Hydrocracking catalyst with high activity and high-medium oil selectivity and preparation method of hydrocracking catalyst

A technology for hydrocracking and high-medium oil, which is used in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., and can solve the problems of high catalyst hydrocracking activity, low catalyst hydrocracking activity, and poor medium oil selectivity. , to prevent skeleton collapse, reduce metal loss, and achieve the effect of high crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0024] Catalyst A is the catalyst prepared by the inventive method, and catalyst weight is composed of: WO 3 22.5%, NiO 8.5%, ZrO 2 6.5%, SiO 235.5%, Al 2 o 3 27.0%, of which the molecular sieve content is 25%, and the specific surface area is 260m 2 / g, the pore volume is 0.35ml / g.

[0025] Concrete preparation steps are as follows:

[0026] (1) Prepare Al-containing 2 o 3 600 ml of aluminum chloride solution with a concentration of 90 g / l, containing NiO 200 ml of nickel chloride solution with a concentration of 140 g / l, containing ZrO 2 150ml of 140g / l zirconium oxychloride solution was mixed in a 5 liter container and diluted with 2000ml of clean water.

[0027] (2) Prepare dilute water glass solution, containing SiO 2 550 milliliters of water glass solution of 75g / l, under stirring situation, (2) is added in (1);

[0028] (3) Add ammonia water to the mixture of (1) and (2) under stirring until the pH value is 5.2;

[0029] (4) Prepare 1000 ml of sodium tungs...

example 2

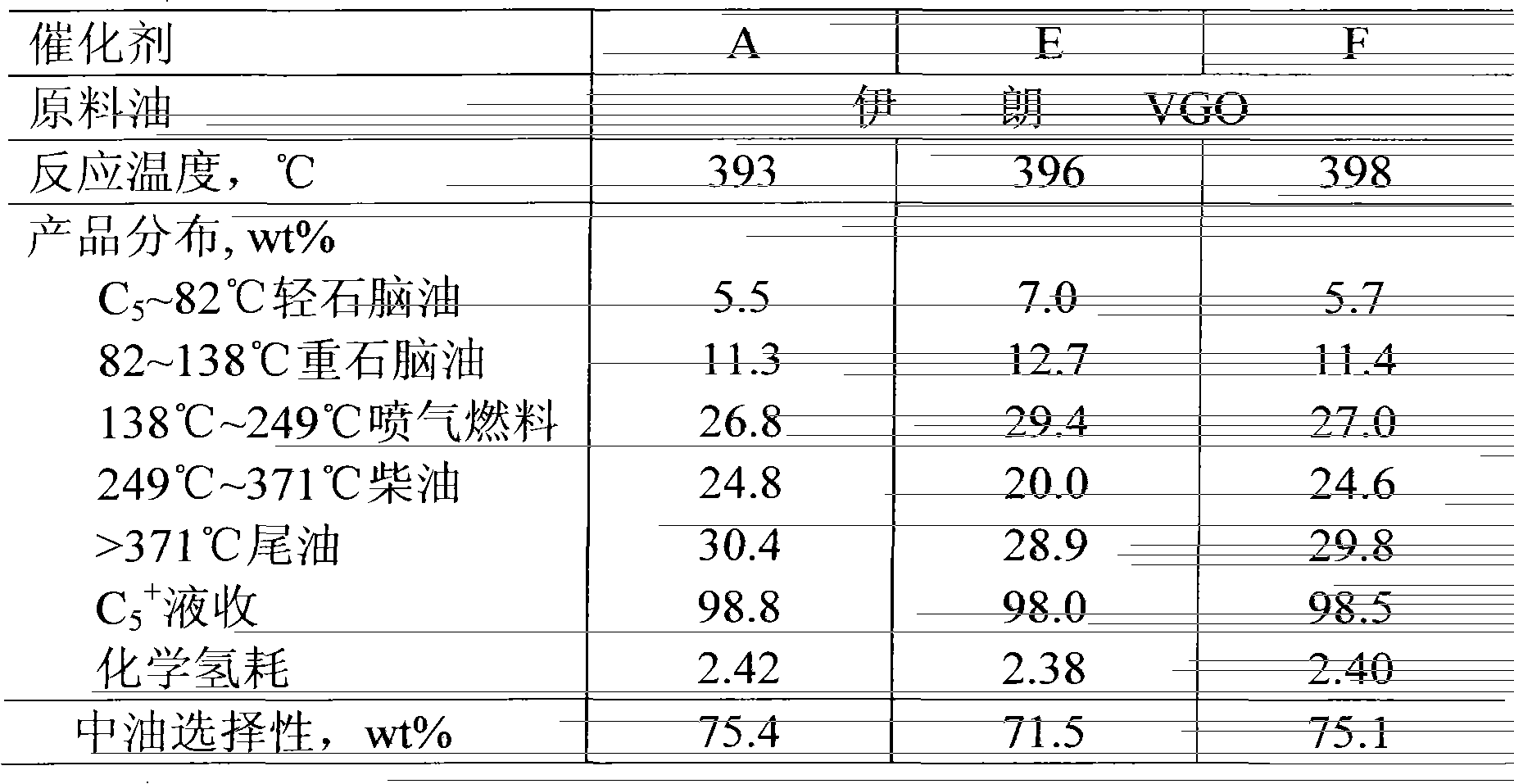

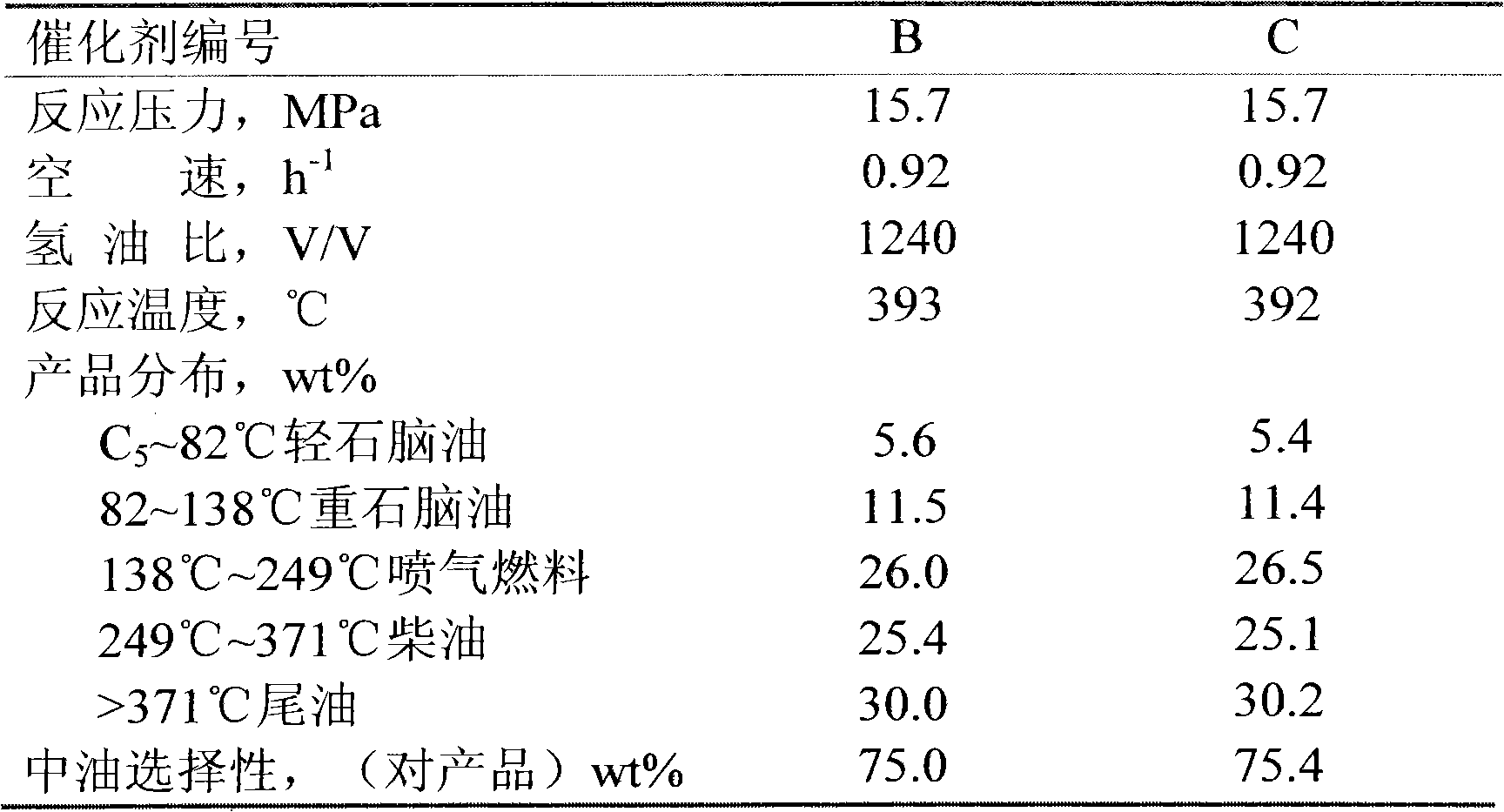

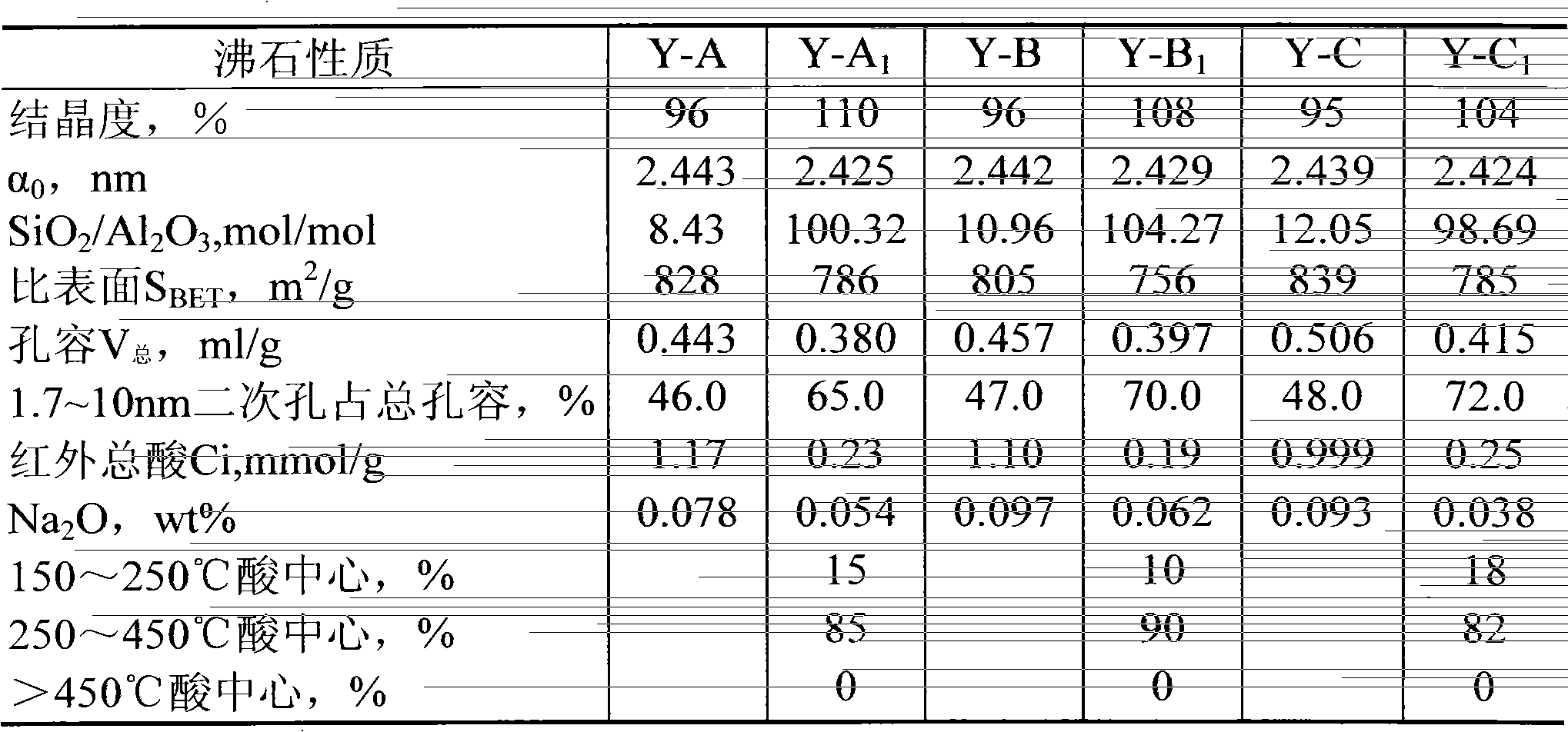

[0037] It is the hydrocracking catalyst B of the present invention, and the preparation method is the same as that of Example 1, except that 20% of the Y-type molecular sieve modified by hydrothermal treatment is added before aging, and the molecular sieve Y-B prepared by ZL96119840.0 Example 2 is used as a raw material for the molecular sieve, and the Hydrothermal treatment, hydrothermal treatment conditions are temperature 780 ° C, pressure 0.3 MPa, ammonia partial pressure 1000 Pa, time 22 hours, then acid treatment, using 2.0 M sulfuric acid 3000 ml, sulfuric acid and molecular sieve weight ratio is 1: 2, temperature 50 ° C , time 12 hours, obtained modified molecular sieve Y-B 1 , Y-B and Y-B 1 The properties are shown in Table 3. Catalyst weight composition is: WO 3 21.0%, NiO 7.5%, ZrO 2 6.5%, SiO 2 35.0%, Al 2 o 3 30.0%, the specific surface is 245m 2 / g, the pore volume is 0.34ml / g.

example 3

[0039] It is the hydrocracking catalyst C of the present invention, and the preparation method is the same as that of Example 1, except that 30% of the Y-type molecular sieve modified by hydrothermal treatment is added before aging, and the molecular sieve Y-C prepared by ZL96119840.0 Example 3 is used as a raw material for the molecular sieve, and the Hydrothermal treatment, hydrothermal treatment conditions are temperature 800 ° C, pressure 0.2MPa, ammonia partial pressure 2500Pa, time 28 hours, then carry out acid treatment, use 4.0M hydrochloric acid 8500 milliliters, hydrochloric acid and molecular sieve weight ratio is 1: 18, temperature 70 ℃, time 15 hours, obtained modified molecular sieve Y-C 1 , Y-C and Y-C 1 The properties are shown in Table 3. Catalyst weight composition is: WO 3 23.6%, NiO 7.4%, ZrO 2 7.0%, SiO 2 34.0%, Al 2 o 3 28.0%, the specific surface is 270m 2 / g, the pore volume is 0.35ml / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com