Isomorphous composite molecular sieve and preparation method and application thereof

A composite molecular sieve and molecular sieve technology, applied in the direction of molecular sieve catalysts, chemical instruments and methods, crystalline aluminosilicate zeolites, etc., can solve the problems of poor hydrothermal stability, collapse of crystal channel topology, and failure to widely promote nanometer Y-type molecular sieves, etc. problems, to achieve the effect of enhanced hydrothermal stability and cracking activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

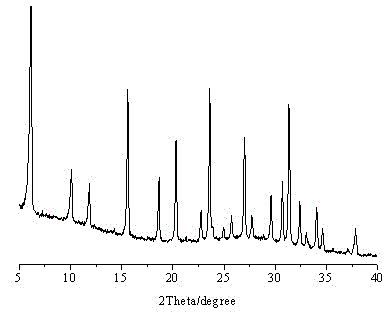

Image

Examples

Embodiment 1

[0018] Prepare guides. Under the condition of stirring, water glass, sodium hydroxide, water and aluminum source were successively added into the beaker, after stirring evenly, it was put into a stainless steel synthesis kettle and aged at 50°C for 48 hours to obtain the directing agent. The molar ratio of each material in the mixture is n (Na 2 O): n (Al 2 o 3 ): n (SiO 2 ): n (H 2 (O)=16:1:15.5:360.

[0019] Preparation of composite molecular sieves. Under the condition of stirring, add water glass, sodium hydroxide, aluminum source and water into the beaker in turn, and then add the required amount of Y-type molecular sieve (the molar ratio of silicon oxide to aluminum oxide is 5.2) into the solution, After stirring evenly, add a directing agent, stir for 1.5 hours, put the gel into a stainless steel reactor, and crystallize at a constant temperature of 100°C for 48 hours, cool, wash, suction filter, and dry to obtain a Y-Y composite molecular sieve. The mass of ...

Embodiment 2

[0021] Prepare guides. Under the condition of stirring, water glass, sodium hydroxide, water and aluminum source were successively added into the beaker, after stirring evenly, it was put into a stainless steel synthesis kettle and aged at 60°C for 18 hours to obtain the directing agent. The molar ratio of each material in the mixture is n (Na 2 O): n (Al 2 o 3 ): n (SiO 2 ): n (H 2 O) =15:1:17:380.

[0022]Preparation of composite molecular sieves. Under the condition of stirring, add water glass, sodium hydroxide, aluminum source and water into the beaker in turn, and then add the required amount of Y-type molecular sieve (the molar ratio of silicon oxide to aluminum oxide is 6.2) into the solution, After stirring evenly, add a directing agent, and after stirring for 1 hour, put the gel into a stainless steel reaction kettle for constant temperature crystallization at 110°C for 24 hours, cool, wash, suction filter, and dry to obtain a Y-Y composite molecular sieve....

Embodiment 3

[0024] Prepare guides. Under the condition of stirring, water glass, sodium hydroxide, water and aluminum source were successively added into the beaker, after stirring evenly, it was put into a stainless steel synthesis kettle and aged at 45°C for 56 hours to obtain the directing agent. The molar ratio of each material in the mixture is n (Na 2 O): n (Al 2 o 3 ): n (SiO 2 ): n (H 2 O) =17:1:16:420.

[0025] Preparation of composite molecular sieves. Under the condition of stirring, add water glass, sodium hydroxide, aluminum source and water into the beaker in sequence, and then add the required amount of Y-type molecular sieve (the molar ratio of silicon oxide to aluminum oxide is 4.8) into the solution, After stirring evenly, add a directing agent, and after stirring for 1 hour, put the gel into a stainless steel reactor and crystallize at a constant temperature of 100°C for 60 hours, cool, wash, suction filter, and dry to obtain a Y-Y composite molecular sieve. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com