Supported polyethylene catalyst ingredient and preparation method thereof, and supported polyethylene catalyst and application thereof

A catalyst and polyethylene technology, applied in the production of bulk chemicals, etc., can solve the problems of low catalytic efficiency and achieve the effects of high catalytic efficiency, narrow distribution, and large pore volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

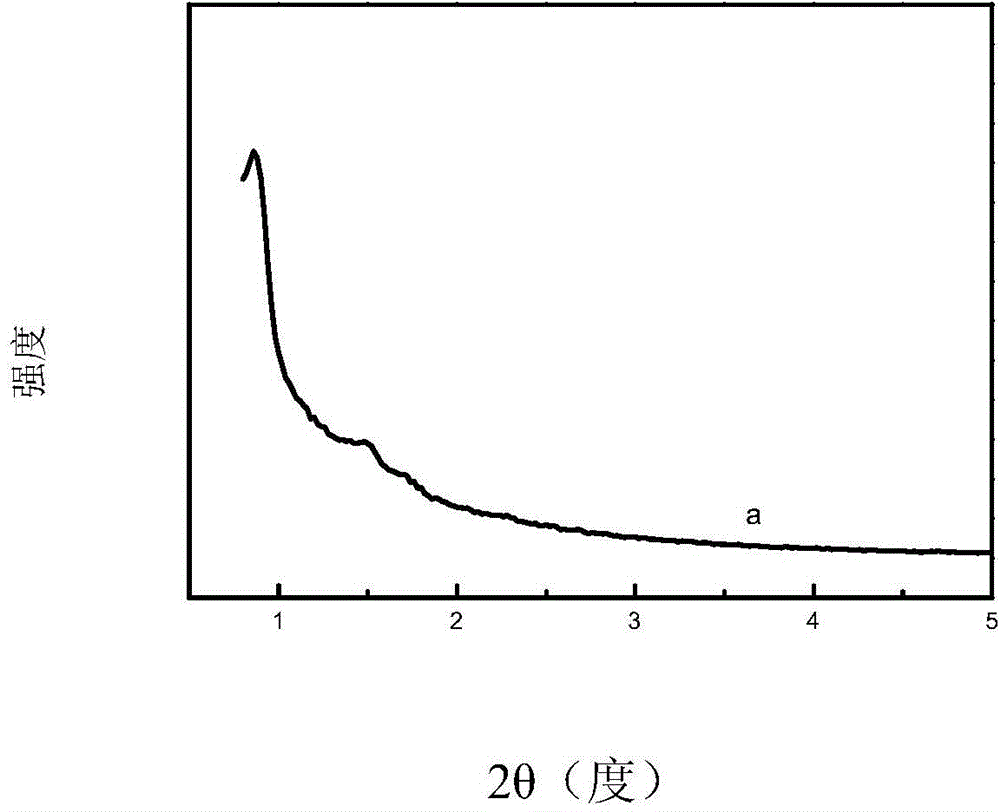

[0057] In step (1), "providing a mesoporous molecular sieve material with a one-dimensional hexagonal pore distribution structure" can be directly weighing or selecting a product of a mesoporous molecular sieve material with a one-dimensional hexagonal pore distribution structure, or preparing a product with a one-dimensional hexagonal pore distribution structure. Mesoporous molecular sieve materials with hexagonal channel distribution structure. The preparation method of the mesoporous molecular sieve material with a one-dimensional hexagonal pore distribution structure can be implemented according to conventional methods, for example, the preparation method can include: preparing the filter material of the mesoporous molecular sieve material with a one-dimensional hexagonal pore distribution structure according to the above method Cake, then the resulting filter cake is dried, and the templating agent in the product obtained after drying is removed. The conditions for removi...

Embodiment 1

[0090] This example is used to illustrate the supported polyethylene catalyst component of the present invention and its preparation method.

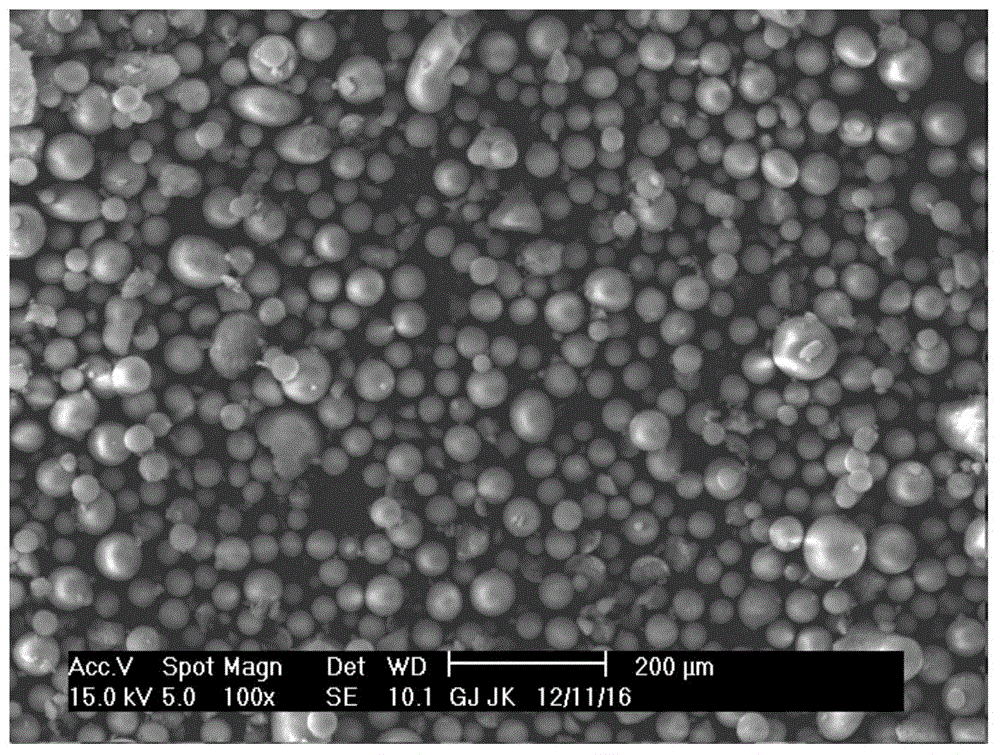

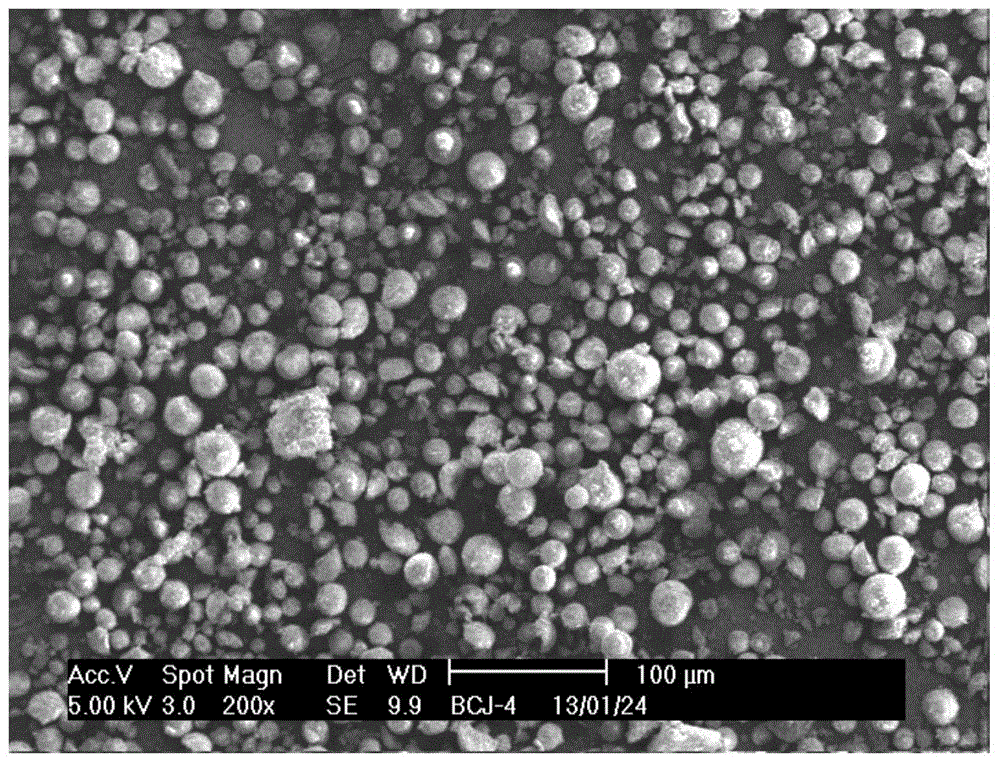

[0091] (1) Preparation of spherical composite carrier

[0092] Add 1.0g (0.0002mol) triblock copolymer surfactant P123 and 2.76g (0.06mol) ethanol to 28ml buffer solution of acetic acid and sodium acetate with a pH value of 4, and stir at 15°C until P123 is completely Dissolve, then add 6g (0.053mol) trimethylpentane to the resulting solution, stir at 15°C for 8h, then add 2.13g (0.014mol) tetramethoxysilane, at 15°C, pH value Stir for 20h under the conditions of 4.5, then transfer the resulting solution to a polytetrafluoroethylene-lined reactor, crystallize at 60°C for 24h, then filter and wash 4 times with deionized water, then suction filter to obtain Filter cake X1 of mesoporous molecular sieve material with one-dimensional hexagonal channel distribution structure;

[0093] Hexadecyltrimethylammonium bromide and tetraethyl orthos...

Embodiment 2

[0113] This example is used to illustrate the supported polyethylene catalyst component of the present invention and its preparation method.

[0114] (1) Preparation of spherical composite carrier

[0115] Add 1.0g (0.0002mol) triblock copolymer surfactant P123 and 1.84g (0.04mol) ethanol to 28ml buffer solution of acetic acid and sodium acetate with a pH value of 5, and stir at 15°C until P123 is completely Dissolve, then add 9.12g (0.08mol) trimethylpentane to the resulting solution, stir at 15°C for 8h, then add 3.04g (0.02mol) tetramethoxysilane, at 25°C, pH Stirred under the condition of 5.5 for 45h, then transferred the obtained solution to a polytetrafluoroethylene-lined reactor, crystallized at 100°C for 20h, then filtered and washed 4 times with deionized water, and then suction filtered to obtain Filter cake X2 of mesoporous molecular sieve material with one-dimensional hexagonal single-pore distribution structure.

[0116] Hexadecyltrimethylammonium bromide and te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com