Block copolymer, block copolymer composition, preparation method of block copolymer, vulcanized rubber, application of vulcanized rubber, tire tread and tire

A technology of block copolymer and composition, which is applied in the tire tread and tire fields, can solve the problems affecting the dispersion of additives, rubber vulcanization and final performance, general wet skid resistance, poor rubber wet skid resistance, etc., to improve Anti-wet performance, reduction of end effect, reduction of rolling resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

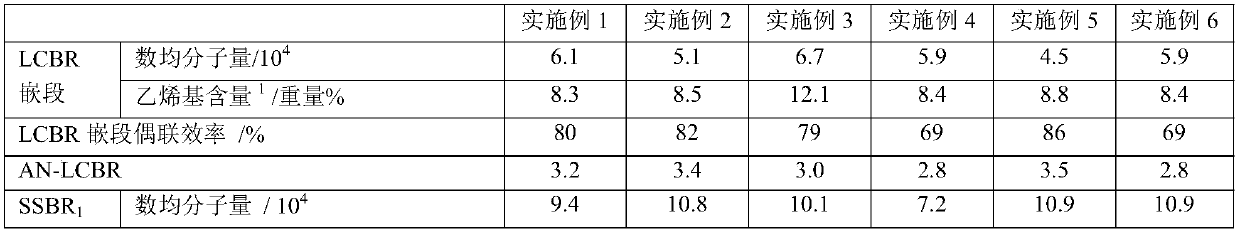

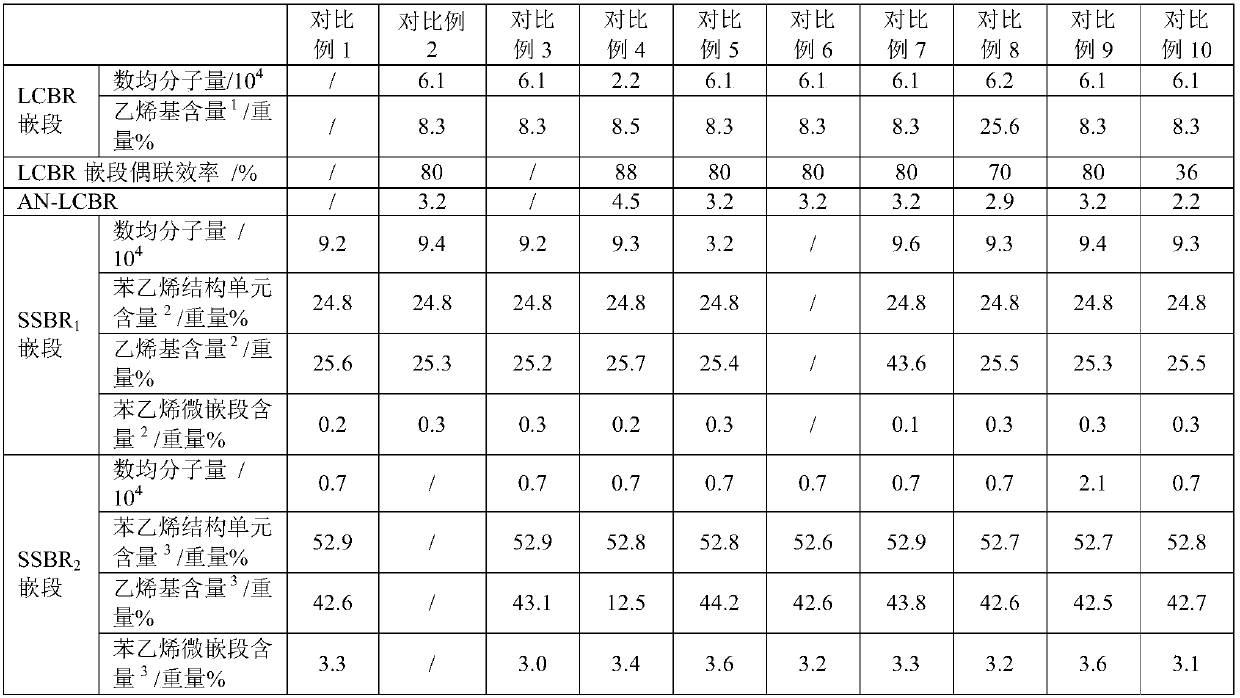

Examples

Embodiment 1

[0125] (1) Under the protection of high-purity nitrogen, add 2200g cyclohexane and 145g butadiene to a 5L batch polymerization reactor equipped with an anchor stirrer in sequence, start stirring, heat the circulating water bath to 55°C, and add 2.4mL n-butyllithium solution (1.0M hexane solution, the same below) initiates the polymerization reaction, reacts at 70°C for 30min (monomer conversion rate is more than 99% by weight), and obtains the first polymerization reaction containing butadiene homopolymerization segment. Mixture.

[0126] (2) Add 4.8mL divinylbenzene hexane solution (mass concentration is 80.32%, wherein, the mass concentration of p-DVB is 26.2%, the mass concentration of m-DVB is 54.12% in the reactor, purchased from Bailingwei Reagent Co., Ltd., dilute the commercially available solution to 0.4M for use, the same below), and react at 70° C. for 25 minutes to obtain the second polymerization mixture.

[0127] (3) Add 2.4mL tetrahydrofuran (THF) and 1.4mL pot...

Embodiment 2

[0131] (1) Under the protection of high-purity nitrogen, add 2200g cyclohexane and 135g butadiene to a 5L batch polymerization reactor equipped with an anchor stirrer in sequence, start stirring, heat the circulating water bath to 60°C, and add 2.7mL of n-butyllithium solution initiated the polymerization reaction, reacted at 70°C for 30min (monomer conversion rate above 99% by weight), and obtained the first polymerization mixed liquid containing butadiene homopolymerization segment.

[0132] (2) Add 5.4 mL of a hexane solution of divinylbenzene into the reactor, and react at 60° C. for 30 min to obtain a second polymerization mixture.

[0133] (3) Add 2.9mL THF and 1.8mL t-AmOK hexane solution in the reactor, then add 292g butadiene and styrene mixed monomer (wherein, butadiene 219g, styrene 73g, adopt butyllithium solution out of the kettle); polymerization at 70° C. for 80 minutes (monomer conversion rate above 99% by weight) to obtain the third polymerization mixed liquid...

Embodiment 3

[0137] (1) Add 2200g of cyclohexane, 0.2mL of tetrahydrofuran and 147g of butadiene to a 5L batch polymerization reactor equipped with an anchor stirrer under the protection of high-purity nitrogen, start stirring, and heat to 60°C in a circulating water bath. Add 2.3mL of n-butyllithium solution into the reactor to initiate the polymerization reaction, and react at 70° C. for 30 minutes (monomer conversion rate is above 99% by weight), to obtain the first polymerization mixed liquid containing butadiene homopolymerization segment.

[0138] (2) Add 4.6 mL of a hexane solution of divinylbenzene into the reactor, and react at 70° C. for 30 min to obtain a second polymerization mixture.

[0139] (3) Add 2.3mL THF and 1.9mL sodium dodecylbenzenesulfonate (SDBS) hexane solution (concentration is 0.3M, purchased from Bailingwei Reagent Company, the same below) in the reactor, then add 226g butadiene Mix monomers with styrene (among them, butadiene 170g, styrene 56g, use butyllithium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com