Preparation method for sulfate-compatible polycarboxylic water reducer

A polycarboxylic acid-based and sulfate technology is applied in the preparation of water-reducing agents, and in the field of sulfate-compatible polycarboxylic acid-based water-reducing agents, which can solve the problem of increasing application costs and increasing a large number of polycarboxylic acid-based water-reducing agents. Popularization and application, etc., to achieve the effect of good adaptability, high cost performance, simple and easy-to-control preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

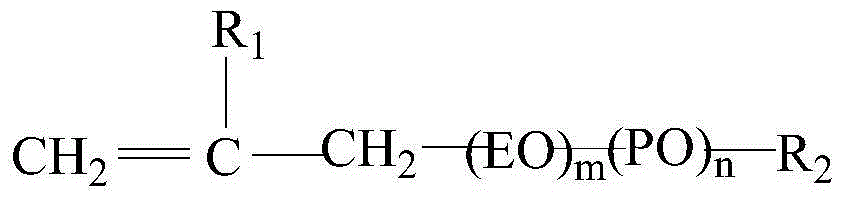

Image

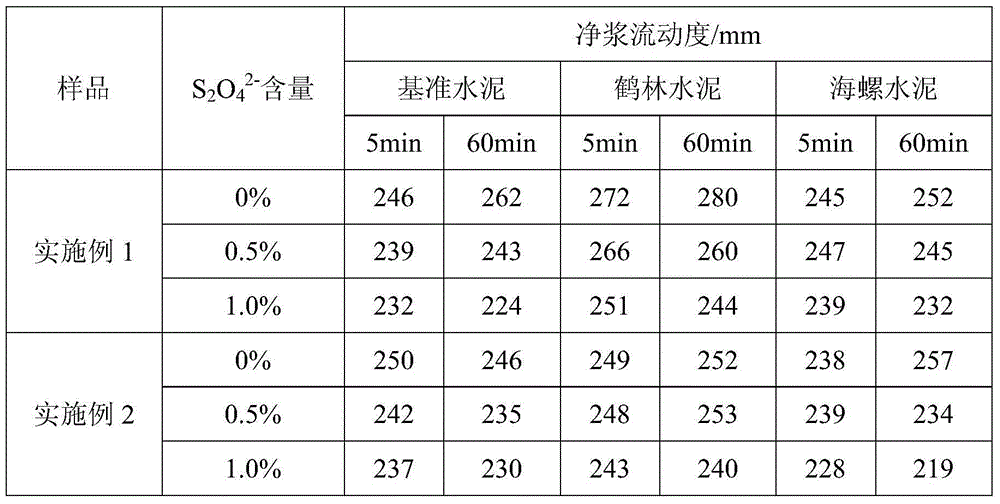

Examples

Embodiment 1

[0024] (1) Preparation of terpolymer: Add 292.8 parts of 2-acrylamide-2-methylpropanesulfonic acid and 258 parts of water in a four-necked flask equipped with stirrer, thermometer, water separator and nitrogen pipe Stir and dissolve at 35°C-40°C, then add 146 parts of liquid caustic soda to adjust the pH value to 7-7.5, add 3.3 parts of sodium lauryl sulfate and 26.6 parts of p-methylstyrene; stir for 0.5 hours while feeding nitrogen, and 13.3 parts of methacrylamide and 80 parts of water are premixed into 1 # Mixed solution; 12.4 parts of ammonium persulfate and 7.6 parts of sodium metabisulfite plus 160 parts of water are made into 2 # Mixed solution; drop the two mixed solutions at the same time at 38°C-40°C, drop them at a constant rate within 2h-3h; continue to keep warm at 38°C-40°C for 4h-6h after dropping; the terpolymer is obtained.

[0025] (2) Preparation of sulfate-compatible polycarboxylate water reducer: Add 42.6 parts of the prepared terpolymer, 416.7 parts of ...

Embodiment 2

[0027] (1) Preparation of terpolymer: Add 289.4 parts of 2-acrylamide-2-methylpropanesulfonic acid and 224 parts of water in a four-necked flask equipped with stirrer, thermometer, water separator and nitrogen pipe Stir and dissolve at 35℃~40℃, then add 193.5 parts of liquid caustic soda to adjust the pH value to 7~7.5, add 3.2 parts of sodium lauryl sulfate and 19.3 parts of styrene; Amide and 80 parts of water are pre-mixed into 1 # Mixed solution; 12.2 parts of sodium persulfate and 5.5 parts of sodium bisulfite plus 160 parts of water are made into 2 # Mixed solution; drop the two mixed solutions at the same time at 38°C-40°C, drop them at a constant rate within 2h-3h; continue to keep warm at 38°C-40°C for 4h-6h after dropping; the terpolymer is obtained.

[0028] (2) Preparation of sulfate-compatible polycarboxylate water-reducer: Add 53.2 parts of the prepared terpolymer and 415.7 parts of isopentenyl polyoxyethylene to a four-necked flask equipped with a stirrer and a...

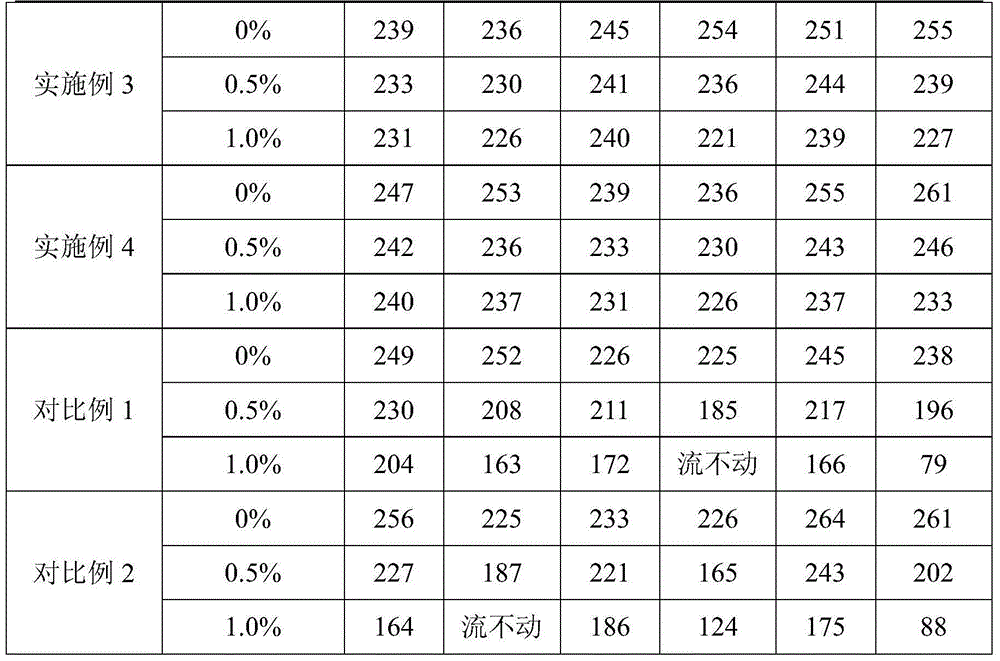

Embodiment 3

[0030] (1) Preparation of terpolymer: Add 277.4 parts of 2-acrylamide-2-methylpropanesulfonic acid and 234 parts of water in a four-necked flask equipped with stirrer, thermometer, water separator and nitrogen pipe Stir and dissolve at 35°C to 40°C, then add 180.2 parts of liquid caustic soda to adjust the pH to 7 to 7.5, add 2.9 parts of sodium lauryl sulfate and 22.6 parts of p-methylstyrene; stir for 0.5 hours while feeding nitrogen, and 22.6 parts of acrylamide and 80 parts of water are premixed into 1 # Mixed solution; 14.2 parts of ammonium persulfate and 6.1 parts of sodium metabisulfite plus 160 parts of water are made into 2 # Mixed solution; drop the two mixed solutions at the same time at 38°C-40°C, drop them at a constant rate within 2h-3h; continue to keep warm at 38°C-40°C for 4h-6h after dropping; the terpolymer is obtained.

[0031](2) Preparation of sulfate-compatible polycarboxylate water reducer: Add 70.4 parts of the prepared terpolymer, 393.2 parts of met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com