Nitrogen-resisting hydrocracking catalyst and preparation method thereof

A hydrocracking and catalyst technology, applied in the direction of physical/chemical process catalysts, catalyst carriers, molecular sieve catalysts, etc., can solve the problems of low cracking activity, poor nitrogen tolerance, poor catalyst activity, etc., to improve liquid yield, increase The number of secondary holes, the effect of facilitating contact reaction and

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

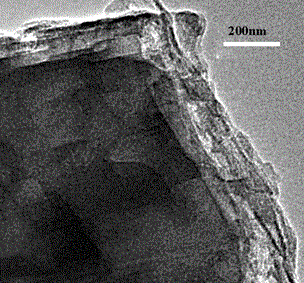

Image

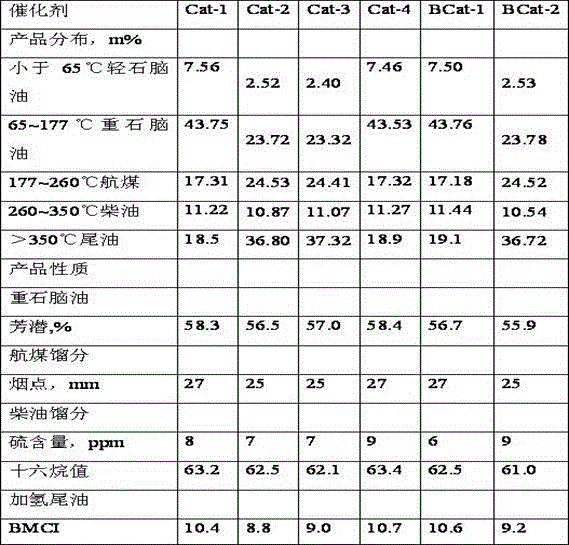

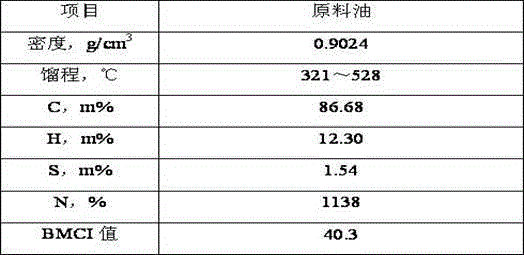

Examples

Embodiment 1

[0039] Molecular sieve modification process:

[0040] (1) Take 200g of NaY molecular sieve raw powder prepared in the laboratory, mix it with ammonium nitrate with a concentration of 0.5mol / L according to the liquid-solid ratio of 3:1, exchange at 70°C for 3 hours, repeat this process 3 times, and the exchanged Y molecular sieve Na content in Na 2 O is calculated as 2.5%;

[0041] (2) Hydrothermally treat the Y molecular sieve obtained in step (1) at 540°C and 0.1Mpa for 2 hours;

[0042] (3) Molecular sieve obtained in step (2) according to liquid-solid ratio of 5:1 and 0.3mol / L citric acid solution (concentration in H + Total) 300ml mixed, then heated up to 40°C, and reacted at constant temperature for 2 hours;

[0043] (4) The molecular sieve obtained in step (3) was dried at 150°C for 8 hours;

[0044] (5) Take the molecular sieve obtained in step (4) and place it in a closed container filled with butene atmosphere, control the pressure of 0.3MPa and fully contact it f...

Embodiment 2

[0054] Molecular sieve modification process:

[0055] (1) Take the NaY molecular sieve raw powder prepared in the laboratory, mix it with ammonium nitrate with a concentration of 0.8mol / L according to the liquid-solid ratio of 3:1, exchange at 70°C for 3 hours, repeat this process 3 times, and the Y molecular sieve after exchange Na content in Na 2 O is calculated as 2.0%.

[0056] (2) Hydrothermally treat the Y molecular sieve obtained in step (1) at 560°C and 0.1Mpa for 2 hours;

[0057] (3) Step (2) sieve the citric acid solution (concentration in H + Total) 400ml mixed, then heated up to 50°C, and reacted at constant temperature for 2 hours;

[0058] (4) The molecular sieve obtained in step (3) was dried at 200°C for 4 hours;

[0059] (5) Soak the molecular sieve obtained in step (4) in heptene for 4 hours, and then heat at 200°C for 22 hours in an air atmosphere;

[0060] (6) The molecular sieve treated in step (5) is directly put into a muffle furnace heated to 500°...

Embodiment 3

[0069] Molecular sieve modification process:

[0070] (1) Take the original NaY molecular sieve powder prepared in the laboratory, mix it with ammonium nitrate with a concentration of 0.5mol / L according to the liquid-solid ratio of 5:1, exchange at 90°C for 1.5 hours, repeat this process twice, and the Y molecular sieve after exchange The Na content is 1.8% as Na2O.

[0071] (2) Hydrothermally treat the Y molecular sieve obtained in step (1) at 550°C and 0.1Mpa for 2 hours;

[0072] (3) Step (2) sieve the citric acid solution (concentration in H + Total) 400ml mixed, then heated up to 60°C, and reacted at constant temperature for 2 hours;

[0073] (4) The molecular sieve obtained in step (3) was dried at 250°C for 2 hours;

[0074] (5) Soak the molecular sieve obtained in step (4) in heptene for 4 hours, and then heat at 200°C for 10 hours in an air atmosphere;

[0075] (6) The molecular sieve treated in step (5) is directly put into a muffle furnace heated to 500°C in adv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com