Phosphorus-containing high-silicon molecular sieve and its preparation method and application

A molecular sieve, high silicon technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of difficult to achieve long-range order and short-range order of materials, and achieve high hydrocracking activity. , The effect of good anti-nitrogen stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

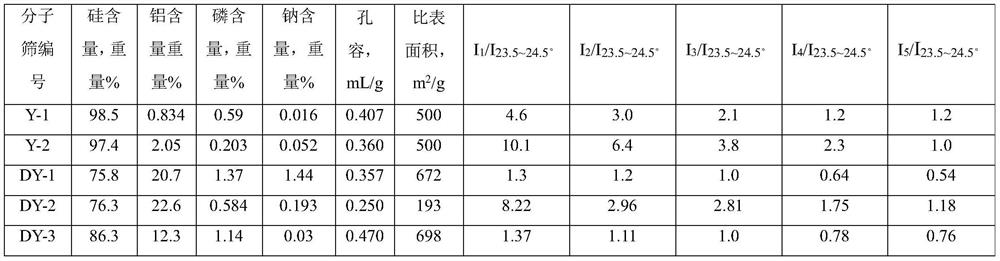

[0060] Get RY molecular sieve (produced by Sinopec Catalyst Changling Branch Company, unit cell constant is 2.456nm, specific surface area is 672m 2 / g, the pore volume is 0.357mL / g, Na 2 O content is 1.44 wt%, P 2 o 5 The content is 1.37% by weight) 500g was put into a hydrothermal kettle, 100% steam was introduced, hydrothermal treatment was carried out at 560° C. and 0.8 MPa for 3 hours, and then the hydrothermally treated molecular sieve material was taken out.

[0061] Take 50 g (dry basis) of the molecular sieve material after hydrothermal treatment obtained above, add 500 mL of deionized water, stir and beat to obtain the first slurry, heat it up to 80 ° C, add 2.0 mol / L sulfuric acid solution, and detect the When the pH value of the first slurry was 2.8, the addition of acid was stopped, then the reaction was carried out at constant temperature for 4 hours, and filtered to obtain 40 g of the first solid product.

[0062] Add the first solid product above to 400 mL o...

preparation Embodiment 2

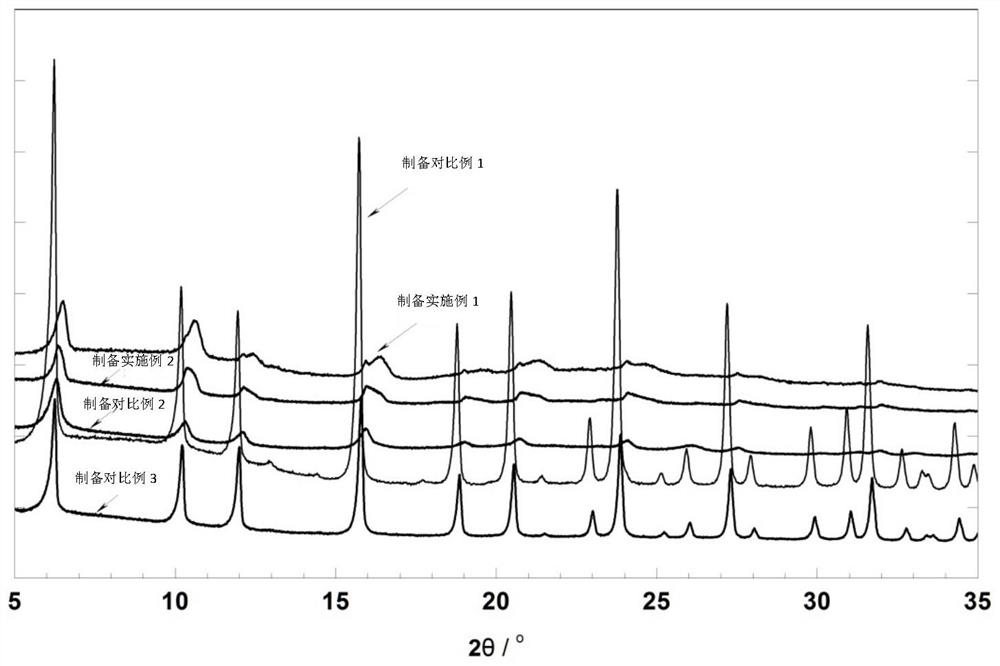

[0064] The molecular sieve with high silicon content was prepared according to the method of Preparation Example 1, with the difference that when adding the second acid solution, it was added at a rate of 15 mol / h. Prepared molecular sieve Y-2, its XRD spectrum is as follows figure 1 As shown, it can be seen that the diffraction angle position of the first strong peak is 6.1-6.8°, the diffraction angle position of the second strong peak is 10.2-10.7°, the diffraction angle position of the third strong peak is 15.8-16.5°, and the fourth strong peak The diffraction angle position of the peak is 20.8-21.4°, and the diffraction angle position of the fifth strongest peak is 12.1-12.6°. Other properties are shown in Table 1.

Embodiment 1

[0079] 80g Y-1 dry basis molecular sieve is mixed with 20g pseudoboehmite (produced by Sinopec Catalyst Changling Branch Company, trade name PB90, dry basis 70% by weight) and extruded into a trefoil strip with a circumscribed circle diameter of 1.6 mm , dried at 120°C for 3h, and calcined at 600°C for 3h to obtain carrier CS-1. After being cooled to room temperature, get 100g CS-1 carrier with ammonium metatungstate (Sichuan Zigong Cemented Carbide Factory, tungsten oxide content is 82% by weight) 34.65g, nickel nitrate (product of Beijing Xinguang Chemical Reagent Factory, nickel oxide content is 27.85% by weight) 24.37g was impregnated in 70mL aqueous solution, dried at 120°C for 3h, and calcined at 480°C for 4h to obtain the catalyst prepared in this example.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com