A kind of fluorine rubber compound with low temperature flexibility and high wear resistance and preparation method

A fluororubber raw rubber and fluororubber technology is applied in the field of low-temperature flexible and high-wear-resistant fluororubber compounding and preparation, which can solve the problems of no special mention of wear resistance and no mention of wear resistance, and achieve reliable sealing performance, low temperature performance improvement, and the effect of improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

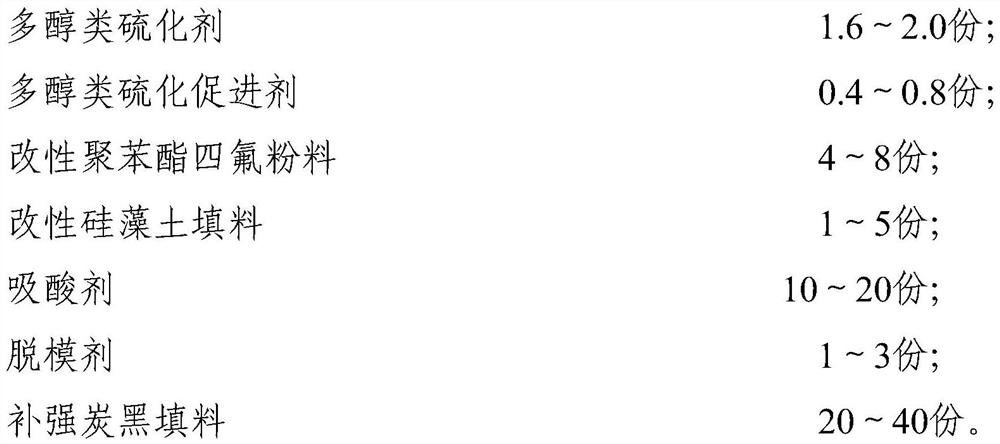

[0095] This embodiment provides a kind of fluorine rubber compound with low temperature flexibility and high wear resistance, the formula is as follows: (by weight)

[0096]

Embodiment 2

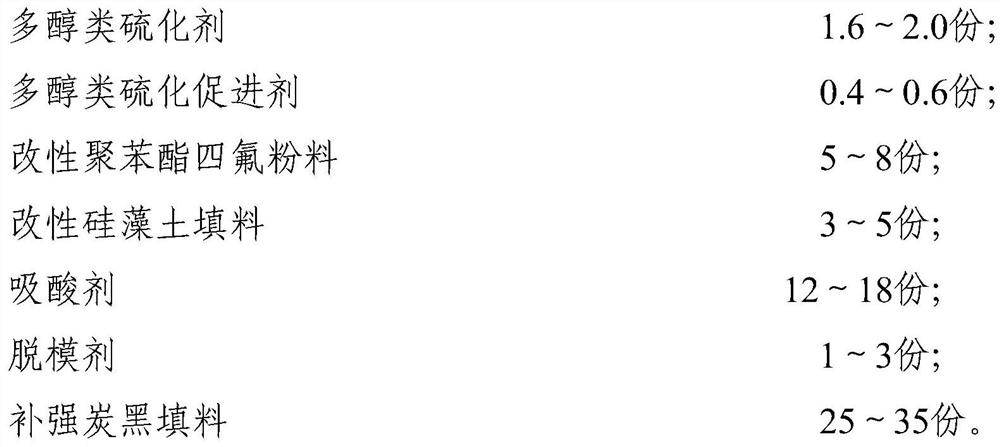

[0098] This embodiment provides a fluororubber compound with low temperature flexibility and high wear resistance, the formula is as follows (by weight):

[0099]

[0100]

Embodiment 3

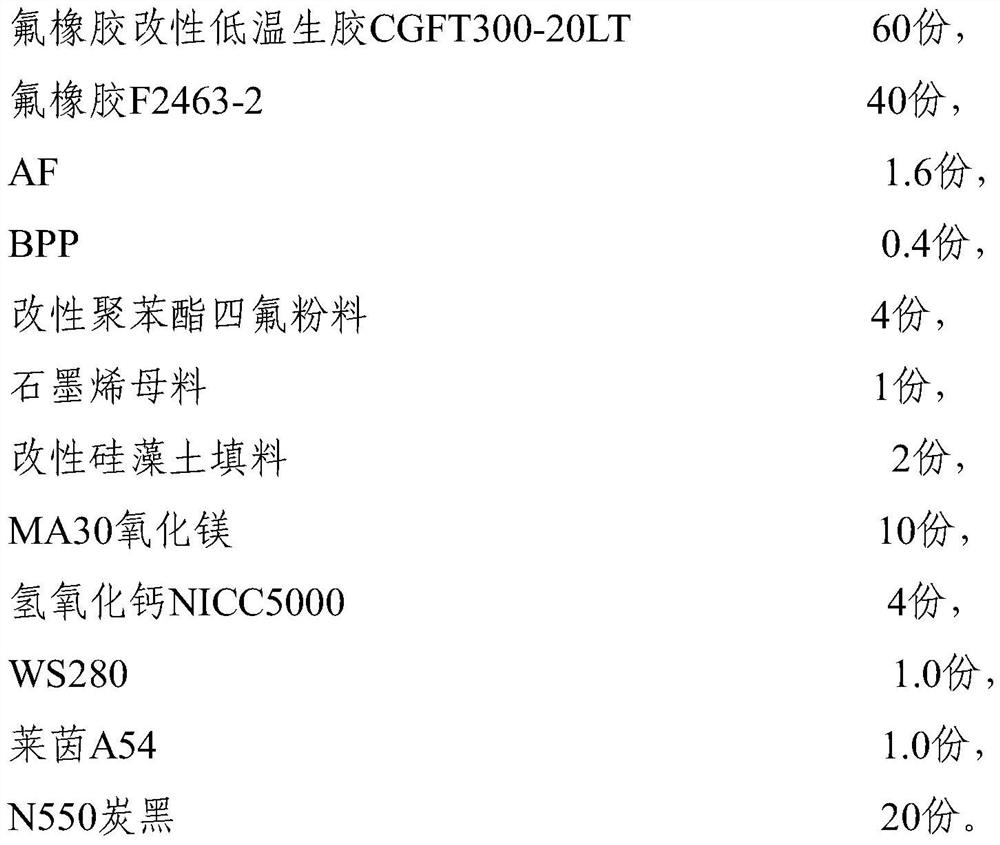

[0102] This embodiment provides a fluororubber compound with low temperature flexibility and high wear resistance, the formula is as follows (by weight):

[0103]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com