Patents

Literature

38results about How to "High hydrocracking activity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrocracking catalyst with high activity and high-medium oil selectivity and preparation method of hydrocracking catalyst

ActiveCN102441411AHigh crystallinityLow cell parametersMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveNitrogen

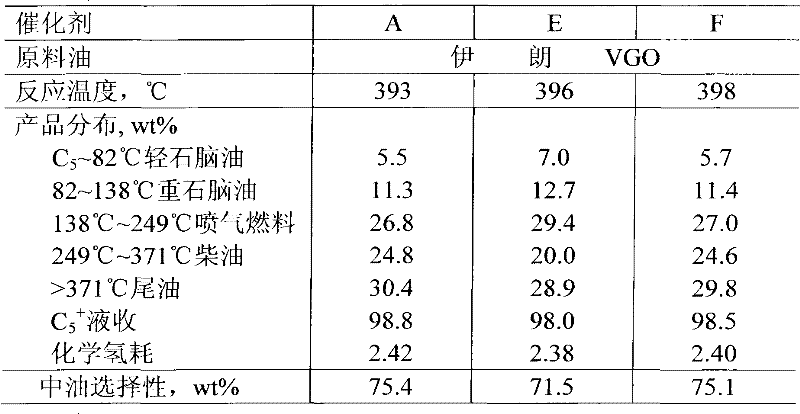

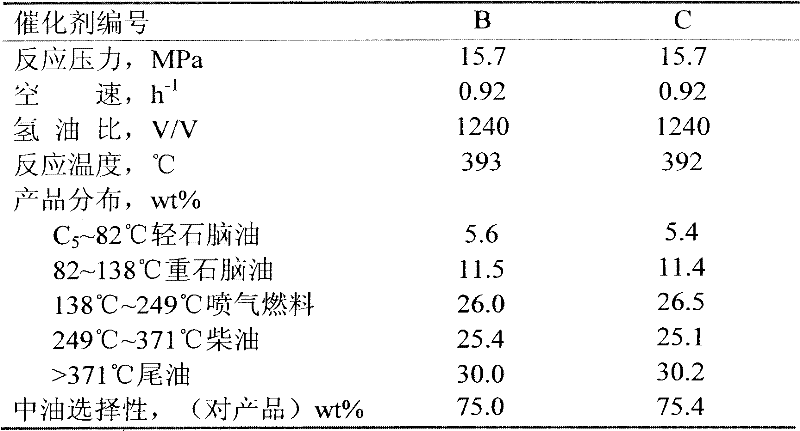

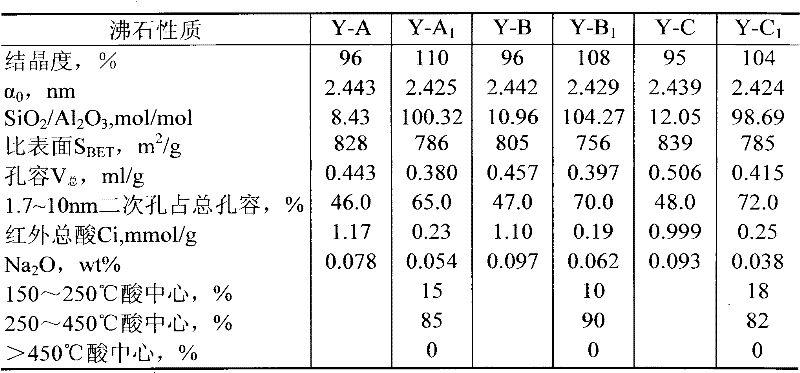

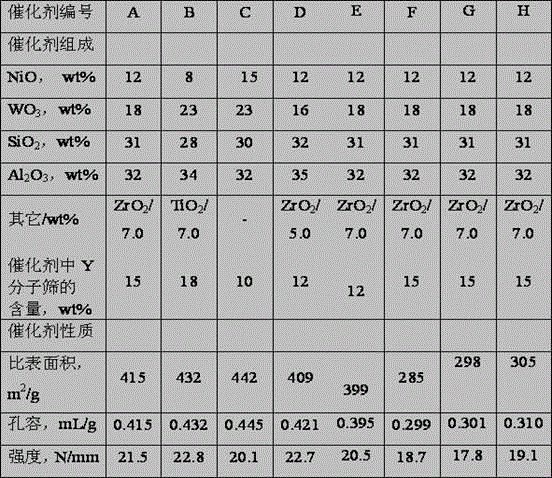

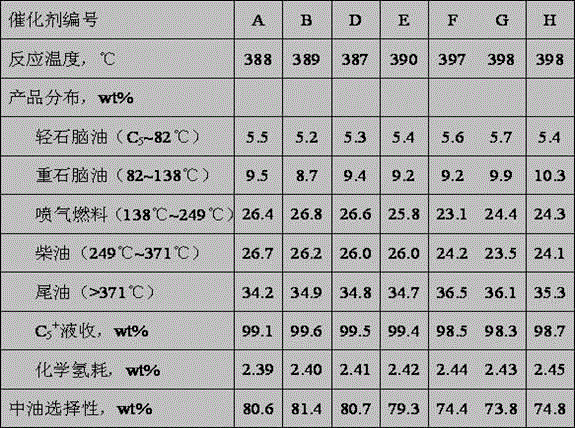

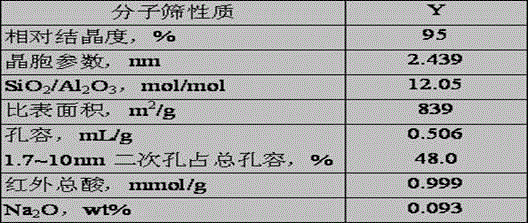

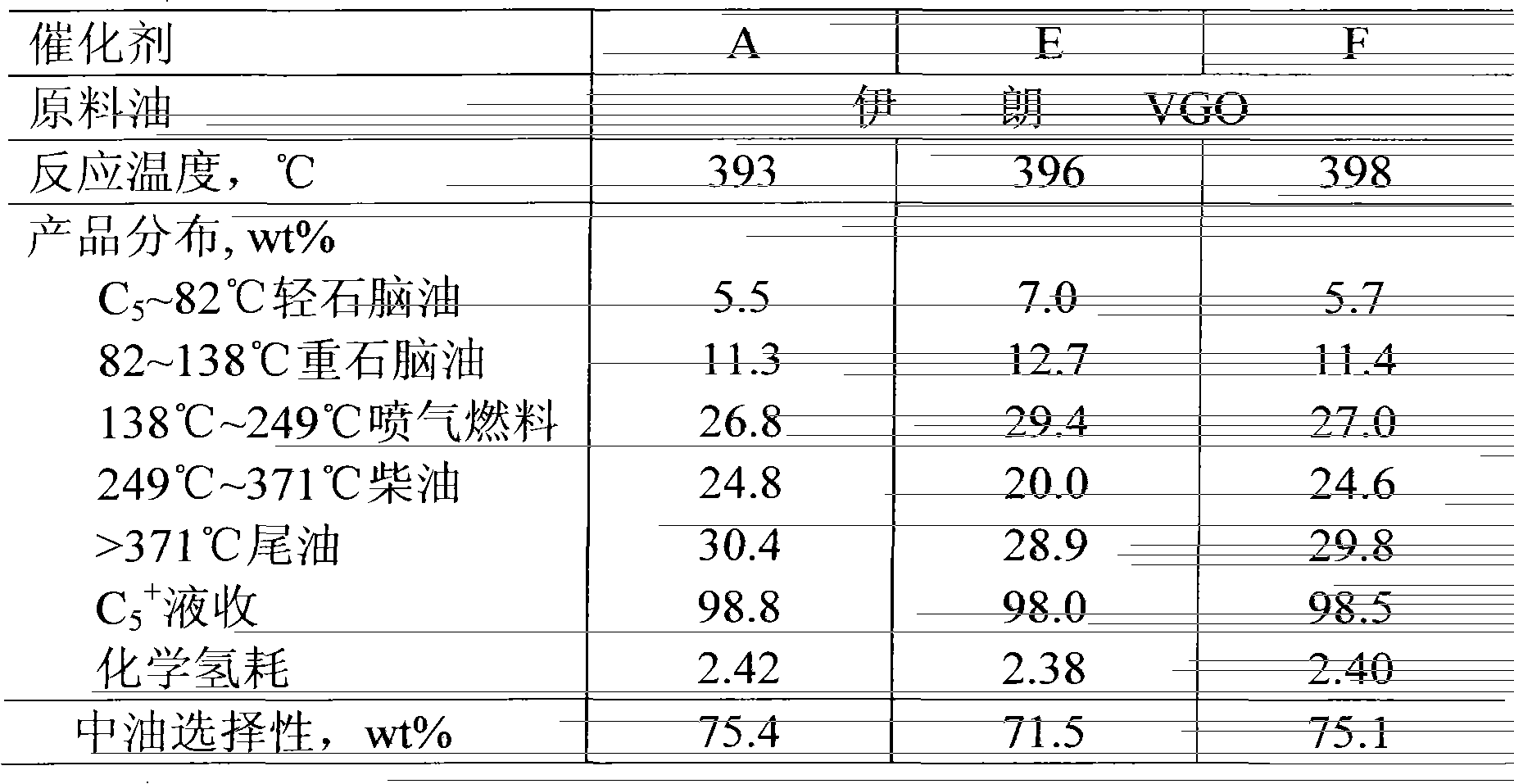

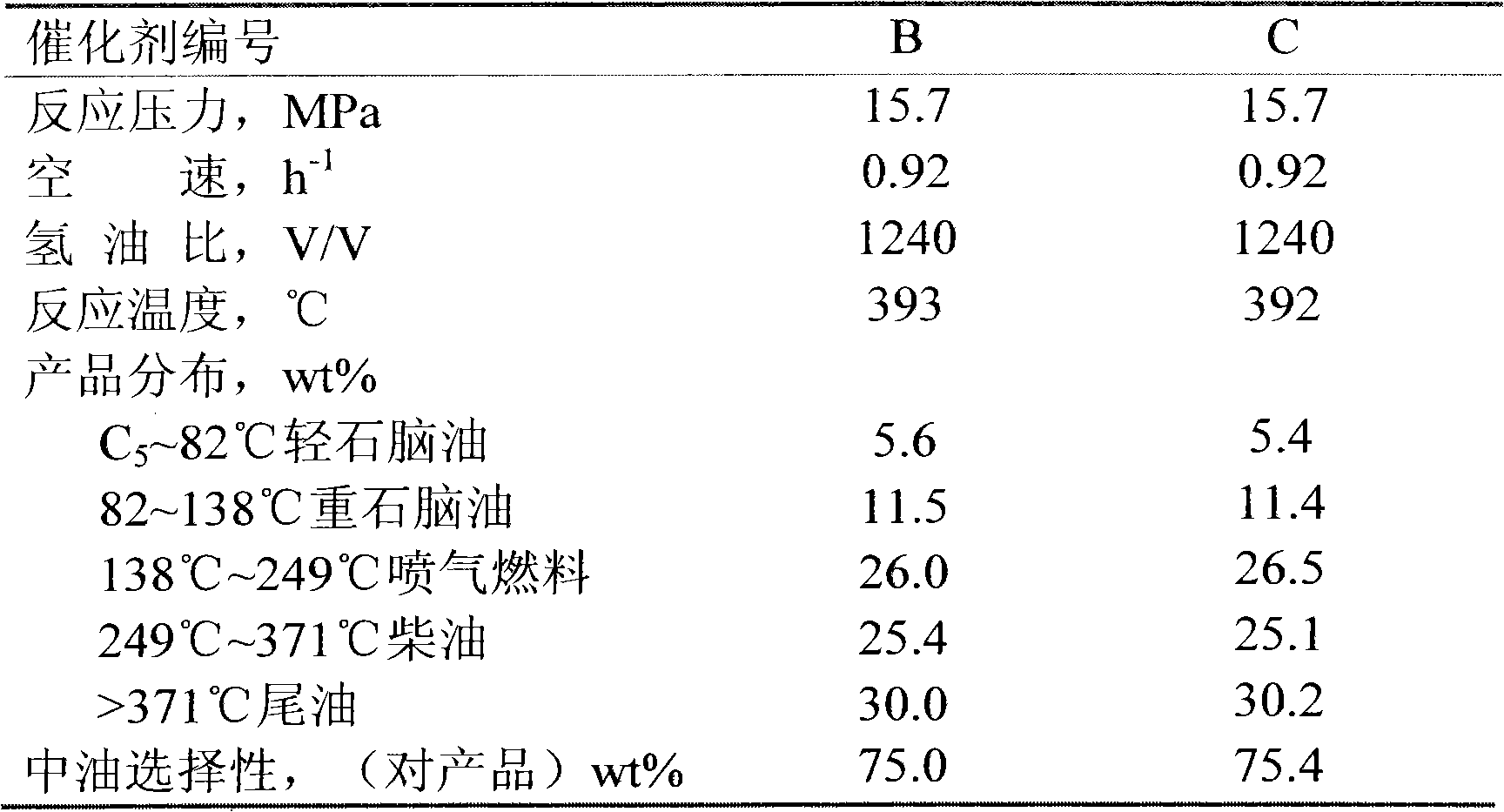

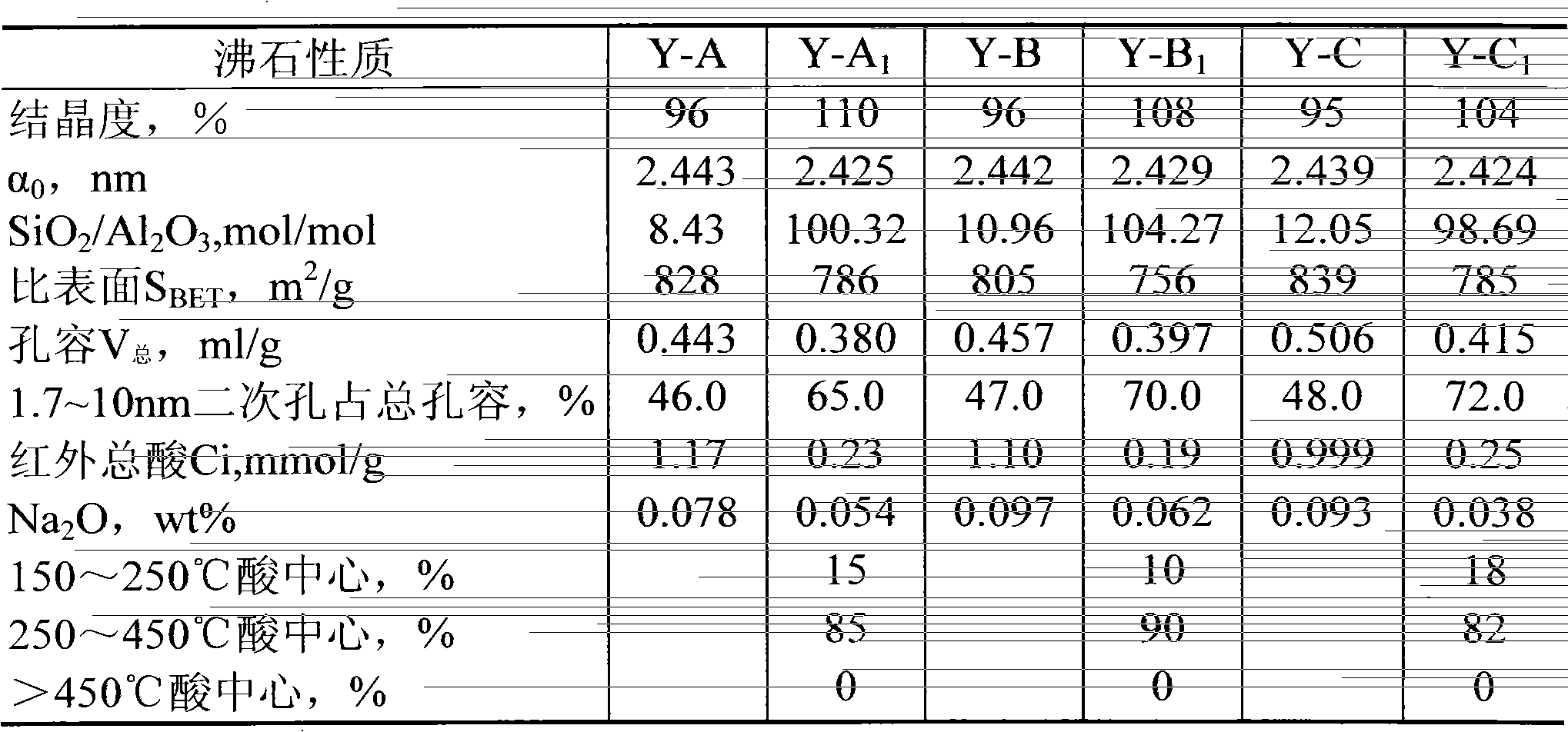

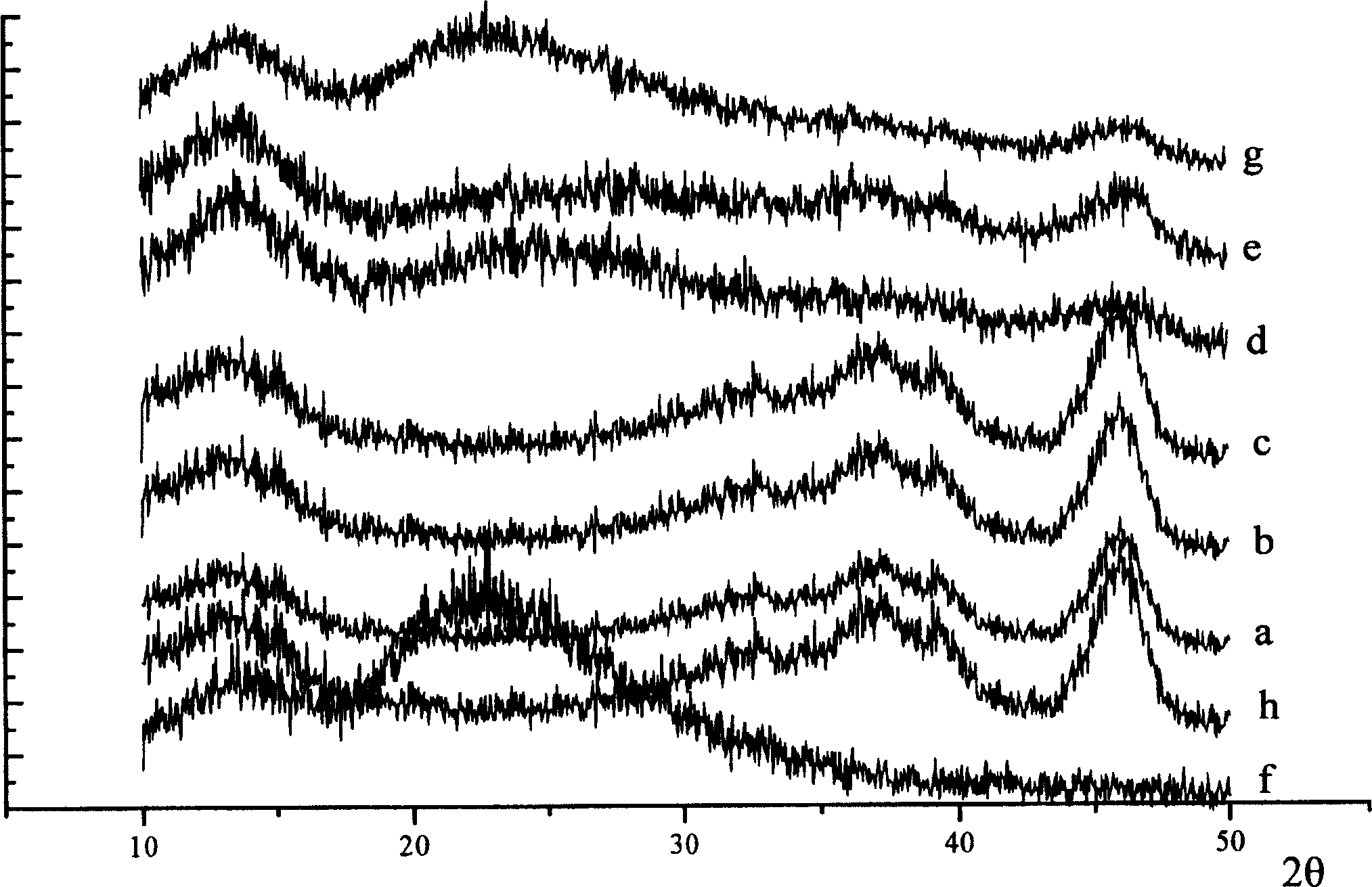

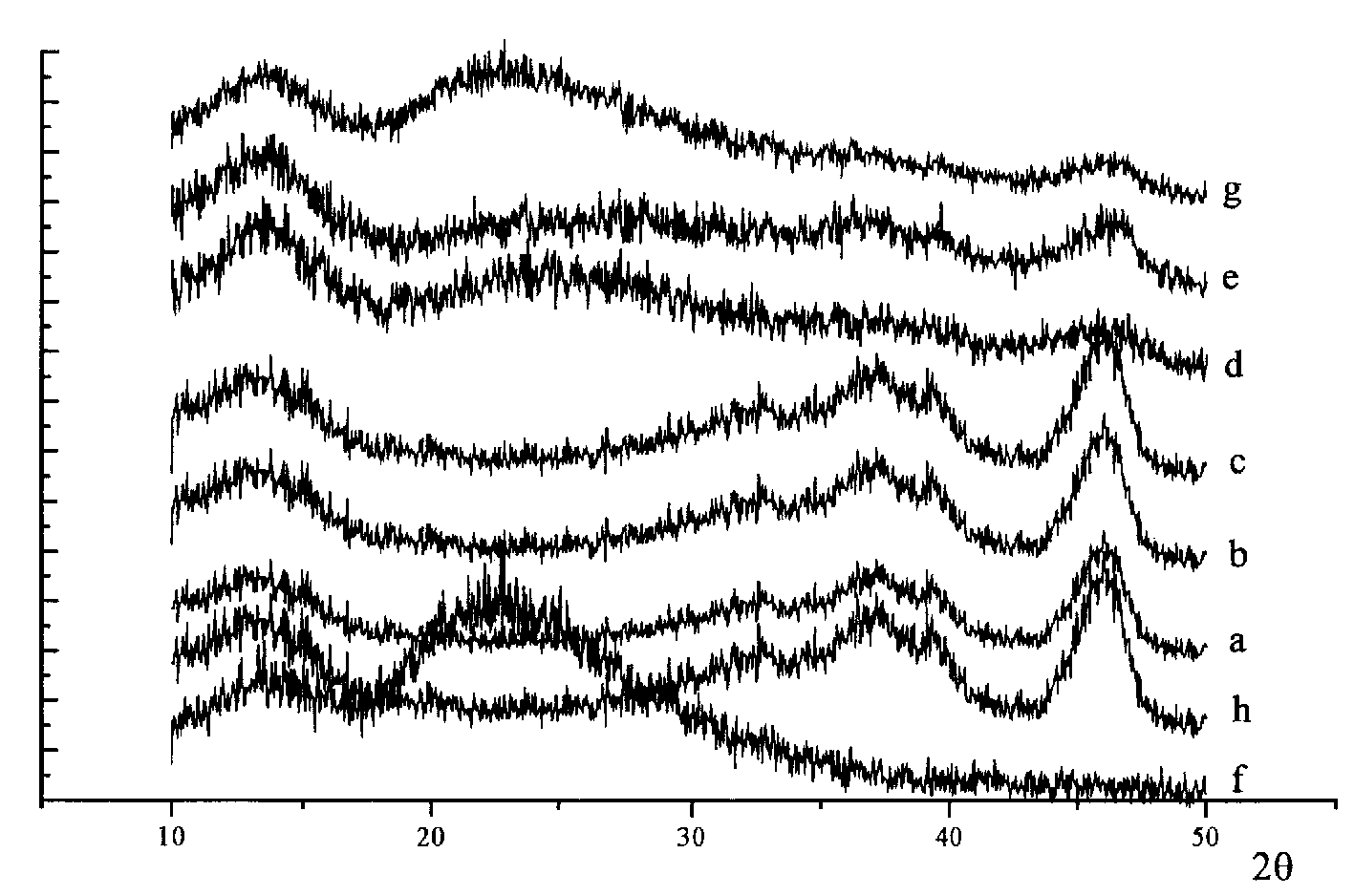

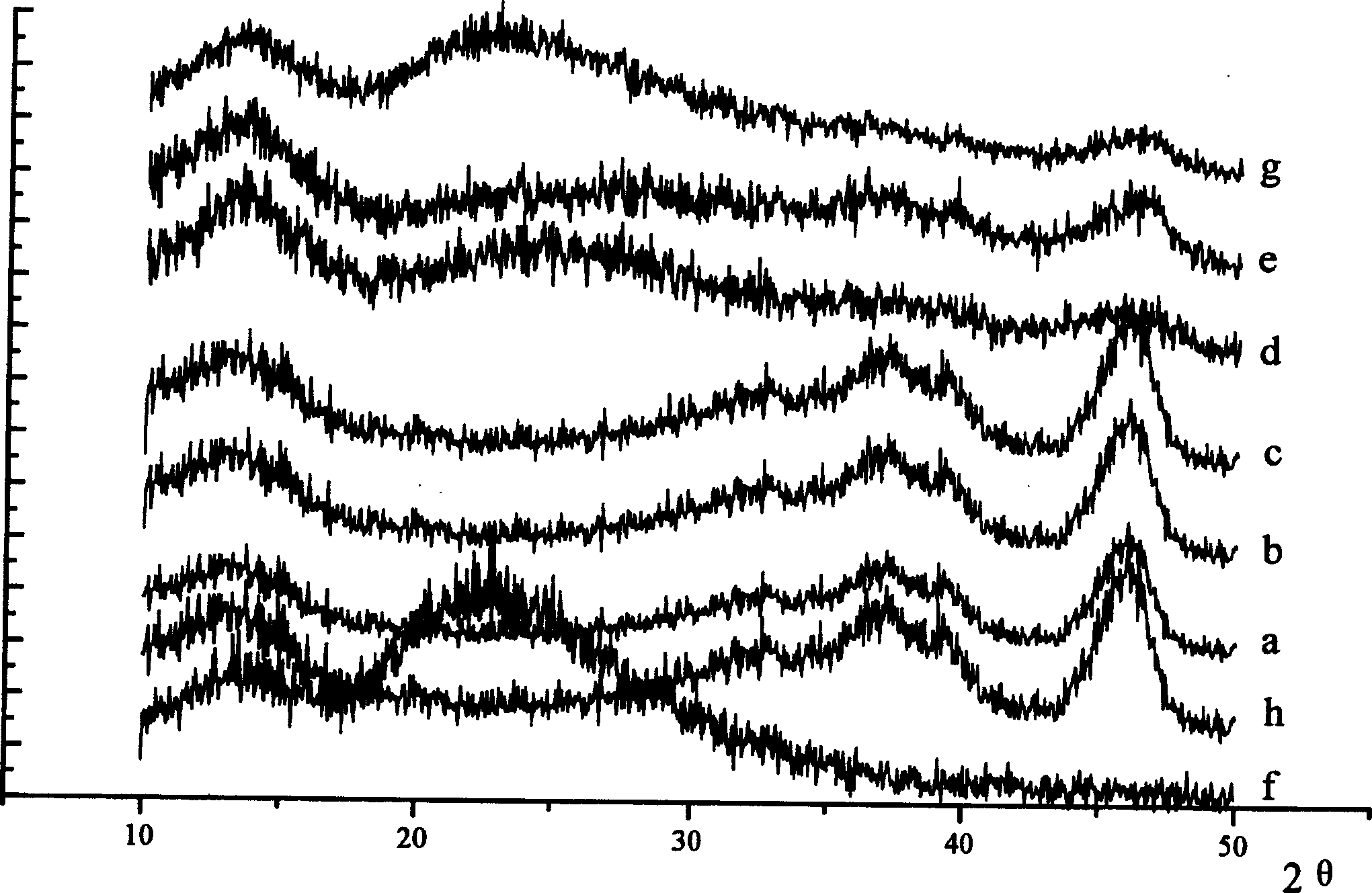

The invention relates to a hydrocracking catalyst with high activity and high-medium oil selectivity. According to the hydrocracking catalyst, amorphous silicon aluminum is used as a carrier, and a specially-modified Y-type molecular sieve is used as acid component, the molecular sieve has high degree of crystallization and low cell parameters, rich secondary holes, large surface area, less uniformly-distributed acid sites, no strong acid center, and most of medium-strength acid centers, and also has strong nitrogen-resisting performance and better damage capacity; and the hydrocracking catalyst using the molecular sieve has high hydrocracking activity and high middle oil selectivity, and stronger nitrogen resisting capacity. The catalyst provided by the invention is used in the process of producing an intermediate distillate product by adopting a heavy hydrocarbon single-section or one-section hydrocracking process, and has better activity and middle oil selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

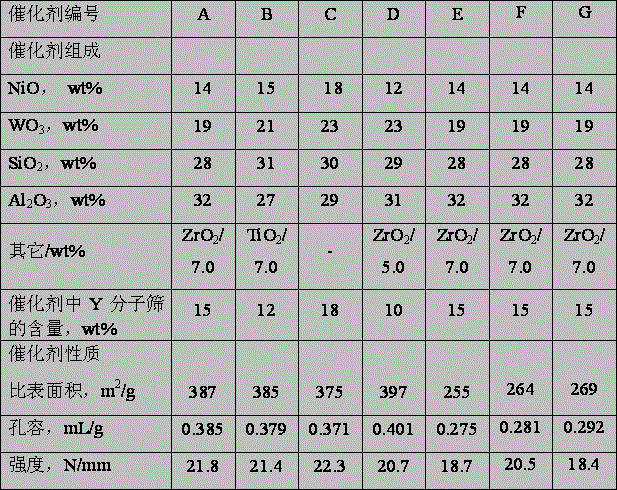

Preparation method of hydrocracking catalyst

ActiveCN103055923AUnlimited capacityGood dispersionMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveDispersity

The invention discloses a preparation method of a hydrocracking catalyst. The method comprises the steps of preparing an acidic mixed solution A containing hydrogenation reactive metals and silicon, preparing a sodium metaaluminate alkaline solution B, and then adding the acidic mixed solution A, the alkaline solution B and CO2 to a reaction tank filled with clear water in parallel to prepare gel; and then adding turbid liquid of a Y type molecular sieve, mixing the substances uniformly, filtering, drying and forming the mixture, and then washing, drying and roasting the product, thus preparing the hydrocracking catalyst. The method has the beneficial effects that a clean preparation method is adopted, so not only can the catalyst be easily formed and the strength of the catalyst be improved, but also the pore volume and specific surface area of the catalyst can be increased and the dispersity of metals in the catalyst can be improved, thus the catalyst has higher hydrocracking activity, middle oil selectivity and stability; and the catalyst prepared by the method can be used for a single-section hydrocracking process of a non-refining section or a one-section serial hydrocracking process of a refining section.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking catalyst for hydrocarbon oil, method for producing hydrocracking catalyst, and method for hydrocracking hydrocarbon oil with hydrocracking catalyst

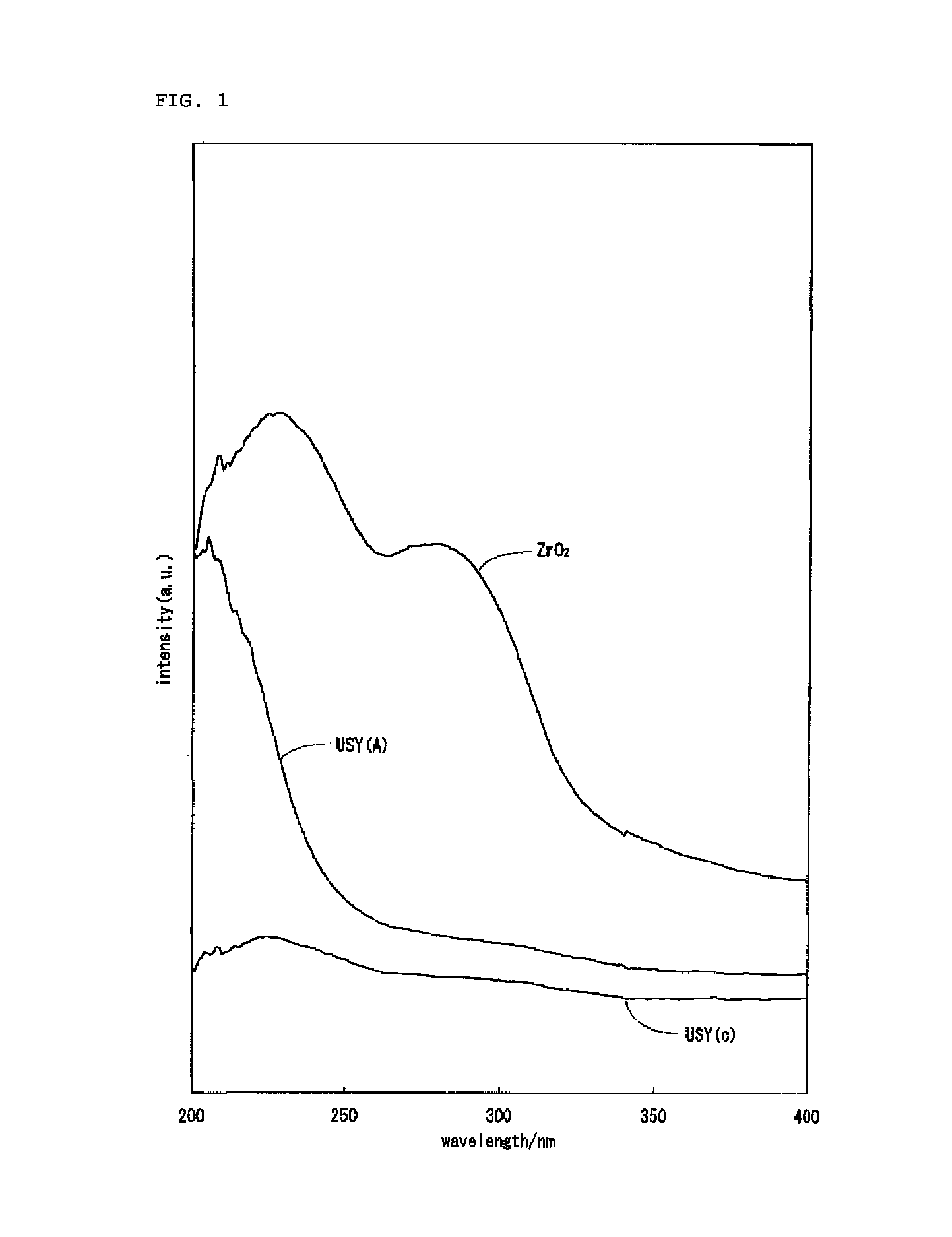

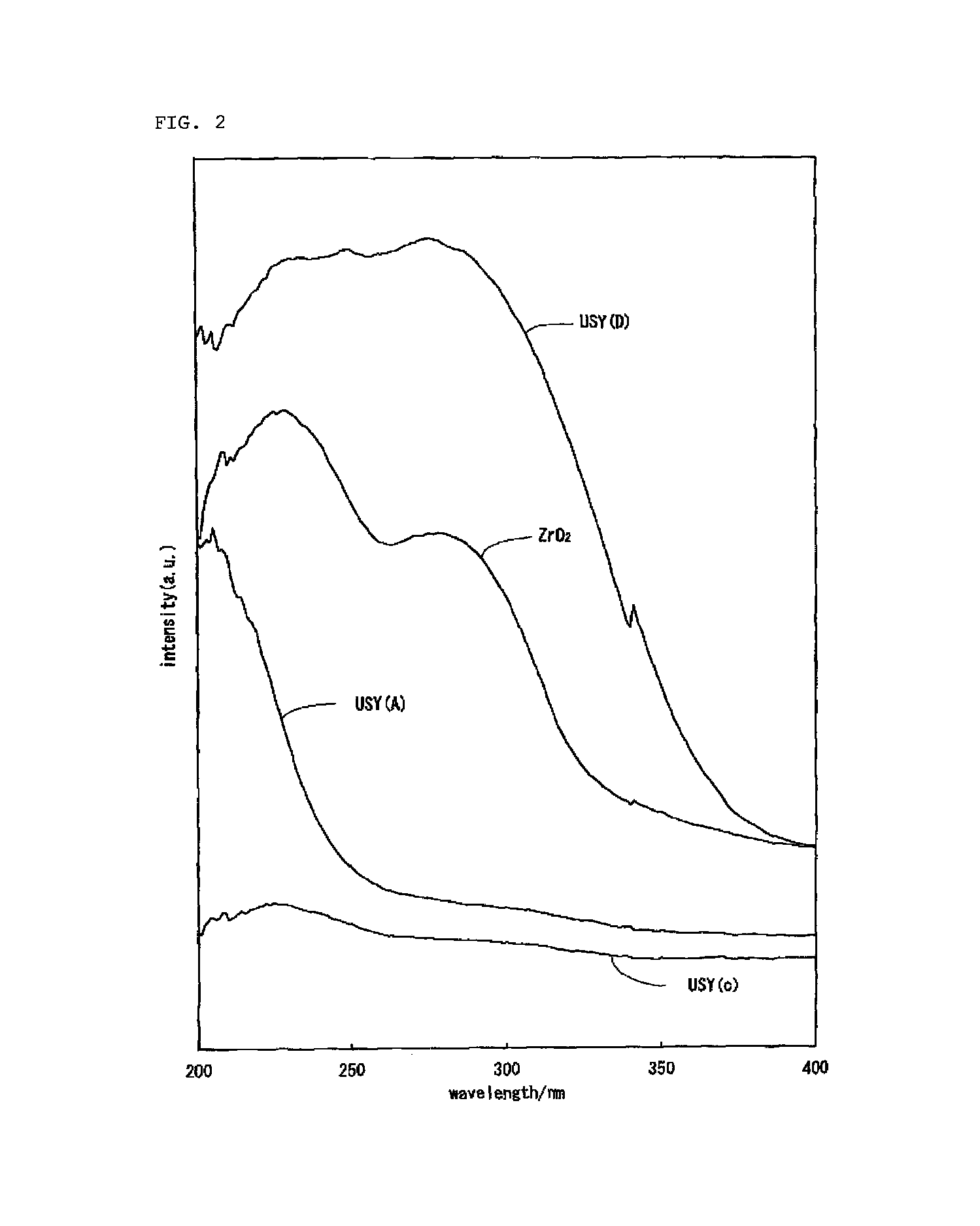

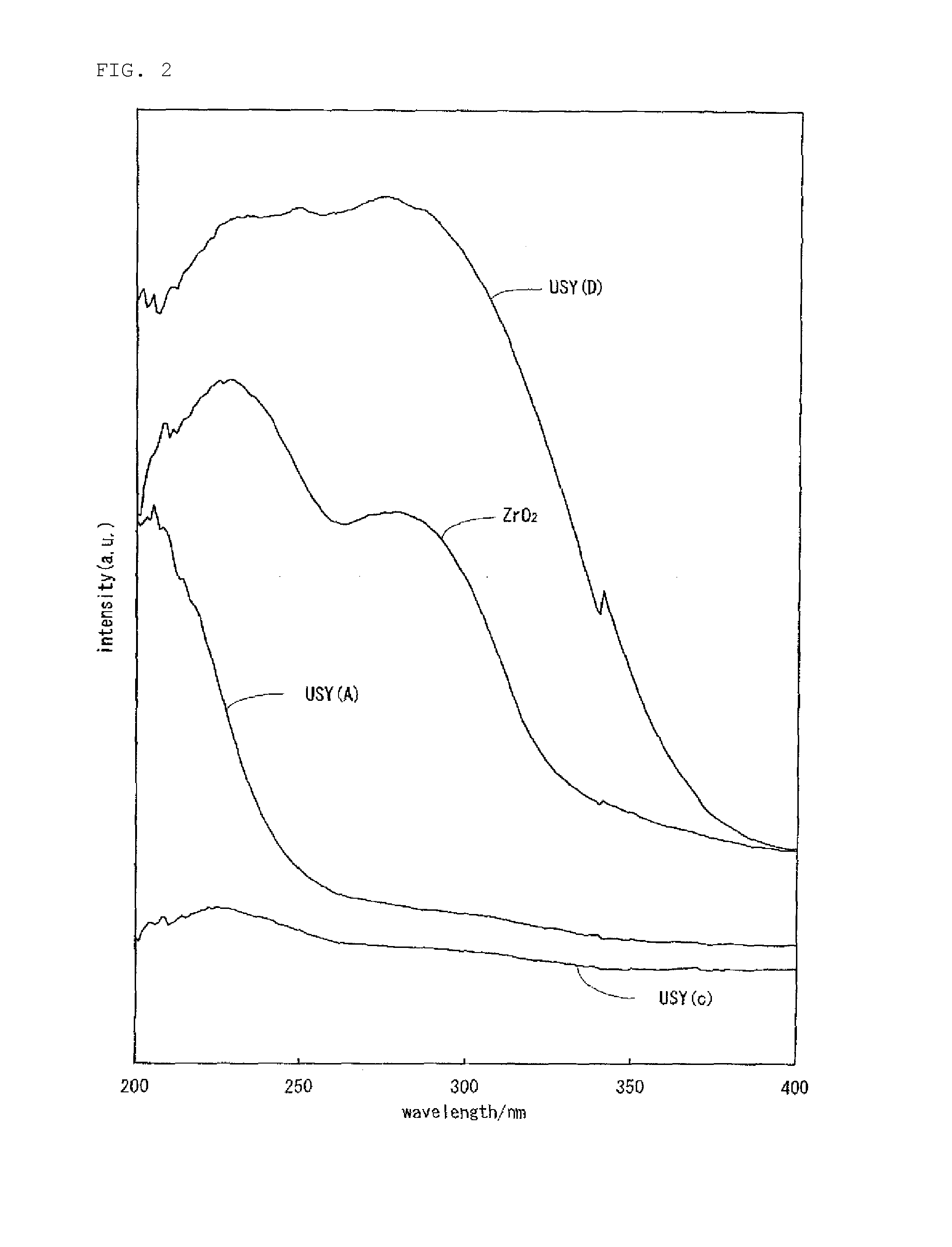

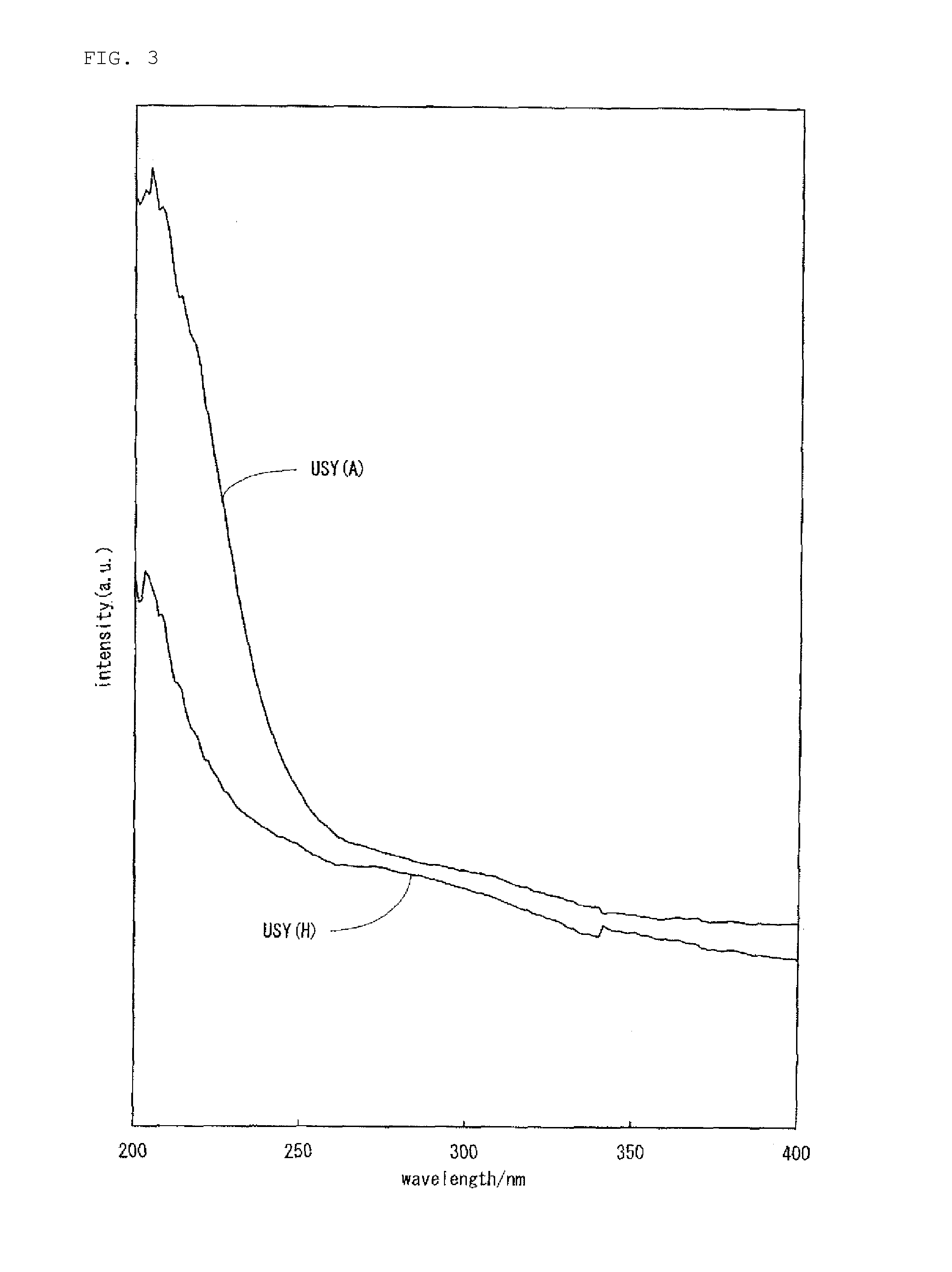

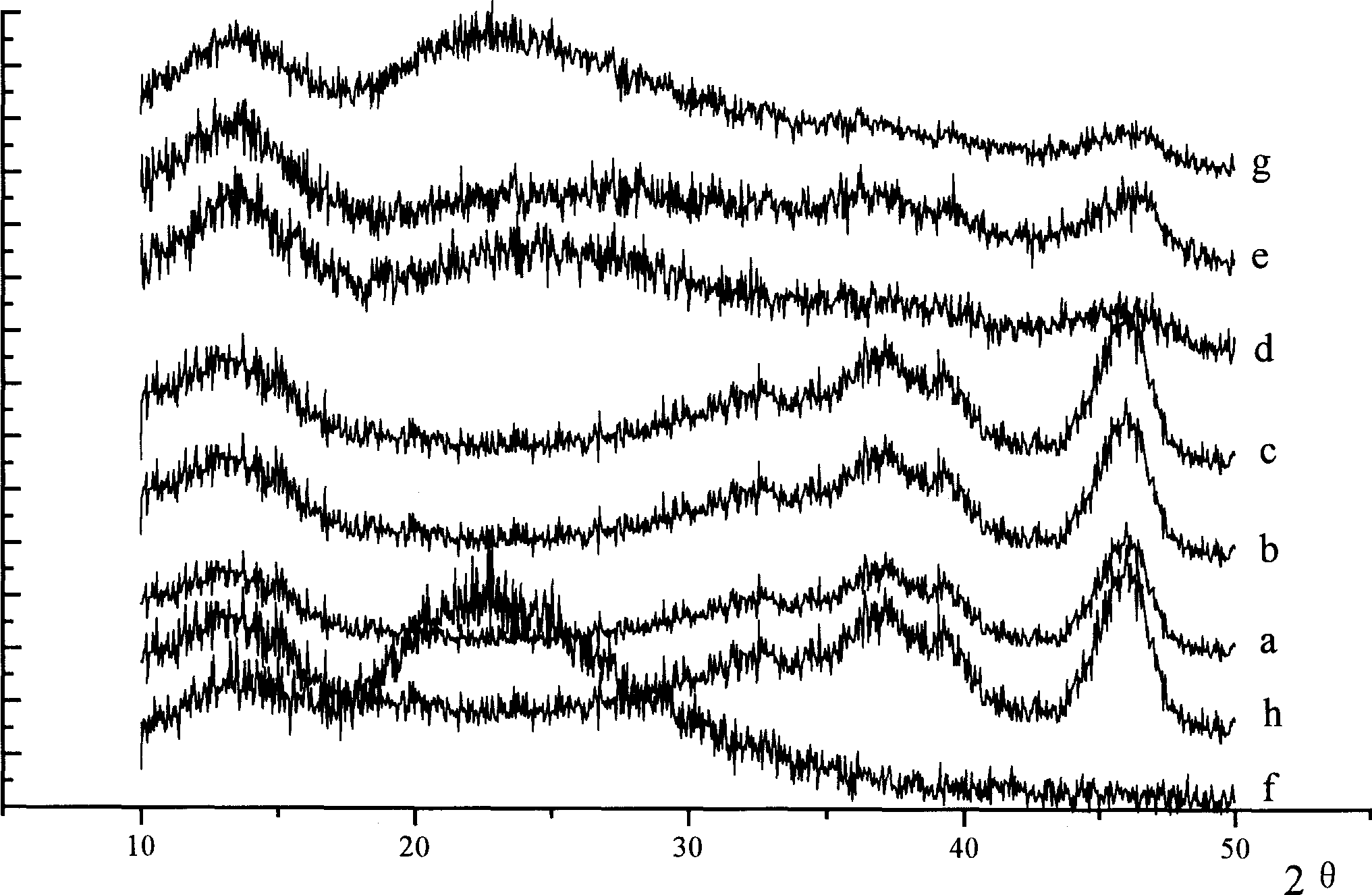

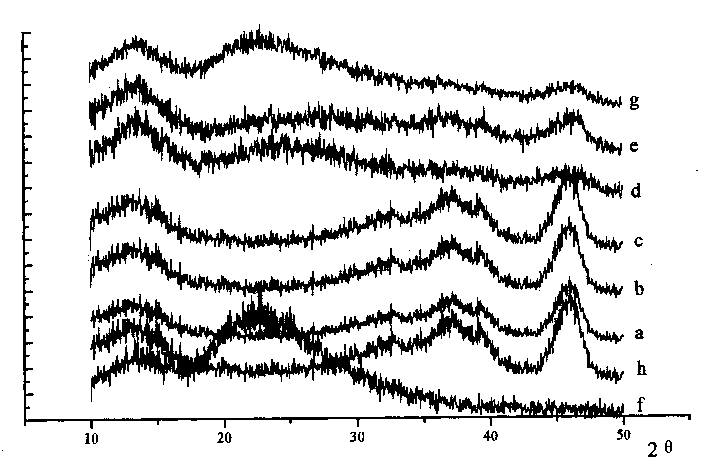

ActiveUS9221036B2Improve responseDisadvantageously reducing yieldMolecular sieve catalystsCatalyst activation/preparationHafniumTitanium

Owner:JAPAN COOP CENT FOR PETROLEUM & SUSTAINABLE ENERGY +2

Hydrocracking catalyst containing compound molecular sieve and preparing method thereof

InactiveCN1488726AImprove nitrogen resistanceHigh hydrocracking activityHydrocarbon oil crackingMolecular sieveNitrogen

The present invention relates to a hydrocracking catalyst containing compound molecular sieve and its preparation method. Said catalyst composition uses amorphous aluminosilicate and a compound molecular sieve as carrier, in which the amorphous aluminosilicate content is 30-60% of catalyst weight, compound molecular sieve content is 1-20% of catalyst weight, and is the mixture of modified Y molecular sieve and SAPO molecular sieve, VIB group metal oxide content is 10-40%, VIII group metal oxide content is 1-20% of IVB group metal oxide content is 1-10%. Said invented catalyst is prepared by adopting co-precipitation method, and its strength and performance can be raised and improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking catalyst preparation method

ActiveCN104588082AEasy to useControl distributionMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveHigh activity

The invention discloses a preparation method of a hydrocracking catalyst. According to the method, a nickel and aluminum precipitate is prepared with a straight addition method; a tungsten, silicon and aluminum precipitate is prepared with a parallel flow precipitation method; the two precipitates are mixed, and a suspension liquid of Y type molecular sieve is added, such that the catalyst is prepared. With the method, the distributions of different hydrogenation active metals can be controlled; high-activity phase can be formed among active metals tungsten and nickel; and the interaction between active metals and the carrier can be improved. Therefore, the hydrogenation activity and the cracking activity of the obtained hydrocracking catalyst can cooperate well, and the application performance of the hydrocracking catalyst can be improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

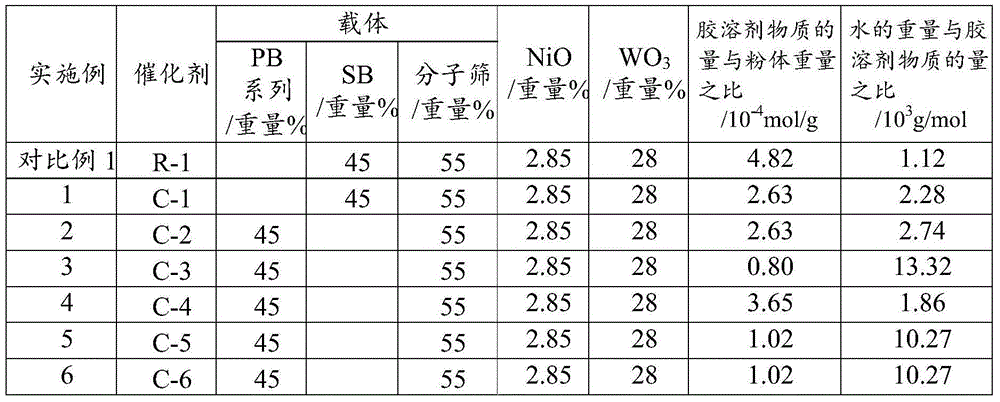

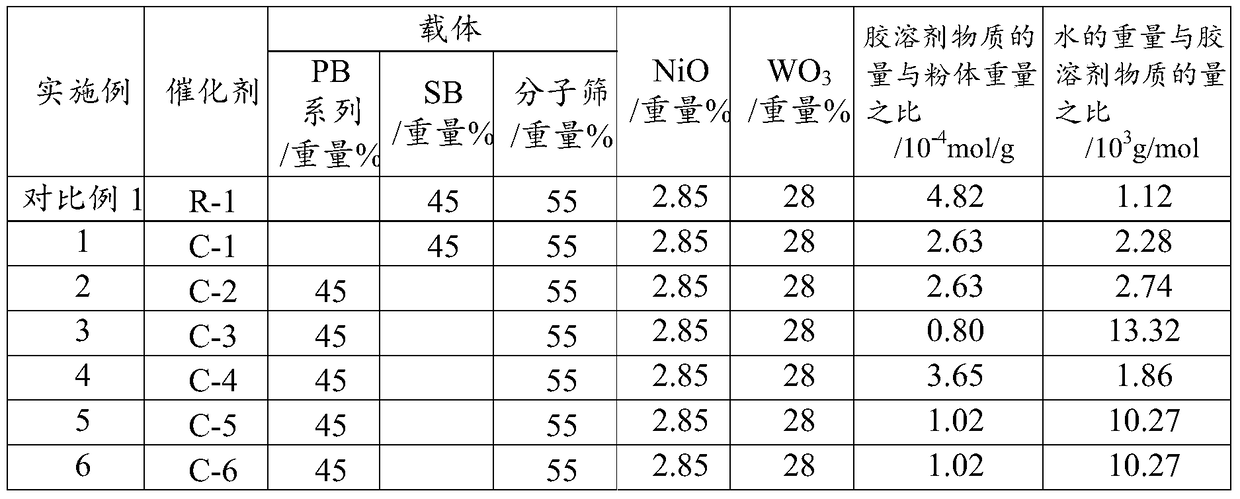

Preparation method of bulk phase hydrocracking catalyst

ActiveCN103055922BLarge specific surface areaLarge hole volumeMolecular sieve catalystsHydrocarbon oil crackingMolecular sievePolymer science

The invention discloses a preparation method of a bulk phase hydrocracking catalyst. The method comprises the steps of preparing an acidic mixed solution A containing hydrogenation reactive metals, silicon and organic solvents, and preparing a sodium metaaluminate alkaline solution B; filling clear water into a reaction tank and filling CO2 into the clear water; and then adding the acidic mixed solution A and the alkaline solution B to the reaction tank in parallel to prepare gel, controlling the pH value of pulp in the reaction tank to be 7.0-9.0, then adding turbid liquid of a Y type molecular sieve, mixing the substances uniformly, filtering and drying the obtained mixture, and then forming, washing, drying and roasting the filter cake, thus preparing the hydrocracking catalyst. The catalyst prepared by the method has the advantages of big specific surface area, big pore volume, high strength and high dispersibility of reactive metal components, and is especially suitable to serve as a high-activity middle oil type hydrocracking catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

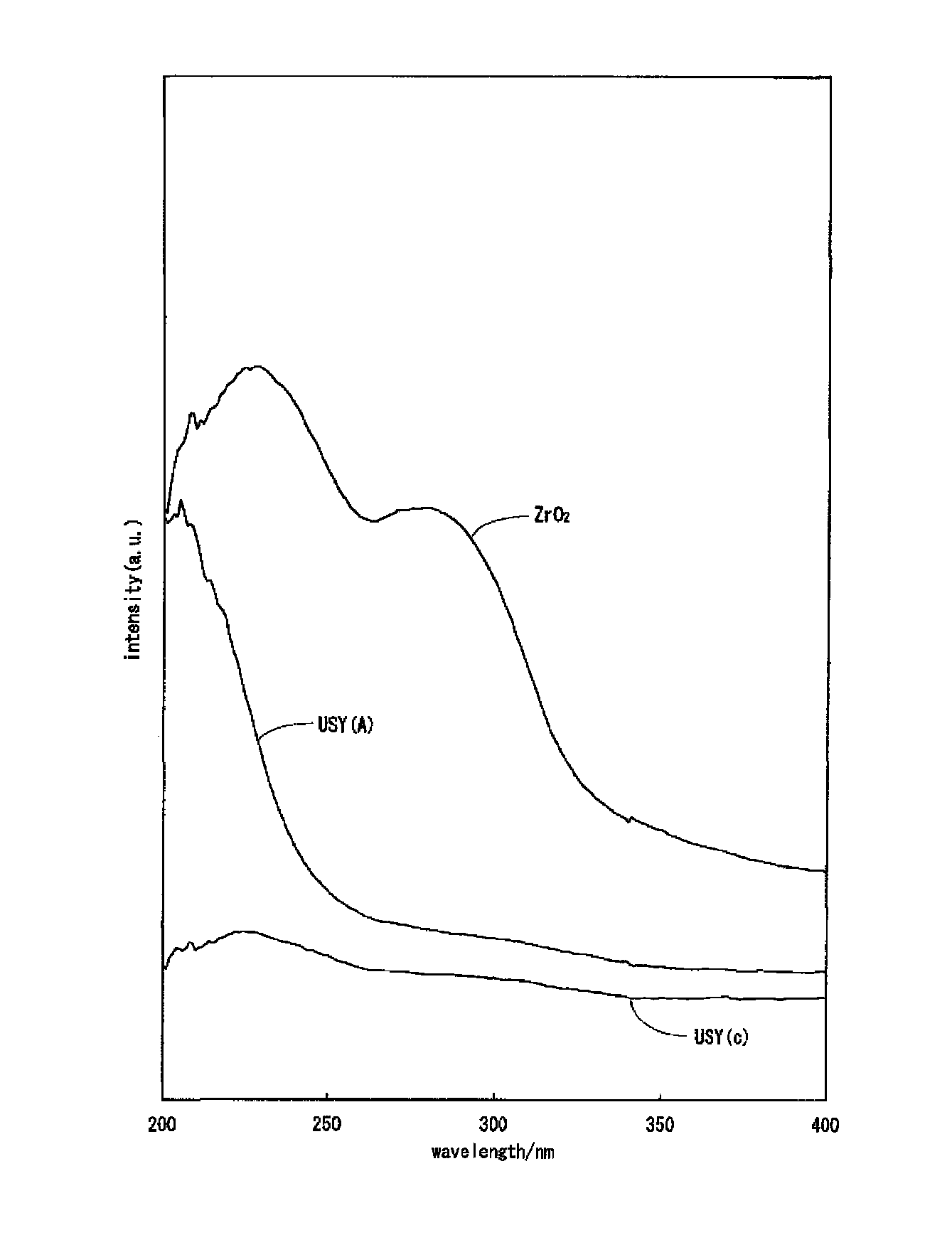

Hydrocracking catalyst for hydrocarbon oil, method for producing hydrocracking catalyst, and method for hydrocracking hydrocarbon oil with hydrocracking catalyst

ActiveUS20130175202A1High yieldCracking activity is improvedMolecular sieve catalystsCatalyst activation/preparationPtru catalystProcess engineering

The present invention relates to a hydrocracking catalyst for hydrocarbon oil comprising a support containing a framework-substituted zeolite-1 in which zirconium atoms and / or hafnium atoms form a part of a framework of an ultrastable y-type zeolite and a hydrogenative metal component carried thereon and a method for producing the same. The hydrocracking catalyst of the present invention makes it easy to diffuse heavy hydrocarbon oils such as VGO, DAO and the like into mesopores, is improved in a cracking activity and makes it possible to obtain a middle distillate at a high yield as compared with catalysts prepared by using zeolite comprising titanium and / or zirconium carried thereon.

Owner:JAPAN COOP CENT FOR PETROLEUM & SUSTAINABLE ENERGY +2

Monox-alumina containnig hydrocracking catalyst

InactiveCN1552818AHigh hydrocracking activityGood choiceHydrocarbon oil crackingMolecular sieveFaujasite

A hydrocracking catalyst containing Si-Al oxides contains two molecular sieves, one's metal components selected from Fe, Co or Ni of VIII family, at least one of them, and another's selected from Mo or W of VIB family, at least one of them. Its K value is 0.4 - 15A.(cm2.g)-1. One molecular sieve with octahedral zeolite structure with the content of Si-Al oxides of 10 - 90wt% of the catalyst, and another's limiting exponential is 0.5 C10G 47 / 20 1 15 3 2003 / 5 / 30 1552818 2004 / 12 / 8 1261542 2006 / 6 / 28 2006 / 6 / 28 2006 / 6 / 28 SINOPEC Beijing 100029 Shi Jianwen Nie Hnog Mao Yichao xu shu pang lizhi 72001 The Company Ltd. of the Chinese Patent Agency (Hong Kong) Zi Building 22, Yingjun Centre, No.23, Gangwan Road, Hong Kong Wanzi

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of hydrocracking catalyst

ActiveCN104588085AHigh hydrocracking activityHigh oil selectivityMolecular sieve catalystsMolecular sieveActive phase

The invention discloses a preparation method of a hydrocracking catalyst. The method includes preparing nickel-aluminum precipitate by a normal precipitation method and tungsten-silicon-aluminum precipitate by a parallel-flow precipitation method, adding an organic amine in gelling process of any one step or two steps above, mixing the two precipitates, adding a molecular sieve suspension, and performing aging and forming to obtain the catalyst. The inventive method can control the distribution of different metals with hydrogenation activities, is conducive to forming a highly active phase between active metals tungsten and nickel, can improve the interaction between the active metals and a carrier, so that the hydrogenation activity and cracking activity of the obtained hydrocracking catalyst can be well coordinated, and the use performance of the hydrocracking catalyst is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Support for hydrocracking catalyst of hydrocarbon oil, hydrocracking catalyst, and method for hydrocracking of hydrocarbon oil

ActiveUS9512371B2Long catalyst lifeHigh hydrocracking activityMolecular sieve catalystsCatalyst activation/preparationTitaniumModified zeolite

A support for hydrocracking catalyst of hydrocarbon oil, which comprises a modified zeolite obtained by incorporating titanium into a faujasite-type zeolite, wherein the modified zeolite satisfies conditions (a) to (e) as described, and to a hydrocracking catalyst employing the support and a method for hydrocracking of hydrocarbon oil containing aromatics using the catalyst.

Owner:COSMO OIL CO LTD

Heavy fraction oil hydrgenation cracking catalyst

InactiveCN1552817AHigh hydrocracking activityHigh viscosity indexHydrocarbon oil crackingProtonCobalt

A hydrocracking catalyst for heavy fractional oil, contains a Si oxide-Al oxides composition and Mo and / or W and Ni and / or Co loaded on it. Its K value is 0.4 - 15A(cm2 g)-1. The catalyst comprises the Si-Al oxides 50 - 90wt%, with oxide as account, the content of Mo and / or W is 5 - 40wt%, the content of Ni and / or Co is 1 - 10wt%; K=B / MSiO2 is proton acidity of the Si-Al oxides, MSiO2 is the molar fraction in the oxides. The catalyst achieves better activity in heavy fraction oil hydrocracking process.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing light steam cracking raw materials by catalytic cracking

InactiveCN104549448AIncreased hydrocracking activityReduce contentMolecular sieve catalystsHydrocarbon by hydrocarbon crackingReaction temperaturePetroleum

The invention relates to a method for producing light steam cracking raw materials by catalytic cracking, and aims at mainly solving the technical problems that the catalyst cracking activity is low and the yields of ethylene and propylene are low when an existing method is used for hydrocracking petroleum hydrocarbon to prepare the light cracking raw materials. The problems are solved very well by adopting the technical scheme, hydrocarbon raw materials are in contact with a catalyst bed layer under the conditions that the reaction temperature is 250-500 DEG C, the reaction pressure is 0.1-8MPa and the raw material weight air speed is 0.1-8 per hour, so that effluents containing ethylene and propylene are obtained, wherein the catalyst is prepared from the following components in percentage by mass: (a) 0.1%-2.0% of at least one of Pd and Pt; and (b) 98%-99.9% of at least one of a ZSM-5 molecular sieve carrier and a ZSM-11 molecular sieve carrier which is prepared by a non-adhesive method. The method can be used for industrial production of hydrocracking to prepare the light cracking raw materials.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking catalyst containing monox-alumina

The invention is a kind of hydrocracking catalysts, which contains nonox-alumine, Y type of crystalline silica, iron or cobalt or niccolum from VIII lombardic and molybdenum or tung component from VIB lombardic. The K value of nonox-alumine is0.4,consulting catalyser's pivot, by weight, the content of nonox-alumine is 10%-90% and Y type is 1%-70%. Consulting oxid, by weight, the content of metal component from VIII lombardic is 1%-10% and metal component from VIB is 5%-40%. The catalyser has higher ac of hydrocrack and better selectivity to center cut oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking catalyst for hydrocarbon

ActiveCN1660495AHigh hydrocracking activityMolecular sieve catalystsRefining by aromatic hydrocarbon hydrogenationAluminium chlorideRare earth

A catalyst for hydrocracking hydrocarbon contains a high-Si zeolite with RE pentacycle structure, an acidic catalyzing component chosen from mordenite, Y zeolite, amorphous silicon oxide-alumina, aluminium chloride oxide, ZSM-4 and ZSM-20, at least one of Fe, Co and Ni, and at least one of Mo and W. Its advantage is high hydrocracking activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Coal-oil hydrogenation co-processing catalyst as well as preparation method and application method thereof

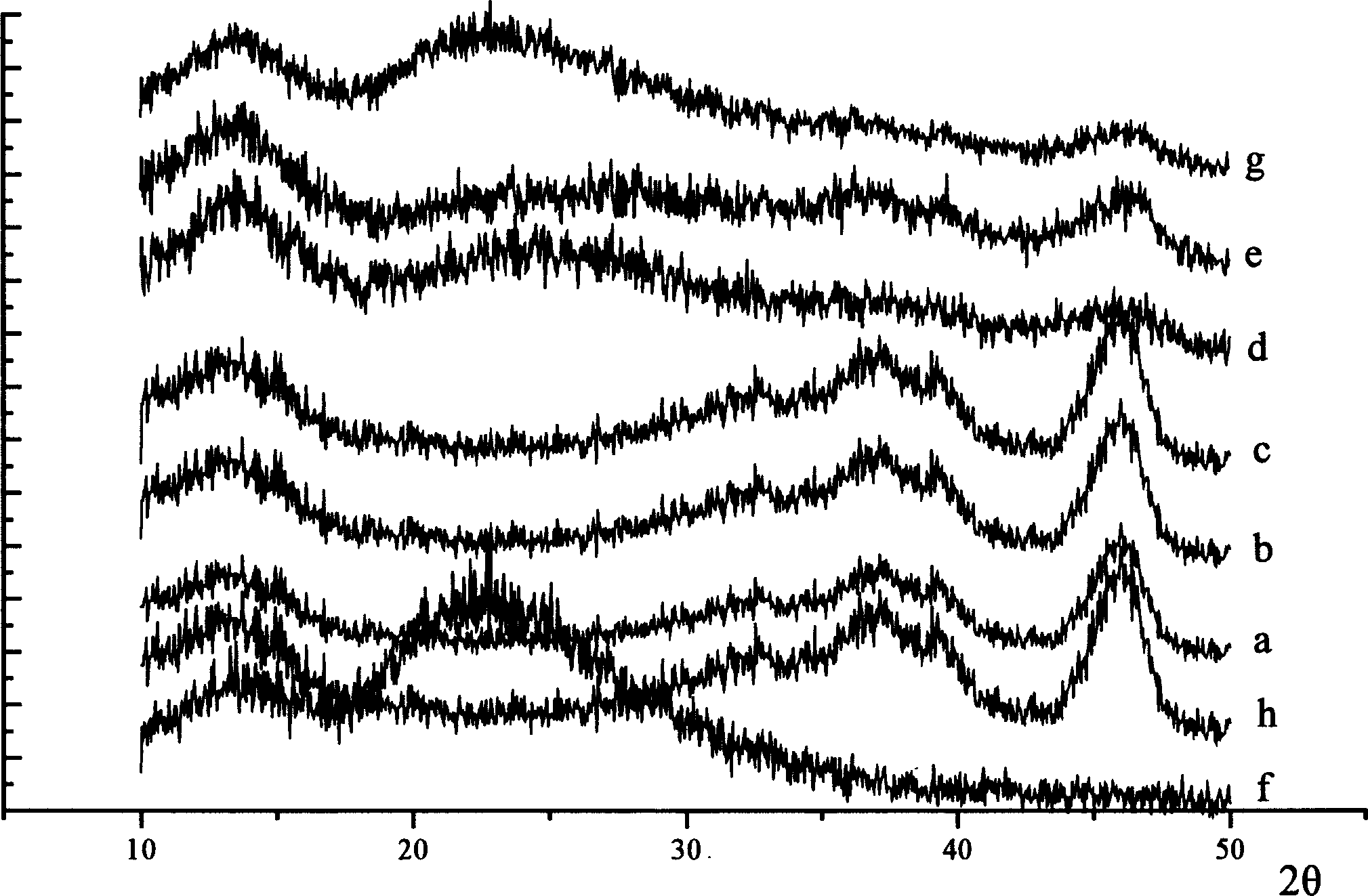

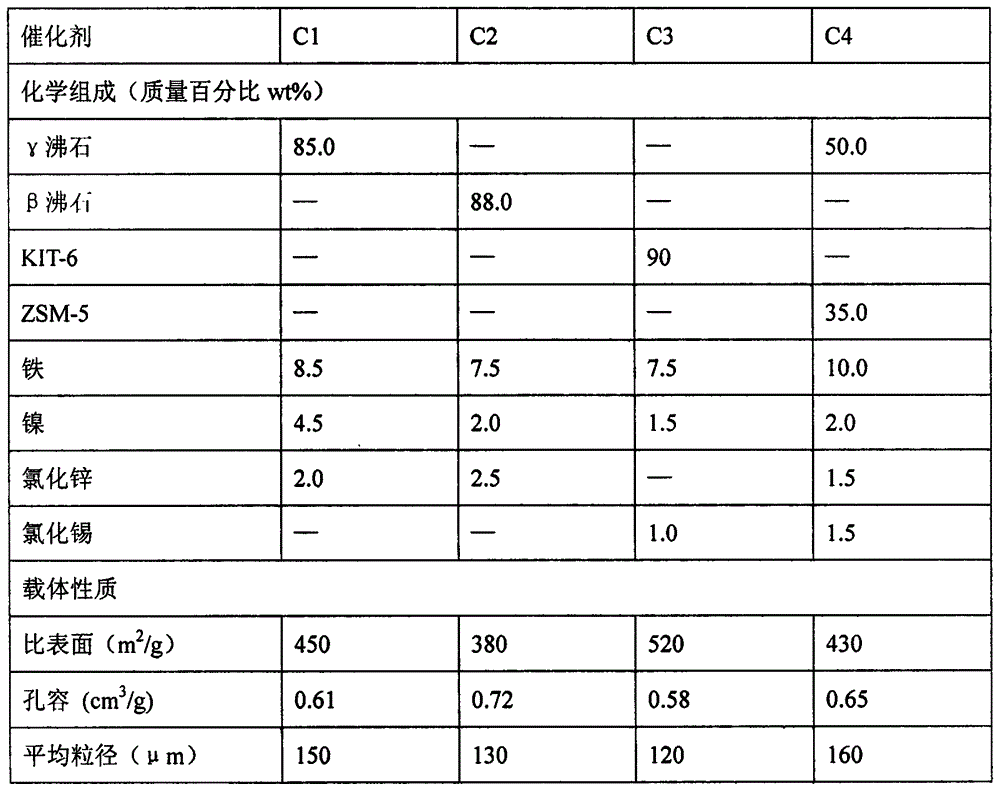

ActiveCN104475148AGood hydrocracking activityHigh hydrocracking activityMolecular sieve catalystsLiquid hydrocarbon mixture productionKeroseneFuel oil

The invention relates to a coal-oil hydrogenation co-processing catalyst as well as a preparation method and an application method thereof. The catalyst consists of a carrier, an active component and an additive, wherein the specific surface area of the carrier is 300 to 600 m<2> / g, the pore volume of the carrier is 0.5 to 1.0 cm<3> / g, the carrier is one or more of gamma zeolite, beta zeolite, ZSM-5 and KIT-6 powder with the particle size less than 200 micrometers, the active component is iron and nickel, and the additive is one or more of zinc chloride and tin chloride. The preparation method comprises the following steps of preparing the carrier, preparing the active component and preparing the additive. According to the application method of the catalyst, the catalyst and raw material coal powder are mixed and then added into a high pressure reaction kettle together with heavy oil, the addition amount of the catalyst is 0.5 to 5 parts by weight of the total mass of the coal and heavy oil, and the mass ratio of the coal to the oil is 1: 1. The catalyst is large in specific surface area, reasonable in preparation process, little in consumption, high in oil yield after the coal-oil hydrogenation co-processing and safe and convenient to use.

Owner:NINGBO RES & DESIGN INST OF CHEM IND

Hierarchically porous hydrocracking catalyst and application thereof

ActiveCN106031880AHigh hydrocracking activityMolecular sieve catalystsHydrocarbon oil crackingMolecular sievePore distribution

The invention provides a hierarchically porous hydrocracking catalyst and an application thereof. The catalyst comprises a carrier and metal components with hydrogenation activity which are loaded on the carrier. The carrier comprises a Y type molecular sieve and aluminum oxide, and metal components with hydrogenation activity are selected from molybdenum and / or tungsten in VIB group as well as nickel and / or cobalt in VIII group. The catalyst is characterized in that pore distribution of the catalyst satisfies the following conditions: the volume of pores whose diameters are less than 2nm accounts for 1.5-75% of total volume of pores of the catalyst, the volume of pores whose diameters are 2-100 nm accounts for 20-85% of total volume of pores of the catalyst, and the volume of pores whose diameters are more than 100 nm accounts for 2.5-65% of total volume of pores of the catalyst. Compared with the catalyst in the prior art, the catalyst has higher hydrocracking activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

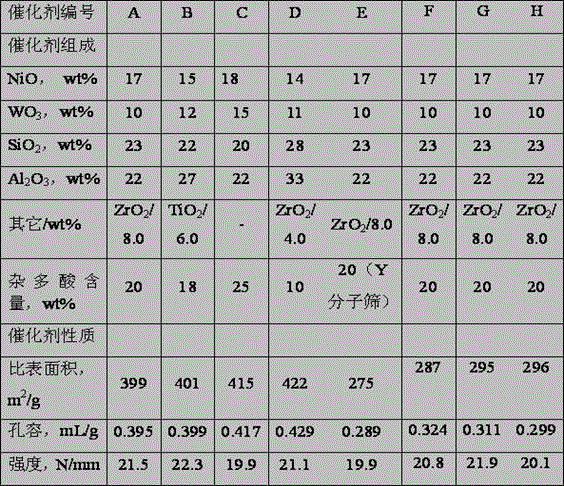

Preparation method for hydrocracking catalyst containing heteropoly acid

ActiveCN104588119AEasy to useImprove pore structureOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbon oil crackingHeteropoly acidAmorphous silicon

The invention discloses a preparation method for a hydrocracking catalyst containing heteropoly acid. The method comprises the following steps: preparing a nickel-aluminum precipitate with larger grain by using a regular addition method; preparing a tungsten-silicon-aluminum precipitate with smaller grain by using a parallel flow method; mixing the two precipitates and carrying out hydrothermal treatment; then carrying out impregnation with a heteropoly acid solution; and carrying out molding and calcination so as to prepare the hydrocracking catalyst. The method enables the catalyst to have high using performance by adjusting distribution of a hydrogenation active metal, heteropoly acid, alumina and amorphous silicon aluminum and promoting coordination and cooperation among the above-mentioned substances.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of multi-stage porous hydrocracking catalyst and its application

ActiveCN106031880BHigh hydrocracking activityMolecular sieve catalystsHydrocarbon oil crackingMolecular sievePore distribution

The invention provides a hierarchically porous hydrocracking catalyst and an application thereof. The catalyst comprises a carrier and metal components with hydrogenation activity which are loaded on the carrier. The carrier comprises a Y type molecular sieve and aluminum oxide, and metal components with hydrogenation activity are selected from molybdenum and / or tungsten in VIB group as well as nickel and / or cobalt in VIII group. The catalyst is characterized in that pore distribution of the catalyst satisfies the following conditions: the volume of pores whose diameters are less than 2nm accounts for 1.5-75% of total volume of pores of the catalyst, the volume of pores whose diameters are 2-100 nm accounts for 20-85% of total volume of pores of the catalyst, and the volume of pores whose diameters are more than 100 nm accounts for 2.5-65% of total volume of pores of the catalyst. Compared with the catalyst in the prior art, the catalyst has higher hydrocracking activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Monox-alumina containnig hydrocracking catalyst

InactiveCN1261542CHigh hydrocracking activityGood choiceHydrocarbon oil crackingMolecular sievePtru catalyst

A hydrocracking catalyst containing Si-Al oxides contains two molecular sieves, one's metal components selected from Fe, Co or Ni of VIII family, at least one of them, and another's selected from Mo or W of VIB family, at least one of them. Its K value is 0.4 - 15A.(cm2.g)-1. One molecular sieve with octahedral zeolite structure with the content of Si-Al oxides of 10 - 90wt% of the catalyst, and another's limiting exponential is 0.5 C10G 47 / 20 1 15 3 2003 / 5 / 30 1552818 2004 / 12 / 8 1261542 2006 / 6 / 28 2006 / 6 / 28 2006 / 6 / 28 SINOPEC Beijing 100029 Shi Jianwen Nie Hnog Mao Yichao xu shu pang lizhi 72001 The Company Ltd. of the Chinese Patent Agency (Hong Kong) Zi Building 22, Yingjun Centre, No.23, Gangwan Road, Hong Kong Wanzi

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking catalyst containing compound molecular sieve and preparing method thereof

InactiveCN1211465CImprove nitrogen resistanceHigh hydrocracking activityHydrocarbon oil crackingMolecular sievePtru catalyst

The present invention relates to a hydrocracking catalyst containing compound molecular sieve and its preparation method. Said catalyst composition uses amorphous aluminosilicate and a compound molecular sieve as carrier, in which the amorphous aluminosilicate content is 30-60% of catalyst weight, compound molecular sieve content is 1-20% of catalyst weight, and is the mixture of modified Y molecular sieve and SAPO molecular sieve, VIB group metal oxide content is 10-40%, VIII group metal oxide content is 1-20% of IVB group metal oxide content is 1-10%. Said invented catalyst is prepared by adopting co-precipitation method, and its strength and performance can be raised and improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

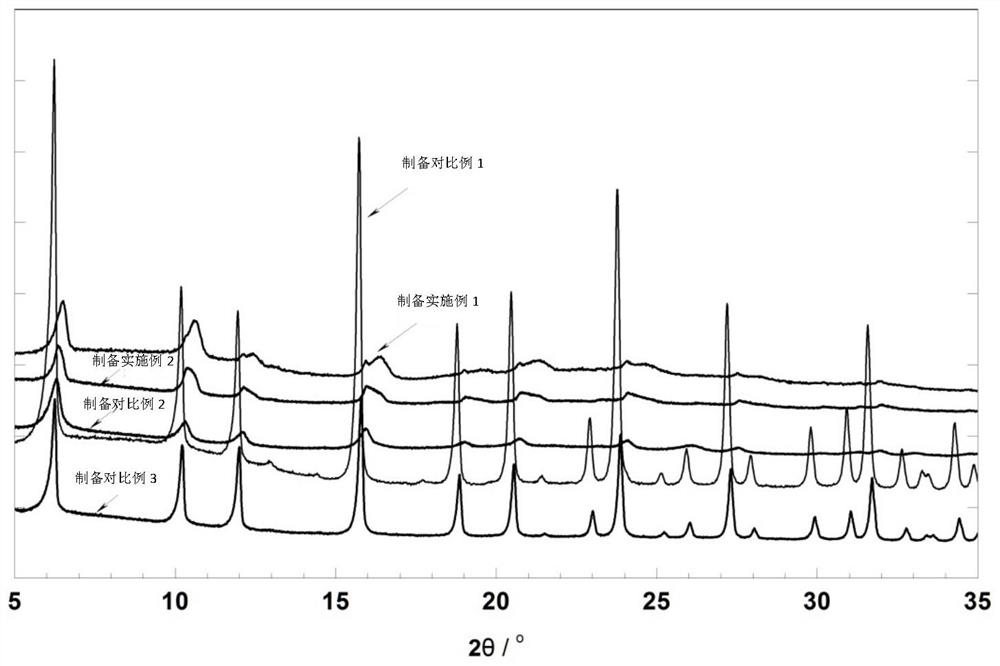

Phosphorus-containing high-silicon molecular sieve and its preparation method and application

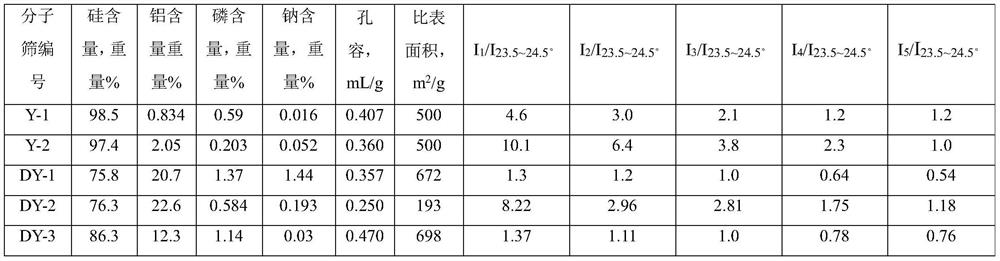

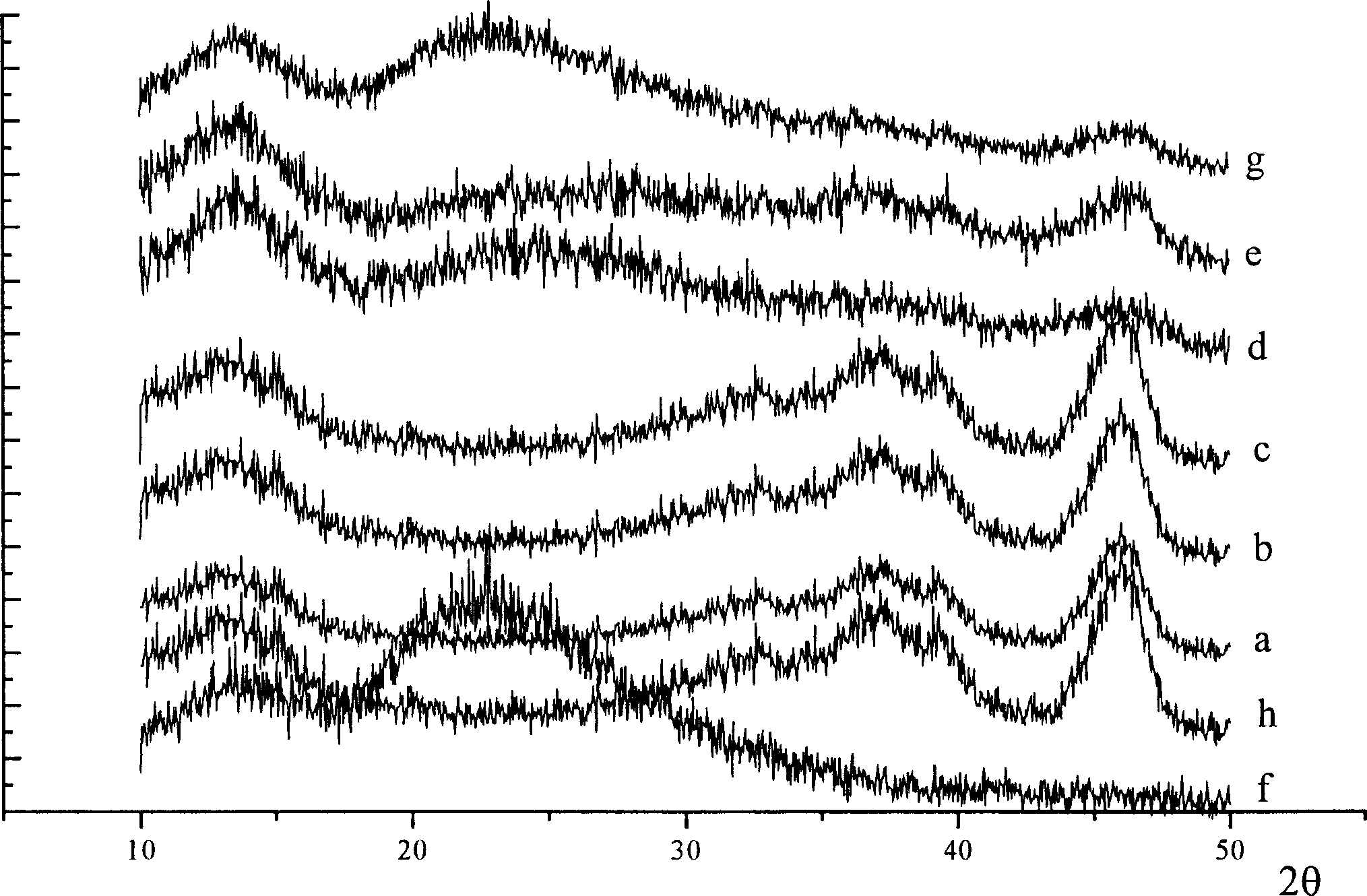

ActiveCN111097482BGood stability against nitrogenHigh hydrocracking activityMolecular sieve catalystsHydrocarbon oil crackingMolecular sievePtru catalyst

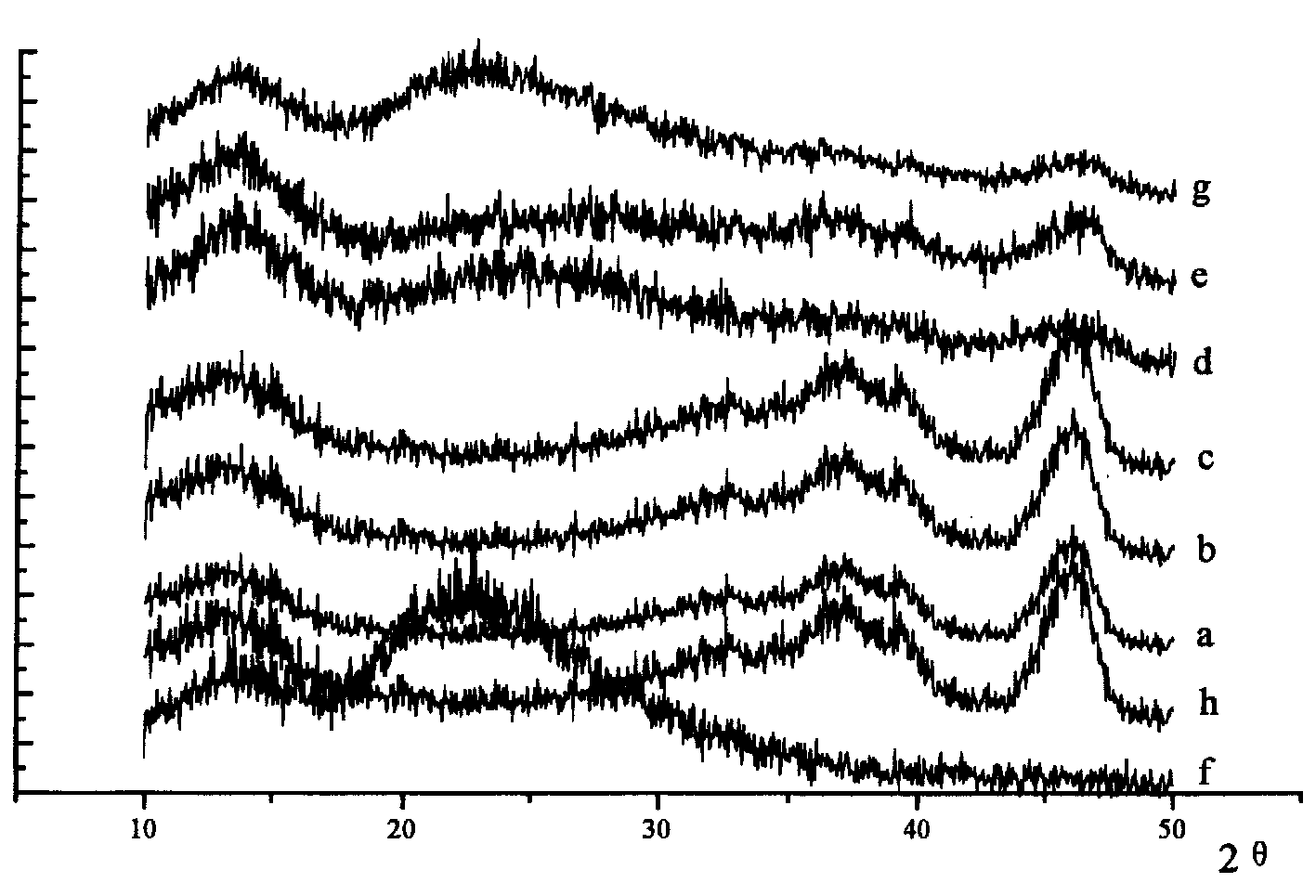

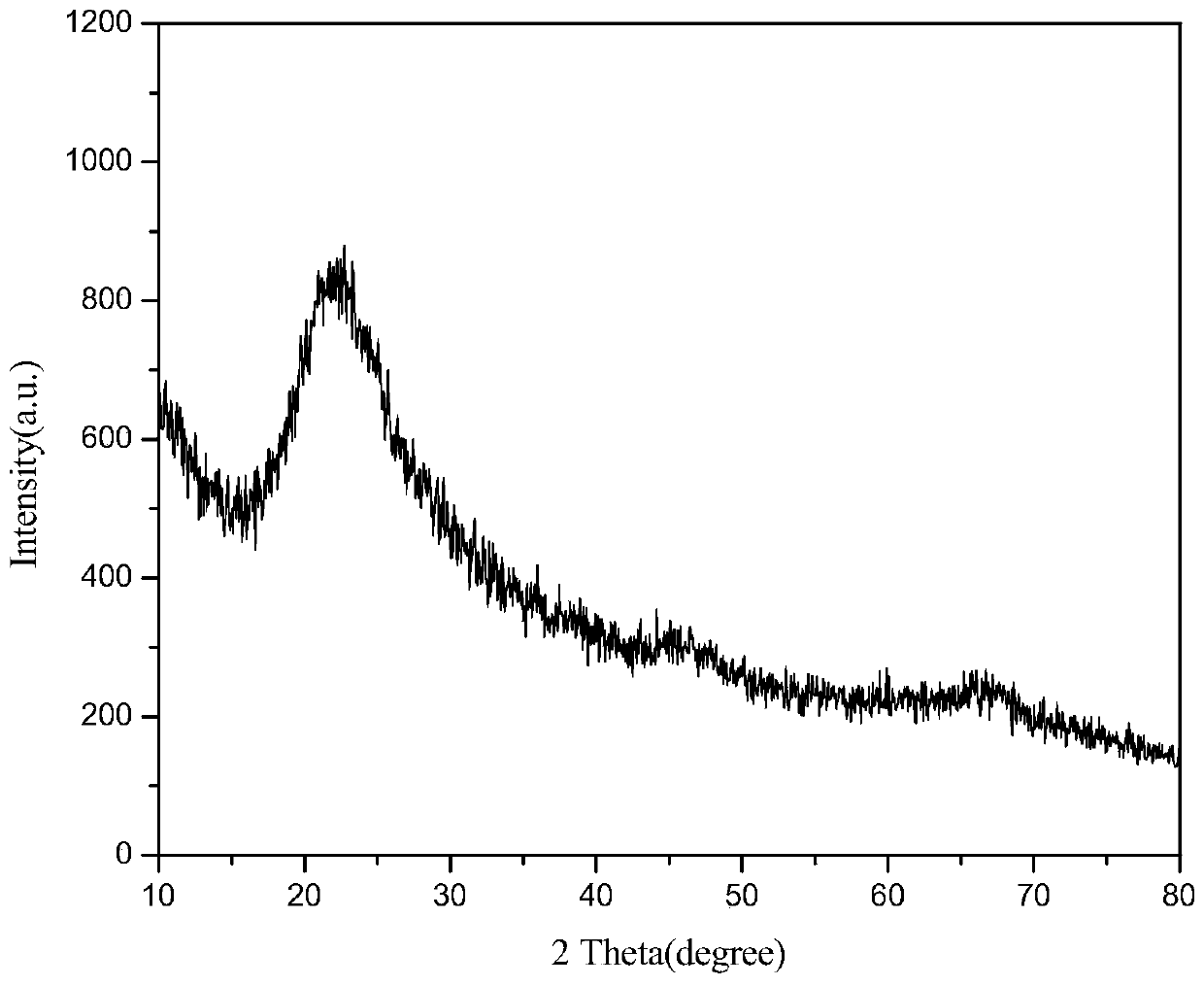

The disclosure relates to a phosphorus-containing high-silicon molecular sieve and its preparation method and application. The molecular sieve has a pore volume of 0.20-0.50mL / g and a specific surface area of 260-600m 2 / g, calculated as oxides and based on the dry weight of the molecular sieve, the silicon content of the molecular sieve is 90-99.8% by weight, the aluminum content is 0.1-9.0% by weight, and the phosphorus content is 0.01-2.5% by weight; In the XRD spectrum of the molecular sieve, the diffraction angle position of the first strong peak is 5.9-6.9°, the diffraction angle position of the second strong peak is 10.0-11.0°, and the diffraction angle position of the third strong peak is 15.6-16.7° . Compared with conventional amorphous silicon-alumina materials, the phosphorus-containing high-silicon molecular sieve disclosed in the present disclosure has better stability against nitrogen, and exhibits higher hydrocracking activity when used to prepare a hydrocracking catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of hydrocracking catalyst composition

ActiveCN103055926AImprove adhesionEasy to shapeMolecular sieve catalystsHydrocarbon oil crackingMolecular sievePtru catalyst

The invention discloses a preparation method of a hydrocracking catalyst composition. The method comprises the steps of preparing an acidic mixed solution A containing hydrogenation reactive metals and silicon, preparing a sodium metaaluminate alkaline solution B, adding clear water to a reaction tank, and then filling CO2 into the clear water; and then adding the acidic mixed solution A and the alkaline solution B to the reaction tank in parallel to prepare gel, then adding turbid liquid of a Y type molecular sieve, mixing the substances uniformly, filtering the obtained mixture, drying the obtained filter cake, and then forming, washing, drying and roasting the filter cake, thus preparing the hydrocracking catalyst composition. The hydrocracking catalyst composition prepared by the method has the advantages of big specific surface area, big pore volume, high strength and high effective utilization rate of reactive metal components, and is especially suitable for a hydrocracking process for producing more middle distillates.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking catalyst containing silicon oxide-alumina

A silicon oxide - aluminum oxide contained hydrocracking catalyst contains a silicon oxide - aluminum oxide, a beta zeolite, metallic component containing at least a ferrum, cobalt or nickel from the VIII group and containing at least a molybdenum or wolfram from the VIB group, and the K value of said silicon oxide - aluminum oxide being from 0.4 to 15 A.(cm2.g)-1, catalyst as the datum, the weigh ratio of silicon oxide - aluminum oxide being from 10 to 99 percent, beta zeolite being from 1 to 50 percent, counted as oxidate, the weigh content ratio of metallic ingredient of the VIII group being from 1 to 10 percent, and the weigh content ratio of metallic ingredient of the VIB group being from 5 to 40 percent. The catalyst has a high hydrocracking activity, and a good selectivity to intermediate fraction oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking catalyst with high activity and high-medium oil selectivity and preparation method of hydrocracking catalyst

ActiveCN102441411BHigh crystallinityLow cell parametersMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveStrong acids

The invention relates to a hydrocracking catalyst with high activity and high-medium oil selectivity. According to the hydrocracking catalyst, amorphous silicon aluminum is used as a carrier, and a specially-modified Y-type molecular sieve is used as acid component, the molecular sieve has high degree of crystallization and low cell parameters, rich secondary holes, large surface area, less uniformly-distributed acid sites, no strong acid center, and most of medium-strength acid centers, and also has strong nitrogen-resisting performance and better damage capacity; and the hydrocracking catalyst using the molecular sieve has high hydrocracking activity and high middle oil selectivity, and stronger nitrogen resisting capacity. The catalyst provided by the invention is used in the process of producing an intermediate distillate product by adopting a heavy hydrocarbon single-section or one-section hydrocracking process, and has better activity and middle oil selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking catalyst containing monox-alumina

The invention is a kind of hydrocracking catalysts, which contains nonox-alumine, Y type of crystalline silica, iron or cobalt or niccolum from VIII lombardic and molybdenum or tung component from VIB lombardic. The K value of nonox-alumine is0.4,consulting catalyser's pivot, by weight, the content of nonox-alumine is 10%-90% and Y type is 1%-70%. Consulting oxid, by weight, the content of metal component from VIII lombardic is 1%-10% and metal component from VIB is 5%-40%. The catalyser has higher ac of hydrocrack and better selectivity to center cut oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of hydrocracking catalyst composition

ActiveCN103055926BImprove adhesionEasy to shapeMolecular sieve catalystsHydrocarbon oil crackingMolecular sievePtru catalyst

The invention discloses a preparation method of a hydrocracking catalyst composition. The method comprises the steps of preparing an acidic mixed solution A containing hydrogenation reactive metals and silicon, preparing a sodium metaaluminate alkaline solution B, adding clear water to a reaction tank, and then filling CO2 into the clear water; and then adding the acidic mixed solution A and the alkaline solution B to the reaction tank in parallel to prepare gel, then adding turbid liquid of a Y type molecular sieve, mixing the substances uniformly, filtering the obtained mixture, drying the obtained filter cake, and then forming, washing, drying and roasting the filter cake, thus preparing the hydrocracking catalyst composition. The hydrocracking catalyst composition prepared by the method has the advantages of big specific surface area, big pore volume, high strength and high effective utilization rate of reactive metal components, and is especially suitable for a hydrocracking process for producing more middle distillates.

Owner:CHINA PETROLEUM & CHEM CORP +1

Heavy fraction oil hydrgenation cracking catalyst

InactiveCN1261541CHigh hydrocracking activityHigh viscosity indexHydrocarbon oil crackingProtonCobalt

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking process for high yield producing intermediate distillate

A hydrocracking method for producing middle distillate oil. After the raw oil is mixed with hydrogen, it is reacted sequentially through a hydrorefining catalyst and a hydrocracking catalyst. The reaction product is cooled, separated and fractionated to obtain a naphtha fraction , middle distillates and tail oil fractions. A hydrocracking catalyst comprising a silica-alumina, a Y-type zeolite, at least one iron, cobalt or nickel selected from group VIII and at least one molybdenum or tungsten metal component selected from group VIB . The invention can process heavy distillate oil with high sulfur, high nitrogen and high aromatic content, and can produce more high-quality middle distillate oil under mild reaction conditions, wherein the kerosene fraction has low sulfur content and aromatic content, which meets jet fuel specifications; Diesel fraction has low sulfur and aromatic content, high cetane number, and is a high-quality low-sulfur diesel fraction.

Owner:CHINA PETROLEUM & CHEM CORP +1

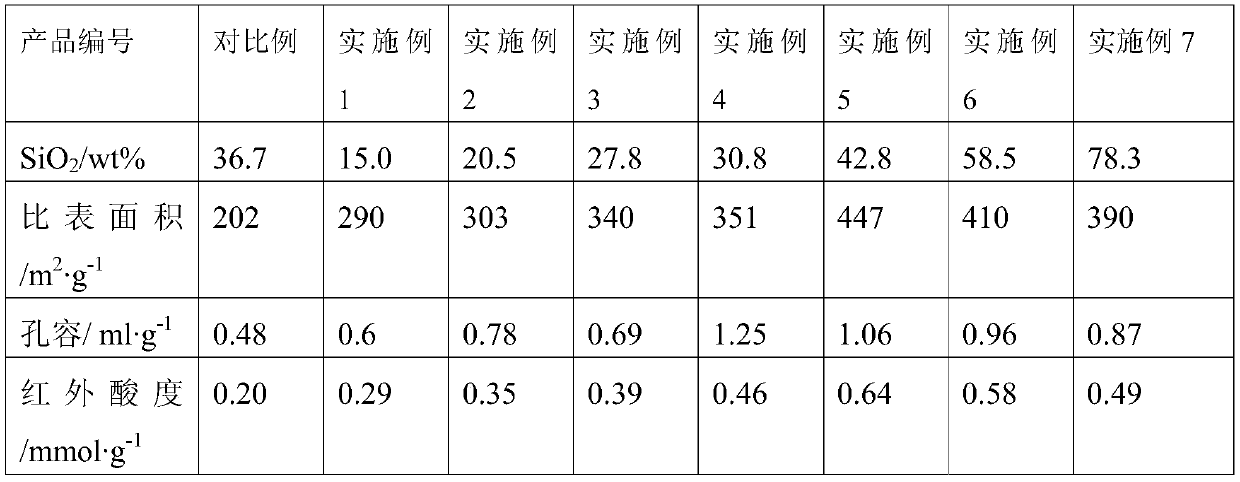

A kind of highly active amorphous silica-alumina, hydrocracking catalyst using it as carrier and their preparation method

ActiveCN106732496BHigh hydrocracking activityGood dispersionCatalyst carriersCatalytic crackingNickel saltAmorphous silicon

Owner:SYNFUELS CHINA TECH CO LTD

Preparation method of hydrocracking catalyst

ActiveCN103055927BUniform grainImprove adhesionMolecular sieve catalystsCatalyst activation/preparationDispersityMolecular sieve

The invention discloses a preparation method of a hydrocracking catalyst. The method comprises the steps of preparing an acidic mixed solution A containing hydrogenation reactive metals and silicon, and preparing a sodium metaaluminate alkaline solution B; adding part of the sodium metaaluminate alkaline solution B to the acidic mixed solution A, and then filling CO2; repeating the step 2 for one-six times; then adding turbid liquid of a Y type molecular sieve, mixing the substances uniformly, and aging the mixture; and filtering, drying and forming the mixture, and then washing, drying and roasting the mixture, thus preparing the hydrocracking catalyst. The method has the beneficial effects that not only can the catalyst be formed easily and the strength of the catalyst be improved, but also the pore volume and specific surface area of the catalyst can be increased, the dispersity of metals in the catalyst can be improved, and the capability of the catalyst in processing macromolecules in heavy oil is enhanced, so that the catalyst has higher hydrocracking activity, middle oil selectivity and stability; and the catalyst can be used for a single-section hydrocracking process of a non-refining section or a one-section serial hydrocracking process of a refining section.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com