A kind of highly active amorphous silica-alumina, hydrocracking catalyst using it as carrier and their preparation method

A hydrocracking and catalyst technology, which is applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, catalyst carrier, etc., can solve the problem of unfavorable catalyst middle distillate selectivity improvement and product failure Content standards, excessive cracking of catalysts and other problems, to achieve the effect of improving reaction efficiency, moderate acidity and improving selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

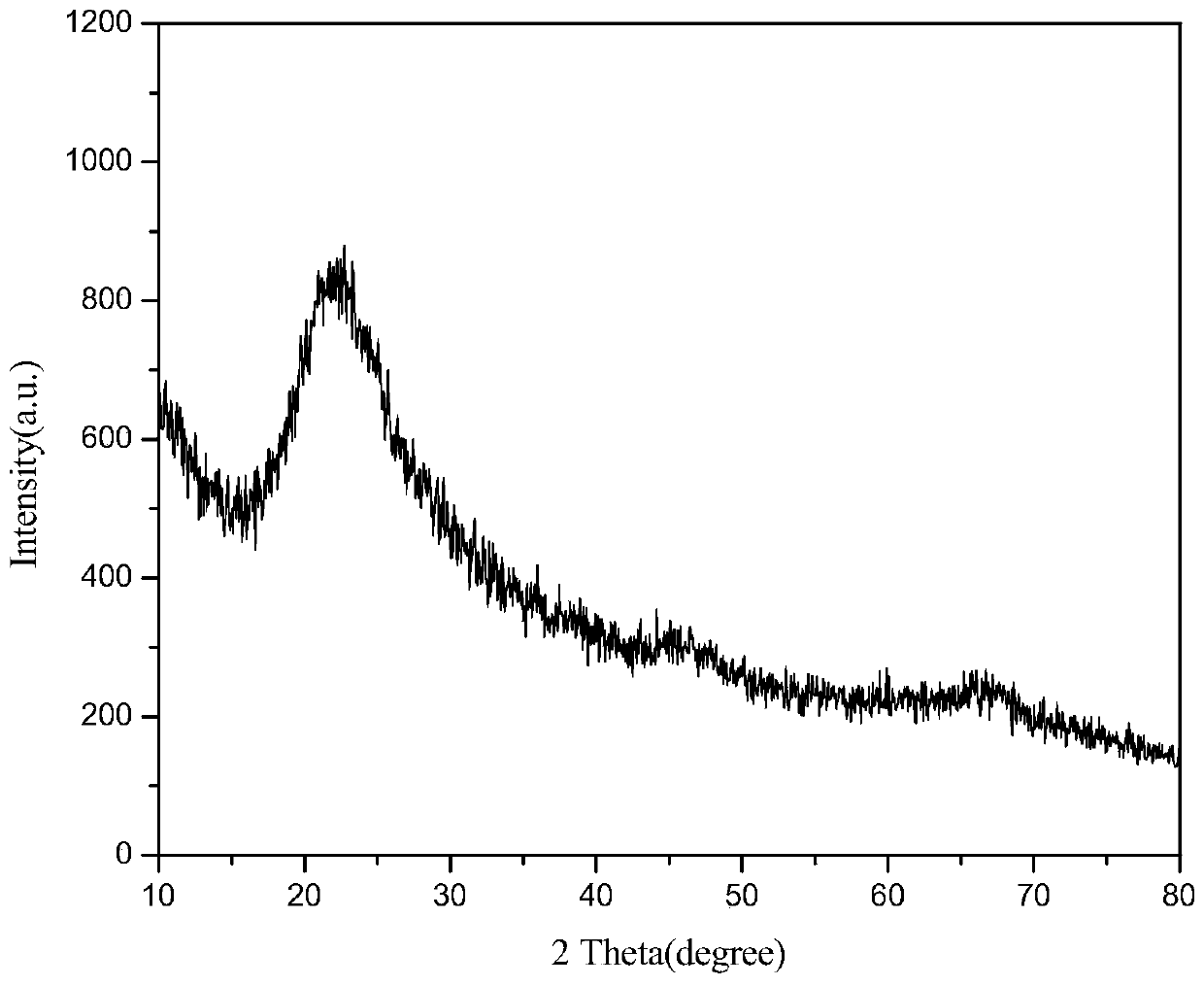

Image

Examples

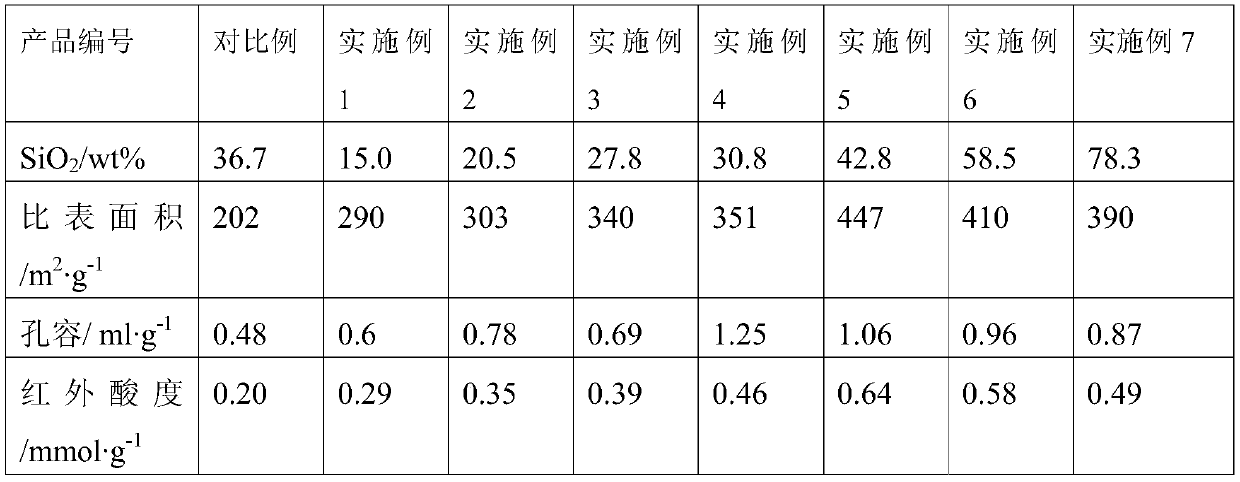

Embodiment 1

[0050] Make aluminum nitrate into a 2mol / L solution, and then add a solution with a specific surface area of 260m 2 / g of white carbon black is stirred evenly, and the mass ratio of silicon oxide to aluminum oxide is 15:85. Sodium carbonate is made into a 2mol / L solution, and the two solutions are co-currently precipitated at 55°C. The precipitation rate is 20mL / min, and the precipitation pH value is 8.5. After the precipitation, continue to stir for 20 minutes, and transfer the mixed material to Crystallization (constant temperature aging) at 95°C for 48 hours in a closed reactor. The crystallized material is cooled, then filtered, washed, moderately dried and extruded. The formed carrier was calcined at 550° C. for 6 hours to obtain an amorphous silica-alumina carrier.

[0051] The weight percent composition of silicon oxide and aluminum oxide in the carrier is: SiO 2 :Al 2 o 3 =15.0:85.

Embodiment 2

[0053] Prepare catalyst by the step of embodiment 1, change silicon source white carbon black into water glass, precipitant is the sodium hydroxide solution of 2mol / L, change the proportioning of silicon oxide and aluminum oxide in aluminum nitrate and sodium silicate solution simultaneously , the rest of the operating conditions remain unchanged to prepare the carrier, and the weight percentage of each component of the carrier is composed of: SiO 2 :Al 2 o 3 =20.5:79.5.

Embodiment 3

[0055] Prepare catalyst by the step of embodiment 1, change silicon source white carbon black into silica sol, aluminum source is aluminum sulfate, precipitating agent is the sodium hydroxide solution of 2mol / L, precipitation temperature is 80 ℃, and precipitation pH value is 10.0, After precipitation, move the slurry into the reaction kettle for crystallization at 180°C for 24 hours, then filter, wash, and dry to form an amorphous silica-alumina carrier. The mass ratio of each component of the obtained carrier is: SiO 2 :Al 2 o 3 =27.8:72.2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com