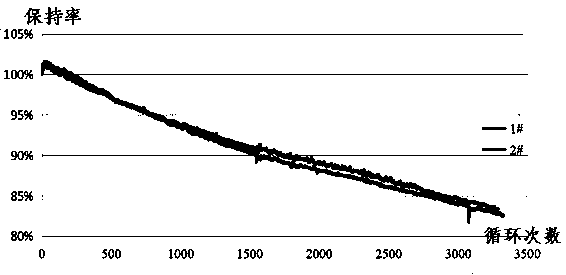

Ternary high-nickel electrolyte and high-nickel anode lithium ion battery containing same

An electrolyte, high nickel technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of deterioration of battery electrochemical performance, deterioration of cell performance, etc., to achieve excellent normal temperature cycle performance, low water sensitivity, low temperature good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

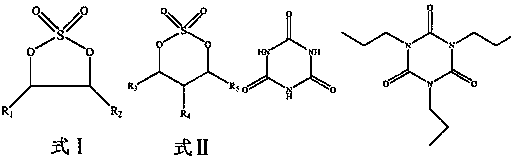

Method used

Image

Examples

Embodiment 1

[0039] Prepare the ternary high-nickel electrolyte in Table 1 according to the raw materials and weight ratio, and the preparation ratio is calculated and prepared in units of weight ratio per KG (this formula is limited to cylindrical lithium-ion batteries):

[0040] Electrolyte

LiPF6

LIFSI

LiBOB

TMSP

FPN

SN

EC

DMC

FEC

DTD

VC

Implementation one

150

2

3

3

10

15

175

554

70

15

3

Implementation two

150

2

3

5

10

15

175

552

70

15

3

Implementation three

150

2

5

3

10

15

175

552

70

15

3

[0041] The first group: Preparation of ternary high-nickel electrolyte

[0042] 1) Preparation of ternary high-nickel electrolyte

[0043] a) Inject the non-aqueous organic solvent cyclic carbonate compound EC, dimethyl carbonate DMC, and ethoxypentafluorotripolyphosphine FPN into the mixer in sequence according to the weight...

Embodiment 2

[0056] A high-nickel positive electrode lithium-ion battery, comprising a ternary high-nickel electrolyte, a positive electrode diaphragm obtained by coating the positive electrode slurry, a negative electrode diaphragm obtained by coating the negative electrode slurry, and a separator;

[0057] The first group: preparation of high-nickel ternary positive electrode slurry, 92% high-nickel positive ternary powder, 2% conductive agent, 2% functional composite binder, among which A-type alkali-resistant bonding in the composite functional binder Agent PVDF: Class B high bond strength binder PVDF=1:2; the chemical formula of the high-nickel ternary positive electrode is: LiNi x co y m z o 2 , where x+y+z=1, 0.6≤x<1, M can represent Mn, Al or other metal elements.

[0058] The solvent is N-methylpyrrolidone, and the amount used ensures that the solid matter content of the slurry is 65%.

[0059] The preparation of the above-mentioned high-nickel ternary positive electrode slurr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com