Deacidifying agent decreasing acid value of liquid organic mixtures and preparation technology

A technology for the preparation of organic mixtures, applied to liquid carbon-containing fuels, biofuels, refined hydrocarbon oils, etc., can solve the problems of incomplete separation, low recovery rate, high energy consumption, etc., and achieve complete deacidification effect and production safety High, low energy consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

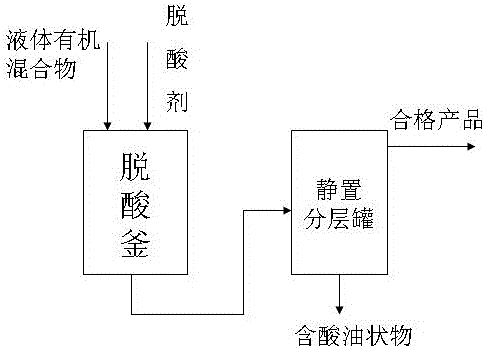

Method used

Image

Examples

Embodiment 1

[0016] After heating the mixed fatty acid methyl esters with an acid value of 7.2mgKOH / g to 35°C, add it into the deacidification tank, then add the deacidification agent of the present invention while stirring, keep stirring for 1 hour, and let it stand for 20 minutes. The material temperature in the deacidification kettle is 55°C and normal pressure. The mass ratio of the deacidifying agent to the fatty acid in the mixed fatty acid methyl ester is 1.6:1; the deacidifying agent is composed of potassium hydroxide and isopropanol. The volume of the deacidification kettle is 3 cubic meters. The preparation process of the deacidification agent is to mix and stir potassium hydroxide and isopropanol at a temperature of 35° C. to form a solution. The mixing and stirring time is 8 hours, and the molar ratio of sodium hydroxide and isopropanol is 1:6.

[0017] After the fatty acid in the mixed fatty acid methyl ester forms a complex with the deacidifying agent, it settles naturally. ...

Embodiment 2

[0019] set the acid value to 3 7.9 mgKOH / 100mL straight-run diesel oil was heated to 25°C, then added to the deacidification tank, then added the deacidification agent of the present invention while stirring, continued stirring for 1 hour, and allowed to stand for 30 minutes. The temperature of the material in the deacidification kettle is 35° C., normal pressure, and the mass ratio of the deacidification agent to the naphthenic acid in the straight-run diesel oil is 1.8:1; the deacidification agent is composed of potassium carbonate and glycerol. The volume of the deacidification kettle is 3 cubic meters. The preparation process of the deacidification agent is to mix and stir potassium carbonate and glycerol at a temperature of 65° C. to form a solution. The mixing and stirring time is 10 hours, and the molar ratio of potassium carbonate and glycerol is 1:4.

[0020] After the naphthenic acid in the straight-run diesel forms a complex with the deacidification agent, it settl...

Embodiment 3

[0022] the acid value 7.9 After the product mixture of the esterification reaction of citric acid and butanol in mgKOH / g is heated to 25 ℃, join in the deacidification kettle, then add the deacidification agent of the present invention while stirring, keep stirring for 1 hour, and stand for 10 minute. The material temperature in the deacidification kettle is 35°C and normal pressure. The mass ratio of the deacidifying agent to the organic acid in the product mixture of the esterification reaction is 1.5:1; the deacidifying agent is composed of magnesium carbonate and propylene glycol. The volume of the deacidification kettle is 3 cubic meters. The preparation process of the deacidification agent is to mix and stir magnesium carbonate and propylene glycol at a temperature of 55° C. to form a solution. The mixing and stirring time is 6 hours, and the molar ratio of magnesium carbonate and propylene glycol is 1:8.

[0023] After the acidic catalyst and residual organic acid in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com