Casting method of low temperature resistant iron cushion plate for high speed railway buckling part

A high-speed railway and iron backing plate technology, applied in the field of casting, can solve problems such as brittle fracture, cracking, and affecting the safety of railway lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

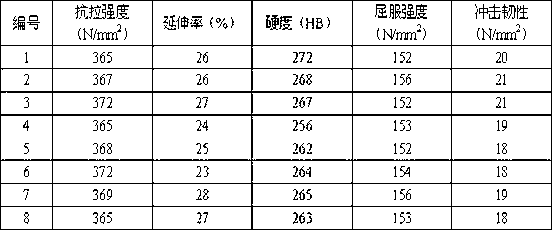

Embodiment 1

[0012] The casting method of low-temperature-resistant iron backing plates for high-speed railway fasteners includes smelting, spheroidizing inoculation and casting. The raw materials for smelting are pig iron and low-carbon steel with P: ≤0.04%, S: ≤0.03%, and the molten iron after smelting is passed through the ball After melting and inoculation, casting and molding are carried out, and heat treatment is carried out after casting and molding to obtain the required iron backing plate. Mn≤0.3% in hot metal, Si≤2.7%, and the total amount of other alloys≤0.3%. Inoculation includes three inoculations: in-package inoculation, in-mold inoculation and in-flow inoculation; in the selection of nodulizers and inoculants, focus on the following aspects of control: First, strictly control the content of ingredients: main elements such as Mg, Re, Ca, Ba, etc. The deviation range should be less than ±0.3%; the second is mainly Mg, supplemented by Re elements, and at the same time with Ca, ...

Embodiment 2

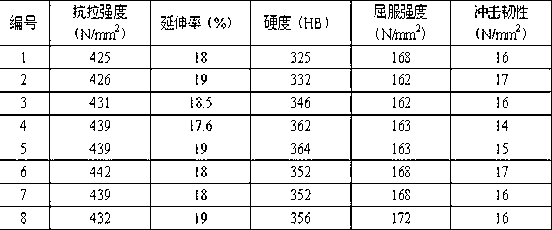

[0021] In this embodiment, the ferrosilicon inoculant with a particle size of 15 mm is used as the inoculant inoculated in the bag, the barium silicon inoculant with a particle size of 3 mm is used as the inoculant for inoculation in the mold, and the silicon barium inoculant with a particle size of 0.65 mm is used as the inoculant for inoculation with the flow. Strontium inoculant. The molten iron temperature is 1520°C, and the pouring temperature is 1440°C. The heat treatment adopts low-temperature annealing treatment, the heating temperature is 740°C, the holding time is 2.5 hours, and it is cooled to 600°C with the furnace. Others are the same as embodiment 1.

Embodiment 3

[0023] In this embodiment, the ferrosilicon inoculant with a particle size of 20 mm is used as the inoculant inoculated in the bag, the barium silicon inoculant with a particle size of 5 mm is used as the inoculant for inoculation in the mold, and strontium silicon with a particle size of 1 mm is used as the inoculant for inoculation with the flow. Inoculants. The molten iron temperature is 1530°C, and the pouring temperature is 1460°C. The heat treatment adopts low-temperature annealing treatment, the heating temperature is 760°C, the holding time is 3 hours, and it is cooled to 600°C with the furnace. Others are the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Impact energy | aaaaa | aaaaa |

| Impact energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com