Hydrocracking catalyst containing monox-alumina

A silicon oxide-containing, hydrocracking technology, applied in hydrocarbon oil cracking, petroleum industry, etc., can solve the problem of low selectivity of middle distillate oil, and achieve the effect of improved hydrocracking activity and good selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0042] 800 grams of NaY type molecular sieve (SiO 2 / Al 2 o 3 =4.8, crystallinity is defined as 100%, Changling Oil Refinery product) is placed in 4000 milliliters, concentration is in the ammonium chloride (Beijing Chemical Plant product, analytical pure) aqueous solution of 1.0 mole, exchange 1 hour under stirring at 90 ℃, Filter, wash with deionized water until no chlorine ions are detected, dry at 120°C, and bake at 550°C for 4 hours. Repeat above-mentioned process twice to obtain the Y-type molecular sieve A of sodium content (in sodium oxide) 0.35% by weight (measured by flame atomic absorption spectrometry), record sample crystallinity with X-ray diffraction method and be 76%, get Y-type molecular sieve A200 gram was placed in 1000 ml of ammonium fluoride (product of Beijing Chemical Plant, analytically pure) aqueous solution with a concentration of 0.2 moles, stirred at room temperature for 1 hour, filtered, dried at 120°C, and roasted at 600°C for 4 hours to obtain ...

example 2

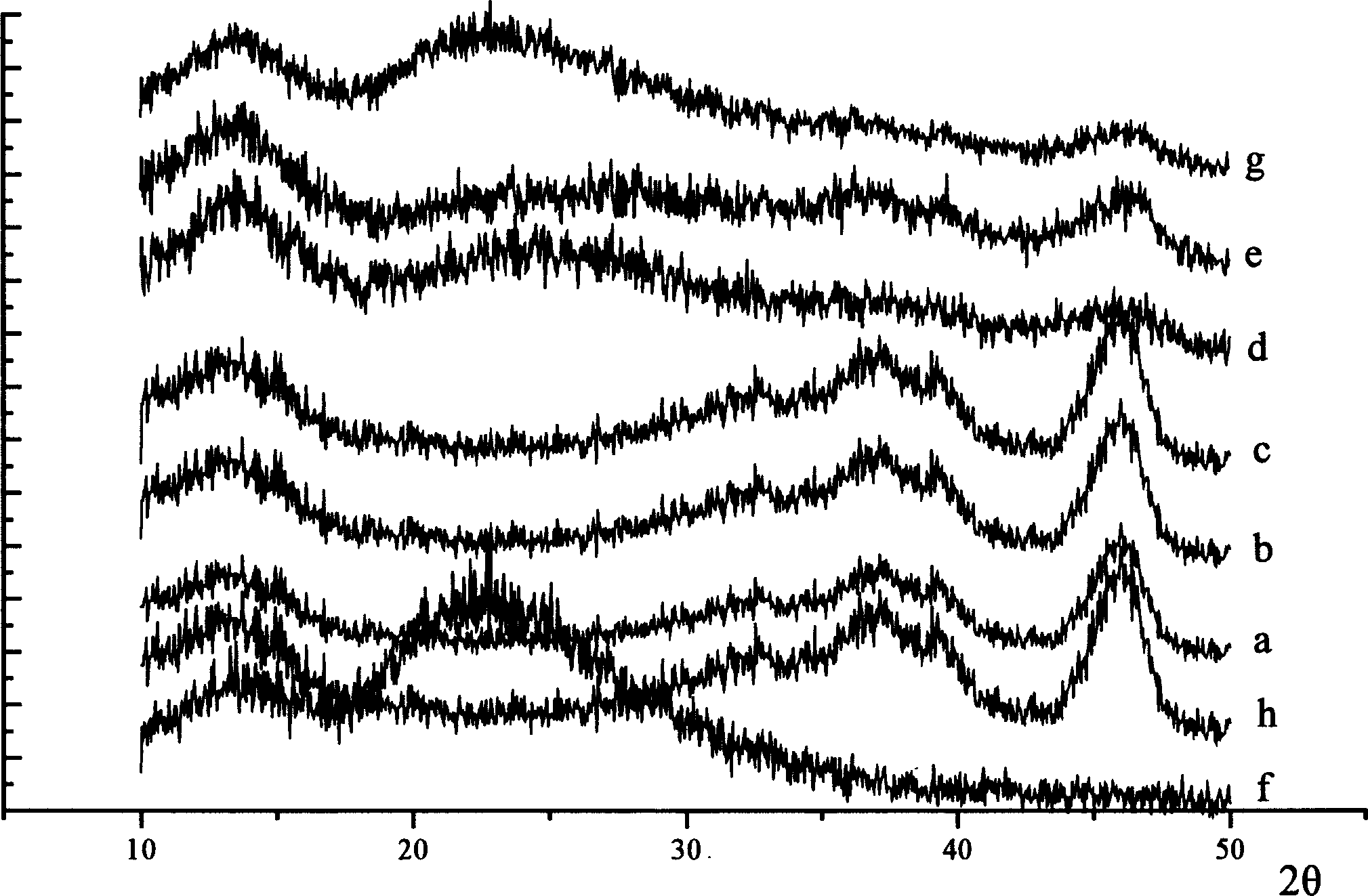

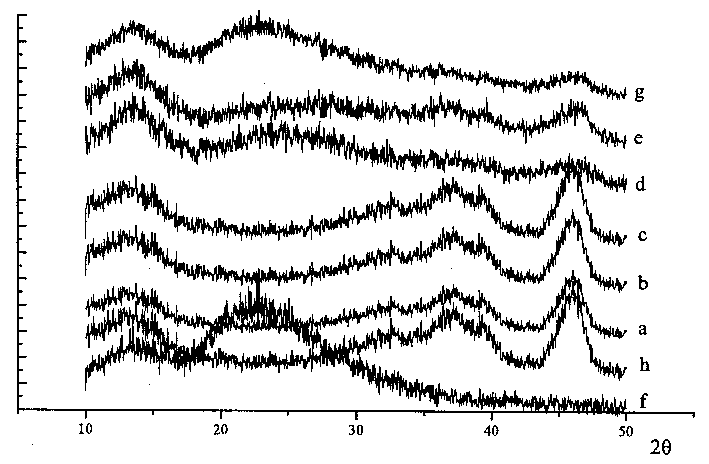

[0044] Take by weighing 12 grams of example 1 disordered Y-type molecular sieve B and 100 grams of SB powder (gibbsite produced by Condea, Germany) and mix to obtain the precursor Si-2 of silicon oxide-alumina (dry basis 74% by weight) , the Si-2 was calcined at 550°C for 4 hours, its X-ray diffraction spectrum is shown in figure 1 b, the silicon oxide content and k value are shown in Table 1

example 3

[0046] According to example 12 in CN1020269C, zeolite containing five-membered ring structure containing rare earth was synthesized to obtain zeolite D containing five-membered ring structure containing rare earth; according to exactly the same conditions, the crystallization temperature was 90°C to obtain partially crystallized zeolite E containing five-membered ring structure containing rare earth. The rare earth-containing five-membered ring structure zeolite E has a silica content of 93.3% by weight, an alumina content of 4.5% by weight, RE 2 o 3 1.5% by weight (RE 2 o 3 Represents rare earth oxides, wherein lanthanum oxide accounts for 26% by weight of the total amount of rare earth oxides, cerium oxide accounts for 51% by weight of the total weight of rare earth oxides, and other rare earth oxides account for 23% by weight of the total weight of rare earth oxides). The degree of crystallinity of the partially crystallized ZSM-5 molecular sieve E was determined to be 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com