New method for recycling vanadium, iron and chromium elements from vanadium and chromium-containing sludge

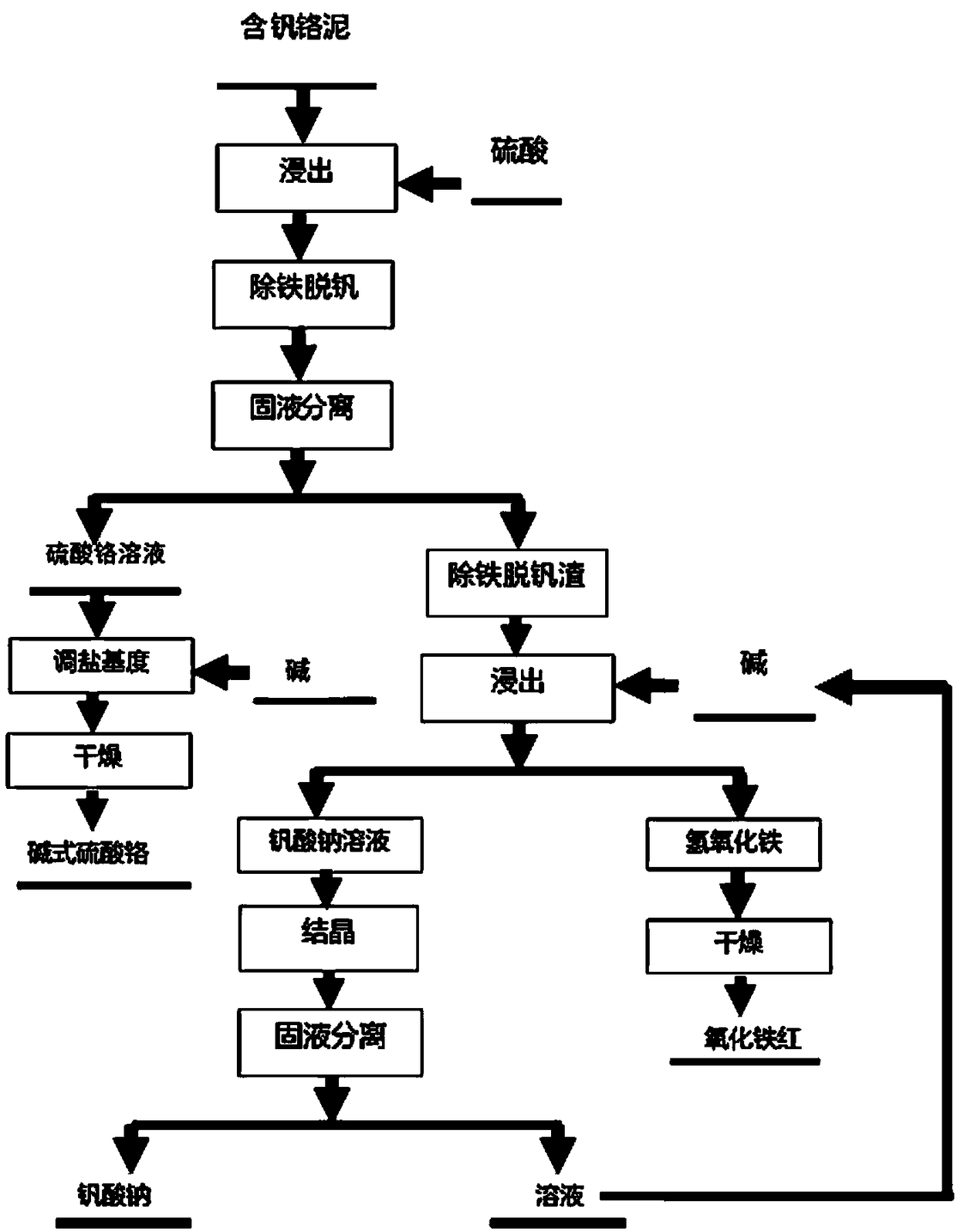

A new method, the technology of vanadium and chromium, applied in chemical instruments and methods, chromium sulfate, iron oxide, etc., can solve the problems of difficult separation, complicated technology, and difficult separation of vanadium and chromium elements, so as to achieve no three waste discharge problems and resource utilization. high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Undried vanadium-chromium-containing mud is used as raw material, sulfuric acid is used as leaching agent, the concentration of sulfuric acid is 5%, the amount of sulfuric acid added is twice the theoretical mass percentage of vanadium-chromium-containing mud, and the way of adding sulfuric acid is one-time addition. The liquid-solid ratio of vanadium-chromium mud is 15:1, the stirring speed is 120 rpm, the leaching temperature is 100°C, and the leaching time is 120min. After leaching, solid-liquid separation is carried out; Iron devanadium treatment, the reaction temperature is 110°C, the reaction time is 180min, and the stirring speed is 20 rpm; then solid-liquid separation is carried out, and the separated solution is a chromium sulfate solution, and the basicity is adjusted to 30% with sodium carbonate. After drying, the basic chromium sulfate product is obtained, and the product of iron and vanadium removal is directly subjected to alkali leaching treatment, the alk...

Embodiment 2

[0020] Using undried vanadium-chromium-containing mud as raw material, sulfuric acid as leaching agent, the concentration of sulfuric acid is 98%, the amount of sulfuric acid added is 0.8 times the theoretical mass percentage of vanadium-containing chromium mud, and the sulfuric acid is added dropwise. The liquid-solid ratio of chromium mud is 5:1, the stirring speed is 20 rpm, the leaching temperature is 20°C, and the leaching time is 20 minutes. After leaching, solid-liquid separation is carried out; the leached solution is deironed in a pressure reactor Vanadium removal treatment, the reaction temperature is 200°C, the reaction time is 10min, and the stirring speed is 120 rpm; then solid-liquid separation is carried out, and the separated solution is a chromium sulfate solution, and the basicity is adjusted to 40% with sodium bicarbonate. After drying, the basic chromium sulfate product is obtained, and the product of iron and vanadium removal is directly subjected to alkali...

Embodiment 3

[0022] Using undried vanadium-chromium-containing mud as raw material, sulfuric acid as leaching agent, the concentration of sulfuric acid is 75%, the amount of sulfuric acid added is 1.1 times the theoretical mass percentage of vanadium-containing chromium mud, and the adding method of sulfuric acid is dripping. The sulfuric acid solution and vanadium-containing The liquid-solid ratio of chromium mud is 10:1, the stirring speed is 60 rpm, the leaching temperature is 80°C, and the leaching time is 60 minutes. After leaching, solid-liquid separation is carried out; the leached solution is deironed in a pressure reactor Vanadium removal treatment, the reaction temperature is 160°C, the reaction time is 60min, and the stirring speed is 80 rpm; then solid-liquid separation is carried out, and the separated solution is a chromium sulfate solution, and the basicity is adjusted to 38% with sodium bicarbonate. After drying, the basic chromium sulfate product is obtained, and the produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com