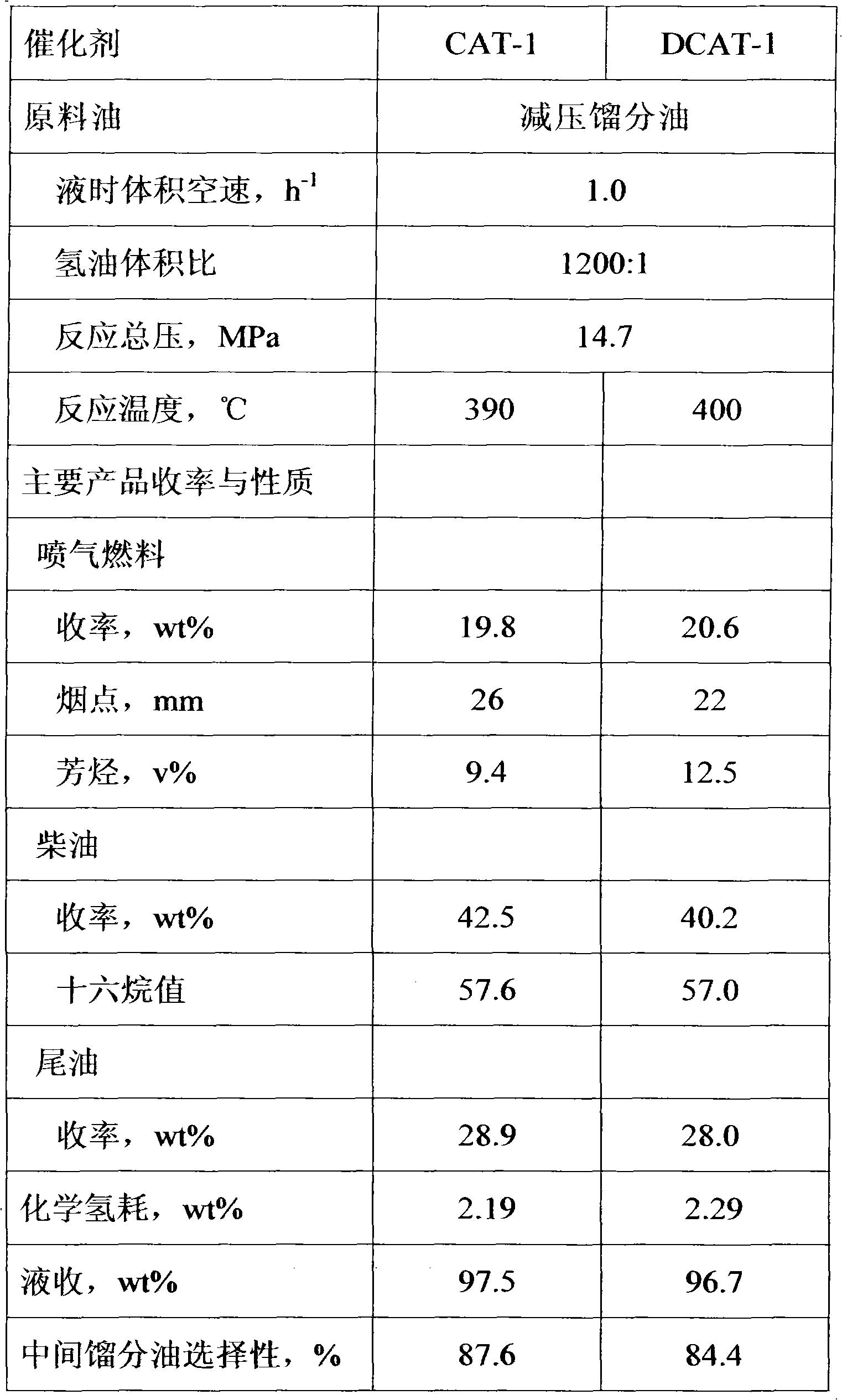

The invention discloses a hydrogenation catalyst carrier which comprises, by weight, 0 to 40% of a molecular sieve, 20 to 75% of amorphous silica-alumina and 5 to 75% of alumina. The hydrogenation catalyst carrier has the following properties: a specific surface area is 200 m<2> / g to 500 m<2> / g; a pore volume is 0.40 cm<3> / g to 0.80 cm<3> / g. A preparation method for the hydrogenation catalyst carrier comprises the following steps: carrying out hydrothermal treatment on amorphous silica-alumina dry glue powder; weighing the above-mentioned components of the catalyst carrier in desired proportion; carrying out mixing and milling, molding, drying and activation on the components so as to obtain the catalyst carrier. Compared to conventional hydrogenation catalyst carriers, the catalyst carrier provided in the invention has the following advantages: the catalyst carrier has a greater pore volume, a greater specific surface area, a proper amount of acid and good nitrogen resistance; a catalyst prepared from the catalyst carrier is applicable to hydrotreatment of vacuum distillates which are heavier and poorer but can produce more middle distillates.

Owner:CHINA PETROLEUM & CHEM CORP +1

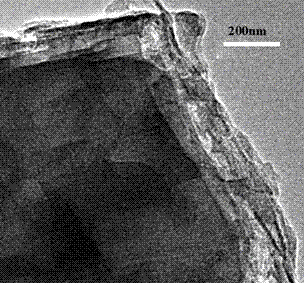

Preparation method and application of modified Y molecular sieve

ActiveCN106669774AHigh ratio of silicon to aluminumImprove nitrogen resistanceMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveBurn treatment

The invention discloses a preparation method and application of a modified Y molecular sieve. The preparation method comprises the following steps: (1) performing ammonium salt ion exchange on NaY zeolite as raw powder; (2) performing hydro-thermal treatment on the obtained Y molecular sieve; (3) treating the Y molecular sieve subjected to hydro-thermal treatment in the step (2) by using an aluminum salt solution; (4) performing rapid drying treatment on the Y molecular sieve obtained in the step (3); (5) contacting the Y molecular sieve obtained in the step (4) with unsaturated olefin and performing carbon deposit reaction; (6) performing desilicication treatment on the molecular sieve obtained in the step (5); (7) filtering and drying the Y molecular sieve obtained in the step (6) and performing carbon burning treatment to obtain the modified Y molecular sieve. According to the method, the outer surface of the Y molecular sieve is selectively subjected to dealumination and silicon reinsertion, so the ratio of silicon to aluminum on the outer surface of the Y molecular sieve is increased, and a hydrocracking catalyst prepared with the Y molecular sieve has high reaction activity and nitrogen resistance.

Owner:CHINA PETROLEUM & CHEM CORP +1

A Catalytic Diesel Hydrogenation Conversion Process

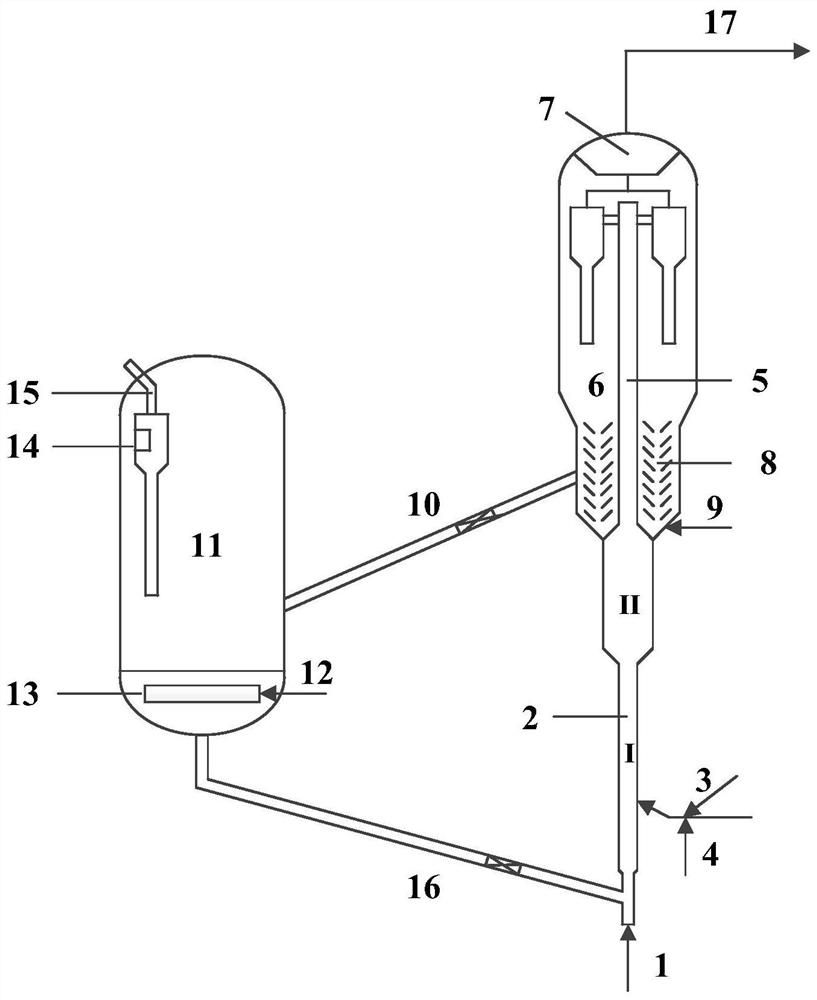

ActiveCN107304373BIncrease secondary crackingLow yieldMolecular sieve catalystsTreatment with hydrotreatment processesMolecular sieveHydrogenation reaction

The invention discloses a hydro-conversion technology for catalytic diesel oil. The technology comprises the following steps: firstly, putting a mixture of catalytic diesel oil and hydrogen into a hydrogenation reactor and performing hydrofining reaction, and then guiding into a cracking reactor and generating contact reaction with hydrocracking catalyst layers, wherein upper and lower catalyst layers are arranged in the hydrocracking reactor; the hydrocracking catalyst in the upper layer has the properties as follows: on the basis of the total weight of the catalyst, 10%-18% of MoO3, 2%-10% of Co, 40%-90% of modified Y-shaped molecular sieve, preferably 50-80%, and the balance of aluminum silicon carrier; the hydrocracking catalyst in the lower layer has the properties as follows: on the basis of the total weight of the catalyst, 15-30% of MoO3 or WO3, 2-15% of NiO, 10%-60% of modified Y-shaped molecular sieve, preferably 20-40%; the filling mass ratio of the hydrocracking catalysts in the upper layer and the lower layer is (1:5)-(5:1). The hydro-conversion technology disclosed by the invention can further increase the device liquid yield, can reduce the hydrogenation saturation of the generated gasoline component and can increase the octane value of the gasoline component under the condition of better meeting the requirement for the conversion rate of catalytic diesel oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

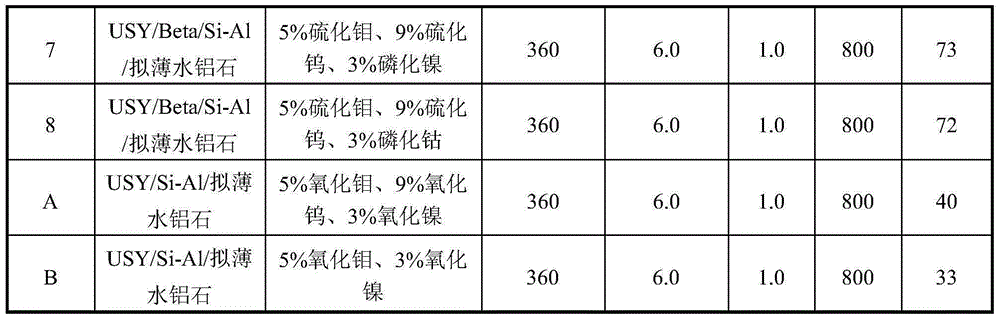

Light cycle oil hydrocracking catalyst and preparation method thereof

InactiveCN106582778AImprove conversion abilityToxic reductionMolecular sieve catalystsHydrocarbon oil crackingChemistryAmorphous silica-alumina

The invention relates to a light cycle oil hydrocracking catalyst and a preparation method thereof. The problems of low light cycle oil cracking activity and poor nitrogen resistance of traditional hydrocracking catalysts are mainly solved in the invention. The catalyst comprises, by weight, 15-35% of at least one of FAU zeolite, BEA zeolite and MFI zeolite, 5-16% of amorphous silica-alumina, 10-20% of pseudo-boehmite, 5-10% of molybdenum sulfide, 9-16% of tungsten sulfide and 3-6% of at least one active component selected from nickel phosphate and cobalt phosphate. The light cycle oil hydrocracking catalyst adopting the above technical scheme well solves the problems, has the advantages of no precurng, high cracking activity, high nitrogen resistance, and flexible and controllable product distribution, and can be used in the field of hydrogenation refining and chemical engineering.

Owner:CHINA PETROLEUM & CHEM CORP +1

Nitrogen-resisting hydrocracking catalyst and preparation method thereof

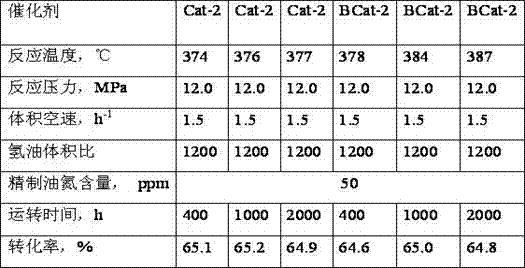

ActiveCN105618122AHigh ratio of silicon to aluminumImprove nitrogen resistanceCatalyst carriersMolecular sieve catalystsMolecular sievePtru catalyst

The invention discloses a nitrogen-resisting hydrocracking catalyst and a preparation method thereof. The nitrogen-resisting hydrocracking catalyst comprises the following components according to the total weight of the catalyst: 55-85% of a silicon-aluminum carrier containing a modified Y type molecular sieve, and 15-45% of an active metal in the form of a metal oxide, wherein the mass percentage of the modified Y type molecular sieve in the silicon-aluminum carrier is 15-90%, and the balance is amorphous silicon-aluminum and / or aluminum oxide; the crystal cell constant of the modified Y type molecular sieve is 2.425-2.455nm; the bulk phase silicon-aluminum ratio is 8-30, wherein the surface layer silicon-aluminum ratio is 20-80, and the surface layer silicon-aluminum ratio is higher than the bulk phase silicon-aluminum ratio; the specific surface area of the modified Y type molecular sieve is 600-800m<2> / g; the pore volume is 0.40-0.70ml / g; the infrared acid content is 0.3-1.5mmol / g; and the relative crystallinity is 70-110%. The hydrocracking catalyst disclosed by the invention has good reactivity and nitrogen resistance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic cracking method for high nitrogen raw material

ActiveCN109694720AImprove nitrogen resistanceHigh hydrothermal stabilityCatalytic crackingHydrocarbon oils treatmentMolecular sieveBoron

The invention relates to a catalytic cracking method for a high nitrogen raw material. The method comprises: feeding a high nitrogen raw material into a catalytic cracking reactor, making the high nitrogen raw material contact a catalytic cracking catalyst, and carrying out a catalytic cracking reaction to obtain a reaction product and a spent catalyst; and carrying out charring regeneration on the spent catalyst to obtain a regenerated catalyst, and feeding the obtained regenerated catalyst as the catalytic cracking catalyst into the catalytic cracking reactor, wherein the catalytic crackingcatalyst comprises a boron-modified phosphorus-containing Y molecular sieve, a heat-resistant inorganic oxide and optionally clay. With the method of the present invention, the conversion rate of thehigh nitrogen raw material can be improved, and the product distribution can be optimized.

Owner:CHINA PETROLEUM & CHEM CORP +1

Cracking catalyst with hydrogen being added for noble metal and its prepn. method

InactiveCN1164719CImprove thermal stabilityGood oil selectivityHydrocarbon oil crackingHigh resistanceHydrogen

A noble metal hydrocracking catalyst is composed of modified Y zeolite alumina as carrier which has been treated hydrothermal twice and by acid, and the active hydrogenating component which is the noble metal chosen from VIII family. Its advantages are high thermal stability, high selectivity to medium oil and high resistance to S and N.

Owner:CHINA PETROLEUM & CHEM CORP +1

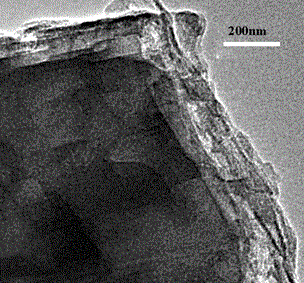

Nitrogen-resistant type hydrocracking catalyst carrier and preparation method thereof

InactiveCN109759124AImprove nitrogen resistanceAvoid inactivationMolecular sieve catalystsHydrocarbon oil crackingMolecular sievePtru catalyst

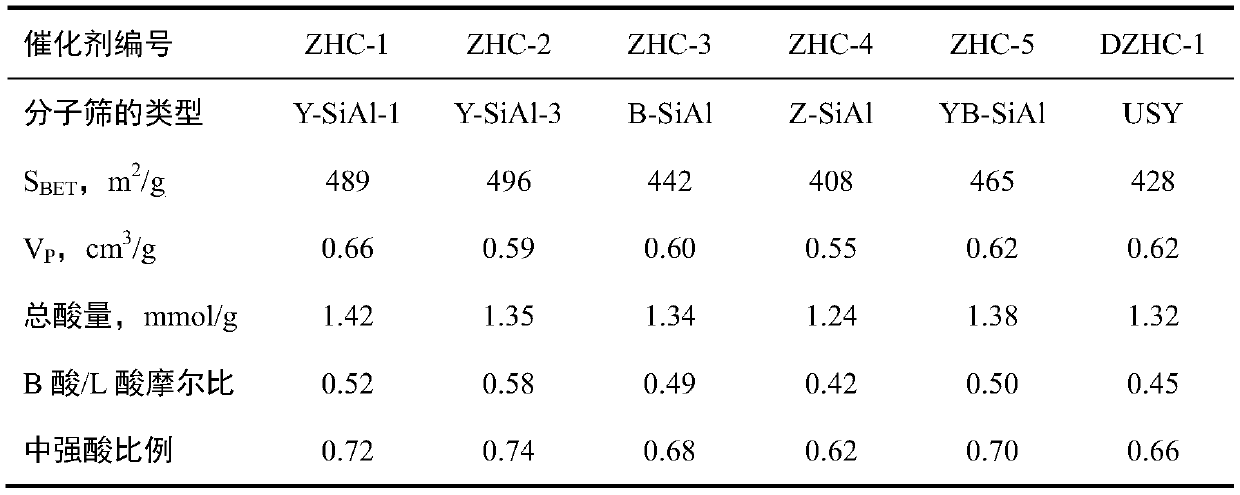

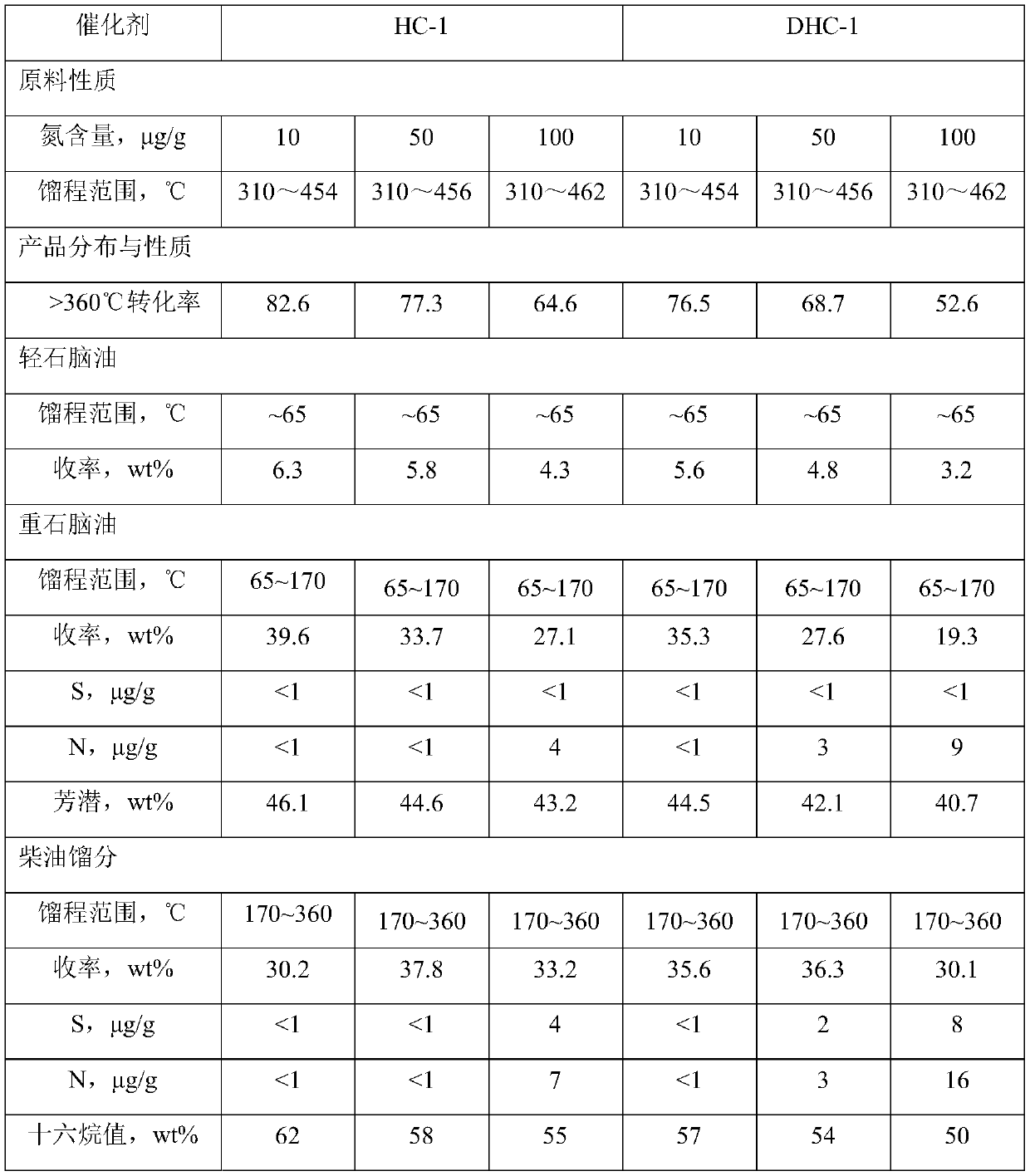

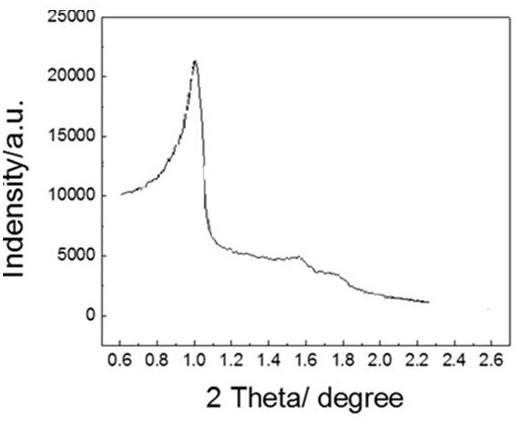

The invention provides a nitrogen-resistant type hydrocracking catalyst carrier and a preparation method thereof. The nitrogen-resistant type hydrocracking catalyst carrier is jointly prepared from asilicon-aluminum molecular sieve / amorphous silicon-aluminum composite material, macroporous aluminum oxide and SB powder. the silicon aluminum molecular sieve / amorphous silicon aluminum composite material is a composite material synthesized by taking the silicon aluminum molecular sieve as a core and wrapping the modified molecular sieve with amorphous silicon aluminum, and the composite materialhas the cascade-distributed acid strength and of a cascade-distributed hole structure, the specific surface area of the carrier is 400-650 m<2> / g, the pore volume is 0.55-0.70 cm<3> / g, the total acidcontent of fourier infrared absorption spectroscopy is 1.1-1.5 mmol / g, the B acid / L acid molar ratio is 0.38-0.58, and the medium strong acid proportion is 50-80%. The carrier is loaded with VI B group metal oxide and VIII group metal oxide to prepare a hydrocracking catalyst, and adapts to a high-nitrogen distillate hydrocracking reaction.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +2

A kind of preparation method of anti-nitrogen hydrocracking catalyst

ActiveCN105618121BIncrease the number of secondary holesHigh ratio of silicon to aluminumMolecular sieve catalystsHydrocarbon oil crackingMolecular sievePtru catalyst

The invention discloses a preparation method of a nitrogen-resisting hydrocracking catalyst. The preparation method comprises the following steps: 1, uniformly mixing a modified Y type molecular sieve, amorphous silicon-aluminum and / or aluminum oxide, adding dilute nitric acid, carrying out slurrying, then performing extrusion molding, and performing drying and calcination to obtain a silicon-aluminum carrier containing the modified Y type molecular sieve; and 2, performing impregnation on the carrier of the step 1 by adopting impregnation liquid containing an active metal, drying the impregnated carrier and calcining the dried carrier to obtain the hydrocracking catalyst, wherein the modified Y type molecular sieve has the following characteristics: the crystal cell constant of the modified Y type molecular sieve is 2.425-2.455nm; the bulk phase silicon-aluminum ratio is 8-30, wherein the surface layer silicon-aluminum ratio is 20-80, and the surface layer silicon-aluminum ratio is higher than the bulk phase silicon-aluminum ratio; and the specific surface area of the modified Y type molecular sieve is 600-800m<2> / g, and the pore volume is 0.40-0.70ml / g. The hydrocracking catalyst prepared by the preparation method disclosed by the invention has good reactivity and nitrogen resistance, and can be applied to different hydrocracking reaction processes such as a process for increasing the production of diesel oil, a process for increasing the production of chemical raw materials, and a process for catalyzing diesel oil hydro-conversion and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

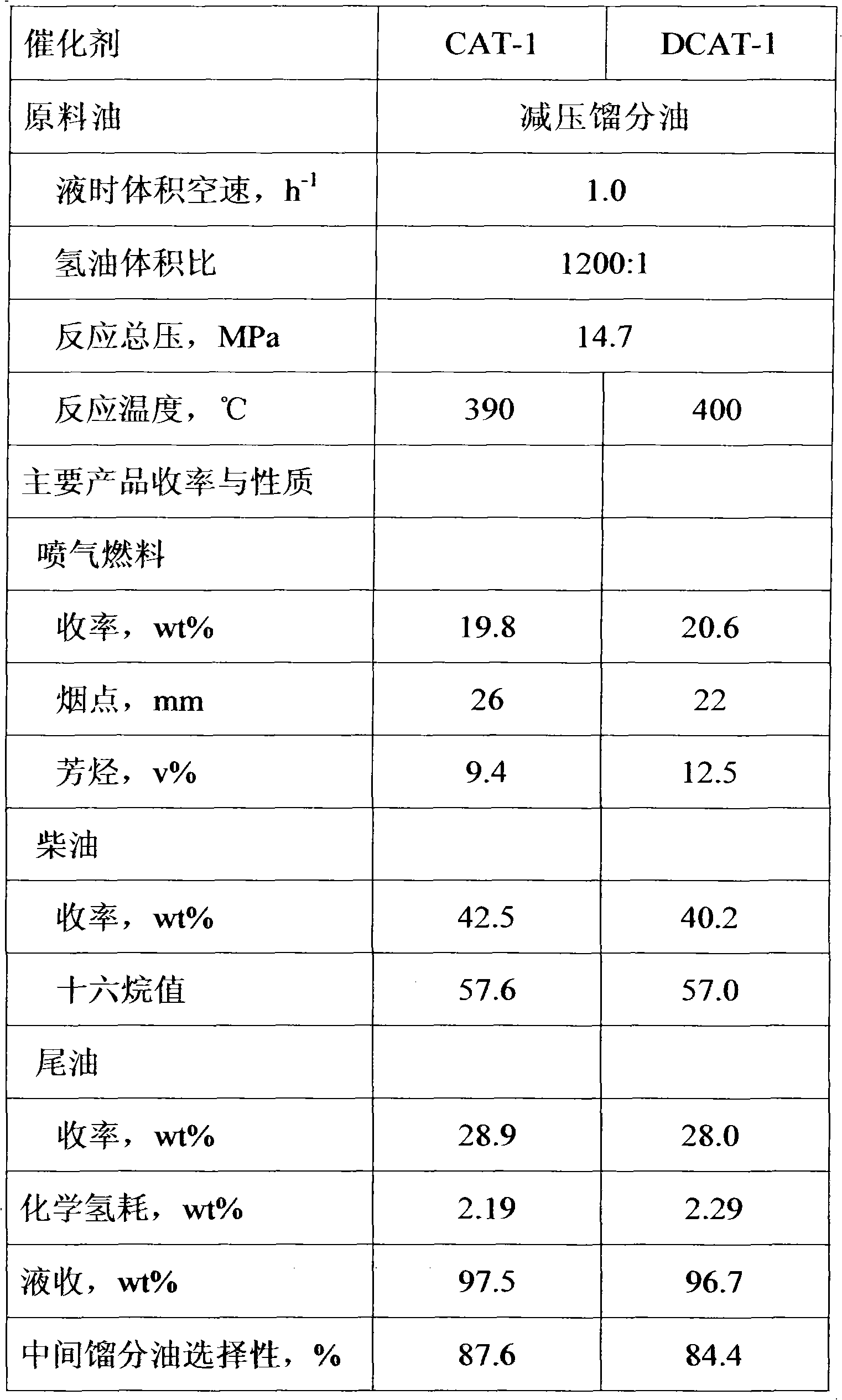

Medium oil type hydrocracking catalyst and its preparation method

ActiveCN102463147BLarge hole volumeIncrease the areaMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveNitrogen

The invention discloses a medium oil type hydrocracking catalyst. Weighed according to the weight of the final catalyst, the catalyst carrier components contain 0-20% of a molecular sieve, 20-50% of amorphous silica-alumina and 5-30% of alumina. Weighed according to the weight of oxide, the catalyst contains 20-50% of a hydrogenation metal component. An amorphous silica-alumina dry rubber powder undergoes hydrothermal processing and then is made with other carrier materials into the catalyst carrier. Then the hydrogenation metal component is loaded by an immersion method to prepare the final catalyst. In comparison with present hydrocracking catalysts, the catalyst provided by the invention has larger pore volume and specific surface area, has appropriate acid content, and has good nitrogen-resistant performance. The catalyst prepared in the invention is applicable to the treatment of vacuum gas oil with heavy and poor quality and hydrotreating process of middle distillate.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking catalyst containing compound molecular sieve and preparing method thereof

InactiveCN1211465CImprove nitrogen resistanceHigh hydrocracking activityHydrocarbon oil crackingMolecular sievePtru catalyst

The present invention relates to a hydrocracking catalyst containing compound molecular sieve and its preparation method. Said catalyst composition uses amorphous aluminosilicate and a compound molecular sieve as carrier, in which the amorphous aluminosilicate content is 30-60% of catalyst weight, compound molecular sieve content is 1-20% of catalyst weight, and is the mixture of modified Y molecular sieve and SAPO molecular sieve, VIB group metal oxide content is 10-40%, VIII group metal oxide content is 1-20% of IVB group metal oxide content is 1-10%. Said invented catalyst is prepared by adopting co-precipitation method, and its strength and performance can be raised and improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method and application of a modified Y molecular sieve and single-stage hydrocracking catalyst

ActiveCN107303495BImprove nitrogen resistanceReduce the ratio of silicon to aluminumMolecular sieve catalystsHydrocarbon oil crackingPtru catalystIon exchange

The invention discloses a preparation method and application of modified Y molecular sieve and a single-stage hydrocracking catalyst. The method includes the following contents: (1) using NaY zeolite as raw powder to carry out ammonium salt ion exchange; (2) carrying out dealumination and silicon filling treatment on the Y molecular sieve of step (1); (3) treating the Y after step (2) The molecular sieve is subjected to hydrothermal treatment; (4) the Y molecular sieve treated in step (3) is subjected to acid dealumination treatment; (5) the Y molecular sieve obtained in step (4) is rapidly dried; (6) the Y obtained in step (5) is The molecular sieve undergoes a carbon deposition reaction; (7) the molecular sieve obtained in step (6) is desiliconized; (8) the Y molecular sieve after desiliconization in step (5) is filtered and dried, and then subjected to charcoal treatment to obtain the modified Y molecular sieve. Y molecular sieve. The single-stage hydrocracking catalyst prepared by the modified Y molecular sieve prepared by the method of the present invention is used in the single-stage hydrocracking process and has good reactivity and nitrogen resistance.

Owner:CHINA PETROLEUM & CHEM CORP +1

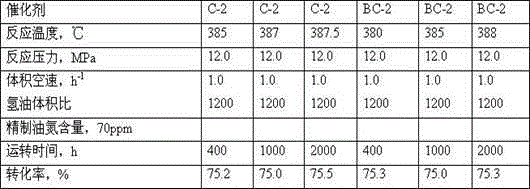

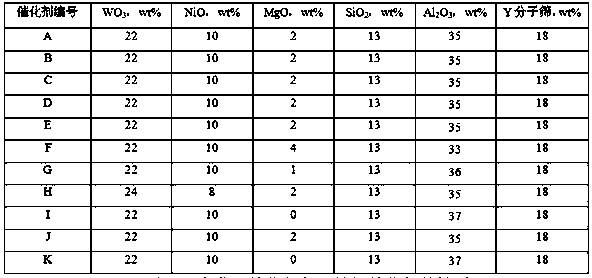

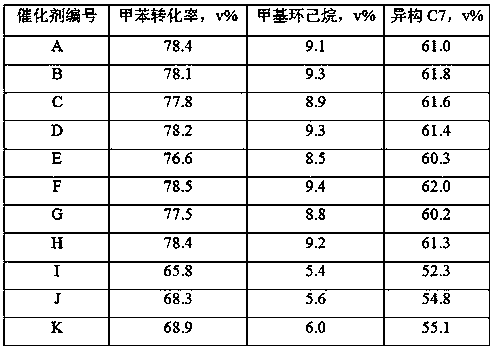

Preparation method of hydrocracking catalyst

ActiveCN106669783BImprove hydrogenation activityImprove performanceMolecular sieve catalystsMolecular sievePolyethylene glycol

The invention discloses a preparation method of a hydrocracking catalyst. The preparation method comprises the following steps: enabling a magnesium, aluminum and silicon-containing acidic solution and a tungsten-containing alkaline solution to form mixed slurry; enabling a nickel-containing acidic solution and the tungsten-containing alkaline solution to form mixed slurry; then mixing the slurries, adjusting the pH value, aging, mixing and grinding Y molecular sieves and high-molecular polyethylene glycol, adding into mixed slurry, filtering and drying; forming to prepare the hydrocracking catalyst. Through improvement in the hydrogenation activity of the catalyst and effective cooperation of acidic functions, the nitrogen resistance of the catalyst is improved, so that the catalyst still has good hydrocracking activity and better performance of delaying carbon deposition under the condition of higher nitrogen content of a reactant.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of preparation method of hydrocracking catalyst

ActiveCN107303494BImprove nitrogen resistanceHigh activityMolecular sieve catalystsHydrocarbon oil crackingMolecular sievePtru catalyst

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of hydrocracking catalyst and its preparation method and application

ActiveCN107303496BImprove nitrogen resistanceHigh activityMolecular sieve catalystsHydrocarbon oil crackingCooking & bakingMolecular sieve

The invention discloses a hydrocracking catalyst and a preparation method thereof. Based on the total weight of the catalyst, it includes the following components: 30% to 80% of silicon-aluminum carrier containing modified Y molecular sieve, and 20% to 70% of active metal, wherein The active metal is calculated as metal oxide; the mass percentage of the modified Y molecular sieve in the silica-alumina carrier is 1% to 13%, preferably 2% to 10%, and the balance is amorphous silica-alumina and / or alumina. ; The unit cell constant of the modified Y molecular sieve is 2.425~2.440; the bulk silicon-aluminum ratio is 20~50, of which the surface layer silicon-aluminum ratio is 50~120, preferably 60~100, and the surface layer silicon-aluminum ratio is 10~ higher than the bulk phase silicon-aluminum ratio. 80, preferably 15~50. Preparation method: Use an impregnating liquid containing active metal to immerse a carrier including modified Y molecular sieve, amorphous silica aluminum and / or alumina, and then dry and roast to obtain a hydrocracking catalyst. The hydrocracking catalyst of the invention is used in a single-stage hydrocracking process and has good reactivity and nitrogen resistance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing chemical raw material by hydrocracking

ActiveCN102533317BImprove nitrogen resistanceImprove stabilityMolecular sieve catalystsHydrocarbon oil crackingCatalytic reformingMolecular sieve

The invention relates to a method for producing a chemical raw material by hydrocracking. A catalyst for producing the chemical raw material by hydrocracking comprises the following components in percentage by weight according to 100 percent by weight of the catalyst: 30-70 percent of mesoporous amorphous silicon-aluminum, 10-30 percent of modified Y-type molecular sieve, 5-15 percent of Beta molecular sieve, 1-10 percent of NiO and 10-29 percent of WO3. The method for producing the chemical raw material by hydrocracking comprises the following steps of: loading metal components including Ni and W on a carrier by adopting a fractional infusion method, wherein a nickel acetate or nickel nitrate solution is used as a nickel source and ammonium meta-tungstate or ammonium tungstate is used as a tungsten source; adding a metric nickel salt solution in the preparation process of amorphous silicon-aluminum, wherein the addition amount of nickel accounts for 20-80 percent of the using amount of NiO in the catalyst; and preparing a mixed carrier and loading residual nickel salt solution and all tungsten salt solution by adopting a co-infusion isovolumetric method. The method disclosed by the invention has higher light oil recovery rate; meanwhile, heavy naphtha with high aromatic latent content and tail oil with BMCI (Bureau of Mines Correlation Index) value, which are respectively used as a favorable catalytic reforming raw material and a raw material for preparing ethylene by steam cracking, can be obtained.

Owner:PETROCHINA CO LTD +1

A kind of preparation method and application of modified Y molecular sieve

ActiveCN106669774BHigh ratio of silicon to aluminumImprove nitrogen resistanceMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveBurn treatment

The invention discloses a preparation method and application of a modified Y molecular sieve. The preparation method comprises the following steps: (1) performing ammonium salt ion exchange on NaY zeolite as raw powder; (2) performing hydro-thermal treatment on the obtained Y molecular sieve; (3) treating the Y molecular sieve subjected to hydro-thermal treatment in the step (2) by using an aluminum salt solution; (4) performing rapid drying treatment on the Y molecular sieve obtained in the step (3); (5) contacting the Y molecular sieve obtained in the step (4) with unsaturated olefin and performing carbon deposit reaction; (6) performing desilicication treatment on the molecular sieve obtained in the step (5); (7) filtering and drying the Y molecular sieve obtained in the step (6) and performing carbon burning treatment to obtain the modified Y molecular sieve. According to the method, the outer surface of the Y molecular sieve is selectively subjected to dealumination and silicon reinsertion, so the ratio of silicon to aluminum on the outer surface of the Y molecular sieve is increased, and a hydrocracking catalyst prepared with the Y molecular sieve has high reaction activity and nitrogen resistance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method and application of modified Y molecular sieve and single-stage hydrocracking catalyst

ActiveCN107303495AHigh Nitrogen ResistanceActiveMolecular sieve catalystsHydrocarbon oil crackingIon exchangeChemistry

The invention discloses a preparation method and application of a modified Y molecular sieve and a single-stage hydrocracking catalyst. The method comprises the following contents: (1) carrying out ammonium salt ion exchange on NaY zeolite as a raw material; (2) carrying out isomorphous substitution treatment on the Y molecular sieve in the step (1); (3) carrying out hydro-thermal treatment on the Y molecular sieve treated in the step (2); (4) carrying out acid dealumination treatment on the Y molecular sieve treated in the step (3); (5) carrying out fast drying treatment on the Y molecular sieve treated in the step (4); (6) carrying out carbon deposit reaction on the Y molecular sieve obtained in the step (5); (7) carrying out desilicication treatment on the molecular sieve obtained in the step (6); and (8) filtering and drying the Y molecular sieve subjected to desilicication treatment in the step (7) and carrying out charking treatment to obtain a modified Y molecular sieve. The single-stage hydrocracking catalyst prepared from the modified Y molecular sieve prepared through the method is applied to a single-stage hydrocracking process and has good reaction activity and nitrogen resistance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrogenation catalyst carrier and preparation method thereof

The invention discloses a hydrogenation catalyst carrier which comprises, by weight, 0 to 40% of a molecular sieve, 20 to 75% of amorphous silica-alumina and 5 to 75% of alumina. The hydrogenation catalyst carrier has the following properties: a specific surface area is 200 m<2> / g to 500 m<2> / g; a pore volume is 0.40 cm<3> / g to 0.80 cm<3> / g. A preparation method for the hydrogenation catalyst carrier comprises the following steps: carrying out hydrothermal treatment on amorphous silica-alumina dry glue powder; weighing the above-mentioned components of the catalyst carrier in desired proportion; carrying out mixing and milling, molding, drying and activation on the components so as to obtain the catalyst carrier. Compared to conventional hydrogenation catalyst carriers, the catalyst carrier provided in the invention has the following advantages: the catalyst carrier has a greater pore volume, a greater specific surface area, a proper amount of acid and good nitrogen resistance; a catalyst prepared from the catalyst carrier is applicable to hydrotreatment of vacuum distillates which are heavier and poorer but can produce more middle distillates.

Owner:CHINA PETROLEUM & CHEM CORP +1

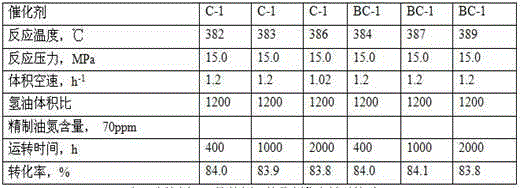

Preparation method for single segment hydro-cracking catalyst

ActiveCN107303493AImprove nitrogen resistanceHigh activityMolecular sieve catalystsHydrocarbon oil crackingMolecular sievePtru catalyst

The invention discloses a preparation method for a single segment hydro-cracking catalyst. The method comprises the following steps: 1) uniformly mixing modified Y molecular sieve, amorphous form aluminum silicon and / or aluminum oxide, adding dilute nitric acid, pulping and then extruding a strip and forming, drying and roasting, thereby acquiring an aluminum silicon carrier containing the modified Y molecular sieve, wherein the mass percent of the modified Y molecular sieve in the aluminum silicon carrier is 1%-13%, preferably, 2%-10%, and the balance is amorphous form aluminum silicon and / or aluminum oxide; 2) adopting a steeping liquor containing active metal for steeping the carrier acquired in the step (1), drying and roasting the steeped carrier, thereby acquiring the hydro-cracking catalyst. The single segment hydro-cracking catalyst prepared according to the method disclosed by the invention has excellent reaction activity and nitrogen resistance in a single segment hydro-cracking process.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking catalyst carrier, hydrocracking catalyst and preparation methods of hydrocracking catalyst carrier and hydrocracking catalyst

ActiveCN114453018AImprove nitrogen resistanceAdjustable acidityMolecular sieve catalystsCatalyst activation/preparationMolecular sievePtru catalyst

The invention discloses a hydrocracking catalyst carrier, a hydrocracking catalyst and a preparation method thereof. The hydrocracking catalyst carrier comprises a Beta / Al-SBA-15 composite molecular sieve, amorphous silica-alumina I and alumina, the acid content of medium and strong acids in the Beta / Al-SBA-15 composite molecular sieve is 0.6-1.2 mL / g, and the ratio of the acid B to the acid L is less than 0.80. The hydrocracking catalyst prepared by adopting the hydrocracking catalyst carrier has excellent comprehensive performance, is especially used in the hydrocracking reaction process of shale oil with a complex raw material structure, and has excellent product quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method for hydrocracking catalyst

ActiveCN107303494AImprove nitrogen resistanceHigh activityMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveNitrogen

The invention discloses a preparation method for a hydrocracking catalyst. The method comprises the following steps: 1) uniformly mixing a modified Y molecular sieve, amorphous silicon aluminum and / or aluminum oxide, adding dilute nitric acid, pulping, extruding into a strip, drying and baking, thereby acquiring a silicon aluminum carrier containing the modified Y molecular sieve, wherein the mass percent of the modified Y molecular sieve in the silicon aluminum carrier is 1%-13%, preferably 2%-10% and the balance is amorphous silicon aluminum and / or aluminum oxide; 2) adopting a steeping liquor containing active metal for steeping the carrier in the step (1), drying and baking the steeped carrier, thereby acquiring the hydrocracking catalyst. The hydrocracking catalyst prepared according to the method disclosed by the invention has excellent reactivity and nitrogen resistance and is especially suitable for a single segment hydrocracking technology.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of catalytic cracking method of high nitrogen feedstock

ActiveCN109694720BImprove nitrogen resistanceHigh hydrothermal stabilityCatalytic crackingHydrocarbon oils treatmentMolecular sievePtru catalyst

The invention relates to a catalytic cracking method for a high nitrogen raw material. The method comprises: feeding a high nitrogen raw material into a catalytic cracking reactor, making the high nitrogen raw material contact a catalytic cracking catalyst, and carrying out a catalytic cracking reaction to obtain a reaction product and a spent catalyst; and carrying out charring regeneration on the spent catalyst to obtain a regenerated catalyst, and feeding the obtained regenerated catalyst as the catalytic cracking catalyst into the catalytic cracking reactor, wherein the catalytic crackingcatalyst comprises a boron-modified phosphorus-containing Y molecular sieve, a heat-resistant inorganic oxide and optionally clay. With the method of the present invention, the conversion rate of thehigh nitrogen raw material can be improved, and the product distribution can be optimized.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of anti-nitrogen hydrocracking catalyst and preparation method thereof

ActiveCN105618122BIncrease the number of secondary holesHigh ratio of silicon to aluminumCatalyst carriersMolecular sieve catalystsMolecular sievePtru catalyst

Owner:CHINA PETROLEUM & CHEM CORP +1

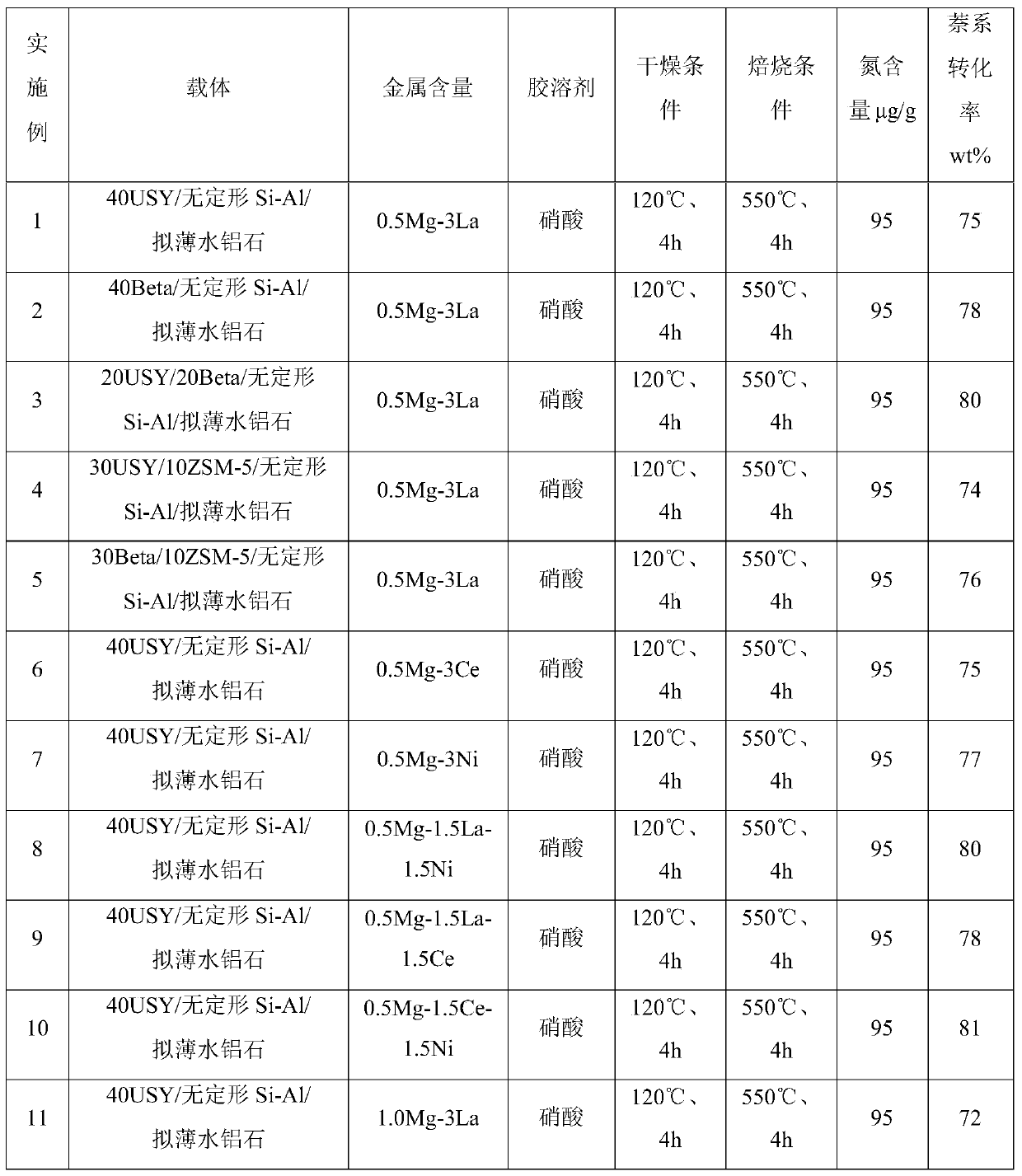

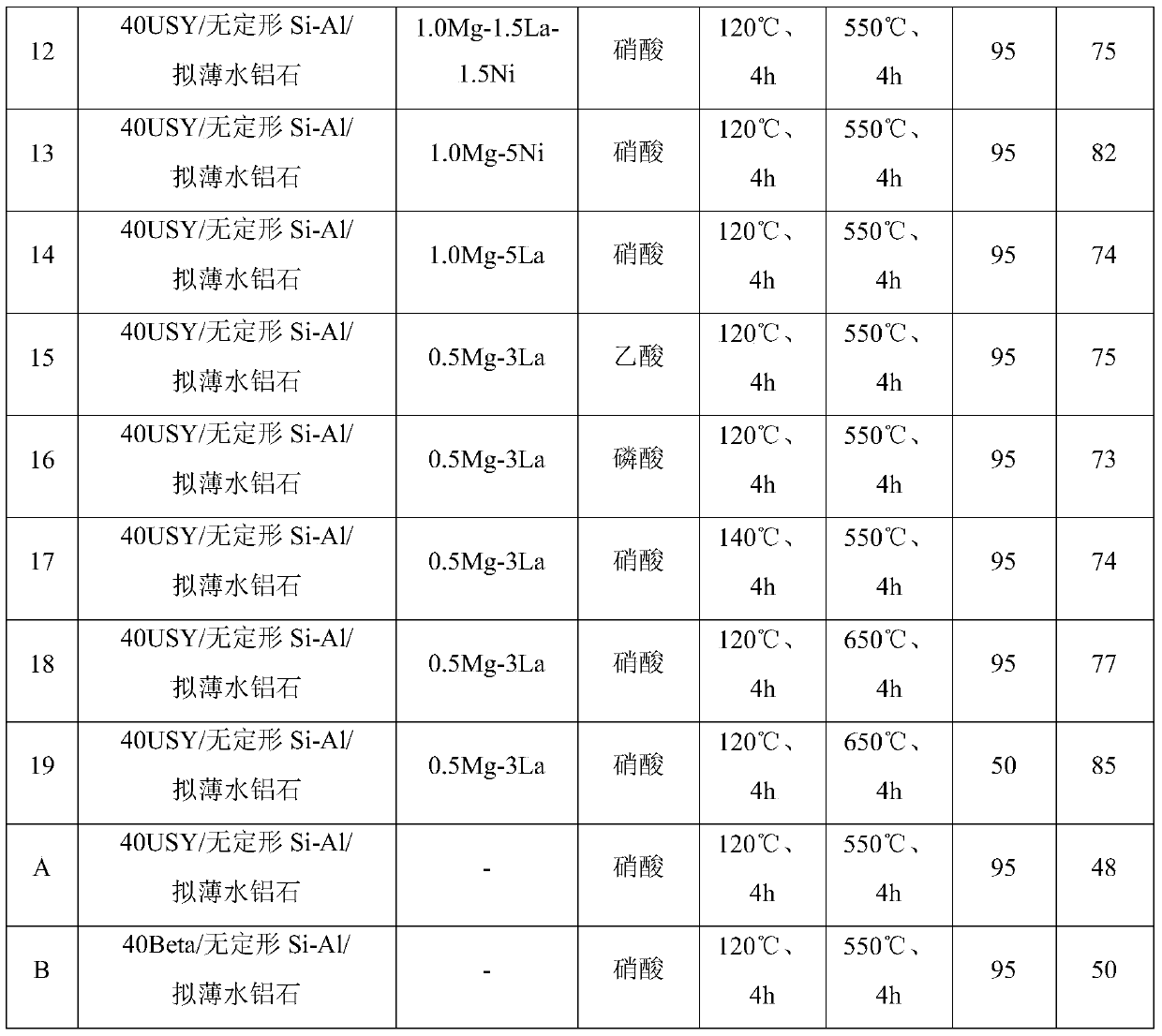

High nitrogen resistance hydrocracking catalyst carrier and preparation method thereof

ActiveCN106582889BObvious advantagesHigh cracking activityCatalyst carriersMolecular sieve catalystsGramNitrogen

The invention relates to a high nitrogen-tolerance hydrocracking catalyst carrier and a preparing method thereof, and mainly aims to solve the problem that a traditional hydrocracking catalyst is poor in nitrogen tolerance. According to the technical scheme, the hydrocracking catalyst carrier is composed of, by weight, 20-40% of at least one of FAU, BEA or MFI type zeolite, 15-36% of amorphous silicon-alumina, 10-20% of pseudo-boehmite, 0.5-3% of metal Mg, and 1-5% of at least one of metal La, Ce, or Ni. In this way, the problem is well solved. The prepared high nitrogen-tolerance hydrocracking catalyst carrier according to the preparing method is applicable to a process of hydrocracking of distillate with nitrogen content lower than 100 microgram / gram, and is high is cracking activity and nitrogen-tolerance property.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of preparation method of single stage hydrocracking catalyst

ActiveCN107303493BImprove nitrogen resistanceHigh activityMolecular sieve catalystsHydrocarbon oil crackingMolecular sievePtru catalyst

The invention discloses a preparation method for a single segment hydro-cracking catalyst. The method comprises the following steps: 1) uniformly mixing modified Y molecular sieve, amorphous form aluminum silicon and / or aluminum oxide, adding dilute nitric acid, pulping and then extruding a strip and forming, drying and roasting, thereby acquiring an aluminum silicon carrier containing the modified Y molecular sieve, wherein the mass percent of the modified Y molecular sieve in the aluminum silicon carrier is 1%-13%, preferably, 2%-10%, and the balance is amorphous form aluminum silicon and / or aluminum oxide; 2) adopting a steeping liquor containing active metal for steeping the carrier acquired in the step (1), drying and roasting the steeped carrier, thereby acquiring the hydro-cracking catalyst. The single segment hydro-cracking catalyst prepared according to the method disclosed by the invention has excellent reaction activity and nitrogen resistance in a single segment hydro-cracking process.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of preparation method of hydrocracking catalyst

ActiveCN106669784BIncrease profitHigh nitrogen contentMolecular sieve catalystsCarboxylic acidSlurry

The invention discloses a preparation method of a hydrocracking catalyst. The method comprises the following steps: forming a magnesium / aluminum / silicon-containing acidic solution and a tungsten-containing alkaline solution into mixed slurry; forming a nickel-containing acidic solution and a tungsten-containing alkaline solution into another mixed slurry; mixing the above two kinds of slurry, regulating the pH value, aging, adding mixed and ground Y molecular sieves and high-molecular polyethyleneglycol into the slurry, filtering, and drying; shaping, and drying to a specific degree; and spraying and soaking with a mixed solution of acetic acid and polybasic carboxylic acid, drying, and roasting to obtain the hydrocracking catalyst. The improvement of the hydrogenation activity of the catalyst effectively matches with the acidic function, and the nitrogen tolerance of the catalyst is improved, so that the catalyst has favorable hydrocracking activity and good performance of postponing carbon deposit generation even under the condition of high nitrogen content of a reaction product.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com