Prepn of chromium subsulfate

A chromium sulfate and basic technology, applied in chromium sulfate, chemical instruments and methods, chromium compounds, etc., can solve the problems of long process flow, difficult disposal of waste residue, environmental hazards, etc., and achieve the effect of simple process flow and solving serious harm.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

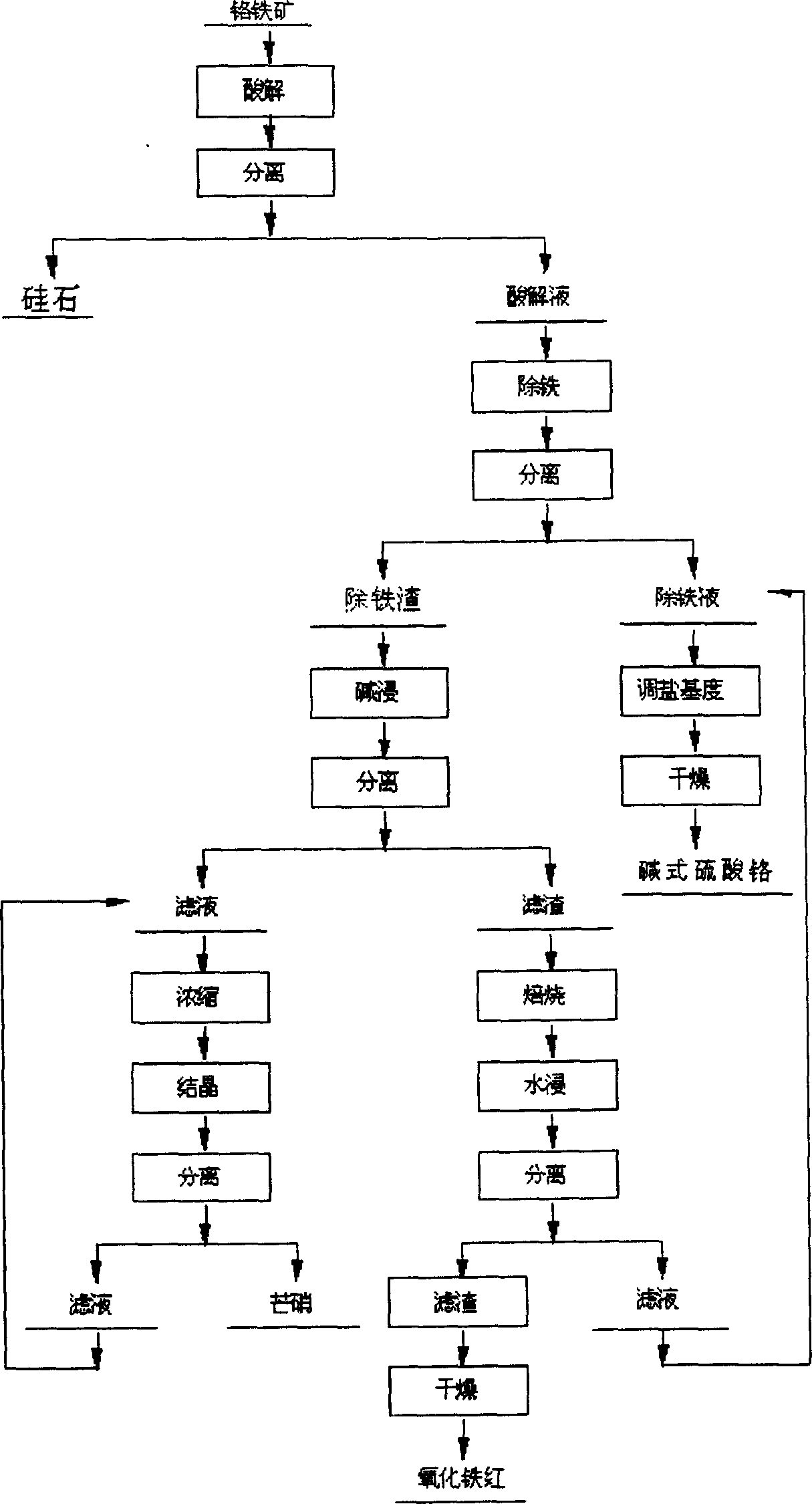

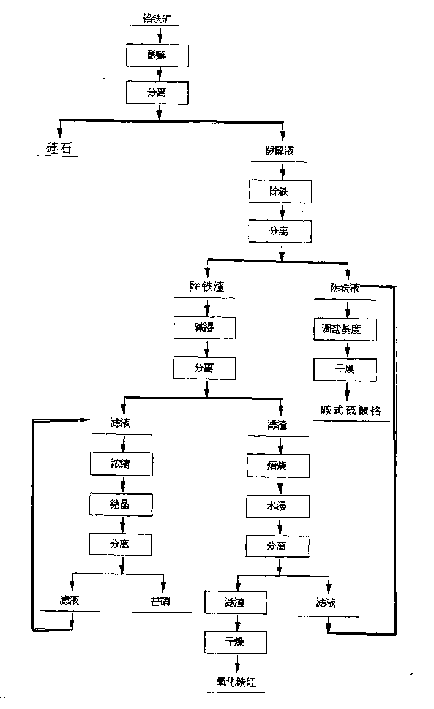

Method used

Image

Examples

example 1

[0010] Grinding 20g of chromite (containing 45% chromium) to a powder with a particle size of 0.05mm is put into a three-necked flask, and the concentration of 60% sulfuric acid 80g is added, the stirring rate is 60 rpm, the temperature is raised to 110°C, and heavy Sodium chromate 2g, heat up to 150°C, keep warm for 6 hours, vacuum filter to obtain 2g of filter residue; add sodium carbonate to the filtrate to adjust free acid to 2.3%, add 7g of calcium oxide, stir at 30 rpm, heat up to 185°C , heating rate is 0.5 ℃ / min, after insulation 50 minutes, filter and obtain filtrate 200g (3.8% containing chromium), add sodium carbonate and adjust basicity to be 33.5%, obtain basic chromium sulfate 33g through drying, the yield of chromium is 81 %.

example 2

[0012] Grinding 20g of chromite (containing 45% chromium) to a powder with a particle size of 0.09mm is put into a three-necked flask, and the concentration is added to 60g of 85% sulfuric acid, the stirring rate is 100 rpm, the temperature is raised to 150°C, and heavy Potassium chromate 3g, be warming up to 160 ℃ again, keep warm for 5 hours, vacuum filter, obtain filter residue 1.8g; Add sodium hydroxide to the filtrate and adjust free acid to 2.5%, add 6g iron oxide, stirring speed is 40 rpm, heating rate 0.9 DEG C / min, heat up to 175 DEG C, and keep warm for 120 minutes, filter to obtain filtrate 174g (containing chromium 4.2%), add sodium carbonate to adjust alkalinity to be 32.8%, obtain basic chromium sulfate 33.2g through drying, the recovery of chromium The rate is 82%.

example 3

[0014] Grinding 20g of chromite (containing 50% chromium) to a powder with a particle size of 0.06mm is put into a three-necked flask, adding 40g of sulfuric acid with a concentration of 95%, stirring at a rate of 120 rpm, heating up to 120°C, and adding heavy Ammonium chromate 1.5g, be warming up to 130 ℃ again, insulation 5 hours, vacuum filtration, obtain filter residue 1.7g; Filtrate adds potassium carbonate and adjusts free acid to 3.1%, adds 6g magnesia, and stirring speed is 60 rev / mins, is heated up to 180 DEG C, heating rate is 0.7 DEG C / min, after insulation 100 minutes, filter and obtain filtrate 187g, add sodium carbonate to adjust alkalinity to be 32.8%, obtain basic chromium sulfate 37.4g through drying, the yield of chromium is 79%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com