Preparation method for preparing foliage fertilizer raw material from leather making chromium containing leather meal

A technology of chrome leather shavings and foliar fertilizers, applied in liquid fertilizers, fertilizer mixtures, nitrogen fertilizers, etc., can solve the problems of backward technology, high price of organic fertilizers, and lack of widespread use, and achieve the effect of increasing the hydrolysis rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

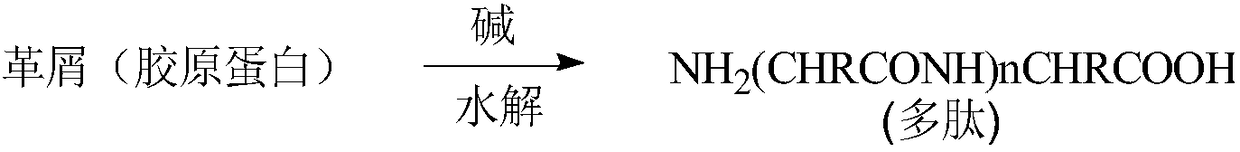

Method used

Image

Examples

example 1

[0024] A method for preparing foliar fertilizer raw materials from tanning chromium-containing leather scraps, characterized in that:

[0025] (1) Accurately weigh 15g of tanning chromium-containing leather shavings in a three-necked bottle, add 5 times of water, and then add 4% sodium hydroxide (based on the weight of tanning shavings, the following percentages are based on the same basis, such as self-made mixed alkali 0.5%, that is, the weight of chromium-containing leather shavings multiplied by the percentage), calcium hydroxide 4% (0.6g) and self-made mixed alkali A0.5% (0.075g), the hydrolysis time is 8h, the stirring hydrolysis temperature is 70°C, and the filter Filter residue, obtain gained filtrate A; (2) with the obtained filter residue of step (1), add 5 times of water (based on filter residue weight, this step other chemicals add all with it as basis), then add sodium hydroxide 1% , 1% of propyltriethoxysilane isocyanate, 3% of aluminum diethylphosphinate and 1% ...

example 2

[0030] A method for preparing foliar fertilizer raw materials from tanning chromium-containing leather scraps, characterized in that:

[0031] (1) Accurately weigh 15g of tanning chrome-containing leather shavings in a three-necked bottle, add 8 times of water, add 10% sodium hydroxide (based on the weight of leather shavings, the same below), 7% calcium hydroxide and homemade Mixed alkali A 1.4%, hydrolysis time is 16h, stirring hydrolysis temperature is 95°C, filter the filter residue to obtain the obtained filtrate A;

[0032] (2) With the filter residue obtained in step (1) (based on the weight of the filter residue, the addition of other chemicals in this step is based on it), add 8 times of water, then add 4% sodium hydroxide, propyl isocyanate Ethoxysilane 2%, aluminum diethylphosphinate 5% and substance A 4%, stirring and hydrolysis time is 12 hours, hydrolysis temperature is 75°C, precipitate and filter to obtain filtrate B;

[0033] (3) Filtrate A and filtrate B wer...

example 3

[0036] A method for preparing foliar fertilizer raw materials from tanning chromium-containing leather scraps, characterized in that:

[0037] (1) Accurately weigh 15g of tanning chromium-containing leather scraps in a three-necked bottle, add 6.5 times of water, add 7% sodium hydroxide (based on the weight of leather scraps), 5.5% calcium hydroxide and self-made mixed alkali A1 %, the hydrolysis time is 12h, the stirring hydrolysis temperature is 80°C, and the filter residue is filtered to obtain the obtained filtrate A;

[0038] (2) Add 6.5 times of water to the filter residue obtained in step (1), then add 2.5% sodium hydroxide, 1.5% isocyanate propyltriethoxysilane, 4% aluminum diethylphosphinate and substance A2.5%, the stirring hydrolysis time is 9.5h, the hydrolysis temperature is 75°C, precipitate and filter to obtain the obtained filtrate B;

[0039] (3) Filtrate A and filtrate B were combined to obtain the raw material for preparing foliar fertilizer from tanning ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com