Medium oil type hydrocracking catalyst and its preparation method

A hydrocracking and catalyst technology, which is applied to physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc. The problem of unfavorable adjustment of the properties of silicon and aluminum, to achieve the effect of good nitrogen resistance, easy load bearing, and large pore volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

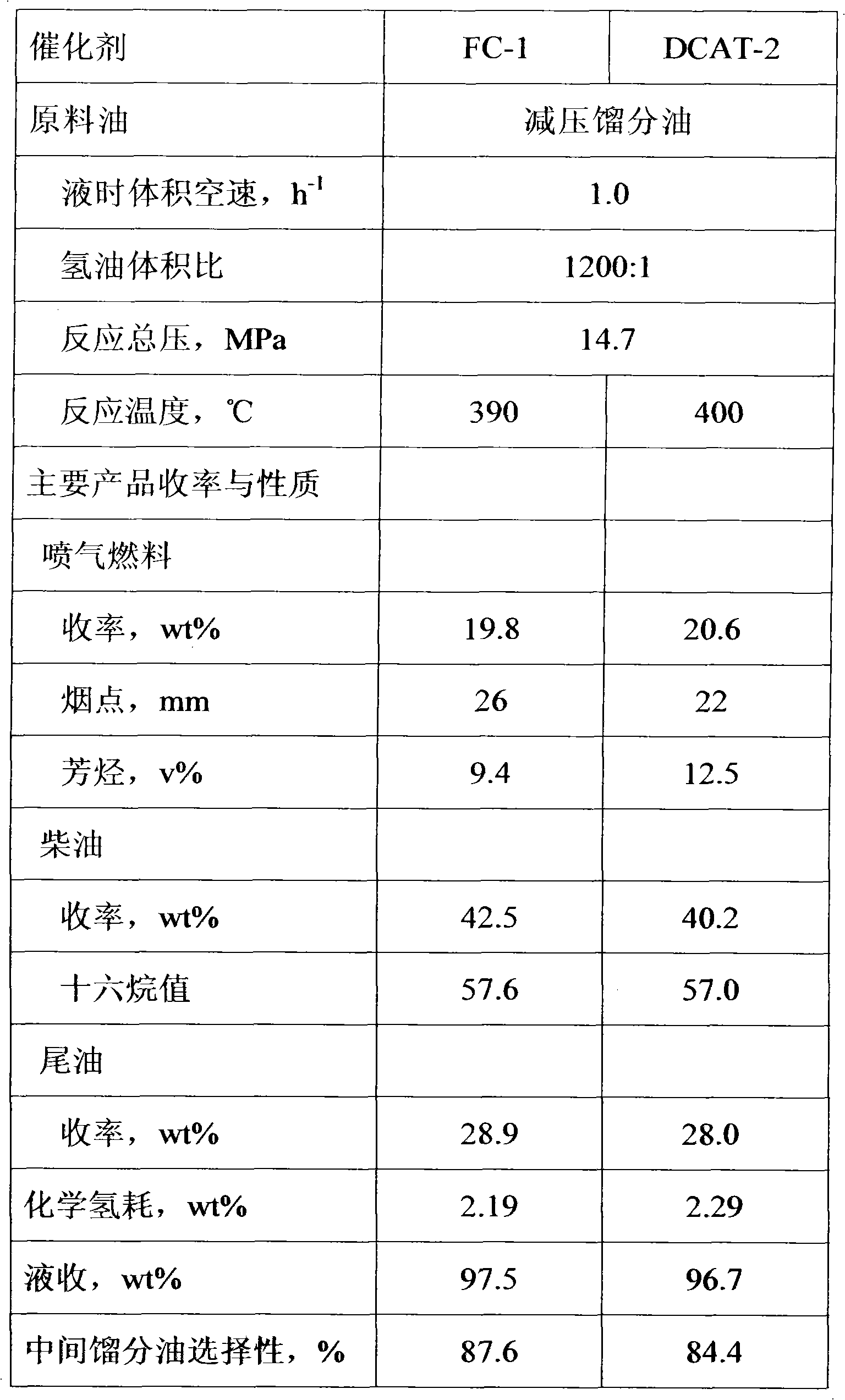

Examples

preparation example Construction

[0027] The preparation method of catalyst of the present invention is as follows:

[0028] (1) Hydrothermal treatment of amorphous silica-alumina dry rubber powder

[0029] The physical and chemical properties of the amorphous silica-alumina powder used in the hydrocracking catalyst of the present invention before hydrothermal treatment (i.e. amorphous silica-alumina dry rubber powder) are: the weight dry basis is 50% to 80%, and the specific surface area is 300 to 600m 2 / g, the pore volume is 0.4~1.2cm 3 / g. The amount of infrared acid (determined by pyridine infrared adsorption spectrometry) is between 0.4 and 1.5 mmol / g.

[0030] The amorphous silica-alumina dry rubber powder of the present invention is subjected to hydrothermal treatment with saturated water vapor, the treatment pressure is 0.05-0.3 MPa, the treatment temperature is 450-750° C., and the treatment time is 0.5-5 hours.

[0031] The properties of amorphous silicon-alumina after hydrothermal treatment are:...

Embodiment 1

[0041] Get amorphous silica-alumina dry rubber powder 1000g (commercially available commodity, dry basis is 70.13%, specific surface area is 458m 2 / g, the pore volume is 0.75cm 3 / g, the silicon oxide weight content is 45%, the infrared acid content is 1.0mmol / g), the hydrothermal treatment temperature is 500°C, the treatment pressure is 0.2MPa, and the treatment time is 2h. The obtained code is GL-1, and the properties of the product are shown in Table 1.

Embodiment 2

[0043] Take 1000 g of amorphous silica-alumina dry rubber powder (same as in Example 1), the hydrothermal treatment temperature is 600° C., the treatment pressure is 0.2 MPa, and the treatment time is 2 hours. The obtained code is GL-2, and the properties of the product are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com