NEPE (nitrate ester plasticized polyether) propellant with good low-temperature mechanical property

A low-temperature performance and propellant technology, which is applied in the field of NEPE propellants, can solve problems such as not fully meeting the use requirements and not being suitable for NEPE propellants, and achieve the effects of improving low-temperature mechanical properties, improving low-temperature performance, and increasing low-temperature elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Propellant composition

[0039] components PET NG TEGDN PTC RDX Content (%wt) 5.33 0 13.32 3 21 components Al AP HDI Content (%wt) 19 38 0.35

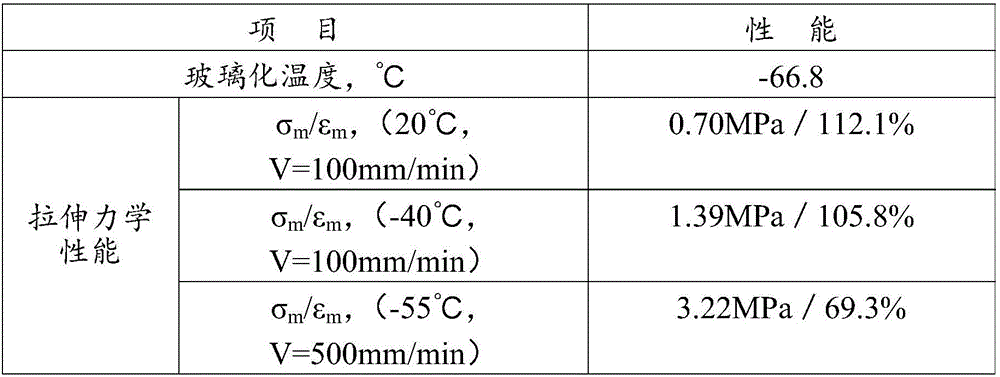

[0040] (2) Propellant performance

[0041]

Embodiment 2

[0043] (1) Propellant composition

[0044] components PET NG TEGDN PTC RDX Content (%wt) 5.61 0 14.02 2 25 components Al AP HDI Content (%wt) 18 35 0.37

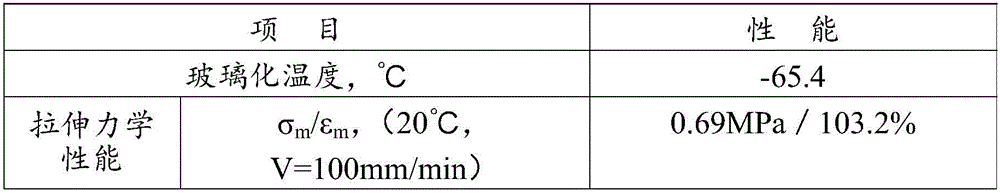

[0045] (2) Propellant performance

[0046]

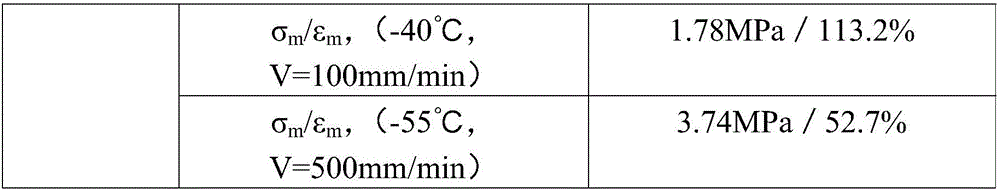

[0047]

Embodiment 3

[0049] (1) Propellant composition

[0050] components PET NG TEGDN PTC RDX Content (%wt) 5.89 0 14.72 1 41 components Al AP HDI Content (%wt) 15 23 0.39

[0051] (2) Propellant performance

[0052]

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com