Hydrocracking catalyst carrier, hydrocracking catalyst and preparation methods of hydrocracking catalyst carrier and hydrocracking catalyst

A catalyst carrier and hydrocracking technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of unsatisfactory industrial requirements, high isomerization content of tail oil, and unsatisfactory product yield and other problems, to achieve the effect of good hydrogenation function, excellent product quality, and improved catalyst activity and selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

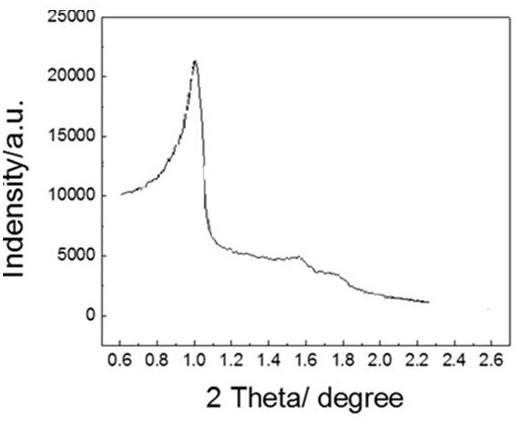

Image

Examples

Embodiment 1

[0078] (1) Preparation of Beta / Al-SBA-15 Composite Molecular Sieve

[0079] (1) Preparation of amorphous silica-alumina dry rubber powder A1 and slurry: sodium aluminate solution concentration 18gAl 2 o 3 / L, the concentration of sodium silicate solution is 80SiO 2 / L, take 0.30L sodium aluminate solution and put it into the gel-forming tank, then add 0.30L sodium silicate solution, control the reaction temperature at 20°C, and feed CO with a concentration of 35v%. 2 gas, CO 2 When the gas accounts for 65% of the total intake, add 0.30L sodium silicate solution while ventilating to control the pH value of the gel to 9.2, then ventilate and stabilize for 20 minutes, filter the slurry and wash it with 65°C deionized water until neutral. The filter cake was beaten with water at a solid-to-liquid volume ratio of 10:1, treated at 130°C and 3.5 MPa steam pressure for 3 hours, dried at 120°C for 6 hours, crushed and sieved to obtain the amorphous silica-alumina product A1. The pr...

Embodiment 2

[0088] (1) Preparation of Beta / Al-SBA-15 Composite Molecular Sieve

[0089] (1) Preparation of amorphous silica-alumina dry rubber powder A2 and slurry: concentration of sodium aluminate solution 32gAl 2 o 3 / L, the concentration of sodium silicate solution is 115gSiO 2 / L, take 0.8L sodium aluminate solution and put it into a gel-forming tank, then add 0.2L sodium silicate solution, control the reaction temperature at 22°C, and feed CO with a concentration of 48v%. 2 gas, CO 2 When the gas accounts for 55% of the total feed volume, add 0.25L sodium silicate solution while ventilating to control the pH value of the gel to 9.8, then ventilate and stabilize for 20 minutes, filter the slurry and wash it with 75°C deionized water until neutral. The filter cake was beaten with water at a solid-to-liquid volume ratio of 8:1, treated at 110°C and 3.0 MPa steam pressure for 3 hours, dried at 120°C for 8 hours, crushed and sieved to obtain amorphous silicon-aluminum product A2, amor...

Embodiment 3

[0098] (1) Preparation of Beta / Al-SBA-15 Composite Molecular Sieve

[0099] (1) Preparation of amorphous silica-alumina dry rubber powder A3 and slurry: sodium aluminate solution concentration 20gAl 2o 3 / L, sodium silicate working solution concentration 85gSiO 2 / L, take 1.08L of sodium aluminate solution and place it in a gel-forming tank, then add 0.2L of sodium silicate solution, control the reaction temperature at 32°C, and feed CO with a concentration of 55v%. 2 Gas, stop when the pH value reaches 9.8, then ventilate and stabilize for 20 minutes, wash until neutral, add water to the filter cake according to the solid-liquid volume ratio of 8:1, and treat it at 130°C for 2.5 hours under 3.9MPa steam pressure. After drying at 120°C for 8 hours, it was crushed and sieved to obtain the amorphous silica-alumina product A3. The properties of amorphous silica-alumina dry rubber powder A3 are shown in Table 1. The prepared amorphous silica-alumina A3 and deionized water were...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com