Chromium(iii)-containing aqueous solution and process for production of same

A manufacturing method and aqueous solution technology, applied in the direction of chemical instruments and methods, chromium sulfate, chromium compounds, etc., can solve the problems of poor practicability, difficulty in obtaining a glossy surface, long time, etc., and achieve the effect of excellent gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0204] Hereinafter, the present invention will be described using examples, but the present invention is not limited to these examples. "%" means "wt%" unless otherwise specified.

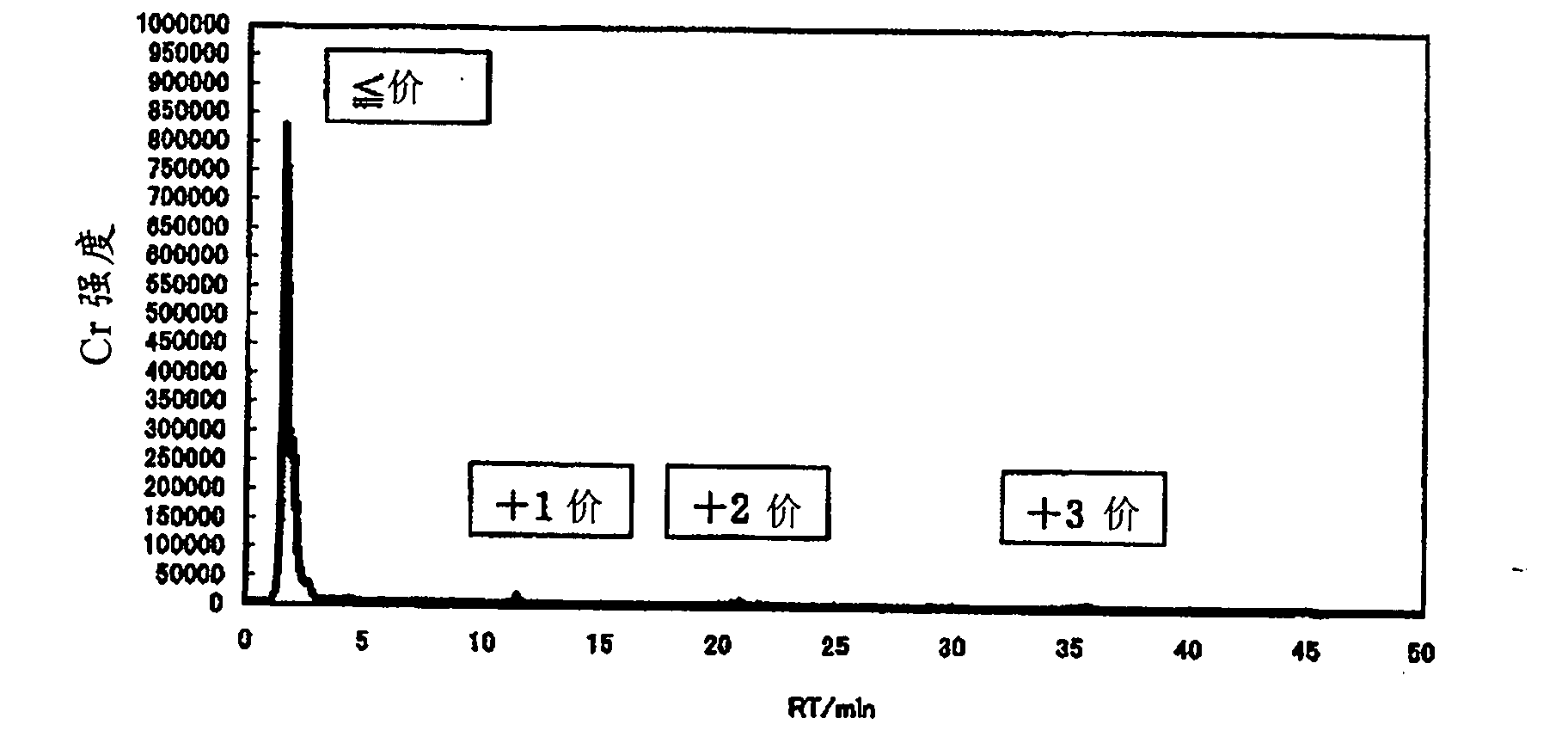

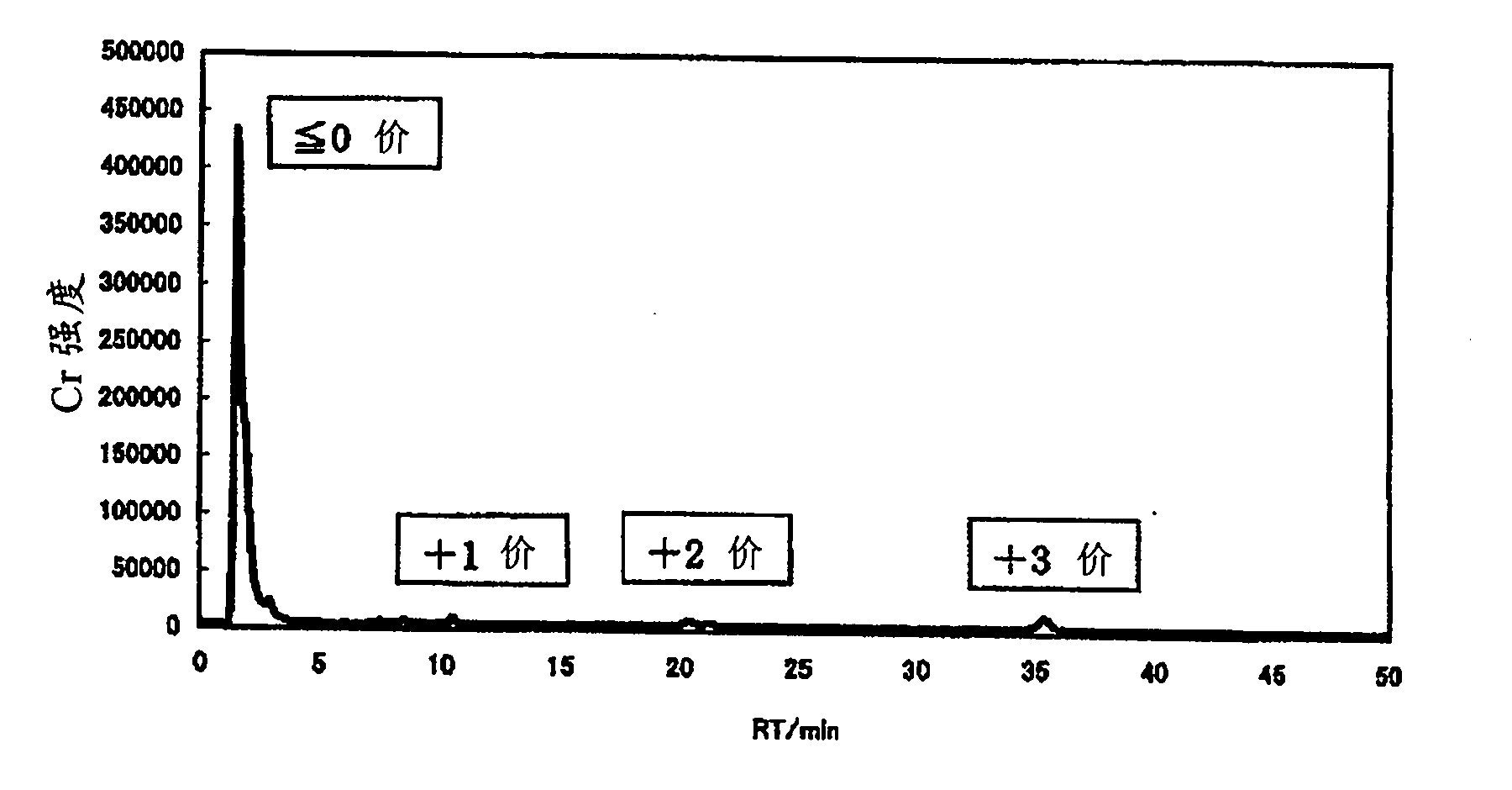

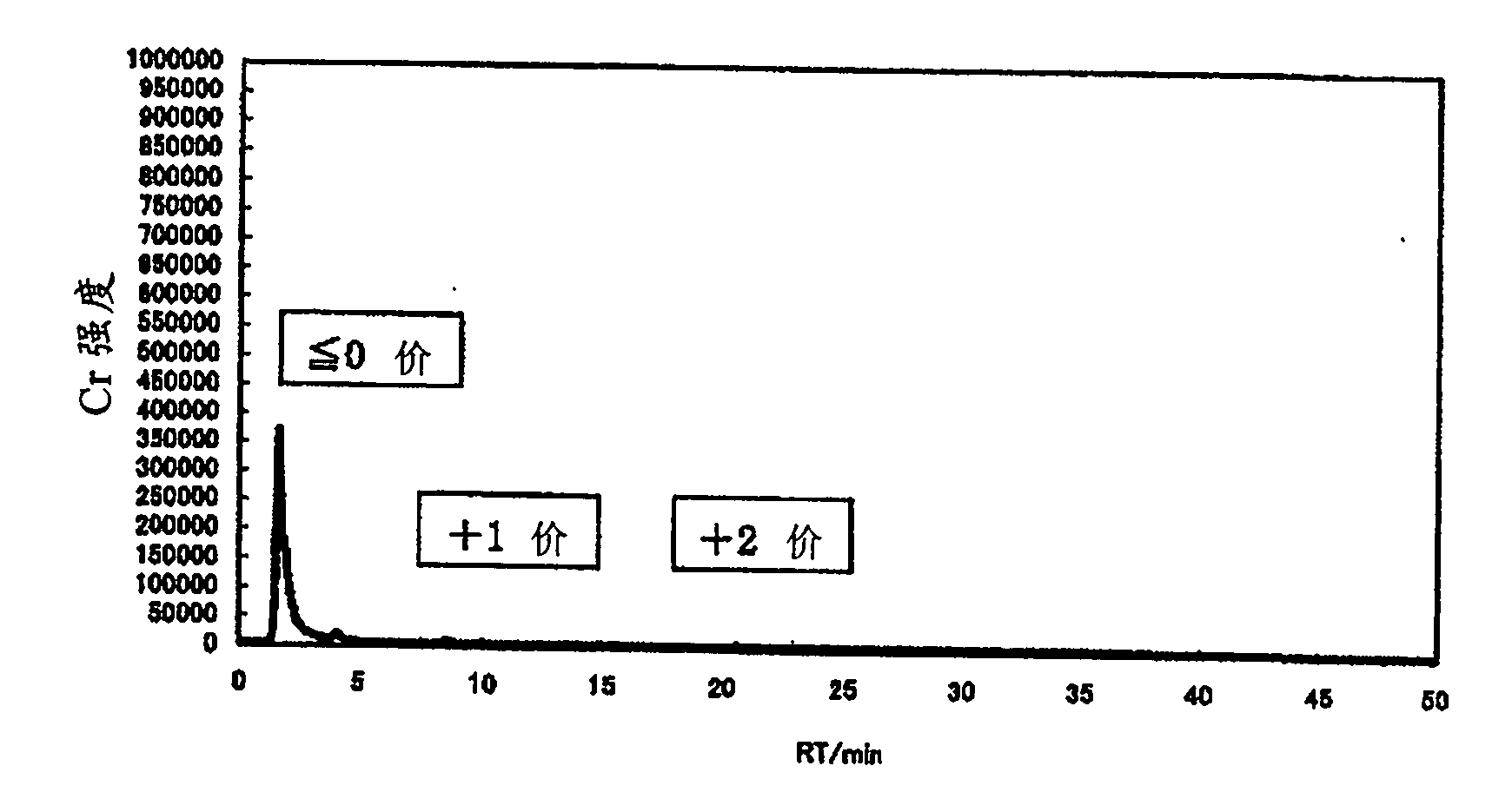

[0205] In an example, charge distribution of an aqueous solution containing chromium (III) was performed by diluting the aqueous chromium (III) solution with water to a total chromium concentration of 100 ppm using IC-ICP / AES (ion exchange separation-ICP emission analysis).

[0206] An ion-exchange separation device (DX-500, manufactured by DIONEX Corporation, Japan) was set to the following conditions.

[0207] Ion exchange resin: ethylvinylbenzene-divinylbenzene polymer (5.5 μm in diameter)

[0208] Eluent: methanesulfonic acid aqueous solution (the concentration of methanesulfonic acid increases linearly from 2mmol / L to 40mmol / L over time in 30 minutes, and is maintained at 40mmol / L after 30 minutes)

[0209] ·Flow rate: 1.2ml / min

[0210] ・Introduction volume of measurement object liquid: 20...

example 1

[0217] {instance 1}

[0218] (step 1)

[0219] 325.3 g of water was put into a glass-made reaction container with a condenser, and 124.9 g of chromium trioxide was further added, and fully stirred to obtain a chromic acid aqueous solution. Next, 292.8 g of 75% phosphoric acid was added to prepare a mixed aqueous solution of chromic acid and phosphoric acid.

[0220] Ethylene glycol is used as a reducing agent. 96.1 g of 20% ethylene glycol aqueous solution obtained by adding 76.6 g of water to 19.5 g of 98.5% ethylene glycol was added to the mixed aqueous solution of chromic acid and phosphoric acid at a rate of about 0.8 mL / min using a metering pump. The addition time was about 2 hours and the temperature was 102°C. 19.5 g of 98.5% ethylene glycol is equivalent to reducing 83% chromic acid.

[0221] (step 2)

[0222] Next, 216.2g of oxalic acid aqueous solution (containing 35% (COOH) 2 ), was added to the solution obtained in the first step at a rate of about 1.6mL / min. ...

example 2

[0224] {instance 2}

[0225] (step 1)

[0226] 512.9 g of water was added to a glass-made reaction vessel with a condenser, and 81.9 g of chromium trioxide was further added, and stirred well to obtain a chromic acid aqueous solution. Next, 106.7 g of 75% phosphoric acid was added to prepare a mixed aqueous solution of chromic acid and phosphoric acid.

[0227] Ethylene glycol is used as a reducing agent. 48.6 g of 20% ethylene glycol aqueous solution obtained by adding 38.7 g of water to 9.9 g of 98.5% ethylene glycol was added to the mixed aqueous solution of chromic acid and phosphoric acid at a rate of about 0.8 mL / min using a metering pump. The addition time was about 1 hour and the temperature was 100°C. 9.9 g of 98.5% ethylene glycol is equivalent to reducing 64% chromic acid.

[0228] (step 2)

[0229] Secondly, 302.4g oxalic acid aqueous solution (containing 35% (COOH) 2 ), was added to the solution obtained in the first step at a rate of about 2.3mL / min. The a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com