High nitrogen resistance hydrocracking catalyst carrier and preparation method thereof

A catalyst carrier and hydrocracking technology, which is applied in the direction of catalyst carrier, physical/chemical process catalyst, molecular sieve catalyst, etc., can solve the problems of poor nitrogen resistance performance, improve nitrogen resistance ability, high cracking activity, and improve anti-sintering ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

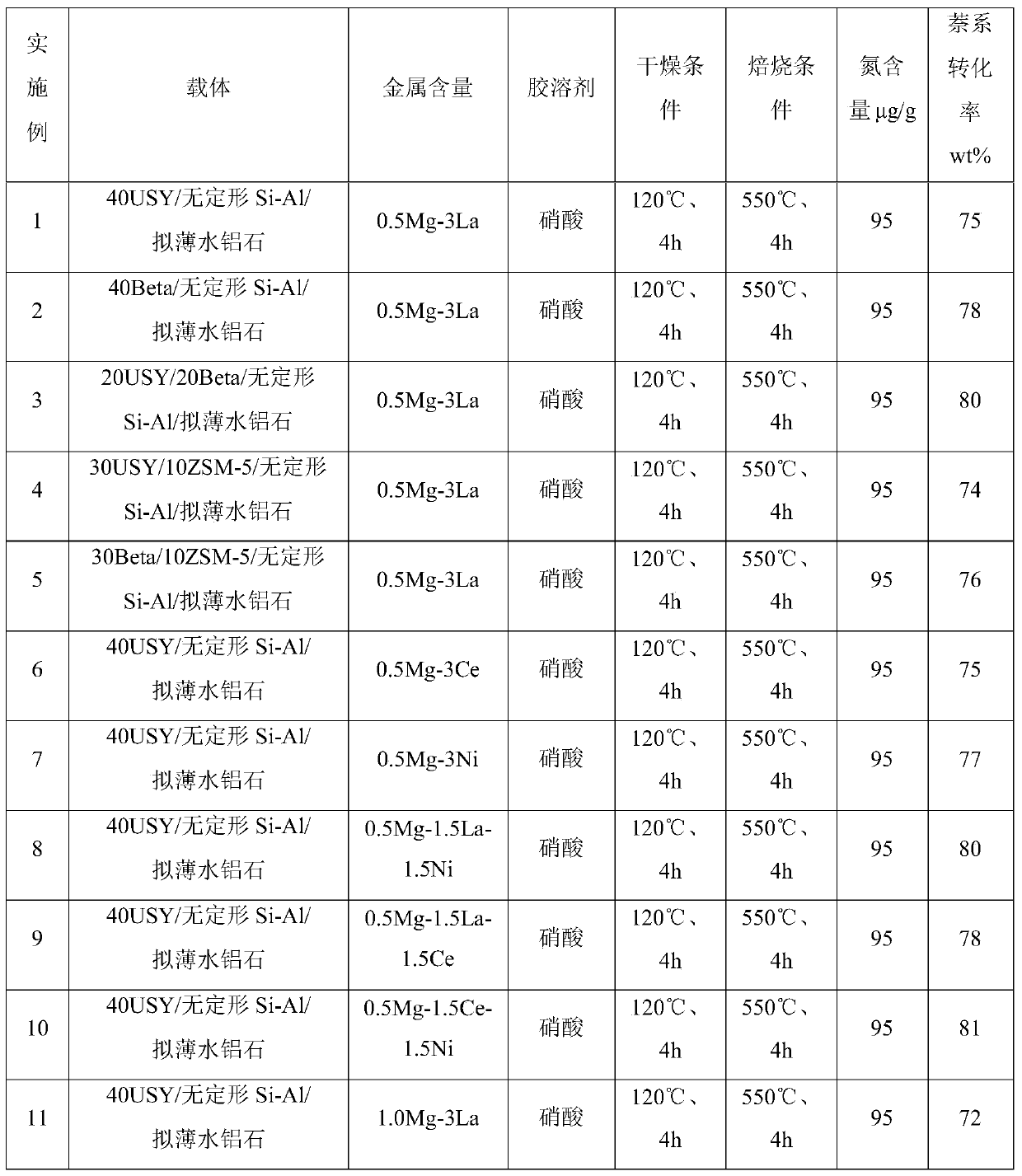

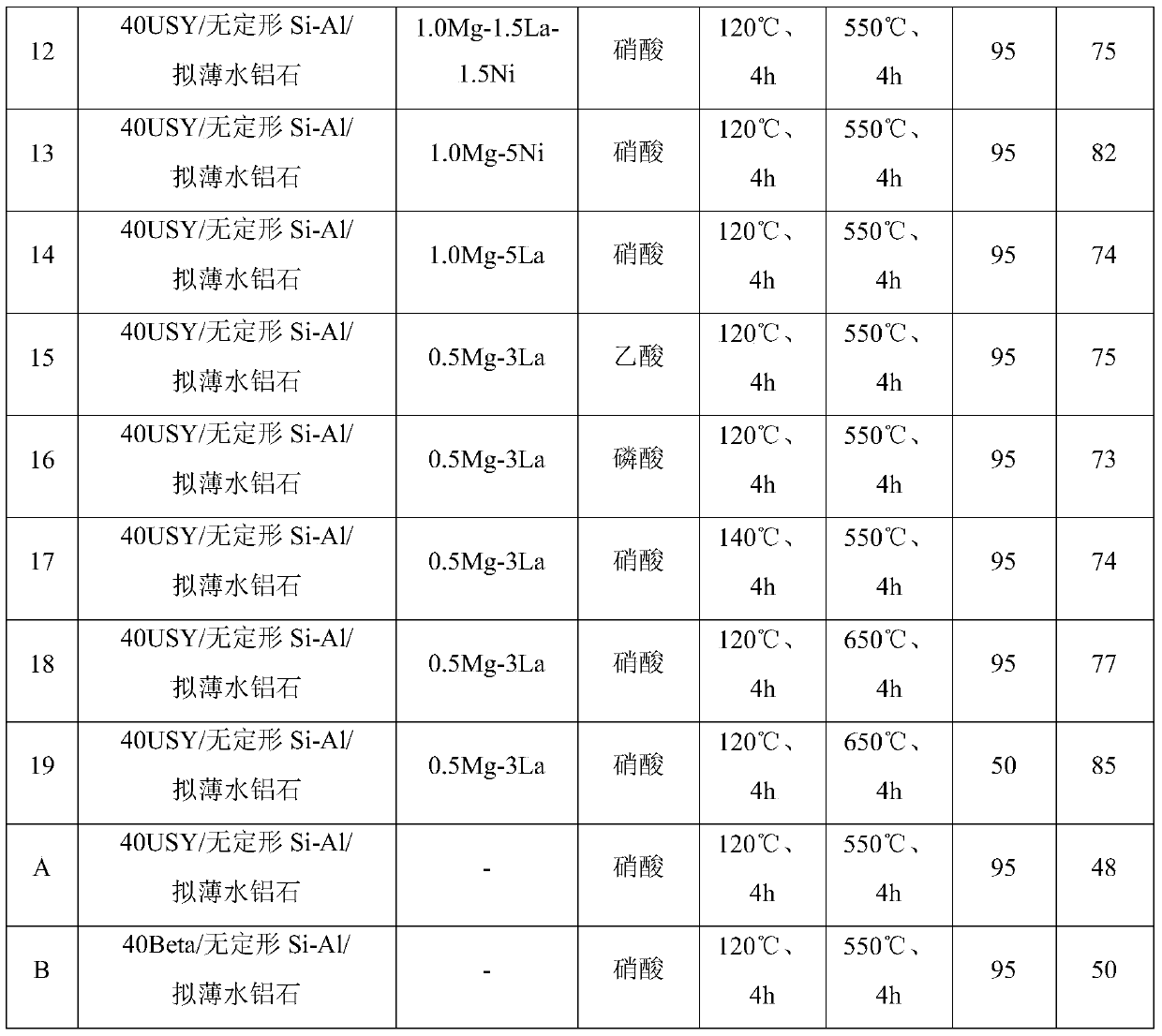

Examples

Embodiment 1

[0029] The USY zeolite (purchased from Zibo, Shandong), 40g of amorphous silica-alumina (purchased from Zibo, Shandong) and 20g pseudo-boehmite (purchased from Zibo, Shandong) that are 15 on a dry basis are added to the mixer until uniform, Then add 3g scallop powder, 5g volume ratio 1:1HNO to the mixture 3 solution and 50g of magnesium acetate and lanthanum nitrate mixed solution (containing Mg 0.5g, La 3g), kneading into a dough suitable for extrusion. It was extruded through a die, and the shape was a slender cylinder (diameter 1.7 mm). It was dried at 120°C for 4 hours and then baked at 550°C for 4 hours. Then it was cut into carrier particles of uniform size (1.7×4.0mm) for use.

[0030] The support was impregnated with 3% NiO and 15% MoO by conventional method 3 After sulfide reduction, it is used to investigate the cracking reaction performance. The reaction raw material is 70% toluene + 20% naphthalene + 10% methylnaphthalene, mixed with 95μg / g tert-butylamine, the re...

Embodiment 2

[0032] Beta zeolite (purchased from Zibo, Shandong), 40g amorphous silica-alumina (purchased from Zibo, Shandong) and 20g pseudo-boehmite (purchased from Zibo, Shandong) on a dry basis are added to the mixer until uniform, Then add 3g scallop powder, 5g volume ratio 1:1HNO to the mixture 3 Solution and the mixed solution (containing Mg 0.5g, La3g) of 50g magnesium acetate and lanthanum nitrate, knead into the dough suitable for extruding. It was extruded through a die, and the shape was a slender cylinder (diameter 1.7 mm). It was dried at 120°C for 4 hours and then baked at 550°C for 4 hours. Then it was cut into carrier particles of uniform size (1.7×4.0mm) for use.

[0033] The support was impregnated with 3% NiO and 15% MoO by conventional method 3 After sulfide reduction, it is used to investigate the cracking reaction performance. The reaction raw material is 70% toluene + 20% naphthalene + 10% methylnaphthalene, mixed with 95μg / g tert-butylamine, the reaction tempera...

Embodiment 3

[0035] The dry basis is 20g USY zeolite (purchased from Shandong Zibo) that silicon-aluminum ratio is 15, 20g Beta zeolite (purchased from Shandong Zibo) that silicon-alumina ratio is 15, 40g amorphous silica-alumina (purchased from Shandong Zibo) and 20g Boehmite (purchased from Zibo, Shandong) was added to the mixer until uniform, and then 3g of celadon powder, 5g of HNO in a volume ratio of 1:1 were added to the mixture 3 solution and 50g of magnesium acetate and lanthanum nitrate mixed solution (containing Mg 0.5g, La 3g), kneading into a dough suitable for extrusion. It was extruded through a die, and the shape was a slender cylinder (diameter 1.7 mm). It was dried at 120°C for 4 hours and then baked at 550°C for 4 hours. Then it was cut into carrier particles of uniform size (1.7×4.0mm) for use.

[0036] The support was impregnated with 3% NiO and 15% MoO by conventional method 3 After sulfide reduction, it is used to investigate the cracking reaction performance. The r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com