Mesoporous catalytic material containing phosphorus, magnesium and rare earth

A catalytic material and rare earth compound technology, applied in the field of mesoporous catalytic materials, can solve the problems of poor cracking activity, high price, large steric hindrance effect, etc., and achieve the effect of high cracking activity and low yield of heavy oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This example illustrates the preparation of the mesoporous catalytic material provided by the present invention.

[0030] Take Al 2 (SO 4 ) 3 The solution and ammonia water are used as the reaction raw materials, and the glue is formed by batch co-flow, the gelation temperature is 45°C, the gelation pH is 10.5, the glue is collected into a liquid and water glass is added in proportion, and the temperature is raised to 60°C for 3 hours; after filtering and washing , according to the dry basis of the precipitate: ammonium salt: H 2 Add NH at a weight ratio of O=1:1:10 4 Cl and deionized water were exchanged for 1 h at 65 °C to Na 2 The O content is washed to below 0.3%; then the obtained solid precipitate is calculated according to the dry basis of the precipitate: H 2 O=1:8 weight ratio mixed with water for beating, and press P 2 o 5 :MgO:Material dry basis=0.016:0.021:1 Add phosphoric acid and magnesium chloride at a weight ratio of 1, then react at 60°C for 2 ho...

Embodiment 2

[0033] This example illustrates the preparation of the mesoporous catalytic material provided by the present invention.

[0034] The preparation process is the same as in Example 1, wherein the solid precipitate after the ammonium exchange is on a dry basis: RE 2 o 3 :H 2 O=1:0.031:8 weight ratio mixed with mixed rare earth chloride and water, then reacted at 60°C for 1 hour, filtered and washed, and then pressed P 2 o 5 : MgO: material dry basis = 0.010:0.015:1 weight ratio directly mixed with phosphoric acid and magnesium chloride, ground evenly, dried at 120°C for 15 hours, and then calcined at 600°C for 2 hours to obtain the mesoporous catalytic material provided by the present invention. Recorded as PRM-2.

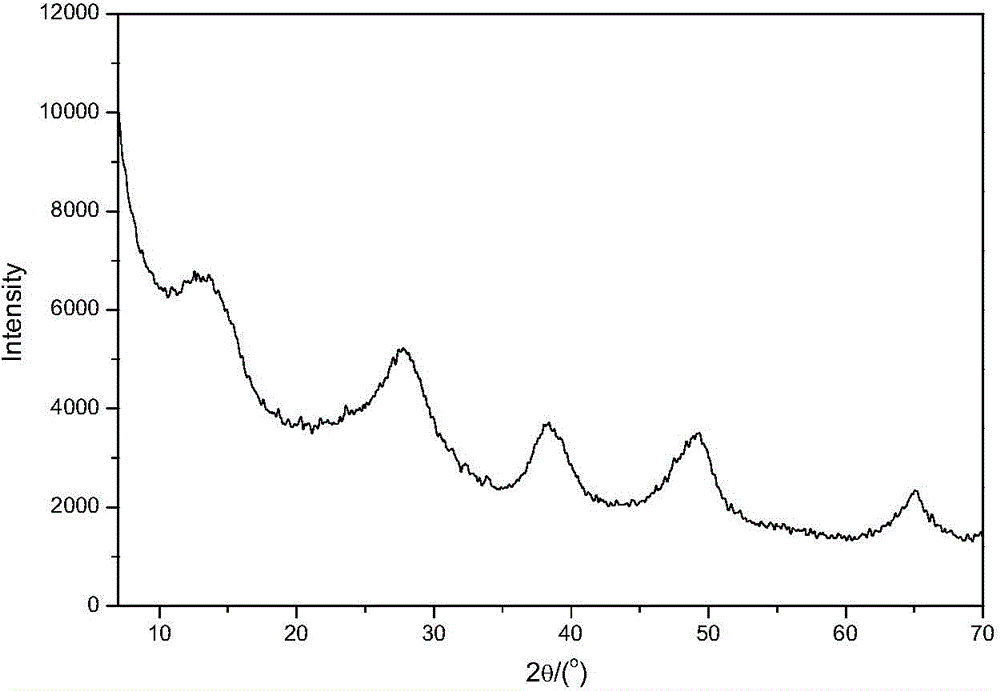

[0035] PRM-2 has a pseudo-boehmite phase structure, and its X-ray diffraction pattern is the same as figure 1 Characteristic shown; its elemental analysis chemical composition is 0.08Na 2 O·73.4Al 2 o 3 20.6SiO2 2 1.0P 2 o 5 1.5MgO 3.0RE 2 o 3 ; Specific ...

Embodiment 3

[0037] This example illustrates the preparation of the mesoporous catalytic material provided by the present invention.

[0038] The preparation process is the same as in Example 1, wherein the solid precipitate after the ammonium exchange is re-pulped, and then pressed on a dry basis: P 2 o 5 :MgO:RE 2 o 3 =1:0.025:0.035:0.015 weight ratio Add ammonium dihydrogen phosphate, magnesium chloride and mixed rare earth chloride solution into the slurry, react at 70°C for 2 hours, filter and wash with water, and dry at 120°C for 15 hours to obtain The mesoporous catalytic material provided by the invention. Recorded as PRM-3.

[0039] PRM-3 has a pseudo-boehmite phase structure, and its X-ray diffraction pattern is the same as figure 1 Characteristic shown; its elemental analysis chemical composition is 0.11Na 2 O·59.2Al 2 o 3 33.2SiO2 2 2.3P 2 o 5 3.4MgO 1.5RE 2 o 3 ; Specific surface area 377m 2 / g, pore volume 0.98cm 3 / g, the average pore diameter is 10.4nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com